5

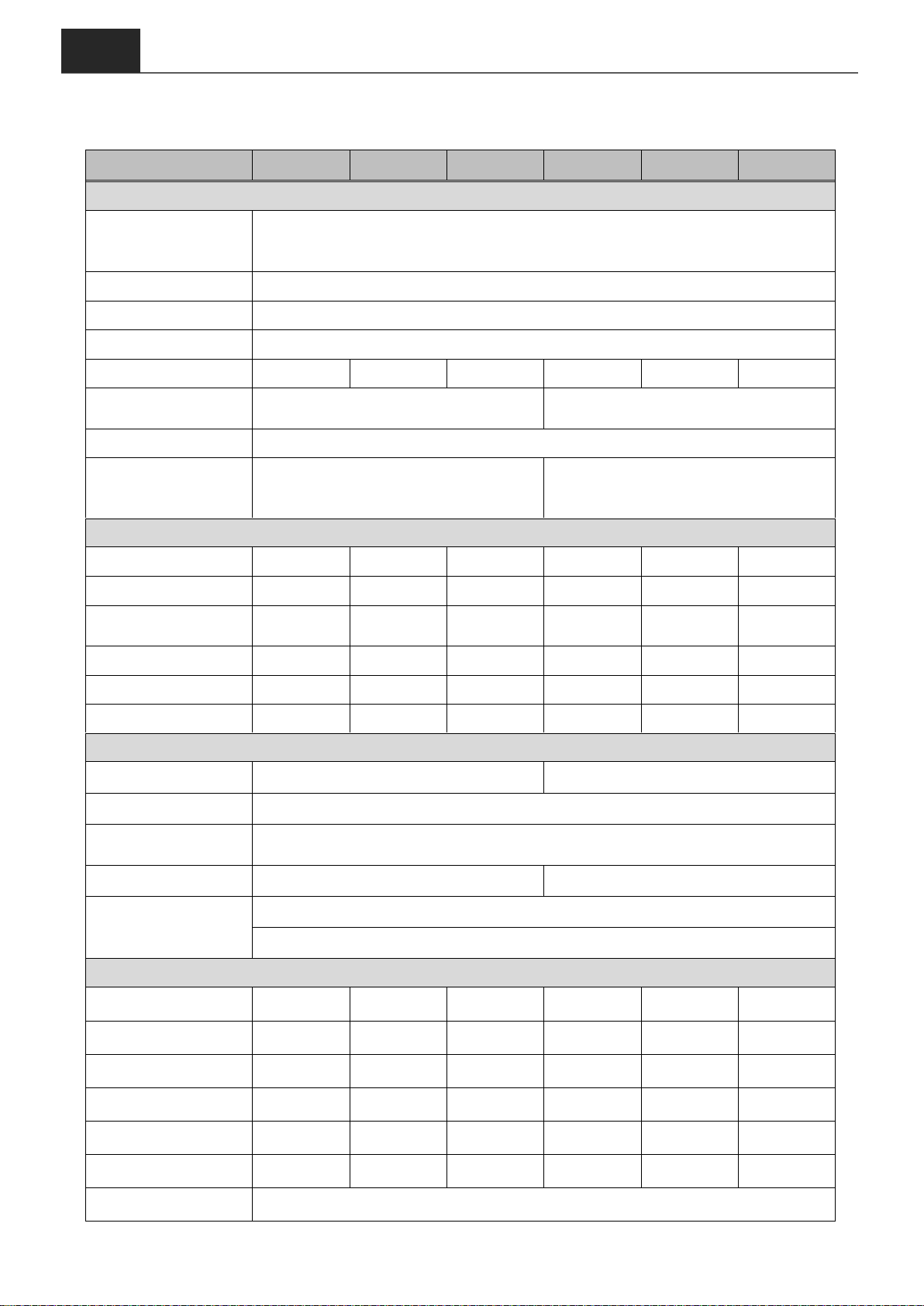

2.Functional Characteristics

2-1. General Information

ECB-series is new generation power inverter equipped with N+1 parallel power

function , 3-phase capability, and AC transfer switch. ECB series is suitable for RV,

Marine and Emergency appliances.

Features

Parallel redundancy design for power expansion

Multiple industrial applications that create 1Ф3W / 3Ф4W power systems

User-friendly remote control

Automatic master mechanism to eliminate single point failure and optimize

reliability

Built-in ATS and AC circuit breaker

Optional STS module, transfer time is less than 4ms.

RS-232 communication

Input & output fully isolation

Output voltage / power saving mode is selectable by DIP switch and remote

control (CR-10)

Input Protection:Reverse Polarity (Fuse) / Under Voltage / Over Voltage

Protection

Output Protection:Short Circuit / Overload / Over Temperature / Over Voltage

Protection

To get the most out of the power inverter, it must be installed and used properly.

Please read the instructions in this manual before installation and operation of this

model.

2-2. Application

2-2-1. Power tools–circular saws, drills, grinders, sanders, buffers, weed and hedge

trimmers, air compressors.

2-2-2. Office equipment –computers, printers, monitors, facsimile machines,

scanners.

2-2-3. Household items –vacuum cleaners, fans, fluorescent and incandescent

lights, shavers, sewing machines.

2-2-4. Kitchen appliances –coffee makers, blenders, ice markers, toasters.

2-2-5. Industrial equipment –metal halide lamp, high pressure sodium lamp.

2-2-6. Home entertainment electronics –television, VCRs, video games, stereos,

musical instruments, satellite equipment.

2-2-7. Vehicle, yacht and off-grid solar power systems.