1

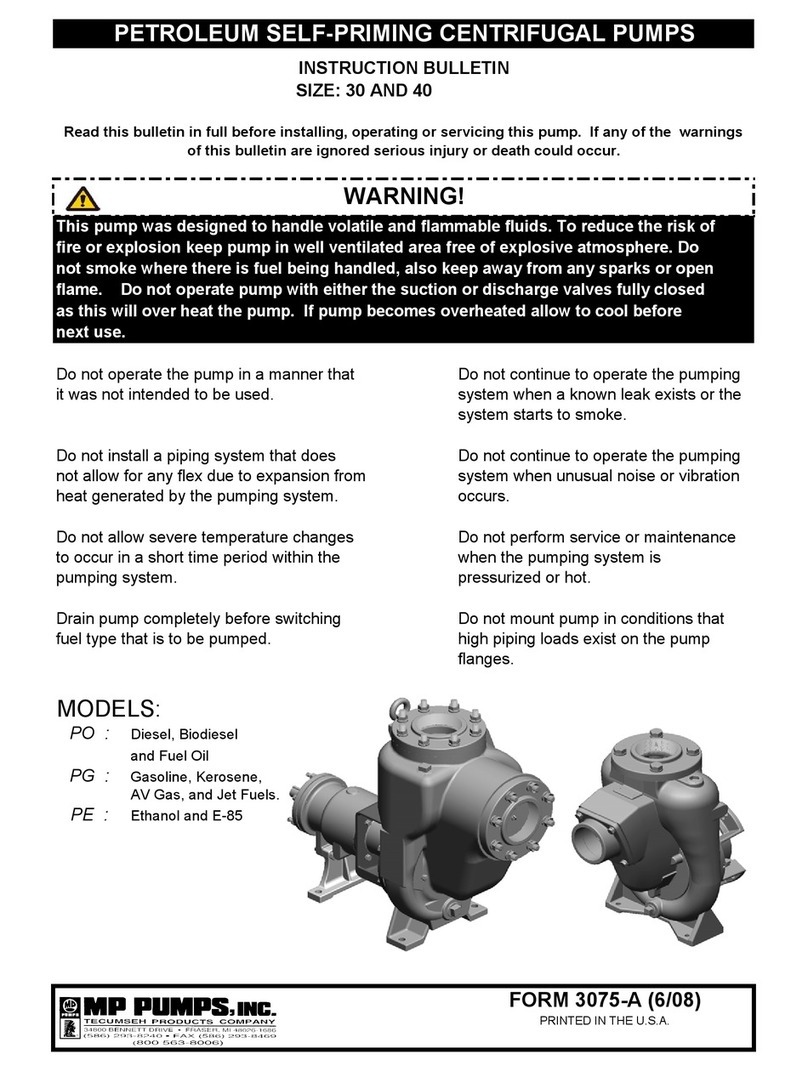

INSTRUCTION BULLETIN

2CT and 2CT-3 Pumpak for 145TC, 184TC and 215TC drive

OVERVIEW:

These instructions pertain to the assembly and

installation of a 2CT pump end. Your 2CT

pump may have included a driver such as close-

coupled electric motor, engine, bearing pedestal

or hydraulic motor pedestal that will hereafter be

referred to as the driver.

♦CAUTION.

2CT pumpaks are shipped

with no running clearance between the

impeller and housing. 2CT pumpak impeller

clearance can only be established after the

pumpak has been secured to the driver. See

Pumpak Assembly.

PUMPAK ASSEMBLY:

(pump end suitable

for mounting to various drivers).

1. Loosen the drive sleeve clamp.

2. Lightly coat the driver shaft with an anti-

seize compound.

3. Slide the pump onto the driver by hand.

This should not require extreme force.

4. Install and tighten fasteners (4) into the

pump adaptor securing the drive.

5. Tighten the drive sleeve clamp fastener to

20 to 26 foot pounds.

6. To establish impeller running clearance:

Loosen the two opposing nuts that fasten

the suction chamber to the pump. Loosen

the locknut of one of the three jackscrews.

Back-off the cleanout chamber by rotating

the jackscrew clockwise ½ turn then re-

tighten the locknut. Repeat this step for the

other two jackscrews. Re-tighten the

suction chamber fasteners.

7.

Rotate the shaft to ensure that the pump

rotates freely before putting the pump into

service.

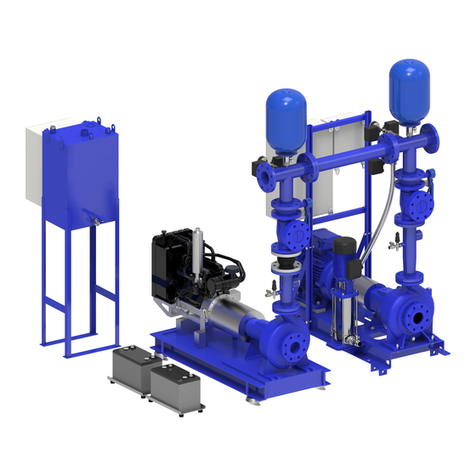

INSTALLATION:

Optimum performance can be attained by

placing the pump as close to the liquid source as

possible. Secure the pump by mounting it to a

foundation or base plate.

Hose or pipe can be used on the suction and

discharge. The suction line must not be reduced

in size. If hose is used, reinforced non-

collapsible type is recommended. The discharge

line must be rated to the maximum pressure

developed by the pump.

Avoid kinks in the hose and unnecessary

restrictions that may affect pump performance.

All pipe connections must be sealed with

adequate thread sealant. A small air leak in the

suction line will affect priming performance. If

a throttling valve is used to adjust the flow rate,

it should be mounted to the discharge piping

only - never in the suction. A large low

restriction de-watering type strainer must be

used whenever solids larger than 1.25” spheres

are present in the liquid source.

OPERATION:

Fill the pump with liquid prior to starting

through a fitting on the discharge piping. The

pump housing should be completely full. If the

pump has a discharge valve it must be fully open

to expel air during priming at initial start-up.

Long horizontal suction lines require extra time

to prime, 2 additional minutes for every 10 feet

of horizontal run.

Start the pump driver. The pump will prime the

suction hose and establish flow in about 5

minutes, more or less, depending upon the lift

distance and length of horizontal run. After

prime, the pump will perform to its full flow

capability.

After the initial prime, the pump will retain

liquid in the housing and may not need to be

refilled after shutdown and restart even if the

suction pipe has air in it.