MP PUMPS FLOMAX 8 User manual

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

OPERATOR’S MANUAL FLOMAX 8

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE RELEASED: 12-17-21

(REV: A)

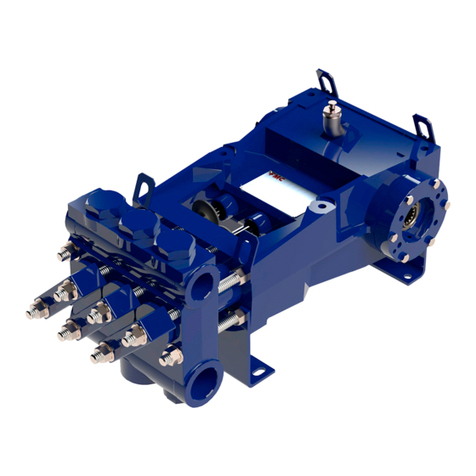

FLOMAX® 8

(Bronze and Aluminum 2” X 2”)

INGERSOLL RAND COMPANY INC

34800 BENNETT DR, FRASER, MI 48026

1-800-563-8006 [email protected] © 2021

www.gardnerdenver.com/en-us/mppumps

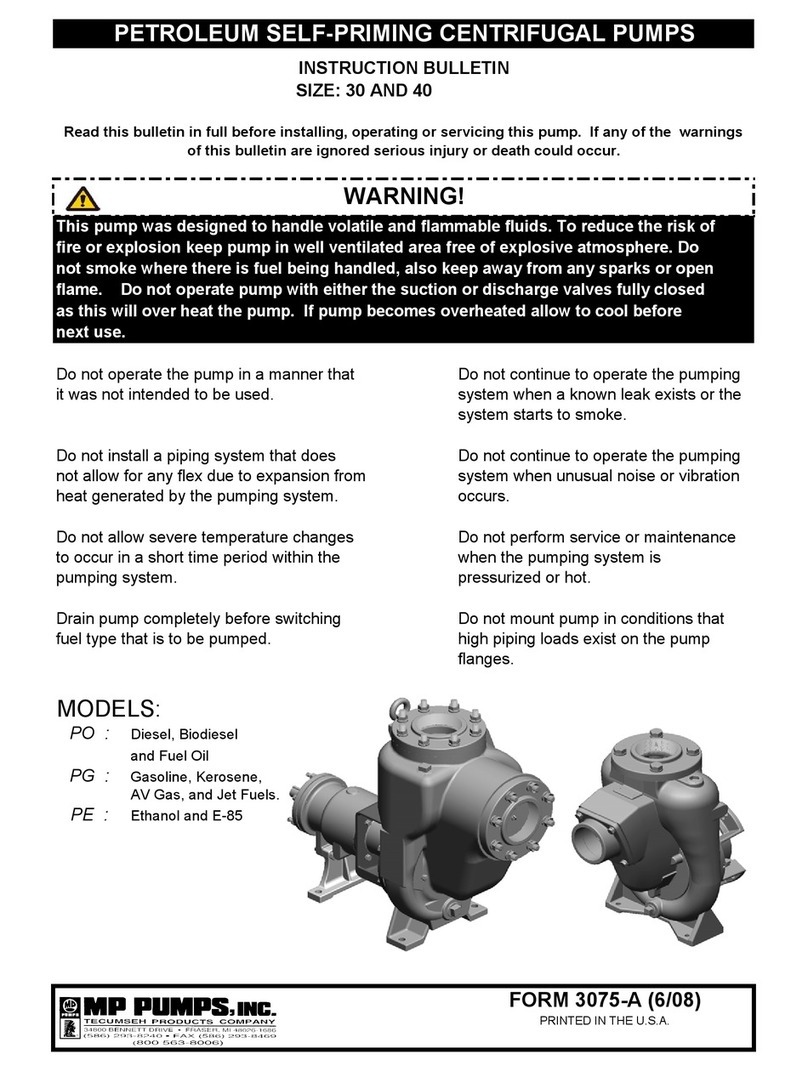

CC Models

Bronze

Pedestal Models

(Bronze / Aluminum)

Pedestal Engine

Mount Models (Bronze / Aluminum)

Clutch Models

(Bronze)

Hydraulic Models

(Bronze)

Aluminum

Figure 1

Page 2 of 24 FLOMAX 8 BZ AL (en)

GENERAL DESCRIPTION

FLOMAX 8:

2” x 2” Self Priming, Hydraulic Self Priming Pump

Flomax® 8 pumps utilize a semi-open impeller design to allow for passage of larger solid sizes. Several seal options are avail-

able in addition to the standard type 2100 carbon / Ceramic / Viton mechanical seal.

SPECIFICATIONS

Suction And Discharge ..............2” x 2” NPT

Application ..........................

Agricultural, Commercial, Industrial, Marine, OEM

Materials of construction ............Bronze, Aluminum

Flow

CC .................................Up to 150 gpm (548.8 lpm)

Hydraulic...........................Up to 200 gpm (662.4 lpm)

Head Feet

CC .................................Up to 100 ft (30.4 m)

Hydraulic...........................Up to 275 ft (70.1 m)

Suction lift ...........................Up to a 25 ft (7.6 m)

Impeller.............................. 5” (127 mm) Semi-open

Motor ................................Up to 3 HP (2.24 kw)

Hydraulic Motor .....................0.37 cu.in. (3.60 ml)

0.45 cu.in. (6.06 ml)

0.58 cu.in. (7.3 ml)

Hydraulic System Pressure...........Up to 1900 psi (175.8 bar)

Hydraulic Fluid Flow .................Up to 12 gpm (41.6 lpm)

Maximum Solid Size .................0.56” (14.2 mm) diameter

Drive Options

........................Close coupled 56C, Engine mount 5.5 HP, Engine mount 6.5 HP

Close coupled 145TC

Pedestal

PumPAK® (without motor)

Seal ..................................Standard carbon / Ceramic / Viton

Special seal material combinations available (Consult factory)

Max Solid Size .......................0.56”

Drive Sleeve .........................316 stainless steel

Options ..............................5 blade impeller available for higher ows, Base plate,

Double seal available for dry run applications, Flanges not included on SS models

Features .............................Renewable wear plate, Stainless steel drive sleeve,

Stainless steel fasteners.

FLOMAX 8 BZ AL (en) Page 3 of 24

OPERATING AND SAFETY PRECAUTIONS

READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE.

EXCESSIVE AIR PRESSURE

STATIC SPARK

HAZARDOUS MATERIALS

HAZARDOUS PRESSURE

WARNING

Be sure hoses and other components can

withstand fluid pressures developed by this pump.

Check any hoses for damage or wear. Be certain dis-

pensing device is clean and in proper working condi-

tion.

WARNING

IMPROPER GROUNDING. Can increase

spark and electrical shock risk, resulting in severe in-

jury or death. Ground pump and pumping system.

yThe pumping system must be grounded when it is

pumping, ushing, recirculating, or spraying amma-

ble materials such as paints, solvents, lacquers, etc.

or used in a location where surrounding atmosphere

is conducive to spontaneous combustion. Ground the

dispensing valve or device, containers, hoses, and any

object to which material is being pumped.

ySecure pump, connections, and all contact points to

avoid vibration and generation of contact or static

spark. Consult local building codes and electrical

codes for specific grounding requirements. After

grounding, periodically verify continuity of electrical

path to ground. Test with an ohmmeter from each

component (e.g., hoses, piping, pump, clamps, motor,

base plate, etc..) to ground to ensure continuity. Ohm-

meter should show 0.1 ohms or less.

WARNING

HAZARDOUS PRESSURE. Can result in

serious injury or property damage. Do not service or

clean pump while the system is pressurized.

WARNING

HAZARDOUS MATERIALS. Can cause se-

rious injury or property damage. Do not attempt to

return a pump to the factory or service center that

contains hazardous material. Safe handling practices

must comply with local and national laws and safe-

ty code requirements. Obtain Material Safety Data

Sheets on all materials from the supplier for proper

handling instructions.

CAUTION

Check pump seals, elastomers, and all

wetted parts to assure compatibility before using

commission of the product.

yVerify the chemical compatibility of the pump wetted

parts and the substance being pumped, flushed or

recirculated. Chemical compatibility may change with

temperature and concentration of the chemical(s)

within the substances being pumped, flushed or cir-

culated. For specific fluid compatibility, consult the

chemical manufacturer.

CAUTION

Maximum temperatures are based on

mechanical stress of seals and elastomers only. Cer-

tain chemicals will signicantly reduce maximum safe

operating temperature. Consult the chemical manu-

facturer for chemical compatibility and temperature

limits.

CAUTION

Be certain all operators of this equipment

have been trained for safe working practices, under-

stand it’s limitations, and wear safety goggles / equip-

ment when required.

CAUTION

Do not use the pump for the structural

support of the piping system. Be certain the system

components are properly supported to prevent stress

on the pump parts.

CAUTION

Prevent unnecessary damage to the

pump. Do not allow pump to operate in a dry run con-

dition or under cavitating conditions for extended

periods.

CAUTION

Use only genuine MP Pumps®replace-

ment parts to assure compatible pressure rating and

longest service life.

CAUTION

The mechanical seal in the pump must

not be operated dry.

CAUTION

If a pump will be idle in freezing weath-

er it should be drained or filled with the proper an-

ti-freeze.

NOTICE

Pump should be installed in the position

consistent with the manufactures specications.

NOTICE

Re-torque all fasteners before operation.

Creep of housing and gasket materials may cause

fasteners to loosen. Re-torque all fasteners to insure

against uid leakage.

WARNING

= Hazards or unsafe practices which could

result in severe personal injury, death or

substantial property damage.

CAUTION

= Hazards or unsafe practices which could

result in minor personal injury, product

or property damage.

NOTICE

= Important installation, operation or

maintenance information.

IOM INFORMATION NEEDED FOR CE

CAUTION

NOISE HAZARD. Long term noise expo-

sure while in close proximity to an operating pump

can lead to noise injuries and hearing loss. Noise can-

celling PPE and/or sound insulation is recommended

if long term exposure is unavoidable.

CAUTION

HIGH SURFACE TEMPERATURE: High sur-

face temperatures that can result in burns may devel-

op near the mechanical seal of the pump. Allow su-

cient time for pump to cool or use proper PPE before

interacting with the pump.

WARNING

EXTREME ENVIRONMENT CONDITIONS.

Consult local building, electrical, and construction

codes before installing pumps in environments prone

to extreme weather and/or geological activity.

WARNING

FLAMMABLE SUBSTANCES. Grease and

oil used in double seal pump is flammable. Avoid

exposing double seal pumps to high temperatures.

Grease Flashpoint 500°F (260°C). Oil ash point 300°F

(149°C).

WARNING

EXPLOSIVE ENVIRONMENTS. Flomax is

not ATEX Certied. Do not install pump in potentially

explosive environments.

WARNING

LIFTING AND TRANSPORT HAZARDS. Per-

sons that cannot lift more than 50lb (23Kg) should not

attempt to lift pump assemblies by hand. Do not at-

tempt to transport pumps by hand for large distances

or from high elevations. Pump and engine assemblies

should not be lifted or transported by hand.

Page 4 of 24 FLOMAX 8 BZ AL (en)

STORAGE PRECAUTIONS

Do not store filled with fluid at or below freezing temp of

process uid.

INSTALLATION

INSTALLATION FOR FLOMAX SELF PRIMING PUMPS

:

For optimum performance, place pump as close to liquid

source as possible to reduce suction lift to a minimum. For

best results, pump should be installed not more than 15 feet

above the liquid supply. Set the unit on solid footing and as

nearly level as possible.

Pipe or hose of the same size as anges provided should be

used. Reinforced rubber suction hose is recommended be-

cause it provides greater flexibility and prevents collapsing

due to vacuum in the suction line when pump is in operation.

Suction line should be as short as possible and have as few el-

bows or bends as possible to keep friction loss at a minimum.

Use pipe dope on all connections and make certain that all

ttings are tight, particularly on the suction line where an air

leak can prevent priming or reduce pump capacity.

A good suction strainer should be used. Suction strainers are

available from your MP Distributor. Refer to the accessory

section of the GENERAL PUMP PRICE LIST for the correct part

number

INSTALLATION FOR FLOMAX PUMPAKS:

Be sure that the pump housing is filled with liquid before

starting the pump. THE MECHANICAL SEAL IN THE PUMP

MUST NOT BE OPERATED DRY.

Pipe or hose of the same size (or larger) as inlet and outlet

openings should be used on the installation. When using

pipe, avoid sharp bends and use long radius elbows wherev-

er possible. This will keep friction loss at a minimum and al-

low the pump to operate more eectively. Use pipe dope on

all connections and be sure all ttings are airtight, especially

on the suction side of the pump. An air leak on the suction

side of the pump will prevent proper operation. A section of

non-collapsible hose between piping and pump may be used

as a vibration dampener.

BEARING INSTALLATION (PEDESTAL MODELS):

Check the shaft to insure that it rotates freely. Shafts should

be aligned in accordance with the instructions of the cou-

pling manufacturer. Final alignment must be performed after

the pump has been completely installed and the pump and

driver are at operating temperature. Proper shaft alignment is

the responsibility of the installer.

Piping should include shuto valves on both the discharge

and suction to isolate the pump for maintenance. Provisions

for suction and discharge pressure gages are recommended

for trouble shooting. The suction line should be as short as

possible, at least as large as the pump suction connection,

include as few ttings as possible and those should be long

radius to keep friction losses at a minimum.

Both suction and discharge piping should be supported in-

dependently of the pump. Never use excessive force to move

the pipe into place. This may impose a strain that will result

in misalignment between the pump and driver or otherwise

adversely aect the operation of the pump. After connecting

pipe to the pump rotate the shaft several times to check for

rubbing or binding.

NSTALLATION FOR FLOMAX SELF PRIMING PUMPS

The permitted forces and moments on pump inlet

and outlet.

LEGENDS

F

L

- Longitudinal shear force

F

C

- Circumferential shear force

F

A

- Axial tension or compression force

M

L

- Longitudinal bending force

M

C

- Circumferential bending force

M

T

- Torsional moment

ALLOWABLE NOZZLE LOADS

Nozzle

Size

(in)

Small Flomax Flanges

Force lbs (N) Moment ft*lbs (N*m)

FL FC FA ML MC MT

1.5” 405

(1800)

405

(1800)

303

(1350)

100

(135)

149

(203)

129

(176)

2” 540

(2400)

540

(2400)

405

(1800)

177

(240)

266

(360)

230

(312)

FLOMAX 8 BZ AL (en) Page 5 of 24

MOTOR MOUNTING

Check rotation of the driver to be sure it coincides with the

required rotation of the pump. When viewed from the driver

end the rotation of the pump is CLOCKWISE.

A Pumpak shaft sleeve is machined to precisely t the shaft

of your driver. No provision is made for drive key and none is

required.

Loosen the drive clamp fasteners but do not remove. NOTE:

If the driver shaft is keyed, remove the key before attempting

to install the Pumpak. Slide the Pumpak assembly onto the

driver shaft, aligning the Cap Screw holes in the adaptor with

the tapped holes in the driver mounting face until the adap-

tor contacts the mounting face.

Install fasteners and tighten to secure Pumpak assembly to

the driver. First center then tighten the drive clamp assembly

to lock the shaft sleeve onto the driver shaft.

After all fasteners are tight including the drive clamp assem-

bly, remove the Assembly shim from the suction connection.

The shim was in place to establish clearance between the

face of the impeller and pump housing. Rotate the driver

slowly by hand to make certain that there is no rubbing.

Mounting Pumpak

Loosen impeller clamp nuts.

Do not use drive shaft key. Remove key if installed on drive

shaft.

Slide PUMPAK assembly onto the drive shaft. WARNING! If

PUMPAK does not slide freely STOP DO NOT HAMMER or

force PUMPAK. Be sure impeller clamp is loose. PUMPAK as-

semblies should slide on with hand pressure. Check for and

remove any burrs from drive shaft or bore of sleeve. Align

holes in adapter with holes in driver mounting face and slide

PUMPAK until adaptor contacts mounting face.

Attach Cap Screws and lockwashers and tighten to secure

PUMPAK assembly to driver. Tighten impeller clamp nuts to

lock impeller onto drive shaft.

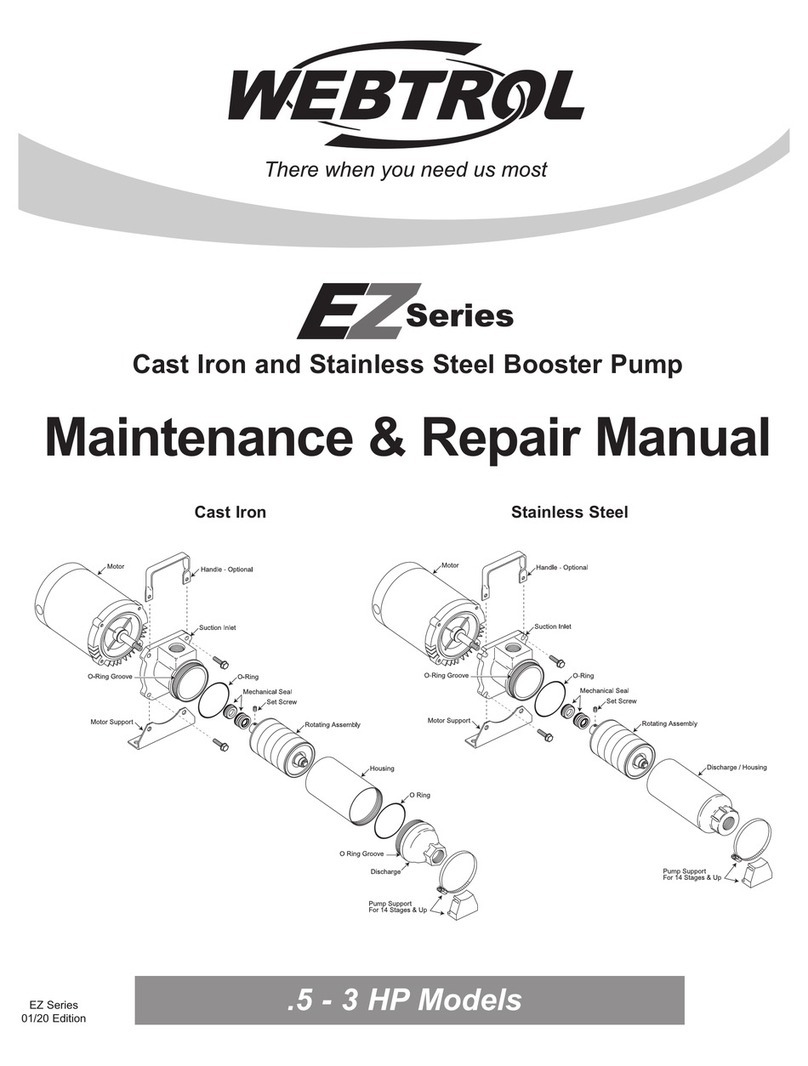

TO ADJUST IMPELLER CLEARANCE:

NOTE: A shipping spacer was inserted at the factory for the

purpose of establishing the proper clearance between the

face of impeller and the wear plate.

1. Remove strip stock spacer only after tightening the

impeller.

2. Clearance between the impeller and wear plate is now

set to approximately 0.020”.

3. Turn over slowly to make certain pump rotates freely.

4. Loosen impeller clamp to adjust clearance between im-

peller and wear plate using a feeler.

5. Gauge in place of spacer. After clearance has been estab-

lished, tighten impeller clamp to lock impeller to shaft.

Torque Specications

Size Stainless Steel (ft-lbs) Steel GR5 (ft-lbs)

5/16” - 18” 10 - 14 14 - 20

3/8” - 16” 20 - 2 6 26 - 32

1/2” - 1 3” 34 - 42 70 - 80

1/2” - 20” 40 - 4 8 N/A

5/8” - 11” 75 - 85 N/A

SHIM

(24 GAUGE)

DISCHARGE

IMPELLER

WEAR PLATE

DISCHARGE

SUCTION

WEAR PLATE

IMPELLER

SHIM

(24 GAUGE)

Figure 2

Page 6 of 24 FLOMAX 8 BZ AL (en)

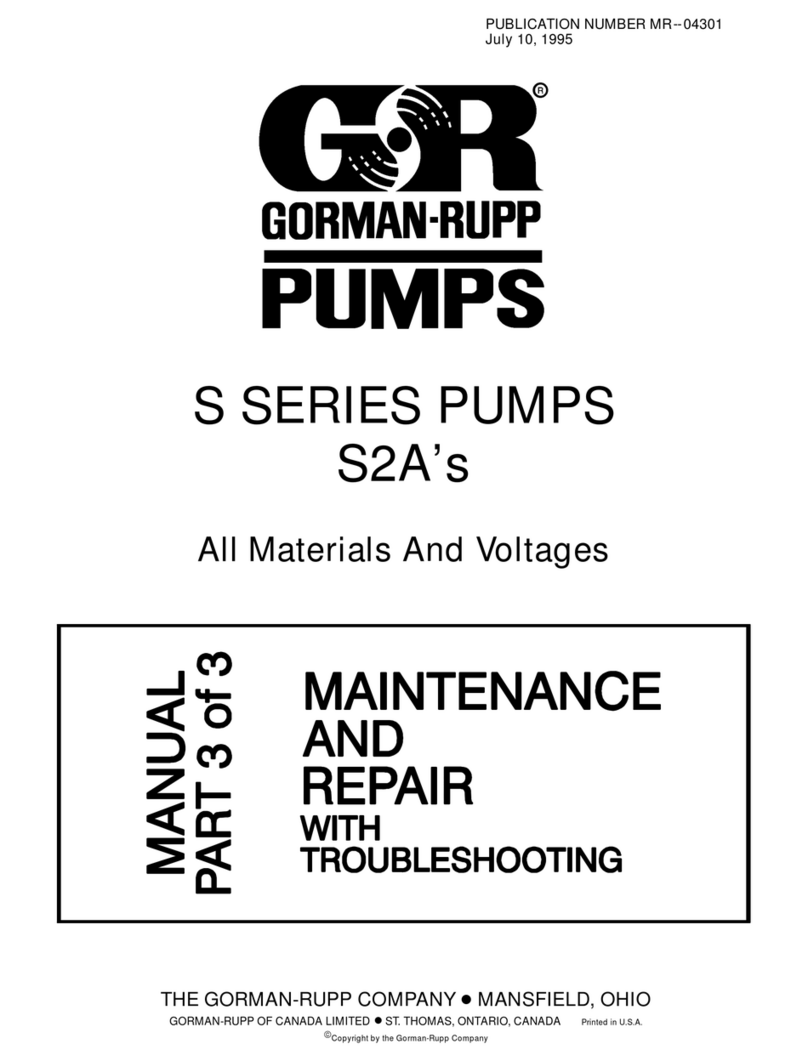

WORKING OF SELF PRIMING PUMP

Hd

DISCHARGE HEA

D

Hs

SUCTION HEAD

(NPSHr)

FILL PLUG

DRAIN PLUG

OVER HEAD

WATER TANK

SUCTION VALVE

UNION FLANGE

UNION FLANGE

DISCHARGE VALVE

DISCHARGE PIPE (2”)

SUCTION PIPE (2”)

MINIMIZE LENGTH & AVOID

SHARP BENDS NEAR INLET

Figure 3

OPERATING INSTRUCTIONS

The FLOMAX pump is a self-priming centrifugal pump and

only requires priming prior to its initial start. The pump will

retain sucient liquid for self priming thereafter.

Provision for a priming plug can be made by using a close

nipple and tee on the discharge opening.

A pipe plug installed in the top opening of the tee is easily

removed when necessary to prime pump. Prime pump by ll-

ing pump housing with liquid

If pump fails to prime or stops pumping, check for the follow-

ing possible causes:

1. No liquid in the pump housing.

2. Air leak in the suction line due to loose connections or

pin holes in the hose.

3. Collapsed suction line or clogged strainer.

4. Seal worn and leaking air.

5. Worn impeller - too much clearance between impeller

and wear plate.

6. Pump not running fast enough.

7. Suction lift is too high.

8. Trying to prime against too high a discharge head

Inspect the Pumpak as soon as it is received to make certain

that no parts are missing or have been broken in shipment.

Damage should be reported immediately to the shipping

company. CAUTION: Do not disturb the assembly shim in

the opening of the pump housing until after the Pumpak has

been completely assembled to the driver.

The Pumpak utilizes a single self-adjusting type mechanical

seal that is lubricated and cooled by the liquid in the pump.

NOTE: The Pump Must Never Be Operated Without Liquid

In The Housing.

WORKING OF SELF PRIMING PUMP:

A centrifugal pump operates through the transfer of rotation-

al energy from one or more driven rotors, called impellers.

The action of the impeller increases the fluid’s velocity and

pressure and directs it towards the pump outlet.

WEAR AND INSPECTION POINTS

Shaft: Inspect threads, keyways and shoulders. Replace if

damaged.

Ball bearings (Pedestal and hydraulic models): Replace if

worn, loose, or rough and noisy when rotated. If dirty, clean

with solvent, dry and coat with a good lubricant. New bear-

ings should not be unwrapped until ready for use.

Impellers: Replace if excessively worn or corroded. The im-

peller should have been statically and dynamically balanced

at the factory, and static and dynamic balance must be main-

tained for proper operation of your equipment.

Mechanical seals: Should be inspected for, lack of lubrica-

tion, misalignment, overheating, abrasive materials damage,

and corrosion.

Alignment: Proper alignment between pump shaft and

motor shaft is key to the performance of shaft seals and

bearings. Improper alignment can lead to premature pump

failure.

Pedestal Style: Inline shaft to shaft spacing is dependent

upon the coupling being used. Check the alignment carefully

between the pump and the drive.

FLOMAX 8 BZ AL (en) Page 7 of 24

SEAL REPLACEMENT INSTRUCTIONS

DISASSEMBLE THE PUMP:

Drain the system of liquid, break suction and discharge pipe

unions, and, if necessary, remove all piping from the suction

and discharge openings. Remove the fasteners holding the

pump adaptor to the driver, loosen the drive clamp assembly,

and remove the PUMPAK.

To disassemble, remove the washers and hexnuts holding the

motor adaptor to the housing. Remove the housing. The im-

peller, drive sleeve, seal bellows, and the spring assembly will

now slide forward Free of the pump adapter.

The seal seat and seat cup will remain in the pump adaptor.

If not damaged or worn, do not remove. If necessary, remove

from the adaptor counter bore with a piece of wood or a

screwdriver handle inserted through the adaptor from the

drive end. A sharp tap or two is usually sucient to knock out

the seal seat. Use caution in removing the seal seat so as not

to crack a ceramic seat.

REMOVE IMPELLER

Remove seal bellows and spring assembly. On some models,

spring keeper can also be removed now before removing im-

peller.

NOTE: The seal bellows will be bonded to the shaft sleeve

and will require some patience and caution in removal in or-

der not to damage the seal bellow and cage.

MP Pumps rebuild kits include a new drive sleeve to avoid the

possibility of damaging the drive sleeve. See back of manual

for list of seal kits and corresponding rebuild kits. Impellers

are also available if wear or damage is present.

Remove locknut from shaft; unscrew the impeller from the

shaft sleeve counter-clockwise from the impeller end.

INSPECTION:

Check all parts for wear. For ease of reassembly shaft sleeve

should have all nicks and burrs removed. Clean with light cro-

cus cloth. Replace damaged parts with new parts.

Inspect the seal seat and washer, seat cup, and seal bellows

for grooves, cuts, scumarks, or other deterioration. If any of

the parts are damaged, a complete new assembly should be

installed.

SEAL ASSEMBLY

7

654 3

2

1

ITEM NO. DESCRIPTIONQTY.

Mating Ring

2

3

4

5

6

7

1

1

1

1

1

1

1

1

O-ring

Primary Ring

Elastomer Bellows

Drive Band

Spring

Spring Holder

inspect the lapped sealing face of carbon washer (Part 3) for

wear which would necessitate replacement.

Inspect lapped sealing face of oating seat (Part 4) in adapter

housing counterbore for scung or cracks. If necessary to re-

place, press out old seat and ring, and proceed as outlined in

paragraph on MOUNTING ADAPTER.

If spring and/or bellows (Part 1 and 2) are damaged and re-

quire replacement, lubricate the impeller sleeve with a clean

light oil and slide parts o sleeve.

REASSEMBLY:

All dirt and foreign matter should be removed. Recommend

only using new seals and elastomers when reassembling a

pump.

Lubricate seal seat cup with liquid soap (P-80 emulsifier) or

clean grease and press seal seat into adaptor counter bore,

seating it firmly and squarely. Use caution so as not to mar

the lapped face of the seal seat.

Assemble shaft sleeve; seal spring keeper, impeller and im-

peller nut. Before installing seal bellows and spring assembly,

lubricate the shaft sleeve and rubber bellows with liquid soap

(P-80 emulsier) or clean grease and press bellows and spring

assembly onto the shaft sleeve. The spring should engage the

spring keeper at the impeller end of the shaft sleeve.

To be properly positioned the washer must be rmly against

the rubber bellows member and the driving lugs of the wash-

er properly engaged. The raised shoulder on the seal wash-

er should be facing away from the impeller to contact the

lapped surface of the seal seat in the adaptor.

Slide impeller and seal assembly into the adaptor. Install drive

clamp assembly on the shaft sleeve but do not tighten.

Make sure the shim is installed between the impeller and the

wear plate. Do not remove the shim material before the drive

sleeve clamp has been tightened to the motor drive shaft.

INSTRUCTIONS FOR SET SCREW TYPE SEAL:

Do not remove the seal retaining clips. Slide the seal into

place on the shaft. The end of the shaft will be recessed

approximately 0.080” ± 0.020” from the end of the seal. The

proper seal working height is achieved when the seal faces

are set ush with the seal clips in place.

With the seal clips still in place tighten the seal fasteners with

a ball end allen wrench. It is important that the allen wrench

not rest upon the seal housing during tightening as this may

aect the position of the seal on the shaft. After the seal fas-

teners have been tightened the seal clips should be removed

and saved.

Do not use the seal shim with setscrew type seal.

For bellows seal install the seal spacer on the backside of the

impeller. Use a light grease or similar tacky material. Thread

impeller onto shaft. Install jam nut. Place O-ring onto seal

plate. Install impeller/bearing housing assembly into pump

housing. Install lock washers and hex nuts. Rotate the shaft

several times to check for rubbing or binding.

BEARING REPLACEMENT INSTRUCTIONS

(PEDESTAL MODELS)

The pump utilizes a single self-adjusting type mechanical seal

that is lubricated and cooled by the liquid in the pump.

THE PUMP MUST NEVER BE OPERATED WITHOUT LIQUID

IN THE HOUSING.

Check rotation of the driver to be sure it coincides with the

required rotation of the pump. When viewed from the driver

end the rotation of the pump is CLOCKWISE.

The pump’s grease lubricated bearings are sealed. They have

been pre-lubricated at the factory and require no further

lubrication or maintenance for the life of the bearing.

Page 8 of 24 FLOMAX 8 BZ AL (en)

Electric motors or other rotating equipment used to drive the

pump should be lubricated in accordance with the manufac-

turer’s instructions.

DISASSEMBLY:

Drain the housing by removing the drain plug. Remove the

hex nuts and lock washers from the housing studs. Slide the

bearing housing/impeller assembly out of the housing. It

may be necessary to rotate the driver shaft out of the way.

With the bearing /impeller assembly on a bench secure shaft,

unthread impeller nut then unthread impeller. Remove the

seal from the shaft. Lift o the seal plate. Place the seal plate

face down on the bench and press the seal seat out.

Remove the snap ring from the backside of the bearing hous-

ing. With a soft mallet, loosen the shaft assembly by tapping

the impeller end then slide the bearing assembly from the

housing. Press the bearings from the shaft.

ASSEMBLY:

Press bearings onto the shaft. Slide the shaft / bearing assem-

bly into the bearing housing and install the snap ring. Place

seal housing face up on bench. Lubricate non-PTFE seal seat

with water-soluble lubricant and gently press into seal hous-

ing. If pinned seat is used be certain that pin is in place, lined

up with groove in seal seat. Place seal housing onto pilot of

bearing housing. Lubricate shaft with water-soluble lubricant.

Slide seal onto shaft.

MAINTENANCE

The FLOMAX pump is of simple construction with only one

moving part. The impeller on the FLOMAX 8 is threaded to

a stainless steel drive sleeve. The sleeve slips over the drive

shaft and is locked to the drive shaft with a two-piece clamp.

This means you use a standard drive shaft - no special tapers

or threads. It's easy to adjust or remove the impeller. FLO-

MAX pumps are available with either a selflubricated shaft

seal, or a grease lubricated shaft seal. The self-lubricated seal

is lubricated by the liquid in the pump. Operating the pump

dry will seriously damage the seal.

To lubricate the grease lubricated seal, turn the wing nut on

the grease cup to the left - counter clockwise. If the pump

is to be left standing idle for any length of time in freezing

conditions, the pump housing should be drained. Draining is

provided for by a drain plug located at the base of the pump

housing.

DISASSEMBLY

Disconnect power (or spark plug wire) to prevent accidentally

starting.

Disconnect lines and drain pump housing.

TO REMOVE PUMP HOUSING

Remove Cap Screws and nuts holding pump housing to mou-

nting base (where used).

Remove nuts and lockwashers holding pump housing to the

adapter.

Loosen the housing and remove carefully to prevent tearing

gaskets.

TO REMOVE IMPELLER

If pump is equipped with a grease lubricated seal, relieve

pressure in grease cup by turning wing handle to the right -

clockwise.

Remove impeller clamp nuts and clamp to unlock impeller

drive sleeve from drive shaft.

Use two “jimmy” bars or large screwdrivers diagonally across

from each other between adapter and end of drive sleeve.

Pry the sleeve o the drive shaft.

Before removing the seal from the impeller, inspect the

carbon washer. If nicked or worn - replace it with a new one.

Inspect the seal seat (still in the pump adapter). If no nicks,

scratches or cracks appear and surface is clean and smooth,

there is no need to replace it. If replacement is necessary,

remove adapter by removing four hex nuts and washers.

Place adapter on at surface, with impeller side down. Press

out seal seat by using wooden end of a screw driver or similar

tool.

TO REPLACE IMPELLER

On the two-piece impeller it is not necessary to remove the

seal. Place impeller drive sleeve between two pieces of wood

in a vise. Hold impeller sleeve carefully so you do not damage

the seal assembly. Hold rmly and unthread impeller by turn-

ing counterclockwise - left hand. Replace with a new impeller.

Be sure seal spring ts over hub on back of impeller.

TO REMOVE ADAPTER

Remove the four nuts and lockwashers. Loosen and remove

adapter.

TO REMOVE WEAR PLATE

After pump housing has been removed from the adapter,

inspect the wear plate. If wear plate is badly worn, it should

be replaced. To remove wear plate, loosen and remove acorn

nuts and gaskets on the outside of the pump housing.

CAUTION: When replacing wear plate, be sure to use new

gaskets under acorn nuts to seal against air leaking in on suc-

tion side during priming cycle.

INSPECTION

After pump has been disassembled, check all parts over care-

fully for wear or damage. When ordering parts for your pump,

be sure to specify model and serial numbers shown on name

plate.

REASSEMBLY

MOUNTING ADAPTER

Before mounting adapter, clean counterbore with cleanser.

Clean and lubricate with light oil the synthetic rubber mem-

ber on seal seat and press (do not drive) the assembly into

the adapter counterbore, seating it rmly and squarely.

Install adapter. Install lockwashers and tighten four nuts

evenly.

CAUTION: In handling, avoid dropping seat and take particu-

lar care not to scratch the lapped face.

MOUNTING SELF-LUBRICATED SEAL ASSEMBLY

Mount seat and seat ring (Part 4 and 5) as outlined above.

Inspect impeller sleeve for nicks and burrs. Polish sleeve with

fine emery or crocus cloth. Then clean and lubricate with a

clean light oil.

Slip the coil spring (Part 1) onto the impeller sleeve making

certain that it is seated properly on the shoulder of the impel-

ler.

FLOMAX 8 BZ AL (en) Page 9 of 24

Lubricate the inside of the washer and bellows assembly (Part

2 and 3) with a clean light oil and slide it onto the impeller

drive sleeve only until it clears the chamfer.

Slide the seal bellows and washer assembly onto the impeller

drive sleeve. Push the seal down over the drive sleeve with

even pressure. Pull the seal head back up to the position

where there is no spring load. This insures proper assembly

on the drive sleeve.

Before sliding the impeller onto the drive shaft, wipe the

lapped sealing faces of the oating seat (Part 4) in the adapt-

er counterbore and the carbon washer (Part 3) on the bellows

assembly perfectly clean. Then lubricate both faces with a

clean light oil.

NOTE: The assembly of impeller and seal to the drive shaft

should take place as soon as the bellows assembly is slipped

on the impeller sleeve so as to avoid bonding of the bellows

to the sleeve at improper working height.

CAUTION: Foreign matter between sealing faces will cause

leakage and shorten the life of the seal.

MOUNTING GREASE LUBRICATED SEAL ASSEMBLY

Apply P80 to seal seat bore in seal housing and around O-ring

on carbon seal seat. Then press seal seat, by hand, into seal

seat bore making sure marked side of seal seat is down. Clean

and inspect for cracks, chips and deformities.

Dot

Groove

O Ring

O Ring

Figure 5

Place gasket over studs and O-ring into groove then install

seal housing over studs with seal facing up with ¼ NPT holes

at 2 o’clock and 7 o’clock position. Inspect and wipe clean if

needed. Apply P80 to impeller drive sleeve and to interior

of seal bellows, and push onto drive sleeve with seal pusher

with silicon carbide seal facing downward towards impeller.

The silicon carbide face is a matte light gray. The carbon face

is a very dark gray/black. See the picture below. Some seals

have the same primary seal face and therefor the direction

does not matter.

Carbon

Seal Face (black)

Silicon Carbide

Seal Face (gray)

To

wards

Impeller

Figure 6

Install seal spring over drive sleeve onto backside of silicon

carbide seal. Apply P80 to interior seal bellows of carbon seal

and push over drive sleeve with seal pusher carbon face up.

Inspect and wipe clean, if necessary. Install gasket over studs

onto seal housing. Apply P80 to seal seat bore of adapter and

around O-ring on seal seat. Push seal seat, by hand, into seal

bore – clean and inspect.

Install O-ring into adaptor groove. Apply P80 to O-ring. Place

adapter onto seal housing gasket, handle hole up, and attach

using 6 hex nuts and lock washers. Assemble clamp assembly

over drive sleeve. Leave loose.

Apply Gasoila onto threads of grease fitting and install to

lower pipe tting hole at 10 o’clock position in seal housing

and tighten by hand. NOTE: Do not get sealant into grease

fitting. Apply Gasoila to 1/8” NPT plug and install into pipe

tting at 5 o’clock position. Apply Gasoila to pressure release

valve threads and install into upper pipe tting hole at the 10

o’clock position.

Fill seal cavity with grease until it comes out of the reservoir

hole. Assembly grease reservoir into adaptor as shown below.

Place smaller O-ring over the piston. Place the large O-ring

over the reservoir cover. Install the piston into the adaptor

hole. Place the spring within the piston. Thread the cover

into the adaptor.

Figure 7

Continue filling seal cavity until high-pressure grease reser-

voir is full. NOTE: When grease reservoir is full it will spit out

of the pressure release valve.

Page 10 of 24 FLOMAX 8 BZ AL (en)

MOUNTING SEVERE-SERVICE SEAL ASSEMBLY

The MP PUMPS Severe-Service Seal is a precision assembly

requiring care in installation. To insure proper operation it is

necessary to install this seal as follows:

1. Thoroughly clean the seal seat cavity in the pump adapter.

2. Lubricate the seal seat O-Ring with light oil and carefully

install the seat into the seal cavity that is inside the

adapter.

3. Using a soft clean cloth, clean and lubricate both seal faces

with light oil.

NOTE: Any foreign matter between seal faces will cause

leakage and shorten seal life.

4. Complete assembly of seal and pump - see above.

5. Rotate by hand before start up.

MOUNTING IMPELLER

Do not use drive key between drive shaft and impeller sleeve.

The clamp will drive the sleeve. Slide the impeller sleeve onto

the drive shaft. Replace impeller clamp and capscrews, lock-

washers and nuts.

Before tightening clamp adjust clearance between back face

of impeller and adapter allowing from 0.015” (0.381 mm) to

0.020” (0.508 mm) clearance. Tighten impeller clamp to lock

impeller onto drive shaft. This automatically sets face clear-

ance of impeller when housing is mounted.

MOUNTING PUMP HOUSING

Replace gaskets on pump housing and mount housing on

the adapter. Replace two lockwashers and nuts on studs di-

agonally across from each other and tighten. Tum drive shaft

over slowly by hand and listen at outlet opening on housing

for any rubbing of impeller on the housing or wear plate.

The clearance between the impeller and wear plate can be

checked with a feeler gauge. Normal clearance is 0.015” (0.381

mm) to 0.020” (0.508 mm). If clearance exceeds 0.025” (0.635

mm) readjust impeller. If the impeller rubs use an additional

gasket to space impeller.

After clearance has been established, replace lockwashers

and nuts on remaining studs and tighten. If capscrews and

nuts are used to hold housing to mounting base, rep{ace

these and tighten.

FLOMAX 8 BZ AL (en) Page 11 of 24

PARTS LIST / FLOMAX 8 CC (56C and 145TC) (BRONZE)

1

7

8

9

2

10

6

5

1

11

12 13

14

15 16

17 18

19

23

21

20

24

22

4

3

2

Figure 8

PARTS LIST / FLOMAX 8 (56C and 145TC) (BRONZE)

Item Description (size) Qty Part No. Mtl

1Cap Screw

(HH 5/16” - 18” x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 8 MP21238 304 SS

3 Suction Flange 1 MP22386 Federalloy I-836

4 Flapper Assembly 1 MP23022 Buna

5 Pipe Plug (HH 1/4” NPT) 1 MP21267 316 SS

6 Housing 1 MP22250 Federalloy I-836

7 Discharge Flange 1 MP22310 Federalloy I-836

8 Square Ring 1 MP39436 Viton

9 Pipe Plug 1 MP22656 303 SS

10 Wear Plate 1 MP22259 Brass

11 Screw (FHS 5/16” - 18” x 5/8”) 2 MP37137 304 SS

12 Hex Jam Nut 1 MP22655 304 SS

13 Impeller 1 MP22292 Federalloy I-836

Item Description (size) Qty Part No. Mtl

14 Drive Sleeve (7/8”) 1 MP25664 303 SS

Drive Sleeve (5/8”) 1 MP22253 303 SS

15 See Table for seal options

16 O-Ring AS-568-158) 1 MP34555 Viton

17 Seal Housing 1 MP38706 Federalloy I-836

18 Cap Screw (3/8”-16” x 7/8”) 4 MP21251 304 SS

19 Lockwasher (3/8” x 1/8”) 4 MP21266 304 SS

20 Adapter 1 MP38704 Aluminum T-6

Cast

21 Hex Jam Nut (1/2 “- 13”) 1 MP22637 Steel

22 Handle 1 MP21938 Steel

23 Cap Screw

(5/16” - 18” x 3/4” Patch) 6 MP24965 304 SS

24

Clamp Assembly

(3/4" and 5/8") 1 MP23002 316 SS

Clamp Assembly (7/8") 1 MP23003 316 SS

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

Page 12 of 24 FLOMAX 8 BZ AL (en)

PARTS LIST / FLOMAX 8 PEDESTAL (BRONZE)

5

10

11

12 13

14

15 16

17

18

19 21

22

20

2

1

7

8

9

2

6

1

4

3

2

Figure 9

PARTS LIST / FLOMAX 8 PEDESTAL (BRONZE)

Item Description (size) Qty Part No. Mtl

1Cap Screw

(HH 5/16”-18” x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 14 MP21238 304 SS

3 Suction Flange 1 MP22386 Federalloy I-836

4Flapper Assembly 1 MP23022 Buna

Flapper Assembly 1 MP26097 EPDM

5 Pipe Plug (HH 1/4” NPT) 1 MP21267 316 SS

6 Housing 1 MP22250 Federalloy I-836

7 Discharge Flange 1 MP22310 Federalloy I-836

8Square Ring 1 MP39436 Viton

O-Ring (AS-568-149) 1 MP37142 Epdm

9 Pipe Plug 1 MP22656 303 SS

10 Wear Plate 1 MP22259 Brass

Wear Plate 1 MP27978 316 SS

11 Screw (FHS 5/16”-18” x 5/8”) 2 MP37137 304 SS

12 Hex Jam Nut 1 MP22655 304 SS

Item Description (size) Qty Part No. Mtl

13 Impeller (5.0”) 1 MP22292 Federalloy I-836

14 Drive Sleeve 1 MP22286 303 SS

15 See Table for seal options

16 O-Ring (AS-568-158) 1 MP34555 Viton

O-Ring (AS-568-158) 1 MP36911 Epdm

17 Gasket 1 MP22255 Lexide Ni-2085

18 Adapter 1 MP22246 Federalloy I-836

19 Cap Screw

(5/16” - 18” x 3/4” Patch) 6 MP24965 304 SS

20 Cap Screw SS

(HH 5/16” - 24” x 0.88”) 4 MP21278 304 SS

21 Clamp Assembly

(3/4" and 5/8") 1 MP23002 303 SS

22 Pedestal Assembly 1 MP26142 Cast Iron

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

MP27969 21 1" Ceramic Carbon Epdm 18-8 SS

FLOMAX 8 BZ AL (en) Page 13 of 24

PARTS LIST / FLOMAX 8 CLUTCH (BRONZE)

5

10

11

12 13

14

15 16

17

18

19 21

20

2

1

7

8

9

2

6

1

4

3

2

22

26

27

29

23

24

28

25

30

Figure 10

PARTS LIST / FLOMAX 8 CLUTCH (BRONZE)

Item Description (size) Qty Part No. Mtl

1Cap Screw

(HH 5/16” - 18” x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 14 MP21238 304 SS

3 Suction Flange 1 MP22386 Federalloy I-836

4Flapper Assembly 1 MP23022 Buna

Flapper Assembly 1 MP26097 EPDM

5 Pipe Plug (HH 1/4” NPT) 1 MP21267 316 SS

6 Housing 1 MP22250 Federalloy I-836

7 Discharge Flange 1 MP22310 Federalloy I-836

8 O-Ring (AS-568-149) 1 MP37142 Epdm

9 Pipe Plug 1 MP22656 303 SS

10 Wear Plate 1 MP22259 Brass

Wear Plate 1 MP27978 316 SS

11 Screw (FHS 5/16” - 18” x 5/8”) 2 MP37137 304 SS

12 Hex Jam Nut 1 MP22655 304 SS

13 Impeller (5.0”) 1 MP22292 Federalloy I-836

Impeller (5.0”) 1 MP22294 316 SS

14 Drive Sleeve 1 MP22286 303 SS

Drive Sleeve 1 MP33592 Duplex 2205

15 See Table for seal options

Item Description (size) Qty Part No. Mtl

16 O-Ring (AS-568-158) 1 MP34555 Viton

O-Ring (AS-568-158) 1 MP36911 EPDM

17 Gasket 1 MP22255 Lexide Ni-2085

18 Adapter 1 MP22246 Federalloy I-836

19 Cap Screw

(5/16” - 18” x 3/4” Patch) 6 MP24965 304 SS

20 Cap Screw

(SS HH 5/16” - 24” x 0.88”) 4 MP21278 304 SS

21 Clamp Assembly 1 MP23002 303 SS

22 Pedestal Assembly 1 MP26289 Cast Iron

23 Clutch Bracket (Right) 1 MP24434 Cold Rolled

Steel

24 Clutch Bracket (Left) 1 MP24433 Cold Rolled

Steel

25 Yok e 2 MP24430 Zinc Plated Steel

26 Clutch (A-B Belt) 1 MP28905 Steel

27 Hexnut (1/4” - 20”) 3 MP21241 304 SS

28 Lockwasher (1/4") 3 MP33564 304 SS

29 Screw (1/4” - 20” x 3/4”) 3 MP21247 304 SS

30 Handle 1 MP24431 Zinc Plated Steel

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

Page 14 of 24 FLOMAX 8 BZ AL (en)

PARTS LIST / FLOMAX 8 PEDESTAL ENGINE MOUNT (BRONZE)

1

7

8

9

2

10

6

5

1

11

12 13

14

15 16

17

18

19

20

21

22

4

3

2

Figure 11

PARTS LIST / FLOMAX 8 PEDESTAL ENGINE MOUNT (BRONZE)

Item Description (size) Qty Part No. Mtl

1 Cap Screw (HH 5/16”-18”x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 10 MP21238 304 SS

3 Suction Flange 1 MP22386 Federalloy

I-836

4 Flapper Assembly 1 MP23022 Buna

5 Pipe Plug (HH 1/4” NPT) 1 MP21267 316 SS

6 Housing 1 MP22250 Federalloy

I-836

7 Discharge Flange 1 MP22310 Federalloy

I-836

8 Square Ring 1 MP39436 Viton

9 Pipe Plug 1 MP22656 303 SS

10 Wear Plate 1 MP22259 Brass

11 Screw (FHS 5/16” - 18” x 5/8”) 2 MP37137 304 SS

12 Hex Jam Nut 1 MP22655 304 SS

Item Description (size) Qty Part No. Mtl

13 Impeller (5.0”) 1 MP22292 Federalloy

I-836

Impeller (5.0”) 1 MP22294 316 SS

14 Drive Sleeve 1 MP22286 303 SS

Drive Sleeve 1 MP33592 Duplex 2205

15 See Table for seal options

16 O-Ring (AS-568-158) 1 MP34555 Viton

O-Ring (AS-568-158) 1 MP36910 Buna

17 Gasket 1 MP22255 Lexide

Ni-2085

18 Adapter 1 MP22246 Federalloy

I-836

19 Cap Screw (5/16” - 18” x 3/4” Patch) 6 MP24965 304 SS

20 Hex Jam Nut (1/2” - 13”) 1 MP22637 Steel

21 Handle 1 MP21938 Steel

22 Clamp Assembly (3/4" and 5/8" ) 1 MP23002 304 SS

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

MP25015 21 1" Ceramic Carbon Buna 18-8 SS

FLOMAX 8 BZ AL (en) Page 15 of 24

PARTS LIST / FLOMAX 8 HYDRAULIC (0.22, 0.37, 0.45 and 0.58) (BRONZE)

5

10

11

12 13

14

15 16

17

18

19 21

22

20

1

7

8

9

2

6

1

4

3

2

Figure 12

PARTS LIST / FLOMAX 8 HYDRAULIC (0.22, 0.37, 0.45 and 0.58) (BRONZE)

Item Description (size) Qty Part No. Mtl

1Cap Screw

(HH 5/16” - 18” x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 10 MP21238 304 SS

3 Suction Flange 1 MP22386 Federalloy I-836

4 Flapper Assembly 1 MP23022 Buna

5 Pipe Plug (1/4” NPT) 1 MP41475 Steel

6 Housing 1 MP22250 Federalloy I-836

7 Discharge Flange 1 MP22310 Federalloy I-836

8 Square Ring 1 MP39436 Viton

9 Pipe Plug 1 MP22656 303 SS

10 Wear Plate 1 MP22259 Brass

11 Screw (FHS 5/16”-18” x 5/8”) 2 MP37137 304 SS

Item Description (size) Qty Part No. Mtl

12 Hex Jam Nut 1 MP22655 304 SS

13 Impeller 1 MP22292 Federalloy I-836

14 Drive Sleeve 1 MP22286 303 SS

15 Seal Assembly 1 MP22272 Ccs Viton

16 O-Ring (AS-568-158) 1 MP34555 Viton

17 Gasket 1 MP22255 Lexide Ni-2085

18 Adapter 1 MP22246 Federalloy I-836

19 Cap Screw

(5/16”-18” x 3/4” Patch) 6 MP24965 304 SS

20 Cap Screw SS

(HH 5/16” - 24” x 0.88”) 4 MP21278 304 SS

21 Clamp Assembly 2 MP23002 303 SS

22 Hyd Ped Asy (0.372”) 1 MP36447 Cast Iron

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

Page 16 of 24 FLOMAX 8 BZ AL (en)

PARTS LIST / FLOMAX 8 CC (56C and 145TC) (ALUMINUM)

1

9

10

11

2

7

8

12

6

5

1

13

14 15

16

17 18

19 22

23

21

20

24

4

3

2

Figure 13

PARTS LIST / FLOMAX 8 CC (56C and 145TC) (ALUMINUM)

Item Description (size) Qty Part No. Mtl

1Cap Screw

(HH 5/16” - 18” x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 10 MP21238 304 SS

3 Suction Flange 1 MP22385 Aluminum

T-6 Cast

4 Flapper Assembly 1 MP23022 Buna

5 Lockwasher (5/16” x 18”) 10 MP21238 304 SS

6 Housing 1 MP22248 Aluminum T356

7 Drive Screw 2 MP21122 304 SS

8 Name Plate 1 MP21183 Aluminum

9 Flange 1 MP22309 Aluminum 356

T-6 Cast

10 O-Ring (AS-149) 1 MP37141 Viton

11 Pipe Plug (1/2" NPT ) 1 MP37140 Zinc Plated Steel

12 Wear Plate 1 MP22258 Aluminum

#6061

13 Screw (FHS 5/16” - 18” x 5/8”) 2 MP37137 304 SS

14 Hex Jam Nut 1 MP22655 304 SS

Item Description (size) Qty Part No. Mtl

15

IMPELLER (4.6”) 1 MP26007 Aluminum

T-6 Cast

IMPELLER (5.0”) 1 MP22291 Aluminum

T-6 Cast

16 Drive Sleeve (5/8”) 1 MP22253 303 SS

Drive Sleeve (7/8”) 1 MP25664 303 SS

17 See Table For Seal Options

18 O-Ring (AS-568-158) 1 MP34555 Viton

19 Gasket 1 MP22255 Lexide Ni-2085

20 Adapter 1 MP25946 Aluminum

T-6 Cast

21 Cap Screw

(5/16” - 18” x 3/4” Patch)6 MP24965 304 SS

22 Cap Screw (3/8” - 16” x 7/8”) 4 MP21251 304 SS

23 Lockwasher (3/8” x 1/8”) 4 MP21266 304 SS

24

Clamp Assembly (7/8”) 1 MP23003 303 SS

Clamp Assembly

(3/4 “and 5/8”) 1 MP21946 303 SS

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

FLOMAX 8 BZ AL (en) Page 17 of 24

PARTS LIST / FLOMAX 8 PEDESTAL (ALUMINUM)

5

10

11

12 13

14

15 16

17

18

19 21

22

20

2

1

7

8

9

2

6

1

4

3

2

Figure 14

PARTS LIST / FLOMAX 8 PEDESTAL (ALUMINUM)

Item Description (size) Qty Part No. Mtl

1Cap Screw

(HH 5/16” - 18” x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 14 MP21238 304 SS

3 Suction Flange 1 MP22385 Aluminum

T-6 Cast

4 Flapper Assembly 1 MP23022 Buna

5 Pipe Plug (HH 1/4” NPT) 1 MP21267 316 SS

6 Housing 1 MP22248 Aluminum T356

7 Flange 1 MP22309 Aluminum

356 T-6 Cast

8 O-Ring (AS-149) 1 MP37141 Viton

9 Pipe Plug (1/2" NPT ) 1 MP37140 Zinc Plated Steel

10 Wear Plate 1 MP22258 Aluminum #

6061

11 Screw (FHS 5/1”6 - 18” x 5/8”) 2 MP37137 304 SS

Item Description (size) Qty Part No. Mtl

12 Hex Jam Nut 1 MP22655 304 SS

13 Impeller 1 MP22291 Aluminum T-6

Cast

14 Drive Sleeve 1 MP22286 303 SS

15 See table for seal options

16 O-Ring (AS-568-158) 1 MP34555 Viton

17 Gasket 1 MP22255 Lexide Ni-2085

18 Adapter 1 MP22245 Aluminum

356 T-6 Cast

19 Cap Screw

(5/16” - 18” x 3/4” Patch) 6 MP24965 304 SS

20 Cap Screw SS

(HH 5/16” - 24” x 0.88”) 4 MP21278 304 SS

21 Clamp Assembly 1 MP23002 303 SS

22 Pedestal Assembly 1 MP26142 Cast Iron

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

MP22560 21 1" Silicon Carbide Silicon Carbide Viton 316 SS

Page 18 of 24 FLOMAX 8 BZ AL (en)

PARTS LIST / FLOMAX 8 PEDESTAL ENGINE MOUNT (ALUMINUM)

1

7

8

9

2

10

6

5

1

11

12 13

14

15 16

17

18

21

19

20

22

4

3

2

Figure 15

PARTS LIST / FLOMAX 8 PEDESTAL ENGINE MOUNT (ALUMINUM)

Item Description (size) Qty Part No. Mtl

1Cap Screw

(HH 5/16” - 18” x 7/8”) 8 MP21242 304 SS

2 Lockwasher (5/16” x 18”) 10 MP21238 304 SS

3 Suction Flange 1 MP22387 Cast Iron

4 Flapper Assembly 1 MP23022 Buna

5 Pipe Plug (HH 1/4” NPT) 1 MP21267 316 SS

6 Housing 1 MP22248 Aluminum

T356

7 Flange 1 MP22311 Cast Iron

8 O-Ring (AS-149) 1 MP37141 Viton

9 Pipe Plug (1/2" NPT ) 1 MP37140 Zinc Plated

Steel

10 Wear Plate 1 MP22258 Aluminum

#6061

11 Screw (FHS 5/16” - 18” x 5/8”) 2 MP37137 304 SS

12 Hex Jam Nut 1 MP22655 304 SS

Item Description (size) Qty Part No. Mtl

13 Impeller (5.0”) 1 MP22291 Aluminum

T-6 Cast

Impeller (5.0”) (5BL) 1 MP33333 CF8M

14 Drive Sleeve 1 MP22286 303 SS

15 See table for seal options

16 O-Ring (AS-568-158) 1 MP34555 Viton

17

Gasket 1 MP22255 Lexide Ni-

2085

Gasket 1 MP35722 Klingersil

C-44332

18 Adapter 1 MP22245 Aluminum

356 T-6 Cast

19 Cap Screw

(5/16” - 18” x 3/4” Patch) 6 MP24965 304 SS

20 Handle 1 MP21938 Steel

21 Hex Jam Nut (1/2” - 13”) 1 MP22637 Steel

22

Clamp Assembly

(3/4” and 5/8”) 1 MP23002 303 SS

Clamp Assembly (7/8”) 1 MP35612 Brass

SEAL TYPE OPTIONS

Seal PN Seal Type Shaft Dia. Mating Ring Material

Primary Ring Elastomer Components

MP22273 21 1" Ceramic Carbon Viton 316 SS

MP35610 2 1" Silicon Carbide Carbon Viton 18-8 SS

FLOMAX 8 BZ AL (en) Page 19 of 24

SERVICE KITS

PUMP MODEL PUMP DESCRIPTION SEAL KIT IMPELLER KIT BEARING KIT

MP36503 FM8PMP A:1.5-3 56C FA 4.1 WBA MP51310 ---- ----

MP38702 FM8PMP A:3-1 56C MTO FA 5.0 WBA MP51310 ---- ----

MP21336 FM8PMP A:PED 5.0 MP51310 ---- MP51315

MP37945 FM8PMP A:PED 5.0 SSC ---- ---- MP51315

MP51157 FM8PMP A:PED/HYD .45 DISP W/FC 5.0 MP51310 ---- #N/A

MP51083 FM8PMP B: 3-3 182T XP 5.0SI SSWP WBA ---- ---- MP51315

MP35752 FM8PMP B:3-1 182T 5.0 WBA ---- ---- MP51315

MP30675 FM8PMP B:3-3 182T 5.0 WBA ---- ---- MP51315

MP21338 FM8PMP B:PED 5.0 ---- ---- MP51315

MP37003 FM8PMP B:PED 5.0SI EP SSWP DUP S-FLG ---- ---- MP51315

MP34138 FM8PMP B:PED 5.0SI T-21 EPDM SSWP DUP ---- ---- MP51315

MP33695 FM8PMP B:PED 5.0SSI SSWP ---- ---- MP51315

MP26858 FM8PMP B:PED/CL .50 SAE 5.0 RD ---- ---- MP51315

MP24550 FM8PMP B:PED/CL 5.0 ---- ---- MP51315

MP29726 FM8PPK A:7/8 SL CC MTR 4.63CAI MP51310 ---- ----

MP39967 FM8PPK A:CCMTR 5/8FA 4.62 MP51310 ---- ----

MP26266 FM8PPK A:CCMTR 7/8 FA 5.0 MP51310 ---- ----

MP21325 FM8PPK A:PEM 3/4 5.0 MP51310 ---- ----

MP21330 FM8PPK A:PEM 3/4 5.0 BCF MP51310 ---- ----

MP30040 FM8PPK A:PEM 3/4 5.0 CI FLANGE MP51310 ---- ----

MP39032 FM8PPK A:PEM 3/4 5.0HF-SI MP51310 ---- ----

DIMENSIONAL DATA

FM8 BZ CC

9.16

12.79

.38

3.00 3.25

8.50

2" NPT

DISCHARGE

1.50 7.84

3.63

10.15

6.06

4.17

.45

1/4" NPT

PIPE PLUG

2" NPT

SUCTION

1.26

5.50

2.74

4.50

(4)

.344

HOLES

3.450

4.506

4.502

45° TYP.

(4)

.438 THRU HOLES

EQ. SPACED AS SHOWN

ON A

5.875 B.C.

Figure 16

Page 20 of 24 FLOMAX 8 BZ AL (en)

FM8 BZ PED

6.25

12.79

8.50

3.253.00

9.16

1/2"

PIPE PLUG

1.504.69

6.06

14.60

3.63

4.561.56

4.17

1.79

.750

.749

2" NPT

DISCHARGE

2" NPT

SUCTION

1/4" NPT

PIPE PLUG

(4)

.41

HOLES

5.00

6.00

2.44

Figure 17

FM8 BZ CLUTCH

6.25

12.79

8.50

3.253.00

9.16

1/2"

PIPE PLUG

1.50

4.17

4.56

16.61

6.06

3.63

4.69

.75

2" NPT

DISCHARGE

2" NPT

SUCTION

1/4"

PIPE PLUG

1.56

2.44

5.006.00

.41

(4) HOLES

Figure 18

Table of contents

Other MP PUMPS Water Pump manuals

Popular Water Pump manuals by other brands

Bestway

Bestway P3052 operating instructions

FMC Technologies

FMC Technologies FMC L06 Operation and maintenance manual

Salamander Pumps

Salamander Pumps SKELECT05 ELECT quick start guide

KSB

KSB Ama-Drainer N 301 Installation & operating manual

Kessel

Kessel Pumpfix S Installation and operating manual

MIT

MIT 160 Installation and user guide

Rapid

Rapid ABS 200 A-LKW manual

EINHELL

EINHELL RG-DP 4525 Original operating instructions

Hyundai power products

Hyundai power products HYWP4300X user manual

KSB

KSB HPK Series Installation & operating manual

Lincoln industrial

Lincoln industrial CENTRO-MATIC 85438 manual

T.I.P.

T.I.P. MSX 85/55 INOX operating instructions