MPFiltri LPA2 Manual

Operators Guide

LPA2 - Aviation Edition

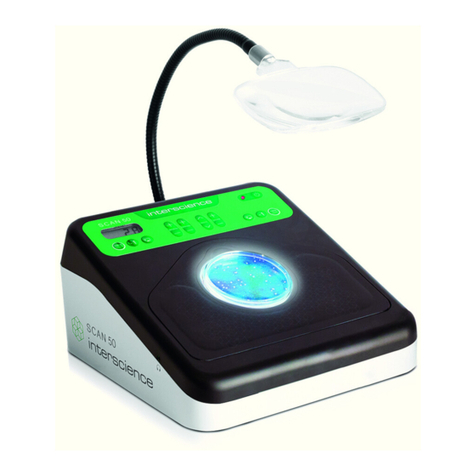

Portable Particle Counter

PRODUCT OVERVIEW

• Approved by Airbus

• Specialist Airbus sampling valve adaptor* and C spanner

• LPA2 - Aviation Edition saves time: online/realtime monitoring

• Immediate hydraulic health check

• Predictive maintenance procedures can be employed

• Reduced downtime for industrial and mobile plants

• Reduced costs associated with downtime

• Fully portable

• Precision Instrument

• Full Calibration based on ISO11171

• Measures and displays the following international standard formats; ISO 4406:2017, NAS 1638, AS 4059E

• Data logging and 600 test result memory

• Manual and remote control exibility

• LPA View software (included)

• Full size QWERTY keyboard

• Normal test 50ml sample volume for Airbus application

• Full accessories kit included

• Internal rechargeable battery capable of performing 100 tests between charges

The LPA2 - Aviation Edition is a highly precise, lightweight & fully portable instrument designed exclusively for the Aviation

Industry.

It can automatically measure and display particulate contamination, moisture and temperature levels in various hydraulic uids.

The LPA2 - Aviation Edition can be connected to the MP range of bottle sampler products to enable laboratory based particle

counting.

Approved by Airbus, the LPA2- Aviation Edition is a solution for online monitoring of contamination in hydraulic uid, providing an

immediate hydraulic health check. It employs predictive maintenance procedures to help reduce downtime and in turn costs.

LPA2 - Aviation Edition - Portable Particle Counter

Features and benets

Automatic Particle Counters

1

Product Presentation

The LPA2 - Aviation Edition is designed to measure and quantify the numbers of solid contaminants in Hydraulic, Lubrication and

Transmission applications. The LPA2 - Aviation Edition is designed to be a laboratory accurate instrument suitable for “on-site’’

applications utilising mineral oil as the operating uid. Please contact local sales ofce for other operating uid options.

The instrument uses the light extinction principle whereby two laser light systems shine through the uid and lands on photodiodes.

When a particle passes through the beam it reduces the amount of light received by the diode, and from this change in condition,

the size of the particle can be deduced.

Hydraulic and lubricating ystems consist of sets of continuously moving metal parts, which use hydraulic uid as the power

medium. Hydraulic uid is also used to create a lubrication lm to keep the precision parts separated and it is also used as a cooling

medium. The very nature of a hydraulic system is that it produces solid par- ticulate contaminants and these are ever present in all

hydraulic systems. There is a revised standard ISO cleanliness code ISO 4406 which classies the numbers of particles that can be

tolerated within the system and it is these levels of contaminants that the par- ticle counter is designed to measure.

Automatic Particle Counters

2

Disclaimer

As a policy of continual improvement, MP Filtri reserves the right to alter the specication without prior notice.

PRODUCT OVERVIEW

Automatic Particle Counters

3

Automatic Particle Counters

4

DECLARATION OF CONFORMITY

EC Declaration of Conformity

Product Manufacturer:

MP Filtri UK

Bourton Industrial Estate

Bourton on the Water

Cheltenham

Gloucestershire

GL54 2HQ

01451 822522

sales@mpltri.co.uk

Product: LPA20PSTA30 - Laser Particle Analyser

The products described are in conformity with the following directives:

BS EN 61326-1:1997 Electrical equipment for measurement, control and laboratory use – EMC requirements

BS EN 61010-1:1993 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

Date: July 2020

Signed:

Phil Keep (Managing Director) on behalf of MP Filtri UK Ltd

Automatic Particle Counters

5

Pg.

Product overview 1

EC Declaration of Conformity 5

Table of Contents 8

1 General warnings and information for the Operator 8

1.1 General safety warnings 8

1.2 Operator position and dangerous areas 10

1.3 Dangers and Hazards that cannot be eliminated 10

1.4 Personal Protective Equipment 10

1.5 Precautions related to product handling of the Liquid Crystal Touchscreen display

2 Transportation and Storage 13

2.1 Transportation and Handling Conditions 13

2.2 Storage 13

3 Warranty, Limitations and Disclaimers 14

4 Technical Specication 16

4.1 Performance 16

4.2 Electrical Interface 16

4.3 Physical Attributes 17

4.4 Fluid Characteristics 17

4.5 Environment 17

4.6 Product Family 17

4.7 Dimensions 18

4.8 Designation & Ordering code 18

4.9 Scope of supply 19

5 Product Installation and Online Operation 20

5.1 Connecting the sample valve adaptor to the aircraft 20

5.2 Connecting and performing an online particle analysis 25

5.3 Disconnecting and shutting down the LPA2 - Aviation Edition and sampling valve adaptor 30

5.4 Pressure transducer 34

5.5 Data logging 34

5.6 Battery changing 34

5.7 Printer paper changing 35

11

6 Computer analysis 36

6.1 Software installation 36

6.2 Results download 36

Automatic Particle Counters

6

7 Spares 37

7.1 Product and part numbers 37

TABLE OF CONTENTS

Pg.

8 Appendices 38

9.1 NSA307110 (SAE AS4059 Rev E) Cleanliness classication for hydraulic uids 38

9.2 Replacement of the adaptor seal 39

9.3 Adaptor tightening tool 41

9.4 Com ports 43

9 Spares 44

9.1 Fault nding 44

Automatic Particle Counters

7

It means that failure to comply with the relevant safety regulations may result in mild injury or property damage.

It relates to important information concerning the product, its use or part of this documentation

to which special attention must be paid

It means that failure to comply with the relevant safety regulations may result in death, serious injury

or serious property damage.

CAUTION

NOTE

DANGER

!

!

!

1 General warnings and information for the Operator

1.1 General safety warnings

Do not operate, maintain or carry out any procedure before reading this manual. Any individual operating the unit shall wear the

following Personal Protective Equipment:

- Protective eyewear

- Safety shoes

- Gloves

- Overalls (or other suitable protective clothing)

Before carrying out any machine installation procedures and/or before use, one should scrupulously follow the in- structions listed

in this manual. Moreover, it is necessary to comply with the current regulations related to occupational accident prevention and

safety in the workplace.

Notices aimed at the prevention of health hazards for personnel operating the machine are highlighted in this document with signs

having the following meaning:

Failure to comply with the relevant safety regulations may result in death, serious injury or serious property damage.

Automatic Particle Counters

8

GENERAL WARNINGS

To allow rapid identication of the employees who must read this manual, denitions have been used with the following meaning:

This is any individual whose task is to use the machine for production purposes. The operator is

aware of all the measures taken by the machine manufacturer in order to eliminate any source

of injury risk in the workplace and takes into account the operational constraints.

This is any individual whose task is to carry out maintenance activities on the machine. The

maintenance technician is aware of the possible danger situations that may arise and takes the

appropriate precautions in order to eliminate the risks of accidents in the workplace.

This is any individual whose task is to carry out maintenance activities on the electrical wiring of

the machine. The electrician is aware of the possible danger situations that may arise and takes

the appropriate precautions in order to eliminate the risks of accidents in the workplace.

This is any individual whose task is to handle the machine or parts of it. Personnel involved in

slinging and hoisting operations are aware of the issues regarding the safe transfer of machinery

or parts of it and, therefore, uses appropriate lifting equipment, following the instructions provi-

ded by the product manufacturer.

This is any individual whose task is to set up the machine for its operation. The machine setter is

aware of the measures taken to eliminate all sources of injury risks in the workplace and takes

into account the operational constraints. The machine setter takes all the appropriate precau-

tions in order to operate in utmost safety conditions.

OPERATOR

MAINTENANCE

TECHNICIAN

ELECTRICIAN

PERSONNEL INVOLVED

IN SLINGING AND

HOISTING OPERATIONS

MACHINE SETTER

Automatic Particle Counters

9

1.2 Operator position and dangerous areas

No operator is required for operating the unit. However, the following areas are to be considered dangerous: The ones

close to the electric motor because of live equipment with potentially hot surfaces.

1.3 Dangers and hazards that cannot be eliminated

- Electric shock risk on the electric motor; in case of motor malfunction

- Burn risk because of high temperatures

- Accidental oil leaks with consequent risk of slipping

- Hose breakage and resulting lubricant loss

- With oil temperatures exceeding 40/45 °C, it is vital to be extremely careful when handling the metal lances/the hoses and

when moving the unit. Avoid direct contact with hot oil and with the lter body.

ALL EQUIPMENT SHOULD BE ALLOWED TO COOL PRIOR TO HANDLING, AFTER IT HAS BEEN IN USE

1.4 Personal Protective Equipment

When operating the unit, personnel must be wearing safety shoes, gloves and goggles. In general, the PPEs to be used according

to the activities on the machinery are listed in the following table:

ACTIVITY

Ordinary operation

Planned maintenance

Shoes, gloves, goggles, overall

Shoes, gloves, goggles, overall

PPE

The unit shall be taken out of service and/or dismantled in accordance with the current regulations in force

in the country where the machinery is installed

The machinery is not suitable for outdoor use and all the electrical devices have a protection class

starting from IP 55 upwards.

NOTE

!

CAUTION

!

Automatic Particle Counters

10

GENERAL WARNINGS

1.5 Precautions related to product handling of the LPA2 - Aviation Edition

Battery

• It is recommended that the LPA2 - Aviation Edition be charged for a minimum of 24 hours prior to rst use, to fully charge the

internal battery

Internal cleaning

• Do NOT clean the LPA2 - Aviation Edition or Bottle Sampler with Acetone or similar solvents that are not compatible with the

seals in the LPA2 - Aviation Edition. The recommended cleaning uid for internal ushing is Petroleum Ether - see also Fault

Finding, page 44.

• Note: it is not always necessary to clean the unit between uses. The 30 second automatic pre ush is sufcient to purge any

previously sampled uid from the unit and its associated accessory hoses.

• The use of a 500μm coarse screen lter, screwed onto the HP connector, is recommended for heavily contaminated systems.

Refer to section 8.1 for the part number.

LCD visibility

• If the LCD screen remains blank then refer to page 34 for recharging instruction. To improve the LCD screen visibility, the

Analyser can be inclined by unlatching the two extension feet tted to the bottom of the case.

Automatic Particle Counters

11

Automatic Particle Counters

12

TRANSPORT / STORAGE

2 Transportation and Storage

2.1 Transportation and handling conditions

The unit is shipped in a cardboard box with appropriate protective packaging and these should be recycled accordingly

where possible.

The packed weight of the LPA2 - Aviation Edition, travel case and accessories is 18.5 kg.

2.2 Storage

The unit should be stored in a suitable location away from the production area when not in use. The unit should be stored with

the caps provided on the ports. This location should not impede any other production or personnel.

Automatic Particle Counters

13

3 Warranty, limitations and disclaimers

MP Filtri warrants that the products that it manufactures and sells will be free from defects in material, workmanship & performance

for a period of 12 months from the date of shipment.

Hardware/Firmware

Should the hardware prove defective during the warranty period, MP Filtri, at its discretion, will either repair the defective product

or replace it with an equivalent product in exchange for the defective unit without charge for parts, labour, carriage and insurance.

Software

MP Filtri warrants that software will operate substantially in accordance with its functional specication for 12 months from date

of shipment provided that the integrity of the operating environment has not been compromised through misuse, inappropriate

handling, abnormal operating conditions, neglect or damage (unintentional or otherwise) or the introduction of third party product

(software or hardware) that in any way conicts with the MP Filtri product.

Eligibility

This warranty extends to the original purchaser only or to the end-user client of a MP Filtri authorised afliate.

How to obtain service?

To obtain service under the terms of this warranty, the customer is required to notify MP Filtri before the expiration of the warranty

period and to return the item in accordance with MP Filtri product return policy. Any product returned for warranty repair must be

accompanied by a full fault report specifying the symptoms and the conditions under which the fault occurs. Should MP Filtri incur

additional cost as a result of a failure to complete the appropriate paperwork, an administrative charge may be levied.

Exclusions

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate care. MP Filtri

shall not be obligated to provide service under this warranty if:

a) Damage has been caused by a failure to make a full and proper inspection of the product (as described by the

documentation enclosed with the product at the time of shipment) on initial receipt of the product following shipment;

b) Damage has been caused by the attempts of individuals, other than MP Filtri staff to repair or service the product;

c) Damage has been caused by the improper use or a connection with incompatible equipment or product including software

applications.

Charges

Under cover of this warranty, MP Filtri will pay the carriage and insurance charges for the shipment of defective product back to

site of manufacture and for its return to the client’s original site of despatch except when:

a) MP Filtri product return policy has not been followed.

b) Product failure is caused by any of the exclusions described above, when the customer will be liable for the full cost of the repair

(parts and labour) plus all carriage and insurance costs to and from MP Filtri premises.

c) The product is damaged in transit and a contributory cause is inadequate packaging. It is the customer’s responsibility to ensure

that the packaging used to return equipment to MP Filtri is the same, or has equivalent protective qualities, to that used to ship

the product to the customer in the rst instance. Any damage resulting from the use of inadequate packaging will nullify MP Filtri

Automatic Particle Counters

14

WARRANTY

obligations under this warranty. Should the customer’s product be damaged in transit following a repair at MP Filtri site, a full

photographic record of the damage must be obtained (packaging and the product) to support any claim for recompense. Failure to

present this evidence may limit MP Filtri obligations under this warranty.

THIS WARRANTY IS GIVEN BY MP FILTRI IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY, NON INFRINGEMENT OR FITNESS FOR A PARTICULAR PURPOSE. MP FILTRI LTD

SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES ( INCLUDING LOSS

OF DATA), WE SPECIFICALLY DISCLAIM ANY AND ALL WARRANTIES TO CUSTOMERS OF THE CUSTOMER. THE CUSTOMER’S SOLE

REMEDY FOR ANY BREACH OF WARRANTY IS THE REPAIR OR REPLACEMENT, AT MP FILTRI DISCRETION, OF THE FAILED PRODUCT.

MP Filtri Ltd maintains a policy of product improvement and reserves the right to modify the specications without prior notice.

It is requested that only the LPA2 - Aviation Edition and adaptor, (not the support case or any other ancilliaries), be returned for

recalibration.

MP Filtri UK will not be held responsible for any items returned as such.

Ensure that the LPA2 - Aviation Edition is packed appropriately for transportation.

3.1 Warranty on recalibration

The LPA2 - Aviation Edition is guaranteed for 12 months upon receipt of goods, subject to it being used for the purpose intended

and operated in accordance with this User Guide.

MP Filtri UK will only verify the accuracy of the LPA2- Aviation Edition if the unit is recalibrated every 12 months.

Please ensure that the test results in the Log are downloaded to LPA-View before the LPA2 - Aviation Edition is

despatched, in case action taken by MP Filtri UK during the service / recalibration causes the Log to be cleared. NOTE

!

Automatic Particle Counters

15

4.2 Electrical interface

Supply Voltage 9-36V DC

Supply Current 2A Max

Power Consumption Charging state: ~40W max

Idle State: 3W max

Note: Power consumption level can vary dependant on uid properties

Test Time: (Dened as total time to sample

and empty the sample)

Time for result to be presented (min)

8 ml. (short): 2:15

50 ml. (normal): 3:30

30 ml. (dynamic): 2:30

24 ml. (bottle sampler): 1:45

15 ml. (continuous): 1:15

Total test time inc emptying cycle (min)

8 ml. (short): 4:00

50 ml. (normal): 6:30

30 ml. (dynamic): 4:30

24 ml. (bottle sampler): 3:00

15 ml. (continuous): 2:30

Data Storage Approximately 600 time-stamped tests in the integral LPA2 - Aviation Edition

memory

Keypad & LCD Full size QWERTY keyboard and backlit graphical LCD

Communication Options 9 pin D type RS232 serial port for direct connection to PC and software

4.Technical Specication

4.1 Performance

Technology Twin laser and twin optical diode detectors based light extinction automatic

optical particle analyser

Particle Sizing >4, 6,14, 21, 25, 38, 50, 70 μm(c) to ISO 4406 Standard

Analysis range ISO 4406 Code 8 to 24

NAS 1638 Class 2 to 12

AS4059 Rev.E. Table 1 Size Codes 2-12

AS4059 rev.E, Table 2 Size Codes, A:000 to 12, B:00 to 12, C:00 to 12, D:2to12,

E:4to12, F:7to12

Calibration Each unit individually calibrated with ISO Medium Test Dust (MTD) based on ISO

11171, on equipment certied by I.F.T.S. to ISO 11943

Accuracy Better than 3% typical

Automatic Particle Counters

16

TECHNICAL SPECIFICATION

4.3 Physical attributes

Dimensions LPA2 - Aviation Edition only

Height 210mm (8.2 inches), Depth 260mm (10.2 inches), Width 430mm (16.9

inches)

LPA2 - Aviation Edition with travel case - boxed

Height 400mm (15.7 inches), Depth 500mm (19.7 inches), Width 600mm (23.6

inches)

Weight 9.8 kg / 31 lbs (Packed weight: 18.5kg / 41lbs)

Hydraulics Connections INLET M16x2 test point

OUTLET Quick release coupling

Seal Material S version: FFKM

4.4 Fluid characteristics

Fluid compatibility S Version - Aviation phosphate esters and mineral oils

Viscosity ≤ 400 cSt

Fluid temperature +5°C (41°F) to +80°C (+176°F)

Sample volume 50ml (normal): 6 mins 30 secs approx

Minimum pressure 2 bar / 29 psi

Maximum pressure 400 bar / 5801 psi static

System pressure measurement +/- 0.5% Full scale accuracy min 10 bar

4.5 Environment

Ambient working temperature -10°C (+14°F) to +80°C (+176°F)

IP Rating IP51 (Lid open)

4.6 Product Family

Airbus Variants A320 family, A330 and A340 family, A380, A350

Automatic Particle Counters

17

AUTOMATIC PARTICLE COUNTER LPA2 -

AVIATION EDITION

Series

LPA2

Moisture Sensor

Accessories

Bottle Sampling Options

Pressure Sensor

Fluid compatibility

0

A

S

T

P

Without moisture and temperature sensor

Twin Laser Particle Analyser

With Airbus Adaptor

Design Ref

30

Standard Unit with Travel Case

With on-screen inlet pressure display

Phosphate ester and aggressive uids (*) (**)

Conguration example:

LPA2 S A0 P T 30

4.8 Designation and ordering code

4.7 Dimensions

Automatic Particle Counters

18

Other manuals for LPA2

2

This manual suits for next models

1

Table of contents

Other MPFiltri Cash Counter manuals