Mr Beam dreamcut [s] User manual

dreamcut & dreamcut [S] & [X]

MANUAL

© 2022 Mr Beam Lasers GmbH | Munich, 23 May 2023 | Revision 2.0

Translation of the original German manual

CONTENTS

Manual

WELCOME

1.1 Using the manual 5

1.2 About Mr Beam 6

OVERVIEW OF COMPONENTS

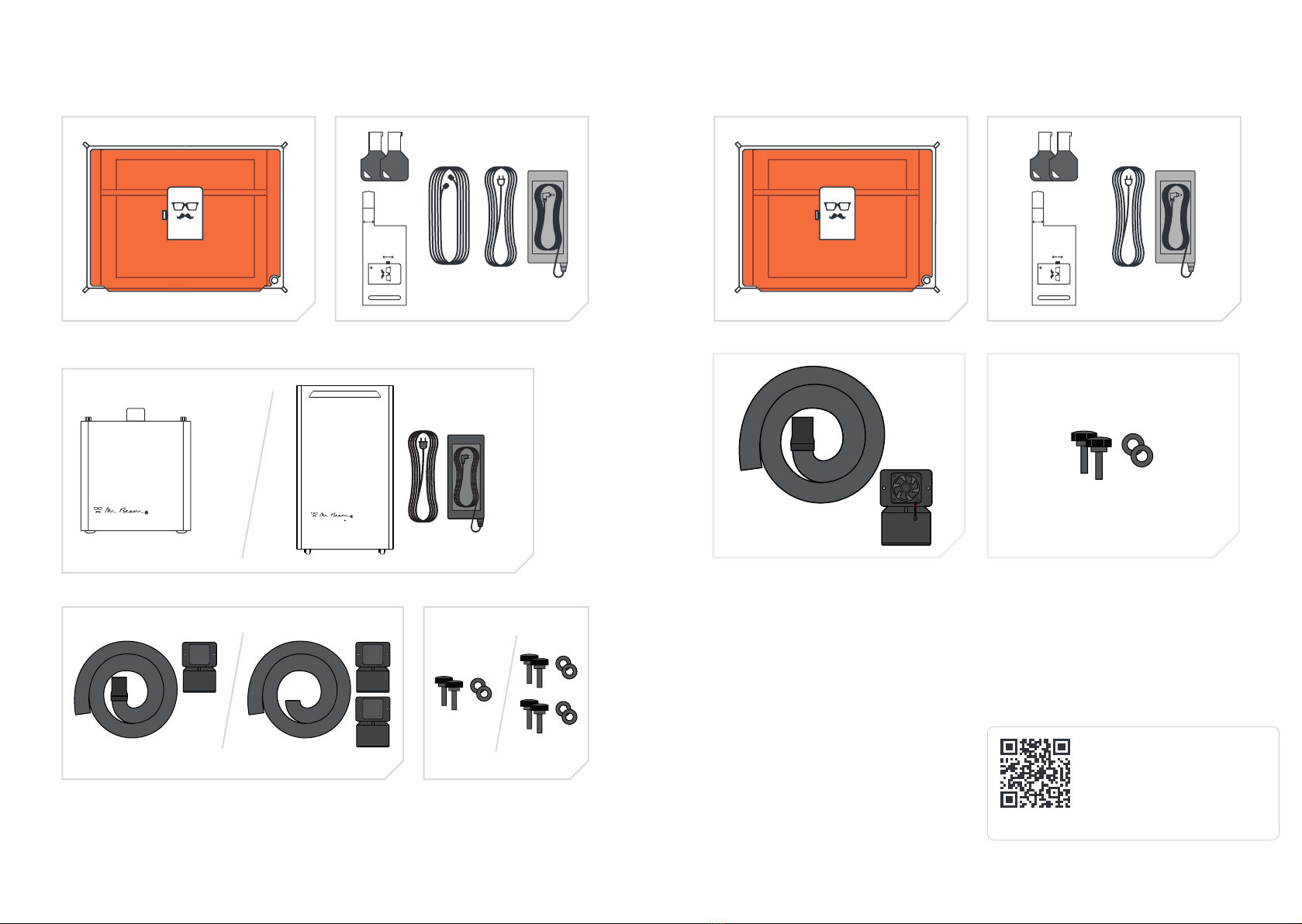

2.1 Scope of supply of Mr Beam with Air Filter System System 8

2.2 Scope of supply of Mr Beam without Air Filter System 9

2.3 Overview of Mr Beam 10

2.4 Connections 11

SAFETY AND CONFORMITY

3.1 Intended use 13

3.2 Basic safety instructions 14

3.3 Notes on preventing damage to property 16

3.4 Qualification of the user 16

3.5 Description of the workplace 17

3.6 Warning and safety signs 18

SETUP

4.1 Unpacking 22

4.2 Connecting the laser head 23

4.3 Connecting the Suction/Air Filter System 24

4.4 Suction/Air Filter System 25

4.5 Switching on the electrical power supply 26

4.6 Switching off the electrical power supply 27

4.7 Connecting to a computer 28

4.8 Option A - Wi-Fi direct connection 30

4.9 Option B - Cable and Router 31

4.10 Option C - Wi-Fi and Router 32

WORKING WITH YOUR MR BEAM

5.1 BeamOS 35

5.2 Materials and maximum workpiece size 36

5.3 Button 36

5.4 Camera 37

5.5 Meaning of the status lights 38

5.6 Focus 39

SERVICING AND MAINTENANCE

6.1 Regular Maintenance & Servicing 41

6.2 Cleaning the base plate / Changing the filter / Repairs 42

ADDITIONAL INFORMATION

7.1 Technical data - Mr Beam 44

7.2 Storage & Transport / Support 45

7.3 Disposal 46

GENERAL TERMS AND CONDITIONS

8.1 General Terms and Conditions 48

8.2 Contact addresses 48

01

02

03

04

05

06

07

08

Welcome to the creative

Mr Beam Community

Finally, the time has come: In front of you

is your Mr Beam laser cutter, ready to help

you realise your creativity.

We have worked hard for this moment for

several years and put a lot of heart and

soul into development and production.

You can find us on many social media using

the hashtag #madewithmrbeam such

as Instagram, Twitter or Facebook, with

inspiration from other members of the Mr

Beam community. Naturally, we would also

be happy if you share your works there and

tell your friends about it. We are curious to

see how you use your Mr Beam and what

you will create with it!

We'd love to hear your feedback, either in

images or text.

If something doesn't work out so well,

please contact us at any time:

www.mr-beam.org/ticket

Have fun with your Mr Beam!

The entire Mr Beam team

WELCOME

Section 01

1.1 Using the manual

Note: Before starting up and using Mr

Beam for the first time, you must read this

manual carefully and follow it precisely.

Not complying with any of the points listed

in this manual can lead to personal injury

and/or damage to property!

The manual is to be regarded as part of the

product.

Mr Beam Lasers GmbH are not liable

for any damage and/or malfunctions

which result from not complying with this

manual.

No part of this manual may be reproduced,

edited or otherwise changed in any way

without prior written permission from Mr

Beam Lasers GmbH. All rights to any form

of reproduction, particularly electronic,

print or other media, are reserved.

Mr Beam Lasers GmbH reserves the

right to change the specifications of the

hardware and software described in this

manual at any time without notice.

Accessories must be compatible with the

basic unit.

For further inquiries, please consult Mr

Beam support: www.mr-beam.org/ticket.

We are delighted that you have chosen a Mr Beam!

Please read this manual thoroughly, even if you are already familiar with some of the

functions.

The following symbols are used to make it

easier to understand this manual:

Note/Attention: In these areas,

there is a risk of material damage

if the instructions of the manual

are not observed!

Caution: These areas represent

a particular danger to the user

or personnel responsible for

maintenance if the manual is not

complied with!

Caution: In these areas, pay

special attention to the possible

dangers of the laser beam!

Please make sure that you have the latest

version of the Mr Beam manual.

The latest version of the manual can be

found at:

www.mr-beam.org/downloads/

Please keep the manual for subsequent

reference. The manual must be passed on

to any new owner or user of the product.

This is a translation of the original German

manual. If your national language is not

included in the manual, you can download

it at

www.mr-beam.org/downloads/

Issue date of this manual:

23 May 2023

i

Digital manual

Knowledge base

www.mr-beam.org/downloads

www.mr-beam.org/support

Page 4 01: Welcome | Page 5

1.2 About Mr Beam

Your Mr Beam is designed for contactless

cutting and engraving of a variety of

materials. With the help of a laser beam,

heat is generated selectively so that

material evaporates, burns or melts in a

targeted manner. This thermal process can

be used to make cuts and engravings on

flat materials. Due to its high precision, the

process is suitable for cutting out complex

shapes and engraving filigree motifs.

The user can connect to a computer via

a router or directly via Wi-Fi to Mr Beam.

With the exception of the Google Chrome

browser, no additional software is required

to operate Mr Beam. Your Mr Beam is

already equipped with all the necessary

software and is operated by the user via

the web interface of BeamOS.

After files in common file formats have

been loaded into the design library, the

user can select settings for the material.

The laser process is prepared by the

computer or tablet and started by pressing

the button. A camera gives a preview of the

work surface, which allows an accurate¹

placement of the design on the workpiece.

Manufacturer

Mr Beam Lasers GmbH

Gollierstr. 70

80339 Munich

Germany

Page 6 | 01: Welcome

OVERVIEW OF

COMPONENTS

Section 02

The following sections provide an overview of the different

components and connections to your MrBeam.

Page 7

2.1

Scope of supply of Mr Beam with Air Filter System

2.2

Scope of supply of Mr Beam without Air Filter System

Page 8 | 02: Overview of the components

For indoor use we recommend

the Mr Beam Air Filter System.

If you do not have one yet, order

it now from our store at

www.mr-beam.org/products

02: Overview of the components | Page 9

Laser head and Mr Beam housing Laser head and Mr Beam housing

Air Filter System (Air Filter II)

Air Filter System (Air Filter III), power cable and power supply

2 screws and 2 washers

Exhaust air hose, 50 mm

suction nozzle and Mr Beam

suction nozzle (Air Filter II)

Exhaust air hose, 2 Mr Beam

suction nozzle (Air Filter III)

2 screws and 2 washers

(Air Filter II)

2 screws and 2 washers

(Air Filter III)

2 keys, focus tool, cable Mr Beam Air Filter

System, power cable and power supply

2 keys, focus tool, power cable and power supply

Exhaust air hose, 50 mm suction nozzle,

Mr Beam suction nozzle and fan

Air Filter System

Air Filter System

2.3 Overview of Mr Beam 2.4 Connections

Page 10 | 02: Overview of the components 02: Overview of the components | Page 11

AIR FIL

TER

S

Y

STEM

Network connection

(Ethernet)

4

3

2

1

6

7

5

Mr Beam laser cutter:

1. Camera

2. Guide rail

3. Laser head

4. Working area

5. Button

6. Suction nozzle

7. Status Light

Mr Beam Air Filter System:

1. Cover

2. Locking screws

3. Exhaust air hose connection

4. Safety sign

5. Connections

4

45

5

3

3

2

2

1

1

Analogue

connection

(old control)

SAFETY AND

CONFORMITY

Section 03

3.1 Intended use

Mr Beam

Your Mr Beam has been developed for

contactless cutting and engraving of a

variety of materials. These include, but are

not limited to, wood, acrylic, cardboard,

paper, leather, selected plastics, anodised

aluminium, etc. For a list of approved and

tested materials and thicknesses, please

refer to the following webpage:

www.mr-beam.org/collections/materialien

For safety reasons, only materials

approved by Mr Beam Lasers GmbH

are approved for processing with your

MrBeam.

It is only permitted to operate Mr Beam

when it is in perfect condition.

The manufacturer is not liable for any

personal injury and/or damage to property

resulting from improper or irregular use of

Mr Beam.

Conversion and disassembly of the Mr

Beam and its laser/laser unit will result

in the loss of laser class 1 and may cause

personal injury and/or damage to property.

The manufacturer accepts no liability for

these.

Repair or maintenance of Mr Beam may

only be carried out by persons who are

familiar with the intended area of appli-

cation and the dangers of Mr Beam. The

case may only be opened after approval

by support. Failure to do so will void the

warranty.

Not complying with the operating, mainte-

nance and servicing rules presented in this

manual will rule out any liability on the part

of Mr Beam Lasers GmbH in all cases.

Please note that this section is particularly important. Your Mr Beam can only work

safely if you comply with all aspects for it to do so. It is therefore crucially important

that you read and understand this section thoroughly before putting your Mr Beam into

operation!

Note: The warranty does not apply

to damage or defects caused by

non-compliance with the manual.

The technical specifications for the

operator according to the

Occupational Health and Safety Ordinance

on Artificial Optical Radiation (Arbeitss-

chutzverordnung zu künstlicher optischer

Strahlung – OStrV) and EC/2006/25 can be

found in the technical specifications (see

Section 7.1 "Technical Specifications - Mr

Beam").

Air Filter System

Your Air Filter System was developed to

extract and filter exhaust air from laser

cutters and 3D printers. Air is extracted

from a closed work area via a hose.

Vapours, particles and odours are then

safely removed from the interior via a

three-stage filter. If you do not use the Air

Filter System with Mr Beam, the additional

purchase of a power supply and manual

control is required.

It is only permitted to operate the Air Filter

System when it is in perfect condition.

In addition, the Air Filter System is also

subject to the rules regarding any improper

or unintended use of Mr Beam.

Page 12

i

03: Safety and conformity | Page 13

3.2 Basic safety instructions

Use the device only in original condition

The use of a device that has recognizable

defects or that has adaptations that have

not been approved by Mr Beam Lasers

GmbH is not permitted and can lead to

damage to property or bodily injury.

»Before each use, you are obliged

to inspect Mr Beam for outwardly recog-

nisable defects, damage or anomalies.

Possible defects include damage to

the exhaust hose and protective cover,

as well as bent parts on the housing.

Any changes or unusual operational

behaviour which are detected must be

eliminated immediately. Further use

of Mr Beam is impermissible until the

defect has been fully repaired.

»To avoid improper adjustments and

thus uncontrolled emission of the laser

beam, adjustment of the laser optics

takes place before delivery and may

only be carried out by specially trained

personnel with measuring equipment.

»Only operate Mr Beam with the devices

and spare parts that are included in the

scope of supply and/or approved by Mr

Beam Lasers GmbH.

»Do not under any circumstances rebuild

or disassemble your Mr Beam or its

laser or laser unit. This excludes the

care and maintenance procedures

as described in Section 6 "Servicing

and Maintenance". Do not operate

any device that has been modified or

disassembled!

»To assess the potential hazard posed

by laser systems, they are divided

into eight safety classes: 1, 1C, 1M, 2,

2M, 3R, 3B and 4. Mr Beam is a class

1 laser. This is ensured by its sealed

protective housing and its safety

devices.

Avoid bodily injury due to improper use

A laser source is contained in the protec-

tive housing of Mr Beam, which emits an

intense and visible laser beam. Failure to

follow safety measures can cause retinal

burns, loss of sight, and burns to the skin

and clothing. Without protective devices,

this direct light or diffusely reflected light

poses a danger to people and objects.

»To ensure safety class 1, refrain from

any operation that compromises the

safety of Mr Beam.

»To avoid injury to third parties, you are

obliged to ensure that Mr Beam is set

up only by authorised persons (e.g., take

precautions against unauthorised use

and/or remove the key).

»Decommissioning and/or disassembly

of safety devices and any conversion or

modification of Mr Beam is at all times

prohibited. Failure to follow this rule

may result in serious injury.

»Never bypass the safety circuit (inter-

lock).

Page 14 | 03: Safety and conformity 03: Safety and conformity | Page 15

Avoid leakage of harmful fumes

During the laser process, the processed

material is vaporised by Mr Beam. The

operation therefore produces burning

odours and vapours that under certain

circumstances can be harmful to health.

»Do not open the protective cover of Mr

Beam during operation. If necessary,

pause the work process by pressing the

button. Then wait a short time for the

suction system to remove vapours. Now

you can open the protective cover. If

possible, we recommend that you do not

interrupt the work process in order to

avoid an incomplete work result.

»Make sure that your Mr Beam is oper-

ated exclusively with the appropriate

extraction/filter system.

»Process only suitable materials. (for

details, see "Notes on how to avoid

damaging property– avoid the use of

unsuitable materials")

Avoid fire

Flammable materials can be ignited by the

laser beam and lead to burn injuries.

»There is a risk of fire and damage to

property when operating the laser.

You are obliged to be present during

operation of the laser.

»You are obliged to remove all workpiece

residues after each operation. Do not

use the inside or immediate surround-

ings of Mr Beam to store combustible

materials.

3.3 Notes on avoiding damage to property 3.5 Description of the workplace

3.4 Qualification of the

user

Page 16 | 03: Safety and conformity 03: Safety and conformity | Page 17

Avoid using unsuitable materials

The processing of certain materials

can damage Mr Beam and thus lead to

operational failures.

»A complete list of all suitable materials

and their tested material thicknesses

can be found in our knowledge base at

www.mr-beam.org/materialien.

»Processing conductive materials

(including carbon fibres) releases dust,

particles and smoke which can lead

to lasting damage to the structural

components and/or electronics, causing

problems such as short-circuits). The

processing of conductive materials will

void the warranty.

»Materials which contain chlorine,

such as PVC, release corrosive

vapours during processing which are

detrimental to health and can damage

the structural components. Processing

materials containing chlorine will void

the warranty.

»Many metals, especially uncoated

aluminium, copper, silver and gold,

must not be processed with the laser

due to the low absorption, as these

materials reflect most of the laser

beam. Under no circumstances should

these metals and/or other reflective

materials be placed in the beam path of

the laser, as directional reflections may

damage and/or destroy the protective

cover.

»The engraving of a commercially

available mirror may only be done on

the non-reflective back, as the front

reflects the light in a directional manner

and can damage and/or destroy the

protective cover.

»Before using the device, ascertain

whether harmful substances can be

produced by the processing of materials

that can harm Mr Beam itself, the Air

Filter System, the environment and/

or people. If the resulting harmful

substances cannot be filtered by the

Mr Beam Air Filter System, it is not

permitted to use these materials. Note

that it is the responsibility of the user

to stay within the national and regional

limits for dust, smoke and gases.

»If several persons are working with

Mr Beam, the owner or, if necessary,

other proprietor or other person

who is responsible for access to the

equipment, is responsible for making

sure that all the users are sufficiently

qualified and familiar with the safety

regulations.

»Persons who are under age are only

permitted to use Mr Beam under the

supervision of an adult.

»Adjustment of the laser optics may only

be carried out by self-trained personnel

using measuring equipment.

»The electrical socket must be easily

accessible and must be in direct prox-

imity to the device. In an emergency, you

must be able to unplug the power plug

and the key.

»Adequately secure the electrical circuit

of the outlet.

»Make sure that cleanliness and freedom

from obstruction to and around the Mr

Beam work area is ensured.

»Make sure that a fire extinguisher and

fire blanket are in close proximity at all

times.

»The ambient temperature must be

between 5°C and 25°C. Avoid large

fluctuations in temperature

»Use Mr Beam indoors only to avoid

contact with moisture. Non-observance

may result in damage to individual

parts. (Air humidity between 30% and

60% and no condensation)

»Use Mr Beam only in dust-free environ-

ments.

»Avoid strong sunlight falling on Mr

Beam.

»Avoid strong mechanical shocks acting

on Mr Beam.

»Provide sufficient air circulation in

the room so that possible harmful

substances do not accumulate.

»To avoid vibrations from other

machines, place Mr Beam on a stable,

flat and horizontal work surface that is

used exclusively for it.

x

Air Filter System

EG Konformitätserklärung

EU Declaration of Conformity

Firma

/

Company:

Mr Beam Lasers GmbH

Adresse / Address:

Gollierstrasse 70

80339

München

Produktkategorie / Product category:

Laserschneide- und Graviermaschine / Laser cutting and engraving machine

Modellbezeichnung / Model name:

Mr Beam

Hersteller / Manufacturer:

Mr Beam Lasers GmbH

Artikelnummer

/

Article number:

MB DC-015, MB DCB-016, 900-#####, 901-#####, 902-#####

Seriennummer

/

Serial number:

0000000012345678-2E (Beispiel)

Erstellungsdatum:

03.05.2019

Änderungsdatum:

13.

04.2023 / Version 1.2

Das Produkt erfüllt die einschlägigen Harmonisierungsrechtsvorschriften der Union:

The product fulfill the relevant European harmonisation legislations:

Rechtsvorschrift / Legislation:

Titel / Title:

2014/53/EU

Funkrichtlinie / Radio Equipment Directive (ABl. L 153, 22.5.2014, p. 62–106)

2006/42/EC

Maschinenrichtlinie / Machinery Directive (ABl. L 157, 9.6.2006, p. 24–86)

2011/65/EU:2014-02-14

RoHS (ABl. L 174, 1.7.2011, p. 88–110)

Die Übereinstimmung mit den Anforderungen der europäischen Harmonisierungsrechtsvorschriften wurde durch die Anwendung der folgenden

harmonisierten Normen und technischen Spezifikationen nachgewiesen:

The compliance with the requirements of the European harmonisation legislations was proved by the application of the following harmonised standards and technical

specifications:

Normen / Standards:

Beschreibung

Description

EN 60825-1:2022-08-01

Sicherheit von

Lasereinrichtungen

Teil 1: Klassifizierung von Anlagen und Anforderungen

EN 60825-4:2011-12

Sicherheit von Lasereinrichtungen

Teil 4: Laserschutzwände

EN ISO 11553-1:2020

Sicherheit von Maschinen - Laserbearbeitungsmaschinen - Teil 1:

Anforderungen an die Lasersicherheit

EN 11553-3:2013

Sicherheit von Maschinen - Laserbearbeitungs-maschinen - Teil 3:

Lärmminderungs- und Geräuschmessverfahren für Laserbearbeitungs-

maschinen und handgeführte Laserbearbeitungs-geräte sowie zugehörige

Hilfseinrichtungen (Genauigkeitsklasse 2)

Safety of laser products –

Part 1: Equipment classification and requirements

Safety of laser products –

Part 4: Laser guards

Safety of machinery - Laser processing machines - Part 1: Laser safety

requirements

Safety of machinery - Laser processing machines - Part 3: Noise reduction and

noise measurement methods for laser processing machines and hand-held

processing devices and associated auxiliary equipment (accuracy grade 2)

EN 12100:2011-03

(inkl. Berichtigung 1:2013-08)

Sicherheit von Maschinen - Allgemeine Gestaltungsleitsätze -

Risikobeurteilung und Risikominderung

Safety of machinery - General principles for design - Risk assessment and risk

reduction

EN 11252:2014-02

Laser und Laseranlagen - Lasergerät - Mindestanforderungen an die

Dokumentation

EN 55032:2022-09 Class B

Elektromagnetische Verträglichkeit von Multimedia-geräten und -

einrichtungen - Anforderungen an die Störaussendung

EN 55035:2022 07 01

Elektromagnetische Verträglichkeit von Multimediageräten -

Anforderungen zur Störfestigkeit

EN 61000-3-2:2020

Elektromagnetische Verträglichkeit (EMV) - Teil 3-2: Grenzwerte -

Grenzwerte für Oberschwingungs-ströme (Geräte-Eingangsstrom <= 16 A

je Leiter)

EN 61000-3-3:2013-08

Elektromagnetische Verträglichkeit (EMV) - Teil 3-3: Grenzwerte -

Begrenzung von Spannungs-änderungen, Spannungsschwankungen und

Flicker in öffentlichen Niederspannungs-Versorgungsnetzen für Geräte mit

einem Bemessungsstrom <= 16 A je Leiter, die keiner

Sonderanschlussbedingung unterliegen

EN 61000-6-1:2019

Elektromagnetische Verträglichkeit (EMV) - Teil 6-1: Fachgrundnormen -

Störfestigkeit für Wohnbereich, Geschäfts- und Gewerbebereiche sowie

Kleinbetriebe

EN 61000-6-3:2022-07-01

Elektromagnetische Verträglichkeit (EMV) - Teil 6-3: Fachgrundnormen -

Störaussendung für Wohnbereich, Geschäfts- und Gewerbebereiche sowie

Kleinbetriebe

DIN EN 300328

BreitbandÜbertragungssysteme - Datenübertragungsgeräte zum Betrieb

im 2,4GHzBand - Harmonisierte Norm zur Nutzung von Funkfrequenzen

(Anerkennung der Englischen Fassung EN 300 328 V2.2.2 (201907) als

Deutsche Norm)

DIN EN 301893

5 GHz RLAN - Harmonisierte EN, die die wesentlichen Anforderungen

nach Artikel 3.2 der EURichtlinie 2014/53/EU enthält

Elektromagnetische Verträglichkeit (EMV) – Standard für

Lasers and laser-related equipment - Laser device - Minimum requirements for

documentation

Electromagnetic compatibility of multimedia equipment - Emission requirements

Electromagnetic compatibility of multimedia equipment - Immunity

requirements

Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for harmonic

current emissions (equipment input current <= 16 A per phase)

Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation of voltage

changes, voltage fluctuations and flicker in public low-voltage supply systems,

for equipment with rated current <= 16 A per phase and not subject to

conditional connection

Electromagnetic compatibility (EMC) - Part 6-1: Generic standards - Immunity for

residential, commercial and light-industrial environments

Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission

standard for residential, commercial and light-industrial environments

Wideband transmission systems; Data transmission equipment operating in the

2,4 GHz band; Harmonised Standard for access to radio spectrum

5 GHz RLAN; Harmonised Standard covering the essential requirements of

article 3.2 of Directive 2014/53/EU

ElectroMagnetic Compatibility (EMC) standard for radio equipment and services;

DIN EN 301489-1

Funkeinrichtungen und dienste – Teil 1: Gemeinsame technische

Anforderungen – Harmonisierte Norm für die elektromagnetische

Verträglichkeit

Part 1: Common technical requirements; Harmonised Standard for

ElectroMagnetic Compatibility

DIN EN 301489-17

Elektromagnetische Verträglichkeit (EMV) für Funkeinrichtungen und -

dienste – Teil 17: Spezifische Bedingungen für

Breitbanddatenübertragungssysteme – Harmonisierte Norm für die

elektromagnetische Verträglichkeit

EN IEC 63000:2018

Technische Dokumentation zur Beurteilung von Elektro- und

Elektronikgeräten hinsichtlich der Beschränkung gefährlicher Stoffe ((IEC

63000:2016) EN IEC 63000:2018)

EN 50689:2021

Sicherheit von Laserprodukten - Besondere Anforderungen an

Verbraucher-Laser-Produkte

ElectroMagnetic Compatibility (EMC) standard for radio equipment and services;

Part 17: Specific conditions for Broadband Data Transmission Systems;

Harmonised Standard for ElectroMagnetic Compatibility

Technical documentation for the assessment of electrical and electronic

products with respect to the restriction of hazardous substances (IEC 63000:

2016); German version EN IEC 63000:2018

Safety of laser products. Particular Requirements for Consumer Laser Products

Weitere Informationen / additonal

information:

keine / none

München / 13.04.2023

Place

/

Date

Sebastian Donner, Head of Engineering

Roland Kaindl (TKRM UG haftungsbeschränkt),

CE Consulting

/

Dokumentenverantwortlicher

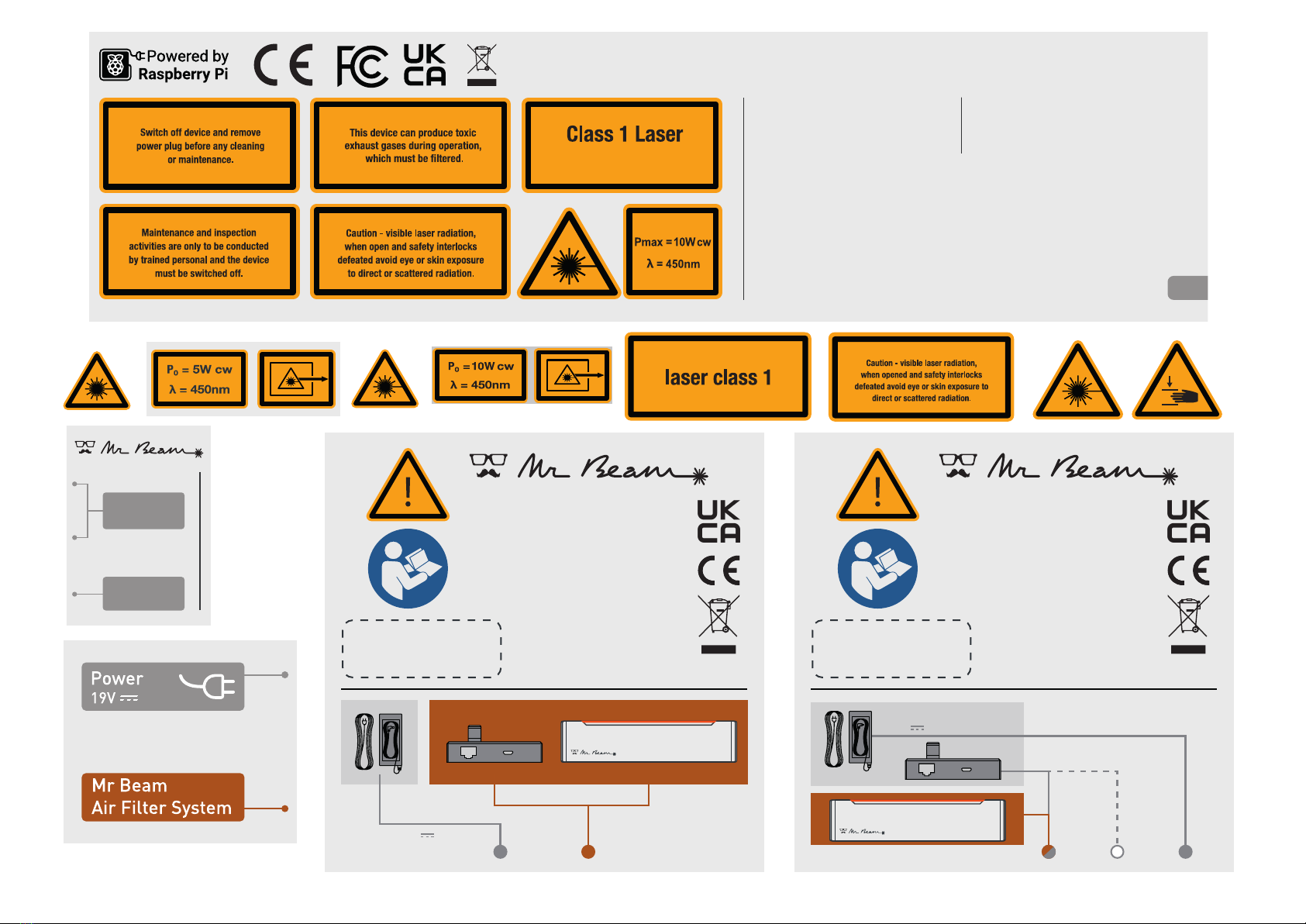

3.6 Warning and safety signs

All warning and information plates which are attached to your Mr Beam are located in

places which can be a source of danger before and/or during operation. Lost or damaged

warning and information plates must be replaced immediately. The missing warning and

information plates can be found via

Mr Beam Support (www.mr-beam.org/ticket) or can be reproduced independently using

the templates on the following page.

Page 18 | 03: Safety and conformity 03: Safety and conformity | Page 19

Laserschneide- und Graviermaschine

Model: Mr Beam

Gewicht: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 München, Germany

www.mr-beam.org

Frequenz 2,4 GHz: Frequenzbereich: 2400 - 2483,5 MHz max. Sendeleistung: 100 mW

Frequenz 5GHz: Frequenzbereich: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Sendeleistung: 200 mW / 100 mW / 500 mW

Hiermit erklärt die Mr Beam Lasers GmbH, dass der Funkanlagentyp "Mr Beam" der Richtlinie 2014/53/EU entspricht.

Der vollständige Text der EU-Konformitätserklärung ist unter der folgenden Internetadresse verfügbar: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Dieses Gerät kann im Betrieb

giftige Abgase erzeugen,die gefiltert

werden müssen. Verbraucher-Laser-Produktder

Klasse1 DIN EN 50689

Laser cutting and engraving machine

Model: Mr Beam

Weight: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 Munich, Germany

www.mr-beam.org

Hereby, Mr Beam Lasers GmbH declares that the radio equipment type “Mr Beam“ is in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Consumer Laser Product

Class 1 DIN EN 50689

Frequentie 2,4 GHz: Frequentiebereik: 2400 - 2483,5 MHz max. zendvermogen: 100 mW

Frequentie 5GHz: Frequentiebereik: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Zendvermogen: 200mW / 100mW / 500mW

Hierbij verklaar ik, Mr Beam Lasers GmbH, dat het type radioapparatuur “Mr Beam“ conform is met Richtlijn 2014/53/EU.

De volledige tekst van de EU-conformiteitsverklaring kan worden geraadpleegd op het volgende internetadres: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

EN

NL

DE

Frequency 2.4 GHz: Frequency range: 2400 - 2483.5 MHz max. transmission power: 100 mW

Frequency 5GHz: Frequency range: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Transmission power: 200mW / 100mW / 500mW

Network

Maintenance

Consumentenlaserproduct

Klasse 1 DIN EN 50689

Laser klasse 1

Netwerk

Onderhoud

Dit apparaat kan tijdens het gebruik

giftige uitlaatgassen produceren,

die moeten worden gefilterd.

Voorzichtig - Zichtbaar laserlicht bij

geopende kap en overbrugde

veiligheidsvergrendeling.Vermijd

bestraling van ogen en huid

door directe of verstrooide straling.

Schakelhet apparaat vóór begin

vanevt.reinigings-en

onderhoudswerkzaamheden

altijd uit en ontkoppel destekker.

Onderhouds- en inspectiewerkzaamheden

mogen alleen worden uitgevoerd

door geschoold personeel.

Gewicht: 9,8 kg

Lasersnij- en graveermachine

On the device: On the laser head:

This copy of the Declaration of Conformity is dated 13 April 2023.

In addition, you can find current versions of the manual and declaration of conformity to

download at: www.mr-beam.org/conformity

Year of manufacture: 20XX

4.7A

or

Laserschneide- und Graviermaschine

Model: Mr Beam

Gewicht: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 München, Germany

www.mr-beam.org

Frequenz 2,4 GHz: Frequenzbereich: 2400 - 2483,5 MHz max. Sendeleistung: 100 mW

Frequenz 5GHz: Frequenzbereich: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Sendeleistung: 200 mW / 100 mW / 500 mW

Hiermit erklärt die Mr Beam Lasers GmbH, dass der Funkanlagentyp "Mr Beam" der Richtlinie 2014/53/EU entspricht.

Der vollständige Text der EU-Konformitätserklärung ist unter der folgenden Internetadresse verfügbar: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Dieses Gerät kann im Betrieb

giftige Abgase erzeugen,die gefiltert

werden müssen. Verbraucher-Laser-Produktder

Klasse1 DIN EN 50689

Laser cutting and engraving machine

Model: Mr Beam

Weight: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 Munich, Germany

www.mr-beam.org

Hereby, Mr Beam Lasers GmbH declares that the radio equipment type “Mr Beam“ is in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Consumer Laser Product

Class 1 DIN EN 50689

Frequentie 2,4 GHz: Frequentiebereik: 2400 - 2483,5 MHz max. zendvermogen: 100 mW

Frequentie 5GHz: Frequentiebereik: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Zendvermogen: 200mW / 100mW / 500mW

Hierbij verklaar ik, Mr Beam Lasers GmbH, dat het type radioapparatuur “Mr Beam“ conform is met Richtlijn 2014/53/EU.

De volledige tekst van de EU-conformiteitsverklaring kan worden geraadpleegd op het volgende internetadres: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

EN

NL

DE

Frequency 2.4 GHz: Frequency range: 2400 - 2483.5 MHz max. transmission power: 100 mW

Frequency 5GHz: Frequency range: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Transmission power: 200mW / 100mW / 500mW

Network

Maintenance

Consumentenlaserproduct

Klasse 1 DIN EN 50689

Laser klasse 1

Netwerk

Onderhoud

Dit apparaat kan tijdens het gebruik

giftige uitlaatgassen produceren,

die moeten worden gefilterd.

Voorzichtig - Zichtbaar laserlicht bij

geopende kap en overbrugde

veiligheidsvergrendeling.Vermijd

bestraling van ogen en huid

door directe of verstrooide straling.

Schakelhet apparaat vóór begin

vanevt.reinigings-en

onderhoudswerkzaamheden

altijd uit en ontkoppel destekker.

Onderhouds- en inspectiewerkzaamheden

mogen alleen worden uitgevoerd

door geschoold personeel.

Gewicht: 9,8 kg

Lasersnij- en graveermachine

Back of Air Filter II:

Back of Air Filter III:

19 V min. 4 A

Modell: AF3

Made in Europe

Gewicht: 19 kg

Typ des Gerätes: Abluftfilter

Mr Beam Lasers GmbH

Gollierstr. 70

80339 München, Germany

www.mr-beam.org

WEEE - DE17853778

19 V min. 3 A

Modell: AF2

Made in Europe

Gewicht: 5,8 kg

Typ des Gerätes: Abluftfilter

Mr Beam Lasers GmbH

Gollierstr. 70

80339 München, Germany

www.mr-beam.org

WEEE - DE17853778

4.7A

03: Safety and conformity | Page 20Print this page in A4 format so that the warning and information plates correspond to their original size.

Laserschneide- und Graviermaschine

Model: Mr Beam

Gewicht: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 München, Germany

www.mr-beam.org

Frequenz 2,4 GHz: Frequenzbereich: 2400 - 2483,5 MHz max. Sendeleistung: 100 mW

Frequenz 5GHz: Frequenzbereich: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Sendeleistung: 200 mW / 100 mW / 500 mW

Hiermit erklärt die Mr Beam Lasers GmbH, dass der Funkanlagentyp "Mr Beam" der Richtlinie 2014/53/EU entspricht.

Der vollständige Text der EU-Konformitätserklärung ist unter der folgenden Internetadresse verfügbar: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Dieses Gerät kann im Betrieb

giftige Abgase erzeugen, die gefiltert

werden müssen. Verbraucher-Laser-Produkt der

Klasse 1 DIN EN 50689

Laser cutting and engraving machine

Model: Mr Beam

Weight: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 Munich, Germany

www.mr-beam.org

Hereby, Mr Beam Lasers GmbH declares that the radio equipment type “Mr Beam“ is in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Consumer Laser Product

Class 1 DIN EN 50689

Frequentie 2,4 GHz: Frequentiebereik: 2400 - 2483,5 MHz max. zendvermogen: 100 mW

Frequentie 5GHz: Frequentiebereik: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Zendvermogen: 200mW / 100mW / 500mW

Hierbij verklaar ik, Mr Beam Lasers GmbH, dat het type radioapparatuur “Mr Beam“ conform is met Richtlijn 2014/53/EU.

De volledige tekst van de EU-conformiteitsverklaring kan worden geraadpleegd op het volgende internetadres: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

EN

NL

DE

Frequency 2.4 GHz: Frequency range: 2400 - 2483.5 MHz max. transmission power: 100 mW

Frequency 5GHz: Frequency range: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Transmission power: 200mW / 100mW / 500mW

Network

Maintenance

Consumentenlaserproduct

Klasse 1 DIN EN 50689

Laser klasse 1

Netwerk

Onderhoud

Dit apparaat kan tijdens het gebruik

giftige uitlaatgassen produceren,

die moeten worden gefilterd.

Voorzichtig - Zichtbaar laserlicht bij

geopende kap en overbrugde

veiligheidsvergrendeling. Vermijd

bestraling van ogen en huid

door directe of verstrooide straling.

Schakel het apparaat vóór begin

vanevt.reinigings-en

onderhoudswerkzaamheden

altijd uit en ontkoppel de stekker.

Onderhouds- en inspectiewerkzaamheden

mogen alleen worden uitgevoerd

door geschoold personeel.

Gewicht: 9,8 kg

Lasersnij- en graveermachine

Laserschneide- und Graviermaschine

Model: Mr Beam

Gewicht: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 München, Germany

www.mr-beam.org

Frequenz 2,4 GHz: Frequenzbereich: 2400 - 2483,5 MHz max. Sendeleistung: 100 mW

Frequenz 5GHz: Frequenzbereich: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Sendeleistung: 200 mW / 100 mW / 500 mW

Hiermit erklärt die Mr Beam Lasers GmbH, dass der Funkanlagentyp "Mr Beam" der Richtlinie 2014/53/EU entspricht.

Der vollständige Text der EU-Konformitätserklärung ist unter der folgenden Internetadresse verfügbar: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Dieses Gerät kann im Betrieb

giftige Abgase erzeugen, die gefiltert

werden müssen. Verbraucher-Laser-Produkt der

Klasse 1 DIN EN 50689

Laser cutting and engraving machine

Model: Mr Beam

Weight: 9,8 Kg

Made in Germany

Mr Beam Lasers GmbH

Gollierstr. 70

80339 Munich, Germany

www.mr-beam.org

Hereby, Mr Beam Lasers GmbH declares that the radio equipment type “Mr Beam“ is in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Consumer Laser Product

Class 1 DIN EN 50689

Frequentie 2,4 GHz: Frequentiebereik: 2400 - 2483,5 MHz max. zendvermogen: 100 mW

Frequentie 5GHz: Frequentiebereik: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Zendvermogen: 200mW / 100mW / 500mW

Hierbij verklaar ik, Mr Beam Lasers GmbH, dat het type radioapparatuur “Mr Beam“ conform is met Richtlijn 2014/53/EU.

De volledige tekst van de EU-conformiteitsverklaring kan worden geraadpleegd op het volgende internetadres: www.mr-beam.org/conformity

This device incorporates a RF module. The RF module is already certified under the

FCC ID:2ABCB-RPI32 and IC ID: 20953-RPI32.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with

IEC 60825-1 Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

EN

NL

DE

Frequency 2.4 GHz: Frequency range: 2400 - 2483.5 MHz max. transmission power: 100 mW

Frequency 5GHz: Frequency range: 5150 - 5250 MHz / 5250 - 5350 MHz / 5470 - 5725 MHz

max. Transmission power: 200mW / 100mW / 500mW

Network

Maintenance

Consumentenlaserproduct

Klasse 1 DIN EN 50689

Laser klasse 1

Netwerk

Onderhoud

Dit apparaat kan tijdens het gebruik

giftige uitlaatgassen produceren,

die moeten worden gefilterd.

Voorzichtig - Zichtbaar laserlicht bij

geopende kap en overbrugde

veiligheidsvergrendeling. Vermijd

bestraling van ogen en huid

door directe of verstrooide straling.

Schakel het apparaat vóór begin

vanevt.reinigings-en

onderhoudswerkzaamheden

altijd uit en ontkoppel de stekker.

Onderhouds- en inspectiewerkzaamheden

mogen alleen worden uitgevoerd

door geschoold personeel.

Gewicht: 9,8 kg

Lasersnij- en graveermachine

19 V min. 4 A

Modell: AF3

Made in Europe

Weight: 19 kg

Type of device: Exhaust air filter

Mr Beam Lasers GmbH

Gollierstr. 70

80339 Munich, Germany

www.mr-beam.org

WEEE - DE17853778

19 V min. 3 A

Model: AF2

Made in Europe

Weight: 5,8 kg

Type of device: Exhaust air filter

Mr Beam Lasers GmbH

Gollierstr. 70

80339 Munich, Germany

www.mr-beam.org

WEEE - DE17853778

SETUP

Chapter 04

4.1 Unpacking

In the following chapter, we will guide you from unpacking Mr Beam to setting up the

network connection.

When setting up your Mr Beam, bear in mind that we have assembled and packed the

equipment with great care. Please take time to unpack it and set it up just as carefully.

Page 21 04: Setup | Page 22

Open the box and remove it from the box

1. Place the box [1] on a flat surface.

2. Open the box [1]. Do not use sharp

objects that could damage the protec-

tive cover.

3. Remove all the accessories [2].

4. Remove Mr Beam [3] from the box and

remove the transport protection on both

sides.

Unpack the Air Filter System (when

purchased as a bundle - Mr Beam and Air

Filter System)

1. Place the box [7] on a flat surface.

2. Open the box [7]. Do not use sharp

objects that could damage the surface.

3. Pull out the upper transport-protective

packing.

4. Remove the Air Filter System [6] and the

box with accessories from the box

Remove the transport lock

1. Remove the vertical transport lock [4].

2. Carefully pull out the horizontal

transport lock [5] from under the guide

rail.

1

2

3

4

5

6

7

Air Filter II

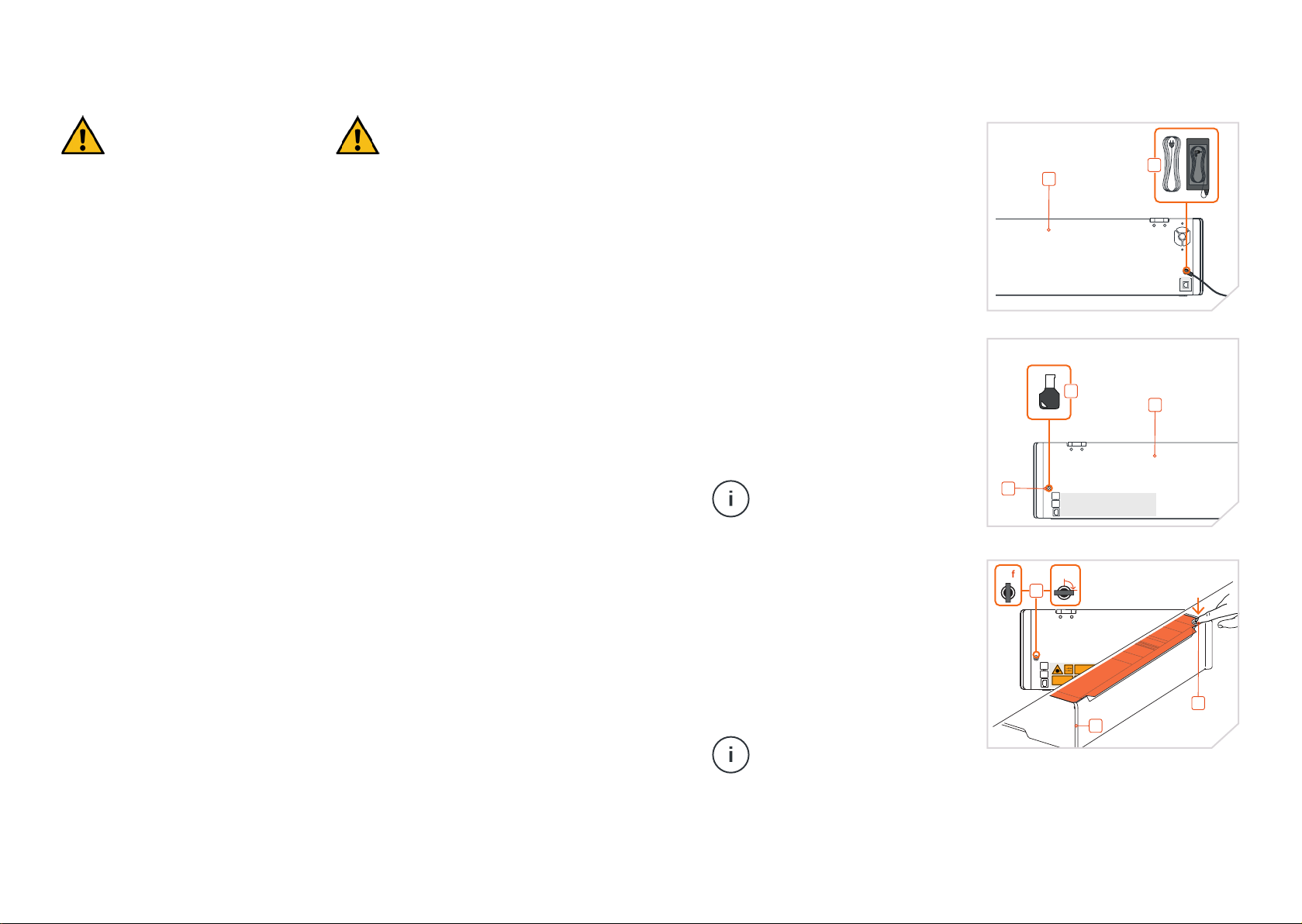

4.2 Connect the laser head 4.3 Connecting the Suction/Air Filter System

Page 23 | 04: Setup 04: Setup | Page 24

Hook the laser head

The laser head can be mounted at different

heights, see also

Section 5.6 "Focusing".

1. First, hook the laser head [9]

in any position at the bottom

2. Then squeeze the carriage [10] slightly and

snap the laser head into place at the top.

Connect the suction nozzle

1. Connect the suction nozzle [14] to the

free end of the ventilation

hose [15].

Note: The exhaust air hose is

fitted with a left-hand thread.

Locking the bracket

1. Lock the ribbon cable [11] with the

bracket [12].

Note: First, loosen the bracket

if you want to remove the ribbon

cable.

2. Then plug in the

hose [13] (only in the "dreamcut",

"dreamcut [S] and dreamcut [X]

models").

Exhaust air

1. If you have a Mr Beam with simple

suction, make sure that the exhaust

hose [15] is fixed and that the exhaust

air can be discharged from the working

area.

2. If you have a Mr Beam with Air Filter

System [8], connect the exhaust air hose

to the air filter system. Then connect

the cable from the air filter system to

your MrBeam.

Plug in the ribbon cable

1. Plug the ribbon cables [11] into the

socket on the back of the laser head [9].

If necessary, extend the black bracket

beforehand.

Note: The ribbon cable may only

be plugged in and unplugged

when Mr Beam is shut down and

switched off! Failure to do so will

make Mr Beam inoperable.

Connecting it to Mr Beam

1. Install the suction nozzle [14] on your

Mr Beam. To do this, use the supplied

knurled screws and washers [16].

Tighten them moderately.

2. Then connect the cable [17] from the

exhaust system to your Mr Beam.

AIR FILTER

SYSTEM

Air Filter System

10

11

11

13

12

9

14

14

16

17

15

9

15

8

Air Filter II

4.4 Suction/Air Filter System 4.5 Switching on the electrical power supply

Page 25 | 04: Setup 04: Setup | Page 26

Plug in the power cable

1. To avoid static charges that could

damage your computer and/or your Mr

Beam, please first connect the power

supply [18] to your Mr Beam [3] and

only then connect the power supply

to a power outlet (100-240V ~, 1.5A

50-60Hz).

Turn the key and press the button

1. Turn the key [20] clockwise to activate

the power supply of your Mr Beam.

2. To switch on the device, briefly press the

button [21] for approx. 2 seconds (for

more detailed information, see Section

5.3 "Button"). The control light of the

laser head comes on immediately and

after 10 seconds the status lights [22]

are come on.

Note: When switched on, the key

cannot be removed and is in the

horizontal position.

Inserting the key

To prevent your Mr Beam [3] from being

switched on by unauthorised third parties,

it is switched on/off with the help of a key

switch [19].

1. Insert the key [20] into the key switch

(key horizontal with "nose" facing

upwards).

Note: The key can only be inserted

into the switch in one position.

Caution: Risk of suffocation.

During the laser process, the

processed material is vaporised

by Mr Beam and burning odours

and fumes are produced.

» Only operate your Mr Beam

with a functional suction

system.

In the following section, the extraction

system is described in two versions: the

extraction system (sucks out exhaust gases

into the open air) and the

Mr Beam Air Filter System. In both

versions, the suction power is regulated

according to the presence of exhaust

gases. This will be accompanied by

fluctuating

noise levels from the corresponding

exhaust. The smoke concentration is deter-

mined by an optical sensor. If the sensor

malfunctions, suction power increases to

the maximum for safety reasons.

Note that it is the responsibility of the user

to stay within the national and regional

threshold limits for dust, smoke and gases

when choosing the filter and exhaust air

extraction system.

Extraction system (without air filter)

The extraction system must not be used

in enclosed spaces. It must be possible

to discharge the exhaust air out of the

working area at all times (e.g., outside).

Caution: Risk of suffocation.

Any backflow of exhaust gases

can lead to suffocation.

» Fix the end of the hose so that

no exhaust air can enter the

operating room.

» Make sure that the hose

opening is guided far enough

into the open air.

» If smoke collects in the device

or strong odours form, stop

work immediately and check

the exhaust air duct.

Mr Beam Air Filter System (with air filter)

The Mr Beam Air Filter System enables

you to operate your Mr Beam in enclosed

areas without exhaust air extraction to

the outside. This ensures that unfiltered

exhaust air cannot escape from your

MrBeam and that the user is never put in

danger.

It is necessary to replace the air filter of

the Mr Beam Air Filter System regularly,

depending on the degree of contamination.

The Air Filter System must be placed on a

flat surface and stand freely.

With the optional manual control and an

external power

supply, the Air Filter System can also be

used on third-party devices. In contrast

to the automatic regulation used with Mr

Beam, when used with third-party devices,

the exhaust air flow rate is controlled

manually.

The user must ensure that the suction

power of the Air Filter System is sufficient

for the intended use.

AIR FILTER

SYSTEM

VorBeginn von Reinigungs- und

Wartungsarbeitendas GerŠt immer

ausschaltenund den Netzstecker ziehen.

P

BeiAbwesenheit

SchlŸsseldes

SchlŸsselschaltersabziehen

Off On

3

3

21

22

19

20

18

20

4.6 Switching off the electrical power supply

Page 27 | 04: Setup 04: Setup | Page 28

Shutdown

To properly turn off your Mr Beam after

finishing work, please shut it down first.

You can shut down your Mr Beam via

BeamOS

( -> System) or by pressing and holding

the button [21] for five seconds. The status

lights [22] immediately turn red and after

15 seconds the whole system shuts down.

Switching off

1. To switch off your Mr Beam, turn the key

[20] counter-clockwise.

2. Pull out the key to exclude any misuse

of your Mr Beam.

Note: Please keep the key in a

place that unauthorised users

(e.g., children) do not know about

and/or cannot access.

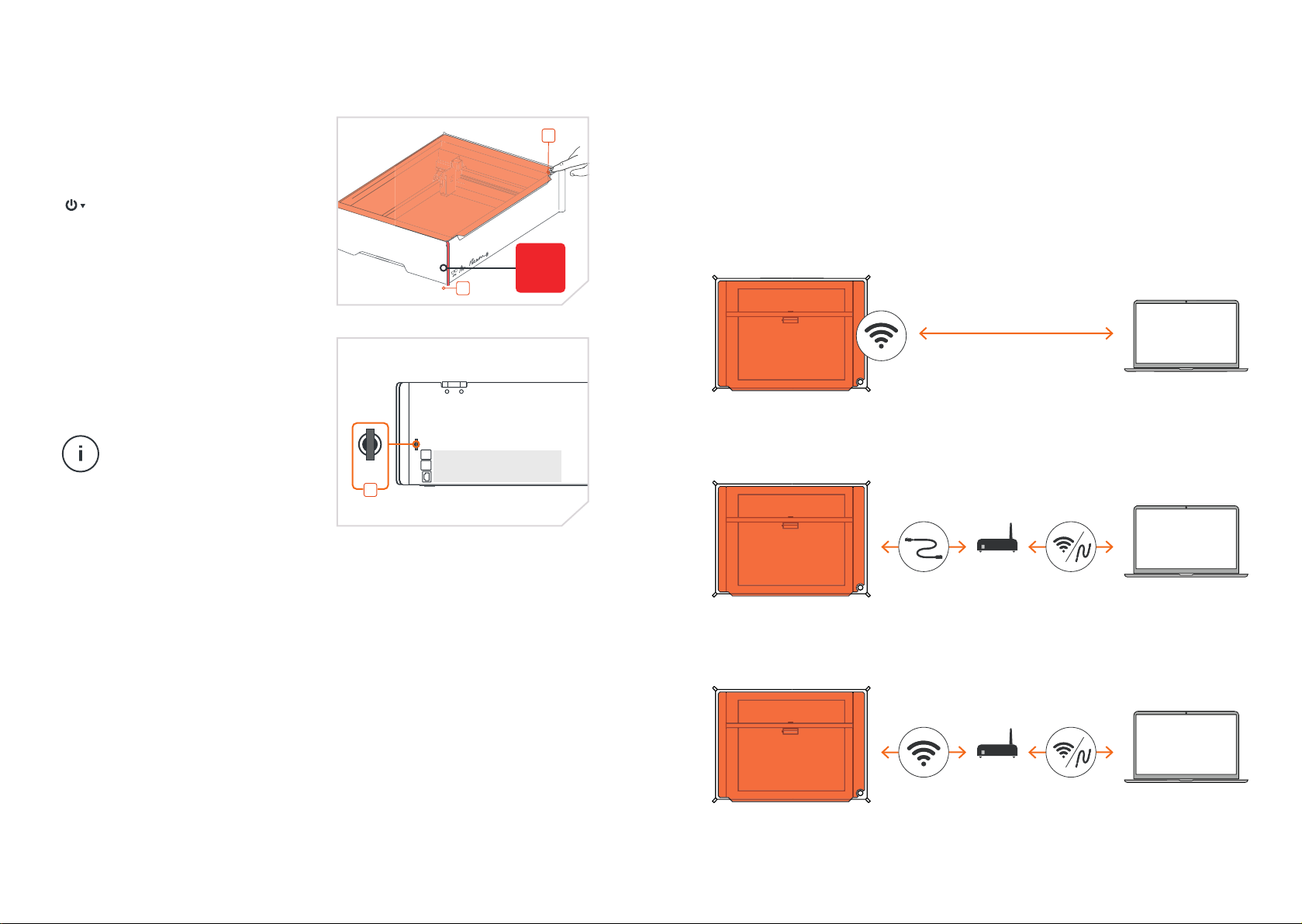

4.7 Connecting to a computer

Connection options with Mr Beam

There are three ways to establish a connection between Mr Beam and your computer or

tablet. The choice of the most suitable option depends on your personal usage preference

and the network available at Mr Beam's place of use.

Option A: WLAN direct connection

Connect your computer directly to the WLAN of your Mr Beam. (see page 30)

Option B: Connection via network cable (Ethernet) and router

Connect Mr Beam to the network router by cable. (see page 31).

Option C: Connection via WLAN and router

Connect Mr Beam to your network via WLAN. (see page 32).

Off

21

22

20

Name: MrBeam-XXXX

S/N: 0000000XXXXXXXXX-2X

Page 29 | 04: Setup

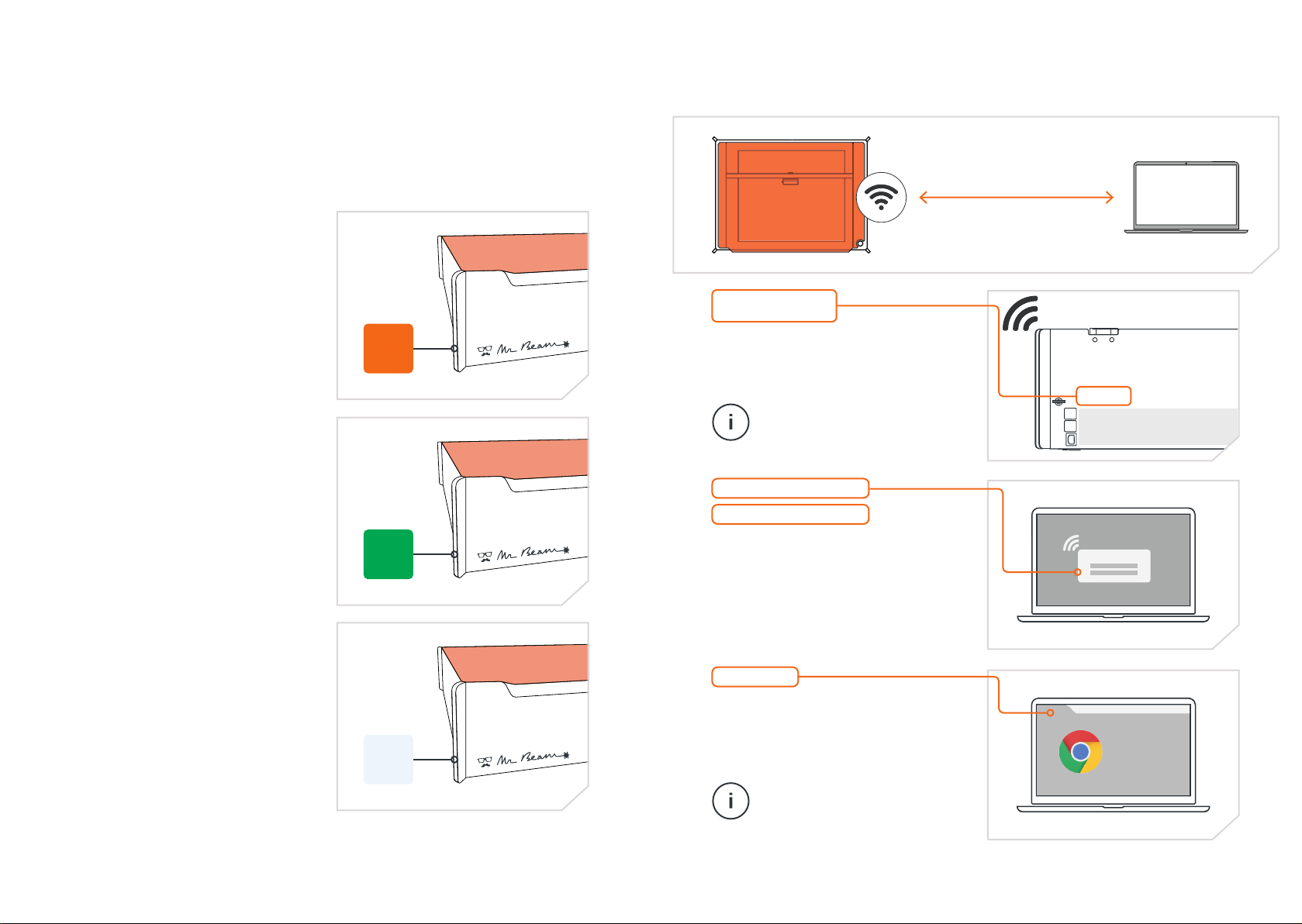

4.7 Connecting to a computer

Status Lights

Whether it's during the first setup or if you've connected to your Mr Beam many times

before, the Mr Beam status lights show you how to connect to Mr Beam right now by

pulsating slowly.

1. On your computer, select the Wi-Fi

network with the name of your Mr

Beam: "MrBeam-XXXX".

Note: XXXX stands for your

specific device name, which can

be found on the back of your

MrBeam.

Orange pulsating

Access your Mr Beam via find.mr-beam.

org. Mr Beam is connected to your router,

has an active Internet connection and can

be accessed in your browser via

find.mr-beam.org.

Green pulsating

Connect directly to the WLAN of your Mr

Beam. In the WLAN

settings on your computer, select the

WLAN with the name "MrBeam-XXXX”

(password: mrbeamsetup).

Once your computer is connected to Mr

Beam, open the Google Chrome browser

and type the following in the address bar:

10.250.250.1

White pulsating

Mr Beam is connected to your local network,

but does not have an active Internet

connection. Visit our Online Knowledge Base

to find possible solutions.

With green and white pulsating lights, both

connection options are available (Wi-Fi and

local network).

04: Setup | Page 30

4.8 Option A - Wi-Fi direct connection

Name: MrBeam-XXXX

S/N: 0000000XXXXXXXXX-2X

Name: MrBeam-XXXX

Password: mrbeamsetup

The password for the WLAN connection is:

mrbeamsetup.

10.250.250.1

2. Enter the following IP address

in the search bar of your Google

Chrome browser to load the web app:

10.250.250.1

Note: During the initial setup,

your Mr Beam will guide you

through the Mr Beam Welcome

Dialogue. There, if desired, you

can set up Wi-Fi connections with

the router.

Google

Chrome

Page 31 | 04: Setup 04: Setup | Page 32

4.10 Option C - Wi-Fi and router4.9 Option B - Cable and router

Welcome Dialogue

1. Connect your Mr Beam to your router

via a network cable (Ethernet). The

network socket is located on the rear

below the USB ports.

Note: Do not confuse the

connection with the connection of

the Air Filter System on the other

side.

2. Make sure your computer is also

connected to the router via cable or

Wi-Fi.

3. After a few seconds (maximum 60) your

Mr Beam orange light will pulsate. Then

you can access your Mr Beam via find.

mr-beam.org in the Google Chrome

browser.

Note: During the initial setup, your

Mr Beam will guide you through

the Mr Beam Welcome Dialogue.

There, if desired, you can set up

Wi-Fi connections with the router.

Welcome Dialogue

For the initial setup, you must first connect

via Connection Option A or B to reach the

Mr Beam Welcome Dialogue, where you

can set up your Wi-Fi.

If you select Option A, connect your

computer directly to the Wi-Fi of your

MrBeam. Then enter the IP address

10.250.250.1 in your Google Chrome

browser.

If you have a cable on hand, select Option B

to connect Mr Beam to your router with a

cable. Now use the find.mr-beam service to

connect to your Mr Beam for the first time.

This process is described in detail on page

12.

Regardless of the connection option you

choose, your Mr Beam will greet you with

the Welcome Dialogue. There you have the

option to connect your Mr Beam to your

Wi-Fi. Click the "Connect" button that

appears next to the name of your WLAN,

and then enter your WLAN password.

Name: MrBeam-XXXX

S/N: 0000000XXXXXXXXX-2X

Name: MrBeam-XXXX

S/N: 0000000XXXXXXXXX-2X

Name: MrBeam-XXXX

S/N: 0000000XXXXXXXXX-2X

Slow connection

If you experience a slow connection while

using your Mr Beam (e.g. pictures from

the camera do not load or load slowly), this

may be due to a poor Wi-Fi connection.

The range of the Wi-Fi connection can be

reduced by walls, ceilings and furnishings.

Other devices that also work with high-

frequency signals can interfere with the

Wi-Fi connection.

Note: Keep the distance between

your Mr Beam and Wi-Fi router

as small as possible to ensure

a good connection. If necessary,

amplify the signal with commerci-

ally available WLAN repeaters.

If you still cannot improve the connection,

try option B (network cable and router) in

this case.

Page 33 | 04: Setup Page 34

4.10 Option C - Wi-Fi and router

Section 05

WORKING WITH YOUR

MR BEAM

Further procedure

If you have chosen Option A for the initial

setup and are connected directly to

Mr Beam via Wi-Fi, your Mr Beam will

disconnect the Wi-Fi connection to your

computer to connect to your Wi-Fi router. If

successful, your Mr Beam will soon pulsate

orange and you will be able to connect to

the find.mr-beam.org service.

Note: If this does not succeed,

e.g., because an incorrect

password has been entered, you

will not receive an error message

because you are no longer

connected to your Mr Beam. In

this case, you will have to repeat

the connection process of Option

A from the beginning.

If you have selected Option B with the

cable for the initial setup, your Mr Beam

will indicate whether the Wi-Fi connection

to your router was successful or not.

If successful, you can now unplug the

network cable, use the Wi-Fi connection

and use the find.mr-beam.org service.

After the introduction to Mr Beam, the first steps of working with your device follow.

Time for the first laser job!

Page 35 | 05: Working with your Mr Beam 05: Working with your Mr Beam | Page 36

5.2 Materials and maximum workpiece size

5.3 Button

5.1 BeamOS

Legend:

1. Laser: Proceed to the laser job para-

meters

2. Working area: When the cover of Mr

Beam is fully open, a picture is taken

every 5 seconds and displayed on the

work surface. Double-click anywhere

to move the laser head to the desired

position.

3. Design library: Upload designs here and

select designs that have already been

uploaded.

4. Design store: Choose from a wide selec-

tion of pre-made designs.

5. Support and settings

Software update:

A software update is carried out with an

active internet connection or offline via

USB stick. You can find more detailed

information at:

www.mr-beam.org/offlineupdate

When a software update is available, a

notice appears in the BeamOS in the upper

right corner.

To start the software update, click on

“Update now”. Your Mr Beam will perform

the software update on its own. After a

restart, it will reconnect to your computer

on its own.

As already described in Section 3.2 "Safety

instructions", dangerous fumes can be

produced when lasering certain materials.

Therefore, it is particularly important to

only process materials that have been

declared suitable by Mr Beam Lasers

GmbH. An updated list of materials can be

found online at the following link:

www.mr-beam.org/collections/materialien

The button is a push button on the top of

Mr Beam. It is assigned several functions,

which are explained below.

Switch on

1. Insert the key into the key switch.

2. Turn the key clockwise.

3. Press the button for approx. 2 seconds.

The control light of the laser head is

switched on immediately and after 10

seconds the status lights also come on.

Start laser procedure

1. Prepare the laser process in BeamOS.

2. Start the job on your Mr Beam by

pressing the button once.

Maximum workpiece size

The maximum workpiece size is

500x390x38mm (length, width and

height). Due to edge blurring of the

camera, positioning in the middle of the

work surface is recommended for smaller

workpieces.

Pause

1. Press the button.

2. Next, wait a moment for the suction to

remove vapours. Open the protective

cover

3. Close the protective cover and then

continue the operation by pressing the

button again.

Shutdown

1. Press and hold the button for five

seconds to shut down your Mr Beam

properly. Your Mr Beam will shut down

after about 15 seconds. Shutting down

does not switch off your Mr Beam.

2. To switch it off, turn the key switch

counter-clockwise and pull it out (see

Section 4.6 "Switching off the power

supply").

For more detailed information

about BeamOS, please read

the article on our website:

www.mr-beam.org/pages/

das-beamos

1 2 3 4 5

Page 37 | 05: Working with your Mr Beam 05: Working with your Mr Beam | Page 38

5.5 Meaning of the status lights5.4 Camera

There is a camera in the protective cover of

your Mr Beam which supports you in

positioning the motif on the workpiece.

As soon as the protective cover is

completely open, the camera automatically

takes a picture of the work surface and the

workpiece lying on it. This is then displayed

in

BeamOS after a delay of a few seconds.

The camera's image shows the workpiece

on the work surface, i.e., you can virtually

place your selected motif directly on the

workpiece and then edit it. For an optimal

picture as well as precise positioning,

make sure that the work surface is

illuminated sufficiently and evenly.

For precise positioning, the 4 magen-

ta-coloured round markers are relevant.

If these come off, please contact Mr Beam

Support:

www.mr-beam.org/ticket

Note: If a marker has been

replaced, calibration of the

camera (Setting -> Camera

Calibration) is necessary.

For exact positioning, the placement of the

workpiece must be adjusted by moving the

laser head.

The triangles on the laser head provide a

reference to the exact exit path of the laser

beam.

Camera application

In summary, the following instructions

must be followed for the correct use of the

camera:

1. Open the protective cover to the highest

position.

2. Position the workpiece in the working

area.

3. Wait a few seconds for the picture

to transfer to your computer. If the

picture is not optimal, please wait a few

seconds again until the camera has cre-

ated and transmitted another image.

4. Close the protective cover and proceed

with further settings and work steps.

Live tracking of the laser by camera is not

possible. The pictures are only saved for

the corresponding editing and are then

automatically deleted.

The status lights show different operating states of Mr Beam.

Note: The signals listed here are subject to change with software updates. If this is the case,

it will be announced within the software.

Orange pulsating Connection to Mr Beam

can be established via find.mr-beam.org

Green pulsating Connection to Mr Beam can be established

via a Wi-Fi access point

White pulsating Connection to Mr Beam can be established

via common addresses/host names in the

network

Dripping white on blue Laser job is being prepared

Blue flashing Waiting for confirmation for lasering by

pressing the button

Dripping blue on white Laser job is being carried out

Note: The larger the white part, the more

advanced the laser job.

Blue pulsating at the top, white at the bottom Pause

Orange Lase job is finished

Note: It is recommended to wait for the

suction.

Green Laser job has been completed, protective

cover can be opened

Red flashing Button is held for shutdown

Red fast flashing Error

Red Shuts down

Red/white flashing Button has been pressed, no resulting

action

This manual suits for next models

1

Table of contents