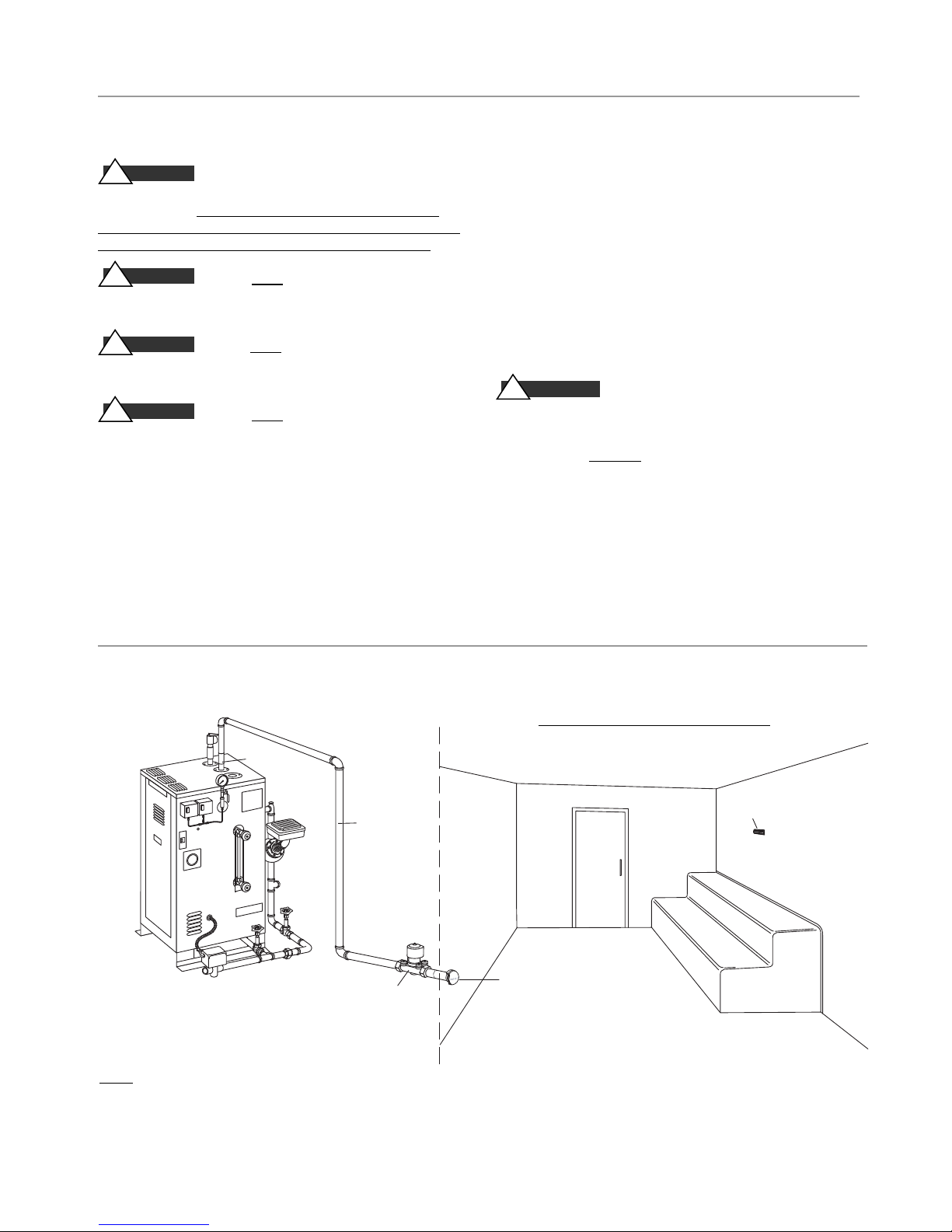

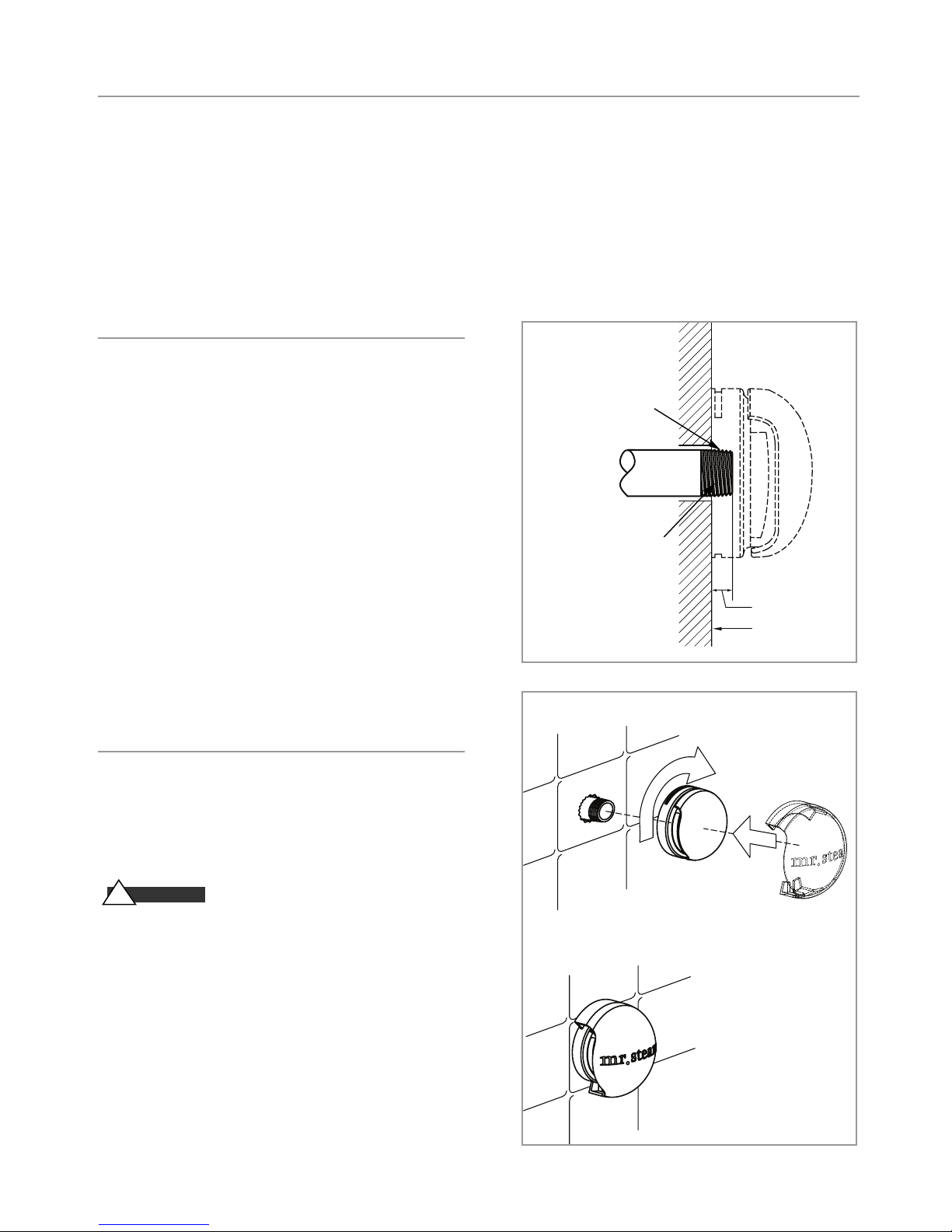

Steam Line

1.

The Digital 1 steam solenoid valve should be plumbed as close as

practical to the steam room using only brass pipe or copper tubing

but should remain accessible for service.

2.

Pitch the steam line a minimum of 1/4”per linear foot of run,

towards the steam outlet on the generator, avoid valleys and trap-

ping of condensate.

3.

Fully insulate steam lines with suitably-rated high temperature

insulation.

4.

Install a suitable strainer or filter between the steam generator and

steam solenoid valve.

5.

Use of unions in plumbing lines is recommended.

Drain

In accordance with Code requirements, provide a drain line

connection from the steambath generator drain valve(s). If an Auto

Blowdown is used, the drain line must be connected to

the automatic blowdown valve. Refer to National and local plumbing

Codes for drain requirements including receptor,

trap, vent requirements and drain lines.

Safety Valve

Where permitted by Code, provide a

connection for safety |valve dis-

charge.

DO NOT

connect a shut off valve or plug at the safety valve outlet.

DO NOT

reduce outlet size of safety valve discharge.

Installation

Plumbing

All plumbing shall be performed by a qualified

licensed plumber and in accordance with applicable

National and local Codes.

Water Supply

1.

Connect to hot or cold water line. A hot water line

is preferable, however incoming hot water should

not exceed 160°F

I PORTANT:

The low temperature setting on many

hot water heaters provides 120°F water

2.

Provide a service shut off valve and water-line

strainer in the water supply line upstream to the

steambath generator

3.

Flush the inlet water line thoroughly before mak-

ing connection to the steambath generator.

4.

Incoming water supply should be at least 25 psig

and is not to exceed 100 psig.

5.

Install a back flow preventor as required by Code.

6.

Provide anti-water hammer device as required in

accordance with Code.

7.

Use of unions in plumbing lines is strongly

recommended.

8.

Recheck all factory and field plumbing connec-

tions for tightness.

mr.steam®CU Series Installation, Operating & Maintenance Manual

6

!WARNING

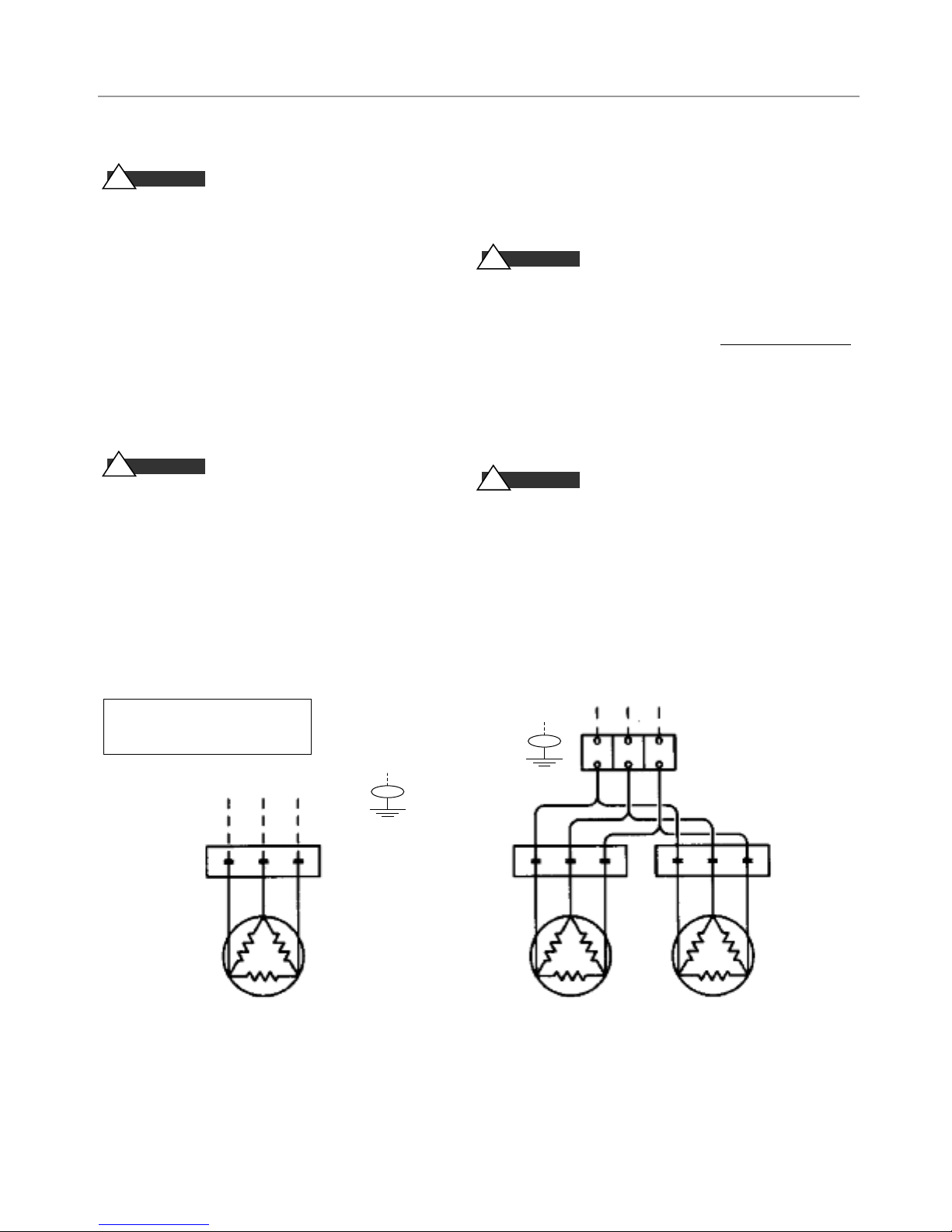

P I P E S I Z E G U I D E

_____________________

Steam Outlet: 1"

Steam Solenoid Valve:3/4"

Steam Head: 3/4"

Water Quality Information

For optimum results, the feedwater supply should be

tested prior to initial startup. If the mineral content

exceeds the following recommended limits, various

external treatment processes may be used to correct the

problem.

NOTE:

An analysis of the on-site boiler feedwater must

be made by a recognized and reliable water treatment

company to ascertain the existing condition and treat-

ment required.

Recommended Feedwater Quality

Hardness, ppm 8 – 85 (~0.5 – 5 gpg)

P-Alkalinity, ppm 85 – 410 (~5 – 24 gpg)

T. Alkalinity, ppm 200 – 500 (~7 – 0 gpg)

pH (strength of alkalinity) 8.0 – 11.4

Blowdown boiler at least a once a day. If boiler water

or feed-water are outside the above limits, a more

frequent blowdown is required

Recommended Limits Within a Boiler

Total Dissolved Solids, ppm 3500 Sulfite (SO3), ppm 25 – 50

Total Alkalinity, ppm 850 Phosphate, ppm 30 – 60

Suspended solids, ppm 300 P-Alkalinity as CaCO3, ppm 900

Silica (SiO2), ppm 125 Iron, ppm 2

Water quality can affect efficiency or result in boiler damage if neglect-

ed. Boiler feedwater contains impurities in solution and suspension.

These impurities concentrate in the boiler. The concentration of these

impurities increases as more feedwater is introduced into the boiler and

steam is produced. If the suspended solids are allowed to concentrate

beyond certain limits, a deposit or “scale” will form on the boiler

internal surfaces. This deposit can interfere with the proper boiler

operation and cause boiler failure.

The concentration of these impurities is generally controlled by the

feedwater quality and by blowdown. Blowdown refers to removing a

portion of the boiler water with high solids concentration and replac-

ing it with makeup water of a lower concentration.