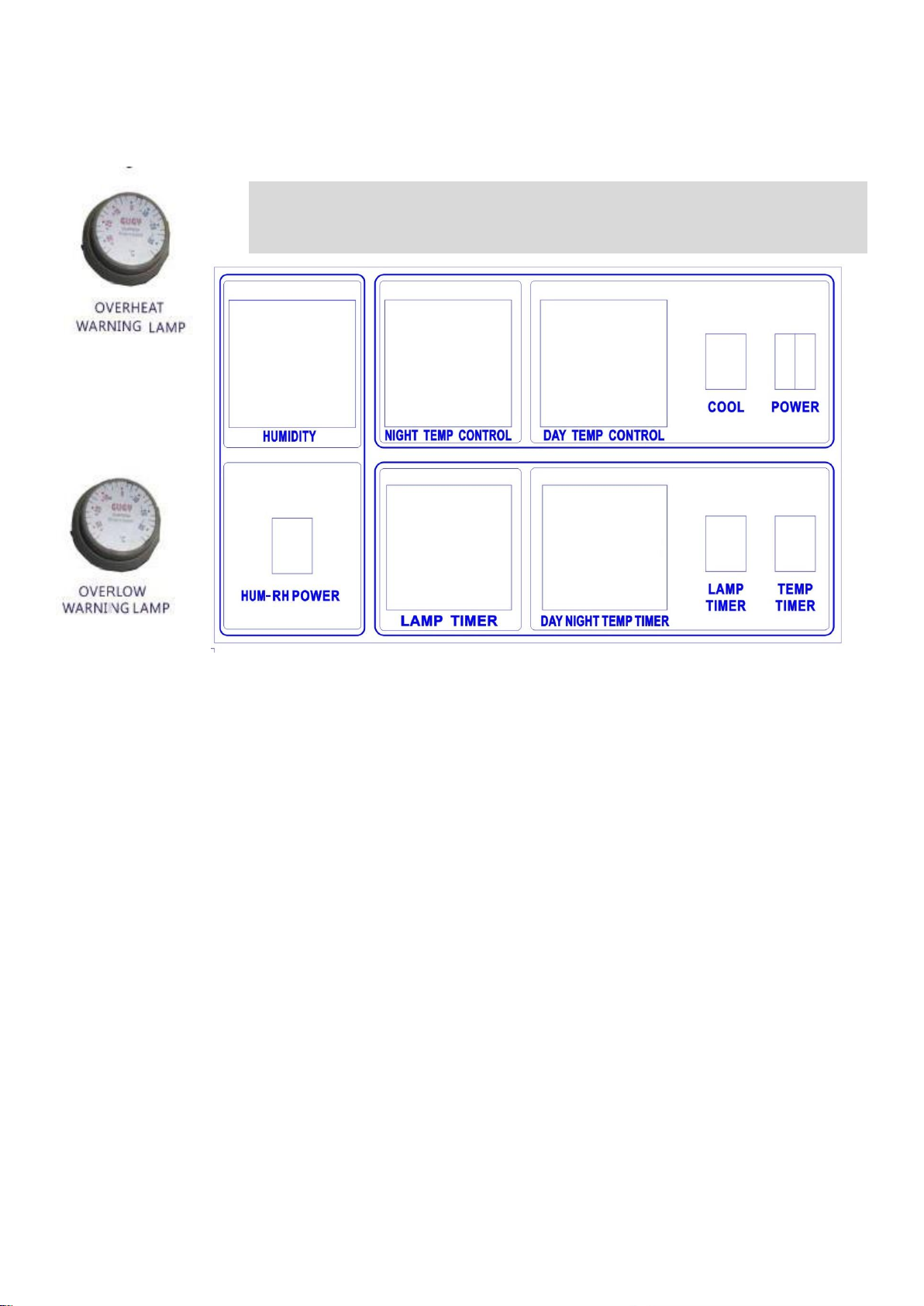

1.9 Over low alarm lamp and knob

2.Operation Manual

1. POWER

1.1 Check the working voltage is □110V/60Hz or □220/50Hz

1.2 After confirming the working voltage is correct, insert the power cord to socket

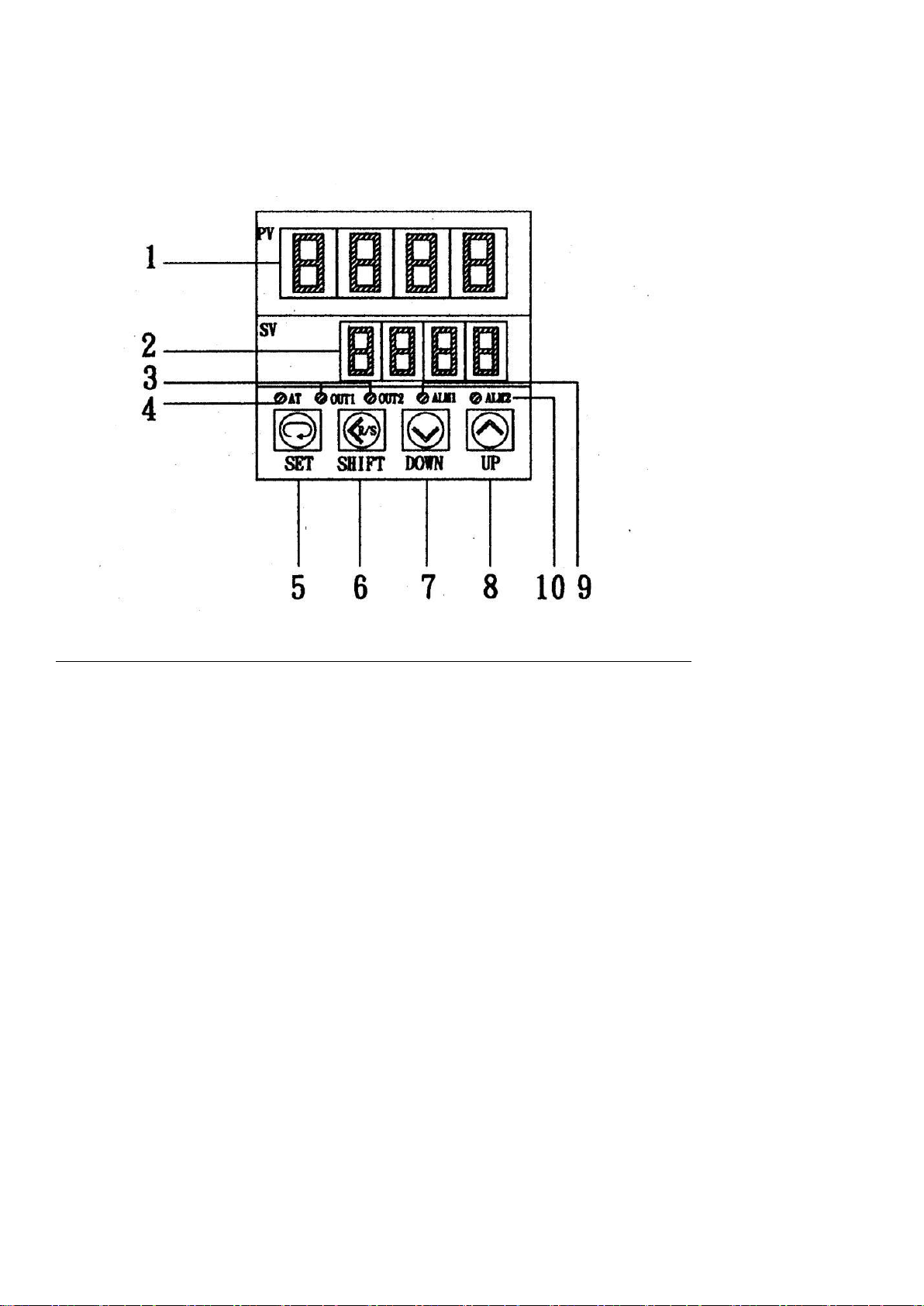

1.3 Turn on the power, the present temperature will display on the temperature control; PV is the

actual temperature of inner box; SV is the set temperature

1.4 Humidity

1.5 Turn on the DEFROST switch at the upper right side of the incubator.

2. COOLER r

Auto. Time-delay 6-7 min. compressor running, every 6 hour automatically power cut to eliminate

mildrew For 6 min. then re-start.(if over low protection start to bounce back, accompanying with alarm

at the same time, after that, automatically delay for 6 min. then re-start running.

3. DAY TEMPERATURE CONTROL

3.1 Setting temperature : First to press the key of “<”, the “SV” key will be in flashing, then start to set

the temperature. The monitor of “SV” will be in high light, then set the required temperature at the

position of high light. To press the key of shift left “►”, the position of high light will be moved

accordingly.

3.2 To press the key of shift up “▲”, the temperature will go up;

To press the key of shift down “▼”, the temperature will go down

3.3 When complete the temperature setting, the “SV” key is still in flashing, need to press the key of

“SET” again, the setting temperature will be on the “SV”

(“PV”) is the actual temperature .

3.4.The heating light of “ Out” is in light , it means the machine is in heating , the light of “OUT” in flash

mean it arrives the required temperature and is normal condition .

4. HUMIDITY CONTROL

Check water bath having water or not , then automatically refill water , setting humidity.Please use RO

water or distilled water