MSA CONTENTS

BD 96 SL 3

GB

Contents

1. Safety Regulations ..................................................................................................4

1.1. Correct Use...................................................................................................... 4

1.2. Liability information ..........................................................................................4

2. Description...............................................................................................................5

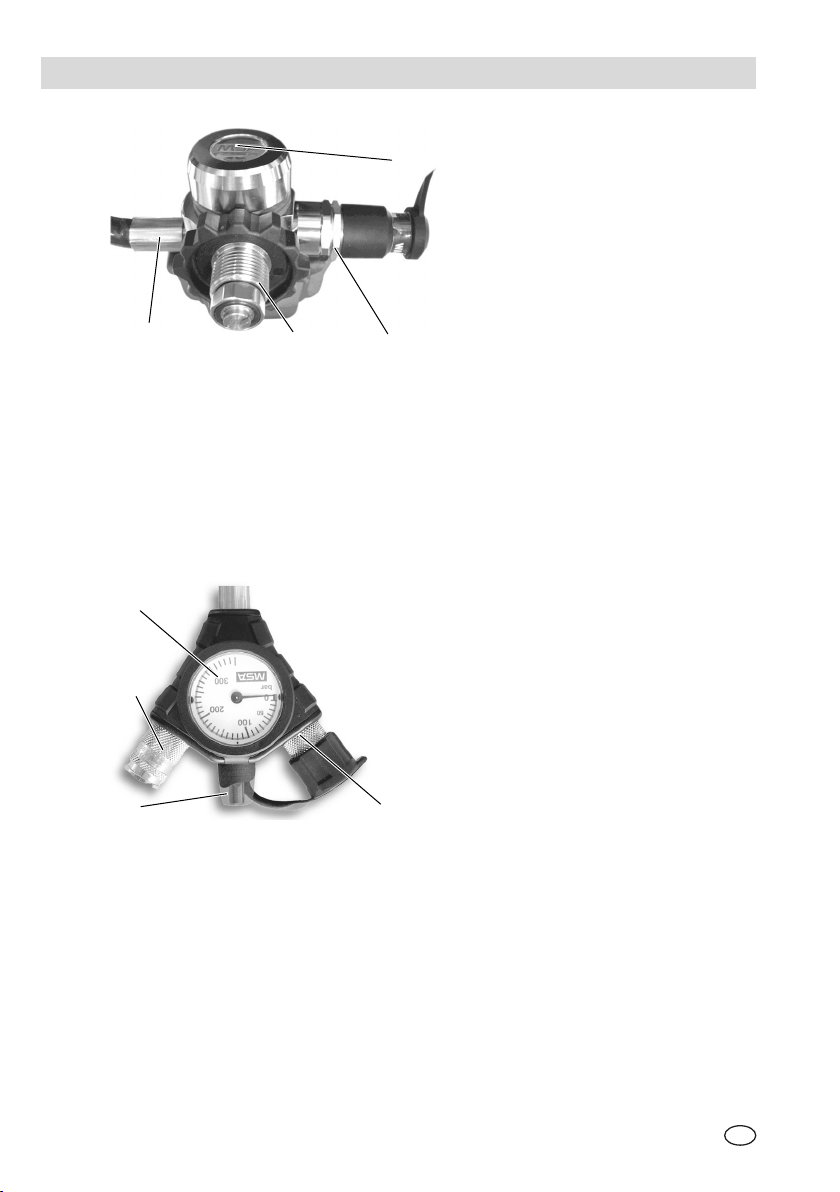

2.1. Standard Model (BD 96 SL) .............................................................................5

2.2. Model with Quick-Fill Coupling (BD 96 SL-Q) ..................................................7

2.3. Technical Data ................................................................................................. 7

3. Using the Compressed Air Breathing Apparatus .................................................8

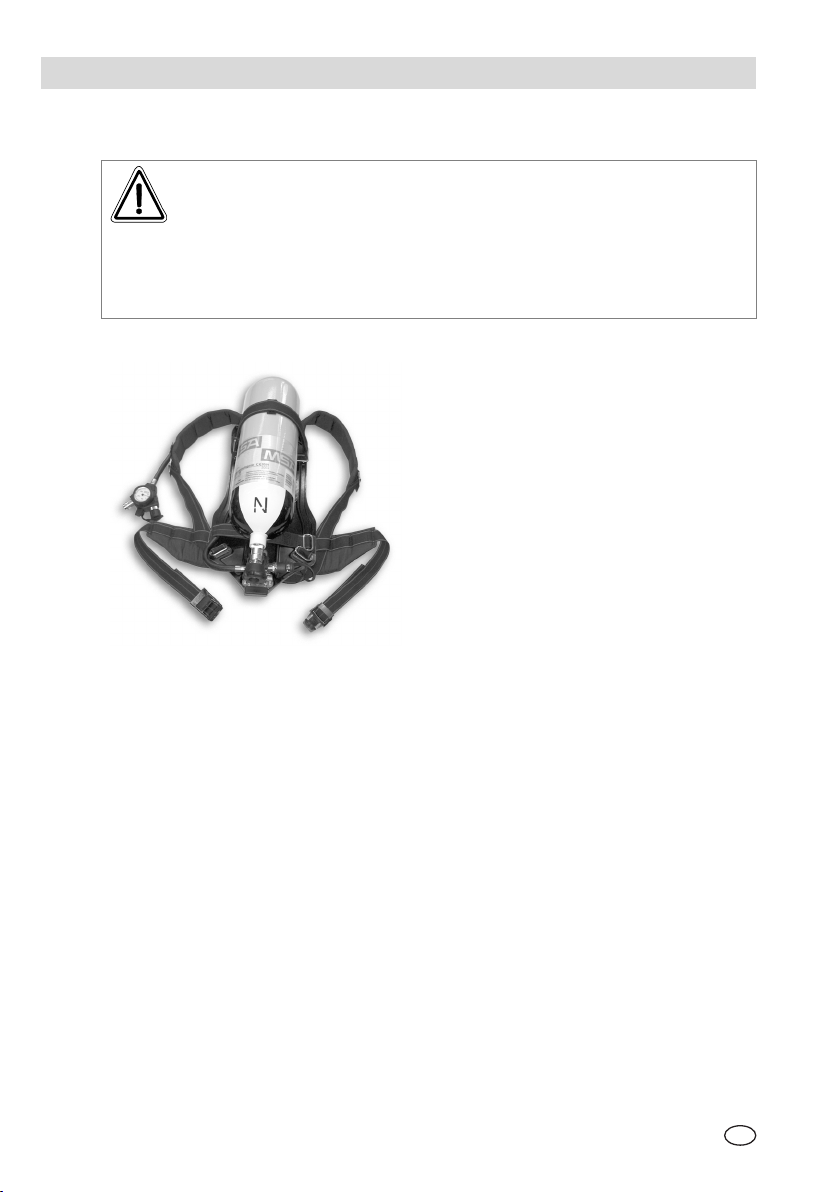

3.1. Connecting one Compressed Air Cylinder .......................................................8

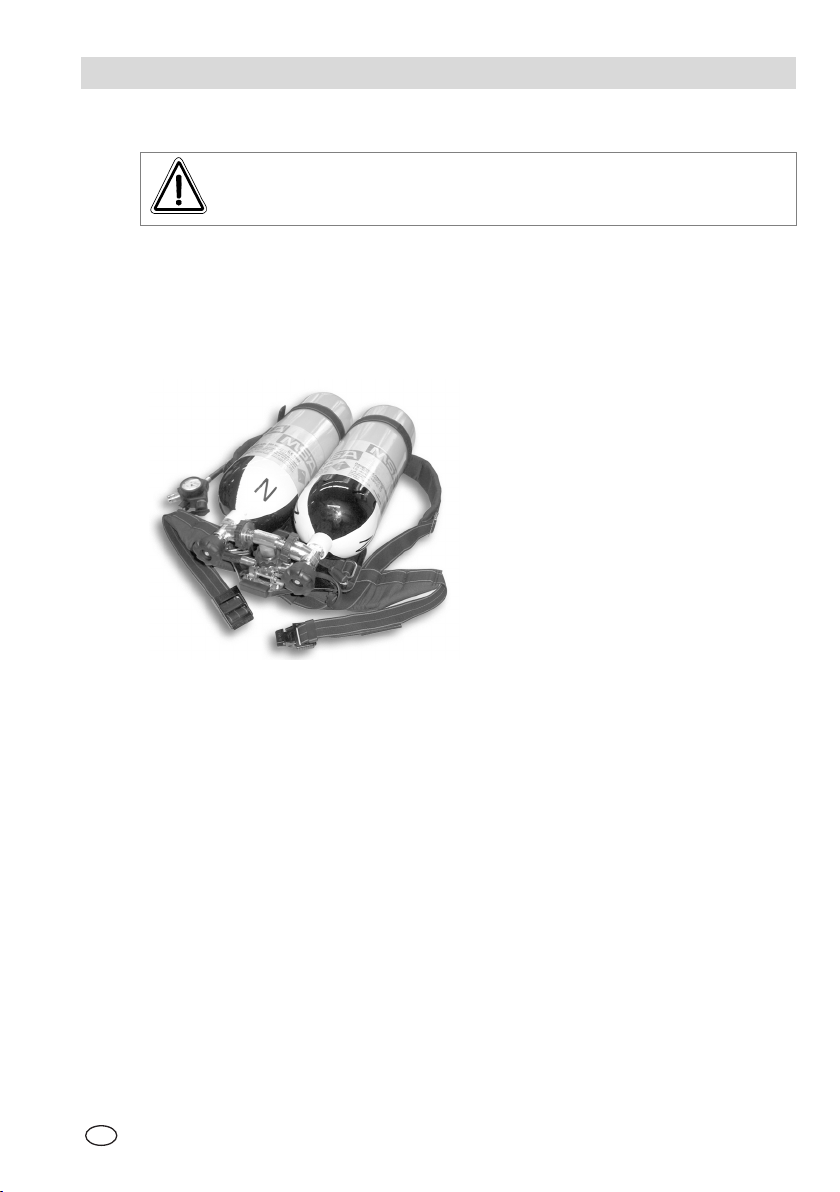

3.2. Connecting two Compressed Air Cylinders......................................................9

3.3. Donning the Compressed Air Breathing Apparatus .......................................10

3.4. Condensed Prior to Use Check...................................................................... 10

3.5. Donning the Face piece (Full Face Mask) .....................................................11

3.6. During Use.....................................................................................................11

3.7. Use of the Second Connection ......................................................................11

3.8. Filling with Quick-Fill ......................................................................................12

3.9. Removing the Compressed Air Breathing Apparatus.....................................12

3.10. Removing the Compressed Air Cylinders ......................................................13

4. Maintenance and Care of the SCBA.....................................................................14

4.1. Maintenance Instructions ...............................................................................14

4.2. Maintenance Intervals....................................................................................14

4.3. Cleaning.........................................................................................................15

4.4. Visual, Function and Tightness Check........................................................... 16

4.5. Warning Device Check ..................................................................................16

4.6. High Pressure Gaskets Check .......................................................................16

4.7. Overhaul ........................................................................................................17

4.8. Storage ..........................................................................................................17

4.9. Malfunctions...................................................................................................17

5. Accessories ...........................................................................................................18

5.1. Compressed Air Cylinders .............................................................................18

5.2. Lung Governed Demand Valve / Full Face Mask...........................................18

6. Ordering Information.............................................................................................19

6.1. Compressed Air Breathing Apparatus............................................................ 19

6.2. Lung Governed Demand Valve...................................................................... 19

6.3. Compressed Air Cylinders .............................................................................19

6.4. Accessories ...................................................................................................20

6.5. Test Equipment..............................................................................................20

6.6. Operating Manuals......................................................................................... 20