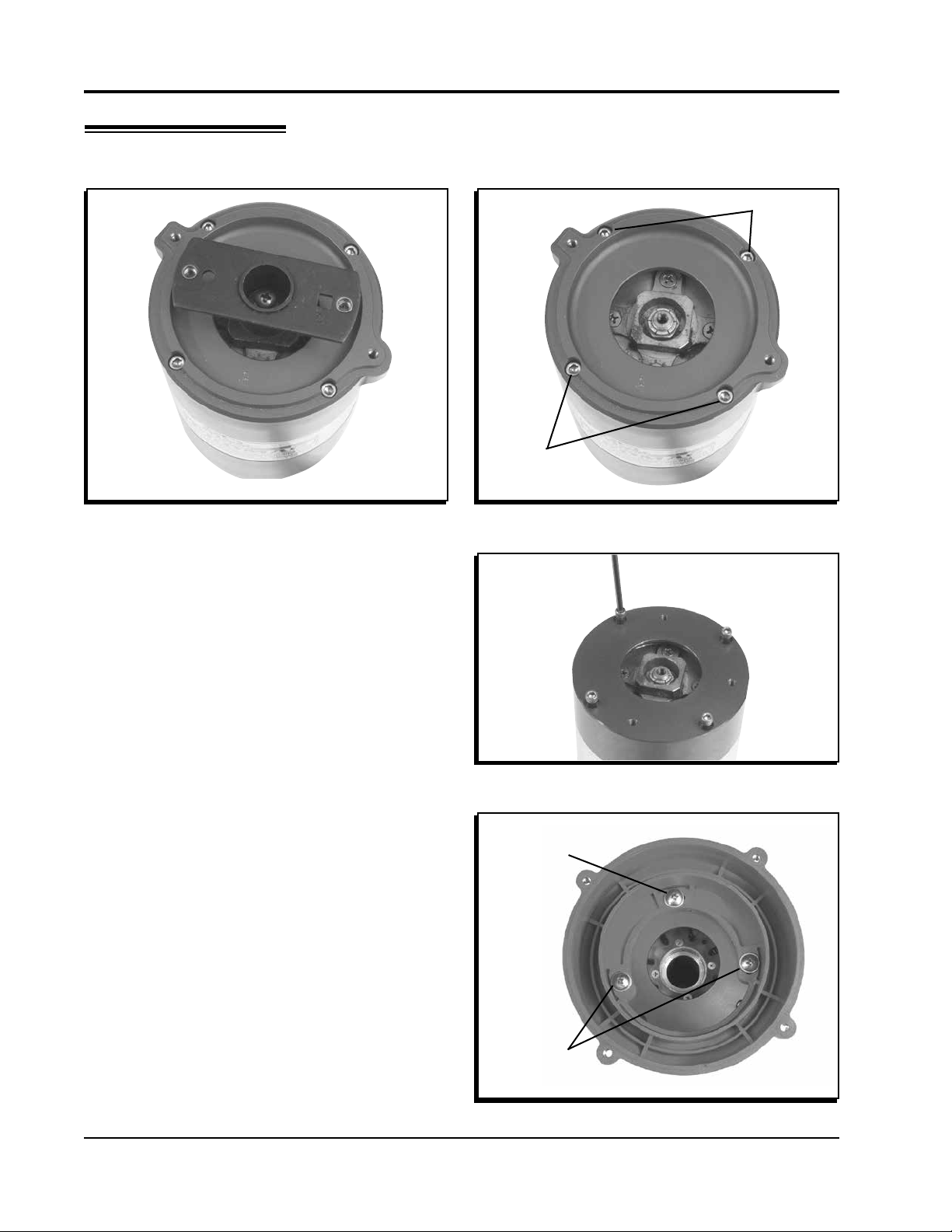

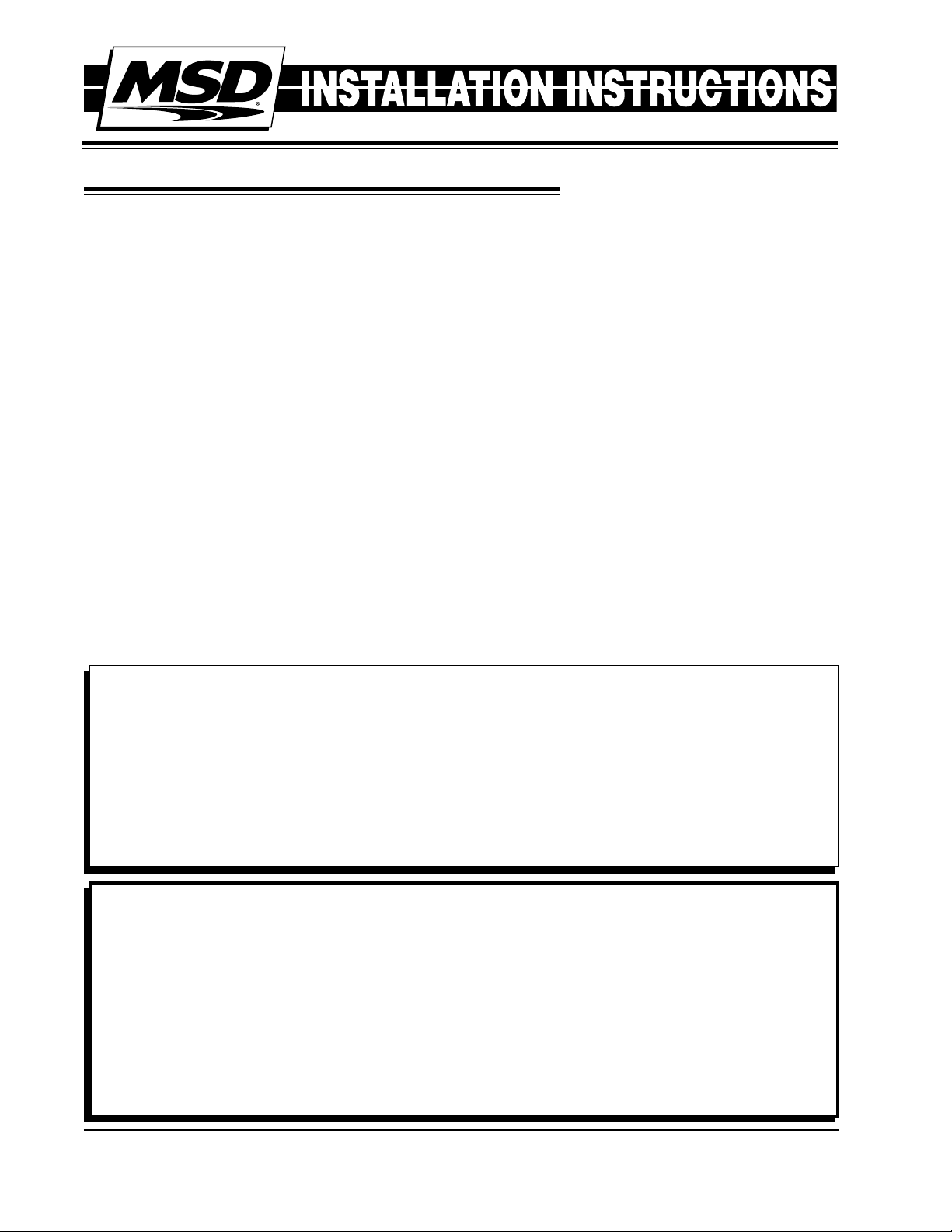

DISTRIBUTOR CAP MAINTENANCE

Like any part of your vehicle, the cap and rotor should be inspected periodically for signs of wear or

carbon tracking.

• Inspect the condition of the rotor tip. The rotor tip should be secure and appear in good shape. Over

time the tip will show obvious signs of wear and deterioration. The center of the rotor tip should

not be burned or appear pitted.

• Check for signs of Carbon Tracking. Carbon tracking can be caused by a crack in the cap or rotor

and could cause a misfire, usually under load when the most voltage is needed to jump the gap

of the spark plug. Carbon tracking appears as small traces that are left when the spark jumps to a

different (easier) path to ground.

• Moisture can affect the transfer of the spark voltage and energy. Make sure the inside of the cap

is clean and dry. Ionization, the build up of conductive gases (ozone) inside the cap, acts as a

conductor and can cause spark scatter.

• In some high humidity areas, it may be necessary to vent the cap to prevent moisture and eventual

buildup of corrosion and ozone gases inside the cap. To vent the cap, drill three or four ¼” holes

in the spacers below the rotor.

• Replacement Parts: Cap, PN 7408

Rotor, PN 7423

Base, PN 7456

Limited Warranty

MSD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

MSD • www.msdPERFORmANCE.COm • (915) 857-5200 • FAX (915) 857-3344

© 2014 MSD LLC

FRM28746 Revised 09/14 Printed in U.S.A.