MSEL Master Relay User manual

Contents

Description..............................................................................................................................1

Safety Precautions...........................................................................................................1

Installation...............................................................................................................................3

Mounting ............................................................................................................................................. 3

Electrical Connection .......................................................................................................................... 3

Switch Connection .............................................................................................................................. 4

PDM / ECU Connection ...................................................................................................................... 5

CAN Bus Connection.......................................................................................................................... 5

Master Relay States ...............................................................................................................6

LED Indicator States........................................................................................................................... 6

Battery Connected .............................................................................................................................. 6

Battery Isolated................................................................................................................................... 7

Resetting the Device...............................................................................................................8

Load Dump Protection ............................................................................................................ 8

Shutdown Delay......................................................................................................................8

Temperature Monitoring .........................................................................................................9

Load Current Monitoring.........................................................................................................9

Power Saving Mode................................................................................................................9

CAN Communications ..........................................................................................................10

Message Format............................................................................................................................... 10

CAN Shutdown ................................................................................................................................. 12

Device Configuration ............................................................................................................13

Changing the base CAN Identifier .................................................................................................... 13

Changing the CAN Baud Rate & Shutdown Delay ........................................................................... 14

Changing the PDM Output Drive Configuration................................................................................ 15

Setting up CAN Shutdown ................................................................................................................ 16

Specifications........................................................................................................................18

Drawing.................................................................................................................................19

Revision History....................................................................................................................20

Master Relay - User’s Manual 1

Description

The Master Relay is a battery isolator that goes much further than just safety in mind. It has

been designed with the sole purpose of a motorsport environment. Utilising solid state

switching components, the Master Relay has excellent temperature resistance, as well as an

aluminium enclosure that is lightweight and robust in even the harshest motorsport

environment.

The Master Relay not only has built in engine shutdown functionality in accordance to FIA

regulations, it also incorporates alternator load dump protection unavailable on most rival

devices. This helps to avoid nasty voltage spikes often seen when disconnecting the battery

source whilst the alternator is still charging.

The device can safely shut down the vehicle under a number of different events including:

external kill switch press, over current / short circuit, over temperature, and can even be shut

down via a remote CAN message. For example, in the event of a severe impact or an

overturned.

When connected to a data logger on a CAN bus, the Master Relay provides valuable

information about the current, voltage and internal temperature, as well as diagnostic

information that makes finding problems a lot easier. As well as transmission to a data logger

the Master Relay has a multi-coloured LED that shows a unique colour combination for each

of the 10 different states. The driver switch can also be connected with an LED to show when

the battery is isolated.

Safety Precautions

These instructions provide vital information to the safe and desired installation of the Master

Relay. Please ensure you are familiar with the entire process before installing this device into

your car. Failure to comply with these instructions could damage the Master Relay or other

components in the vehicle.

The Master Relay must be completely disconnected before any welding is conducted on the

installed vehicle.

The Master Relay should always have the PDM output connected and correctly shutting the

engine down. Failure to do so could damage not only the Master Relay but also other

computers connected in the vehicle such as ECUs, displays, control units etc.

While all efforts are made to ensure the accuracy of the information in this manual, no

responsibility will be taken for the consequences of any omissions in this manual.

2

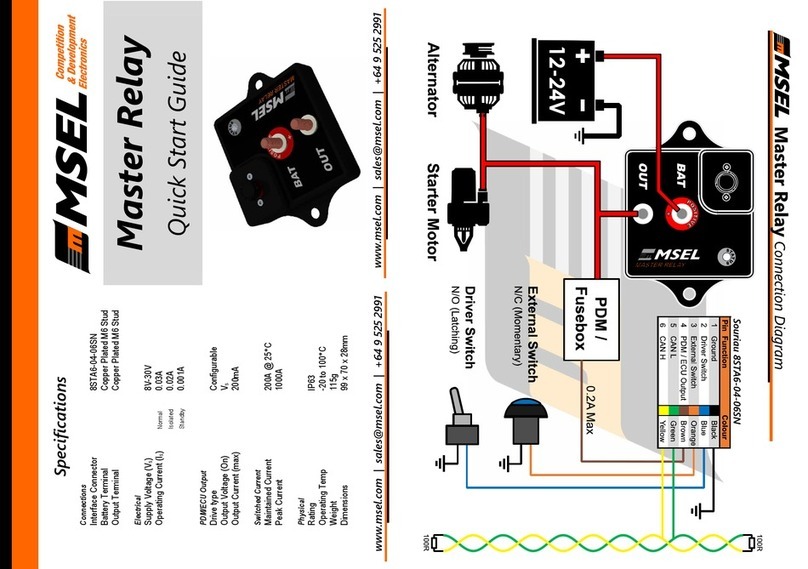

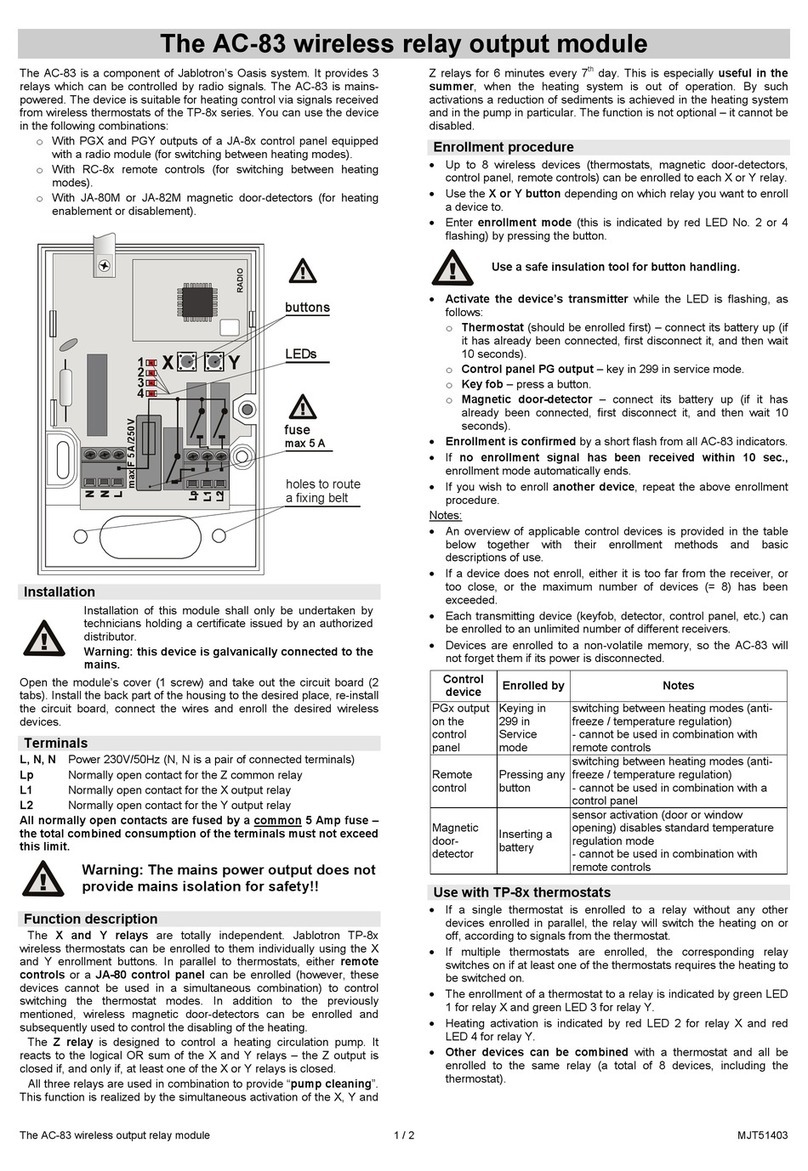

Figure 1: Connection Diagram

Master Relay - User’s Manual 3

Installation

Mounting

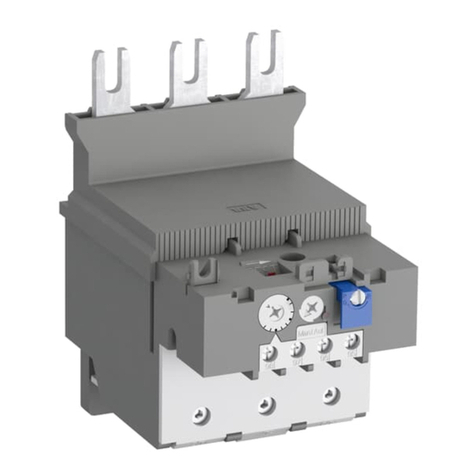

The MSEL Master Relay has two tags designed for mounting the device to a flat surface. The

spacing between the mounting holes is 84mm (see Drawing for details). The location of the

Master Relay, as well as the total current load, can have significant effect on the internal

temperature of the Master Relay. Where possible try to mount the Master Relay away from

significant heat sources.

Electrical Connection

The Master Relay is connected between the positive terminal of the battery and the rest of

the vehicles positive power supply. The device should be positioned as close to the battery

as possible, keeping the positive lead as short as you can. See the Connection Diagram for

a typical installation.

ENSURE THAT THE GROUND CONNECTION IS MADE BEFORE CONNECTING THE

BATTERY AND VEHICLE TERMINALS.

Power Studs

The battery and output terminals are copper plated M6 studs. Care should be taken to

ensure that cables are insulated from the housing and neighbouring studs. It is

recommended to use the supplied nut caps with insulated lugs, or for maximum

protection, rubber insulating boots can be used on each stud.

Interface Connector

All low current connections are made through a single 6-way Souriau mil-spec connector;

keeping things tidy, protected and allowing for quick removal / installation.

The mating connector (Souriau 8STA6-04-06SN) can be purchased individually for

custom installs or a breakout harness with DTM connectors is available for generic

installs.

Table 1: Interface connector pinout

Pin

Function

Colour

1

Ground

Black

2

Driver Switch

Blue

3

External Switch

Orange

4

PDM / ECU Output

Brown

5

CAN L

Green

6

CAN H

Yellow

Table 1 shows the pinout along with the standard wiring colours supplied with the breakout

harness. For those making a custom harness the Souriau connector has #26 terminals

and accept 30AWG through to 24AWG wire.

4

Switch Connection

The Master Relay is controlled by two types of switch, the driver kill switch and the external

kill switch.

Driver Kill Switch

The driver kill switch is generally operated from within the vehicle and is the main control

for the battery isolation. Generally, just a single driver kill switch is used, however multiple

switches can be wired as shown in Multiple Switches, the extra switch could be hidden

and used as an additional security measure.

Wiring of the driver kill switch is carried out as shown in the Connection Diagram. The

switch used should be of a latching type (either toggle or push button). When the switch

is in the off position there should be an open circuit between the two terminals. One side

of the switch connected to pin 2 of the Master Relay connector, and the other side is

connected to ground.

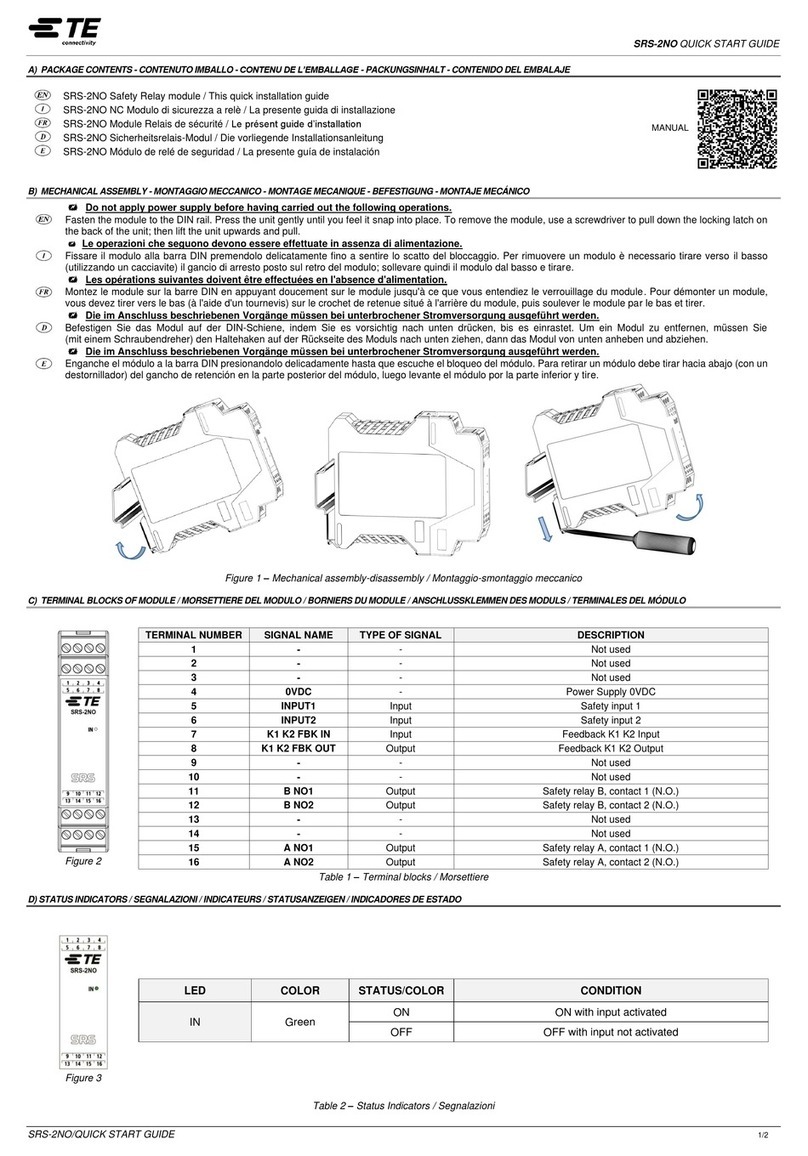

An LED can be added to the circuit as shown in Figure 2. This LED will be on solid when

the device is in the normal state, flash when the battery is isolated, and be turned off when

the driver switch is off.

Figure 2: LED indicator wiring

External Kill Switch

The external kill switch allows remote triggering of the Master Relay. It is often mounted

on the exterior of the vehicle and indicated by a red lightning bolt on a blue triangle.

Multiple external switches can be wired as shown in Multiple Switches. If an external

switch is not required, pin 3 of the Master Relay connector should be permanently

connected to ground.

Wiring of the external kill switch is carried out as shown in the Connection Diagram. The

switch used should be of a momentary non-latching type with a normally closed (NC)

configuration. When the switch is pressed there should be an open circuit between the

two terminals. One side of the switch is connected to pin 3 of the Master Relay connector,

and the other side connected to ground.

Multiple Switches

Multiple external kill switches can be connected in series provided that when all switches

are in the ‘ON’ position there is continuity between the input to the Master Relay and

ground. When any switch is in the ‘OFF’ position the connection to ground should be open

circuit. See Figure 3 for examples of multiple switch configurations.

Master Relay - User’s Manual 5

Figure 3: Example multiple external switch configuration

PDM / ECU Connection

Pin 4 of the Master Relay connector provides a logical output for a PDM / ECU allowing engine

shutdown functionality in accordance with FIA rules. The drive of this output can be configured

in the combinations shown in Table 2 below. The device ships standard with configuration 0

(active high, half bridge). In this configuration when the Master Relay is in an ‘On’ or ‘Normal’

state the output is connected to the battery supply, and when ‘Off’ the output is connected to

ground.

Table 2: PDM output drive configurations

Active State

Output Drive

Config.

Output 'On'

Output 'Off'

High

Half Bridge

0

Vbattery

GND

Low Side

2

-

GND

High Side

1

Vbattery

-

Low

Half Bridge

4

GND

Vbattery

Low Side

6

GND

-

High Side

5

-

Vbattery

In order to change the output drive to one of the other configurations please refer to Changing

the PDM Output Drive Configuration, or specify your requirements when purchasing.

The PDM / ECU output is short circuit protected and current limited to 200mA. To drive larger

loads an external relay is recommended.

CAN Bus Connection

To receive status and channel information from the Master Relay it must be connected to a

compatible device on the same CAN bus. Examples of these include a data logger, dash

display, or ECU. The Master Relay transmits two messages on a configurable address and is

compatible with most CAN capable data loggers on the market. For further information on the

format and transmission refer to the CAN Communications section.

The Master Relay does not have any internal termination resistors and therefore requires

100R termination resistors at each end of the CAN bus.

6

Master Relay States

LED Indicator States

The table below shows the corresponding states for each of the possible colour codes

displayed on the status LED.

Table 3: LED indicator states

Status

LED Colour

Normal

Green

(CAN Error)

/

Green Flashing

Over Temperature Warning

/

Blue Flashing

Over Current Kill

Yellow

Low Voltage Warning

/

Green/Blue Flashing

High Voltage Warning

/

Green/Red Flashing

Over Temperature Kill

/

Blue/Red Flashing

Driver Switch Kill

Red

External Switch Kill

/

Red Flashing

CAN Trigger Kill

Blue

Power On Reset

Purple

Battery Connected

Normal Operation

The battery is connected to the output and the device is operating normally.

Normal Operation (CAN Error)

The device is operating normally; however, the CAN bus has been unresponsive for more

than 2 transmission cycles. CAN communications have been disabled until the CAN bus

is back online (this is checked every 5 seconds).

Over Temperature Warning

The device temperature has exceeded the warning temperature (90°C). The device will

continue to function normally; however, the temperature is getting close to the device

limits. This should be remedied to avoid undesired performance and/or potential damage.

Once the fault is remedied the device will automatically return to normal operation.

Low Voltage Warning

The device voltage has dropped below the lower warning limit (7V). The device will try to

continue to function normally, however the voltage is getting close to the device limits.

This should be remedied to avoid undesired performance and/or potential damage.

Once the fault is remedied the device will automatically return to normal operation.

Master Relay - User’s Manual 7

High Voltage Warning

The device voltage has exceeded the upper warning limit (28V). The device will try to

continue to function normally, however the voltage is getting close to the device limits.

This should be remedied to avoid undesired performance and/or potential damage.

Once the fault is remedied the device will automatically return to normal operation.

Battery Isolated

Driver Kill

The driver kill switch has been turned off or the connection has broken. The battery is

disconnected and the indicator will be solid red.

The device will remain in this state for 30 seconds before entering a low power state. To

return to normal operation a reset is required (see Resetting the Device).

External Kill

The external kill switch has been triggered or the connection has broken. The battery is

disconnected and the indicator will be flashing red.

To return to normal operation a reset is required (see Resetting the Device).

CAN Kill

A CAN message has triggered a shutdown. The battery is disconnected and the indicator

will be solid blue. See CAN Shutdown for further details on the CAN kill function.

To return to normal operation a reset is required (see Resetting the Device).

Over Temperature Kill

The device temperature has exceeded the maximum allowed temperature (110°C). The

battery is disconnected and the indicator will be flashing red and blue.

Once the fault is remedied the device will automatically return to normal operation.

Power On Reset

The device has been powered on with the driver & external switches on. The battery

remains disconnected and the indicator will be solid purple.

To return to normal operation a reset is required (see Resetting the Device).

Over Current Kill

The device temperature has exceeded the maximum allowed current. The battery is

disconnected and the indicator will be solid yellow.

Check for any short circuits between the output terminal and the chassis ground. To return

to normal operation once the fault is remedied, a reset is required (see Resetting the

Device).

8

Resetting the Device

Once the device has been triggered by one of the 5 faults (external kill, driver kill, CAN kill,

over-current kill or over-temperature kill) the device will remain in the off state until reset. The

LED indicator will show the current fault as outlined in LED Indicator States.

Once the fault has been remedied the device can be reset by cycling the driver kill switch off

and then back on.

Load Dump Protection

The Master Relay has on board circuitry that will help protect sensitive electronic devices in

the event of a shutdown during engine operation. The PDM output will be turned off

immediately therefore stopping the engine. However, the battery is not disconnected until the

alternator is no longer charging. This avoids the situation where the alternator may still be

generating as the battery is disconnected, resulting in voltage spikes as large as 120V that

can damage sensitive electronic components.

The Master Relay has a 5 second timeout where by even if for some reason the battery is still

being charged it will be disconnected regardless (this can be extended by specifying a longer

shutdown delay, see Shutdown Delay).

Shutdown Delay

The Master Relay can be programmed to delay switching the battery power off to allow for

diagnostic data logging. The shutdown delay is in addition to the load dump protection delay

described in Load Dump Protection. Therefore, the battery is guaranteed to be connected for

the duration of the shutdown delay, except for an over current event where the battery is

disconnected immediately to prevent potential damage.

The recommended procedure for this is to use a PDM or ECU to shut down the engine and

disable everything except the data logging systems. This allows these devices to receive the

shutdown event information and store it before shutting down.

The table below indicates the recommended delay times for different data logging systems:

Table 4: Recommended shutdown delay times

Data Logging Device

Shutdown Delay

All MoTeC products

1.0 seconds

All devices are shipped with no additional shutdown delay, in order to activate this feature

please request it at the time of purchase, or program the desired delay as described in

Changing the CAN Baud Rate & Shutdown Delay.

Master Relay - User’s Manual 9

Temperature Monitoring

The Master Relay has an on-board temperature sensor for monitoring the internal

temperature of the unit. The temperature is transmitted on the CAN bus as well as used

internally to isolate the battery in case of excessive temperatures. A warning is displayed on

the LED indicator at 90°C (flashing blue) and the device is shut down at 110°C with a blue/red

indication on the LED.

The device will automatically attempt to restart when the temperature drops back down below

100°C, or with a device reset (and temperature is below 110°C).

Load Current Monitoring

The Master Relay has internal bi-directional current sensing for the load to / from the battery.

This current is transmitted as part of message 1 on the CAN bus (see CAN Communications).

The load current is designed as an indication of the total system draw and is accurate to ±10%

or 1A (whichever is greatest). It is not intended to be used for detailed, smaller current draw

analysis. The Master Relay should be used in conjunction with a PDM for accurate

measurement of current for individual devices.

The Master Relay has integrated short-circuit protection and will isolate the battery in the

event of a major short circuit on the main output terminal.

Power Saving Mode

After 30 seconds in the Driver Kill mode the Master Relay will enter a power saving mode. In

this mode the following functions of the device are turned off to save power.

•CAN transmission is disabled

•The LED indicator is turned off

•Temperature and load monitoring are turned off

•The microcontroller is put into a standby state

The device resumes operation as soon as the driver switch is turned on again.

10

CAN Communications

The Master Relay comes preprogramed with a baud rate of 1 Mbps. The user can configure

the device to a baud rate of 500 Kbps or 250 Kbps as detailed in Changing the CAN Baud

Rate & Shutdown Delay, or alternatively request these settings at the time of purchase.

Message Format

The Master Relay transmits status and information on the CAN bus over two addresses.

These addresses are defined by the base CAN address (Default: 0x6E4). This can be

configured using the process detailed in Changing the base CAN Identifier, or alternatively by

requesting a particular address at the time of purchase.

Table 5 & Table 6 below show the format of the transmitted channels. Each message is

transmitted at a rate of 10Hz, and all multi-byte channels are in Big-Endian format (MSB first).

Table 5: Base address (Default: 0x6E4)

Byte

Channel

Units

Length

Base

Signed

Value

Transmitted

0

Voltage Out

V

2

0.01

Unsigned

12.56

1256

1

2

Current Load

A

2

0.1

Signed

54.5

545

3

4

Internal Temperature

°C

2

0.1

Signed

25.2

252

5

6

Warnings

-

1

1

-

see (2)

7

Status

-

1

1

-

see (1)

Table 6: Base address + 1 (Default: 0x6E5)

Byte

Channel

Units

Length

Base

Signed

Value

Transmitted

0

Voltage In

V

2

0.01

Unsigned

12.56

1256

1

2

Serial No.

-

2

1

Unsigned

-

-

3

4

Configuration (3)

-

2

1

Unsigned

-

-

5

6

Time Since Shutdown

s

1

0.1

Unsigned

15.5

155

7

Shutdown Cause 2 (4)

-

4 MSB

1

-

see (1)

Shutdown Cause (4)

-

4 LSB

1

-

see (1)

(1) List of ‘Status’ enumerations are available in Table 7

(2) ‘Warning’ bit masks are available in Table 7

(3) ‘Configuration’ composition is available in Table 8

(4) ‘Shutdown Cause 1’ is the 2nd to last event, and ‘Shutdown Cause 2’ is the last event (from serial no. 61061),

serial no. prior to 61061 just give last event.

Master Relay - User’s Manual 11

Status and Warning Formats

The status and warning channels transmitted in CAN message 1 contain the current

status of the warnings and faults on the device. The status enumerations are listed in

Table 7 below.

The warning channel is made up from 8 individual bits, corresponding to the status or

switch states. Multiple warnings may be present at any single instance. For example, if

both the external switch (0x40) and the driver switch (0x20) are off, the warning channel

will be equal to 0x60.

Table 7: Status enumeration & warning channel bit masks

Status

Status

Enumeration

Warning

Bit Mask

Normal

1

-

Over Temperature Warning

2

0x01

Over Current Warning

3

0x02

Low Voltage Warning

4

0x04

High Voltage Warning

5

0x08

Over Temperature Kill

6

0x10

Driver Switch Kill

7

0x20

External Switch Kill

8

0x40

CAN Trigger Kill

9

0x80

Power On Reset

10

-

Configuration Format

The configuration channel contains information on the current configuration stored in the

Master Relay. Table 8 below shows the composition of this channel from the features

programmed as detailed in Device Configuration.

Table 8: Configuration channel composition

Byte 1

Byte 2

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

CAN Kill

Enable

CAN Baud

Rate

Output Drive

Shutdown Delay

0 = Disabled

1 = Enabled

2 = ADR

0 = 1Mbps

1 = 500Kbps

2 = 250Kbps

0 = Active-Hi, Half Bridge

1 = Active-Hi, High Side

2 = Active-Hi, Low Side

4 = Active-Lo, Half Bridge

5 = Active-Lo, High Side

6 = Active-Lo, Low Side

Shutdown Delay (in 0.1 seconds)

eg. 10 = 1 second shutdown delay

12

CAN Shutdown

The Master Relay has the ability to be shut down remotely via a CAN message. As default

this functionality is disabled. Refer to Setting up CAN Shutdown for information about how to

enable and set up this function, or alternatively request this functionality to be programmed

when ordering the device.

When enabled, upon receiving a message with the format shown in Table 9, and on the

configured CAN kill address, the Master Relay will shut down the engine and isolate the

battery.

Table 9: Example CAN shutdown message for CAN Kill address 0x6E6

Received Address

Byte

0

1

2

3

4

5

6

7

0x6E6

0xFF

0x00

0xFF

0x00

0xFF

0x00

0xFF

0x00

This feature can also be programmed to work with a MoTeC Accident Data Recorder (ADR)

and trigger after a severe event. To enable this feature set the CAN Kill Enable byte to ‘2’,

and the CAN Kill address to the address of the status information transmitted by the ADR

(default is 0x449). See Setting up CAN Shutdown for further instructions.

Please check previous logged data carefully to ensure that the severe event

threshold in the ADR doesn’t false trigger on normal impacts such as ‘curb strikes’.

Master Relay - User’s Manual 13

Device Configuration

Changing the base CAN Identifier

The default base CAN address is 0x6E4, can be changed using any CAN bus interface device

capable of transmitting a message onto the CAN bus. The following procedure changes the

CAN identifier on the Master Relay:

1. Configure the CAN interface device to transmit a single message on address 0x789

with the following format:

Table 10: Example CAN ID configuration message

Byte

0

1

2

3

4

5

6

7

Data

0x07

0x89

CAN_ID

CAN_ID

0x07

0x89

Example*

0x07

0x89

0x06

0xE4

0x06

0xE4

0x07

0x89

* shows the correct message format to change the address to 0x6E4

Where ‘CAN_ID’ is the desired new CAN address in big endian format (MSB first).

Please note that the CAN address must not exceed a length of 11 bits (0x000 to

0x7FF), and must not conflict with any other CAN devices on the network.

2. Press and hold the external kill switch while sending the above message.

3. The Master Relay will send a response message on the base CAN address. See

Table 11 for a list of responses.

Table 11: Responses for CAN ID configuration

0

1

2

3

4

5

6

7

Successful

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

IDs do not match

0x11

0x11

0x11

0x11

0x11

0x11

0x11

0x11

Frame check error

0x22

0x22

0x22

0x22

0x22

0x22

0x22

0x22

Invalid ID

0x33

0x33

0x33

0x33

0x33

0x33

0x33

0x33

4. After a successful response the Master Relay will be configured to send all CAN

information on the new base address.

14

Changing the CAN Baud Rate & Shutdown Delay

The device comes preconfigured with a default CAN baud rate of 1Mbps, and a shutdown

delay of 200ms. These values can be changed using any CAN bus interface device capable

of transmitting a message onto the CAN bus. The following procedure is used to change the

CAN baud rate and shutdown delay on the Master Relay:

1. Configure the CAN interface device to transmit a single message on address 0x789

with the following format:

Table 12: Example CAN baud rate & shutdown delay configuration message

Byte

0

1

2

3

4

5

6

7

Data

0x04

0x56

BAUD

RATE

BAUD

RATE

SHUT

DELAY

SHUT

DELAY

0x04

0x56

Example*

0x04

0x56

0x01

0x01

0x0A

0x0A

0x04

0x56

* shows the correct message format to set the baud rate to 500Kbps and the shutdown delay to 1 second.

Where ‘BAUD RATE’ is from the table below and ‘SHUT DELAY’ is the delay in

tenths of a second that the power is kept on after a shutdown event (in hex).

Table 13: List of baud rate enumerations

Baud Rate Value

‘BAUD RATE’

1Mbps (Default)

0x00

500Kbps

0x01

250Kbps

0x02

2. Press and hold the external kill switch while sending the above message.

3. The Master Relay will send a response message on the base CAN address. See

Table 14 for a list of responses.

Table 14: Responses for CAN baud rate & shutdown delay configuration

0

1

2

3

4

5

6

7

Successful

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Values do not match

0x11

0x11

0x11

0x11

0x11

0x11

0x11

0x11

Frame check error

0x22

0x22

0x22

0x22

0x22

0x22

0x22

0x22

Invalid baud rate

0x33

0x33

0x33

0x33

0x33

0x33

0x33

0x33

4. After a successful response the Master Relay will need to be restarted (by removing

the power) before the new CAN baud rate is implemented. The shutdown delay is

effective immediately.

Master Relay - User’s Manual 15

Changing the PDM Output Drive Configuration

The device comes preconfigured with a default PDM drive output of active high, half-bridge.

This configuration can be changed using any CAN bus interface device capable of

transmitting a message onto the CAN bus. The following procedure is used to change the

PDM output drive on the Master Relay:

1. Configure the CAN interface device to transmit a single message on address 0x789

with the following format:

Table 15: Example PDM output drive configuration message

Byte

0

1

2

3

4

5

6

7

Data

0x0A

0xBC

OUTPUT

DRIVE

OUTPUT

DRIVE

0x00

0x00

0x0A

0xBC

Example*

0x0A

0xBC

0x06

0x06

0x00

0x00

0x0A

0xBC

* shows the correct message format to set the PDM output drive to active low, low side.

Where ‘OUTPUT DRIVE’ is selected from the table below:

Table 16: List of output drive enumerations

Active State

Drive

‘OUTPUT DRIVE’

High

Half Bridge

0x00

Low Side

0x02

High Side

0x01

Low

Half Bridge

0x04

Low Side

0x06

High Side

0x05

2. Press and hold the external kill switch while sending the above message.

3. The Master Relay will send a response message on the base CAN address. See

Table 17 for a list of responses.

Table 17: Responses for PDM output drive configuration

0

1

2

3

4

5

6

7

Successful

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Values do not match

0x11

0x11

0x11

0x11

0x11

0x11

0x11

0x11

Frame check error

0x22

0x22

0x22

0x22

0x22

0x22

0x22

0x22

Invalid configuration

0x33

0x33

0x33

0x33

0x33

0x33

0x33

0x33

4. After a successful response, the Master Relay will need to be reset before the new

PDM output drive is implemented.

16

Setting up CAN Shutdown

The CAN shutdown function is disabled by default. This configuration can be changed using

any CAN bus interface device capable of transmitting a message onto the CAN bus. The

following procedure enables / disables the CAN shutdown function of the Master Relay, as

well as sets the address for shutdown commands to be received. For more information on

how to use the shutdown once enabled, please refer to Configuration Format.

1. Configure the CAN interface device to transmit a single message on address 0x789

with the following format:

Table 18: Example CAN shutdown configuration message

Byte

0

1

2

3

4

5

6

7

Data

0x01

0x23

CAN_KILL

CAN_KILL

0x01

0x23

Example*

0x01

0x23

0x16

0xE6

0x16

0xE6

0x01

0x23

* shows the correct message format to enable CAN shutdown on address 0x6E6

Where ‘CAN_KILL’ is composed as in Table 19 below. The first 4 bits (‘EN’), set the

CAN shutdown mode, where 0 is disabled, 1 is enabled, and 2 is for a MoTeC ADR.

The last 12 bits (‘KILL_ID’) set the receive CAN address in big endian format (MSB

first).

Table 19: Example ‘KILL_ID’ composition

Byte

0

1

Mask

0xF0

0x0F

0xF0

0x0F

Data

EN

KILL_ID

Example*

0x1

0x6

0xE

0x6

* shows the correct byte composition to enable CAN shutdown on address 0x6E6

‘EN’ must be less than 0x2 to enable the function. Setting ‘EN’ to any other value

will disable the CAN shutdown function.

Please note that the CAN address must not exceed a length of 11 bits (0x000 to

0x7FF), and must not conflict with any other CAN devices on the network.

2. Press and hold the external kill switch while sending the above message

The Master Relay will send a response message on the base CAN address. See Table 20

for a list of responses.

Master Relay - User’s Manual 17

Table 20: Responses for CAN ID configuration

0

1

2

3

4

5

6

7

Successfully Enabled

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

IDs do match

0x11

0x11

0x11

0x11

0x11

0x11

0x11

0x11

Frame check error

0x22

0x22

0x22

0x22

0x22

0x22

0x22

0x22

Set to ADR Mode

0x55

0x55

0x55

0x55

0x55

0x55

0x55

0x55

Successfully Disabled

0x66

0x66

0x66

0x66

0x66

0x66

0x66

0x66

3. After a successful response, the Master Relay will need to be restarted (by

removing the power) before the CAN shutdown is enabled.

18

Specifications

Connection

Battery Terminal: Copper Plated Stud M6

Output Terminal: Copper Plated Stud M6

Mating Interface Connector: 8STA6-04-06SN

Pin 1: Ground

Pin 2: Driver Switch

Pin 3: External Switch

Pin 4: PDM / ECU Output

Pin 5: CAN Low

Pin 6: CAN High

Power Supply

Operating Voltage: 8 to 30 V

Operating Current: 0.03 A (Normal)

0.02 A (Isolated)

0.001 A (Power saving)

Operating Conditions

Temperature: -20 to 100 °C

IP Rating: IP63

PDM / ECU Output

Drive Type: Configurable, (see PDM / ECU Connection)

Output Voltage: Vbattery

Max Current: 200mA (maintained)

Switched Current

Maintained Current: 200 A

Peak Current: 1000 A

Current Measurement

Sensitivity: 0.5 A (Up to 100A)

5.0 A (Over 100A)

Calibration Error: ±10% or 1 A

Range: -255 to 600 A

Temperature Measurement

Sensitivity: 0.2 °C

Calibration Error: ± 3°C

Range: 0 to 125°C

CAN Bus

Baud Rate: Configurable (Default: 1Mbps)

Transmit Addresses: Configurable (Default: 0x6E4, 0x6E5)

Termination Resistor: External required

Physical

Mass: 115 g

Other manuals for Master Relay

1

Table of contents

Other MSEL Relay manuals