English

Test bench MS1000+

4

INTRODUCTION

This manual describes how to obtain data on the technical condition of the shock absorber on

the MS1000+ test bench (hereinafter, “the bench”).

WARNING! The manufacturer is not responsible for any damage or harm to human health

resulting from non-compliance with the requirements of this manual.

The bench is designed to record the operating diagram of the shock absorber (resistance force

dependence on the position of the piston) and its working characteristics (shock absorber

resistance dependence on the speed of movement of the piston) by which it is possible to

determine:

• need to repair/replace the shock absorber;

• cause of the fault;

• quality of the repaired shock absorber;

• compliance with the performance characteristics of shock absorbers to technical

requirements.

Also, the bench allows for long-term tests of the shock absorber.

WARNING! It is forbidden to check the shock absorbers with the spring, because this can lead

to the breakdown of the bench.

The bench has the following possibilities:

• Diagnostics of all types of shock absorbers of vehicles with different types of fastenings and

resistance force up to 1000 kg.

• Diagnostics of electronically controlled shock absorbers with MS203 adapter.

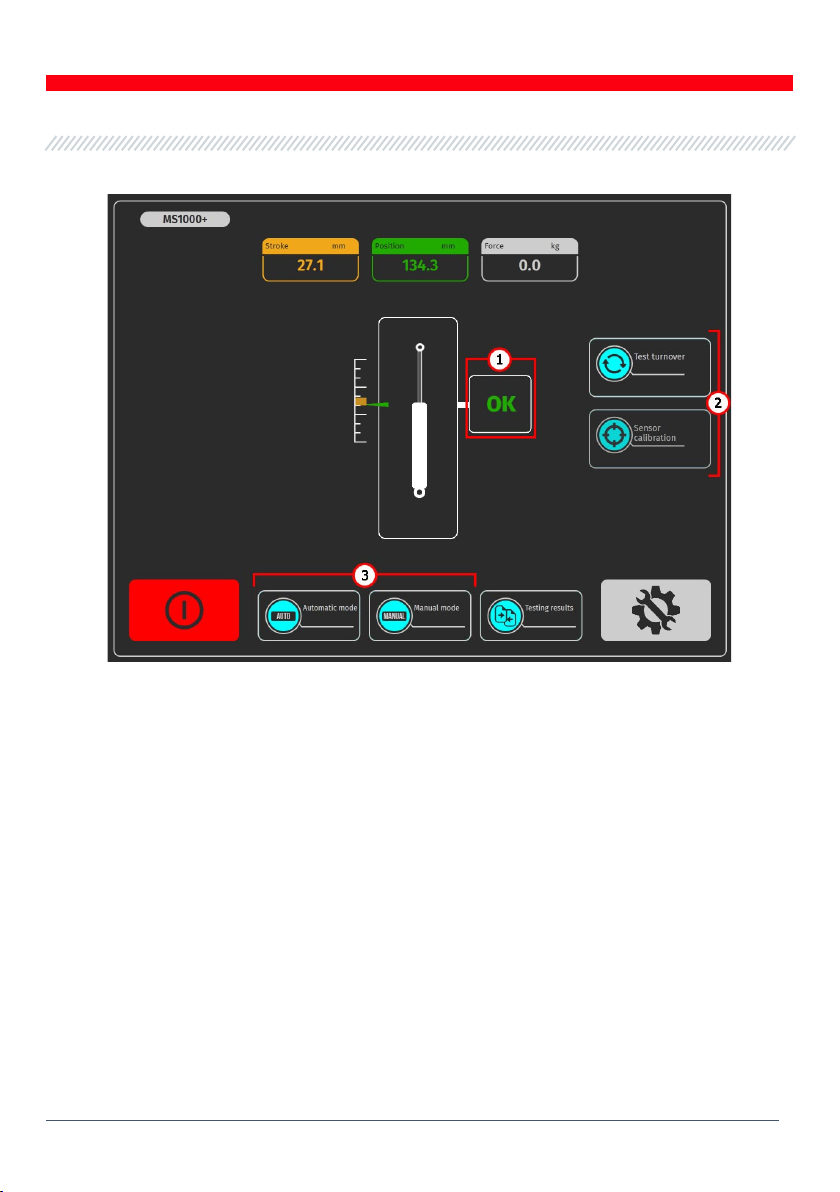

• The diagnostics of the shock absorbers on the bench can be carried out in automatic and

manual modes:

- automatic mode is designed to remove the working diagram and the operating characteristics

of the shock absorber;

- manual mode is designed for shock absorber pumping before diagnostics, shock absorber

analysis at a certain (desired) frequency and required time period, testing of electronically

controlled shock absorbers with MS203 adapter.

• Keeping the results obtained in automatic diagnostic mode and printing them.

• Comparison of diagnostic results with reference data, for example, comparison of test results

of new original shock absorber with diagnostic one.