SECTION 2 GENERAL DESCRIPTION

2.1 Pump Description

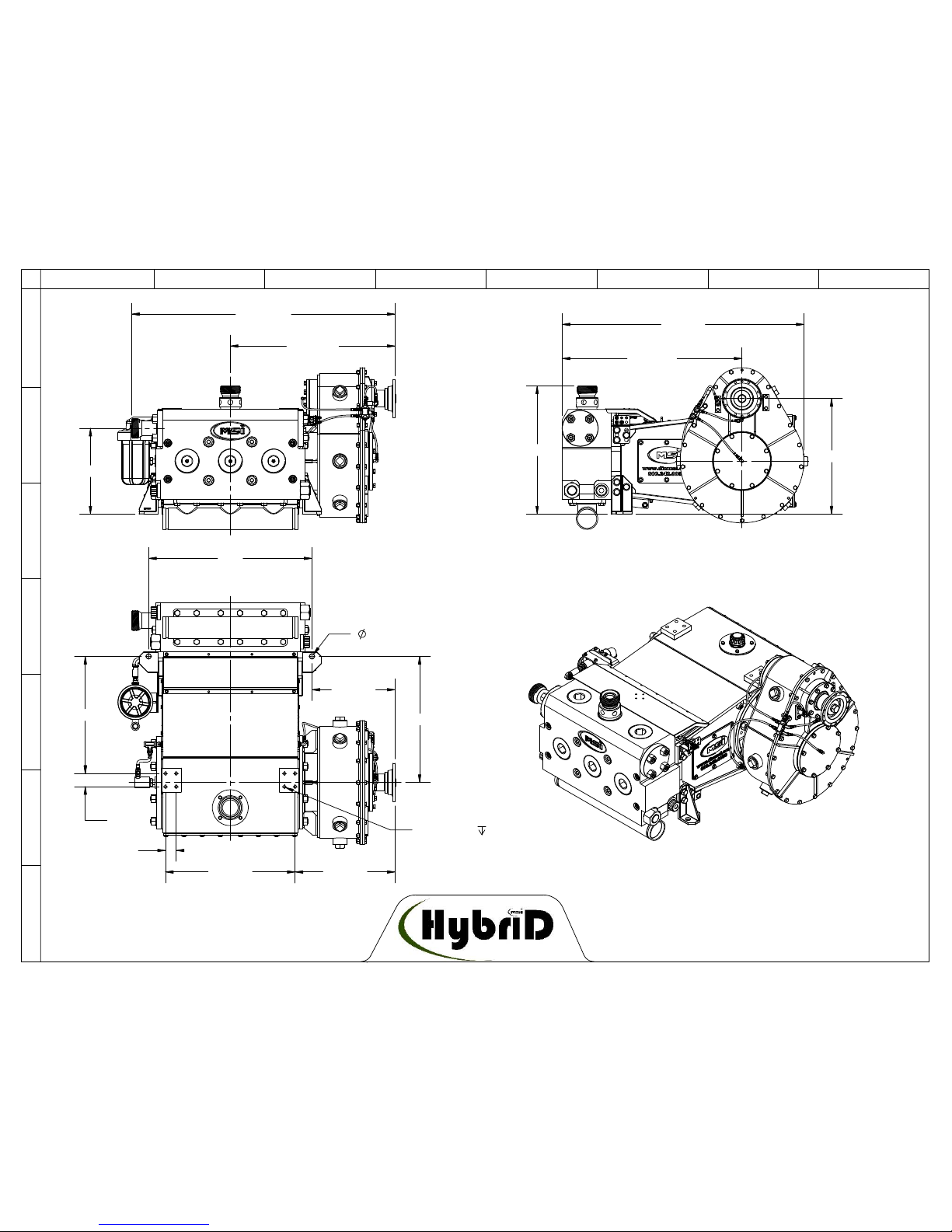

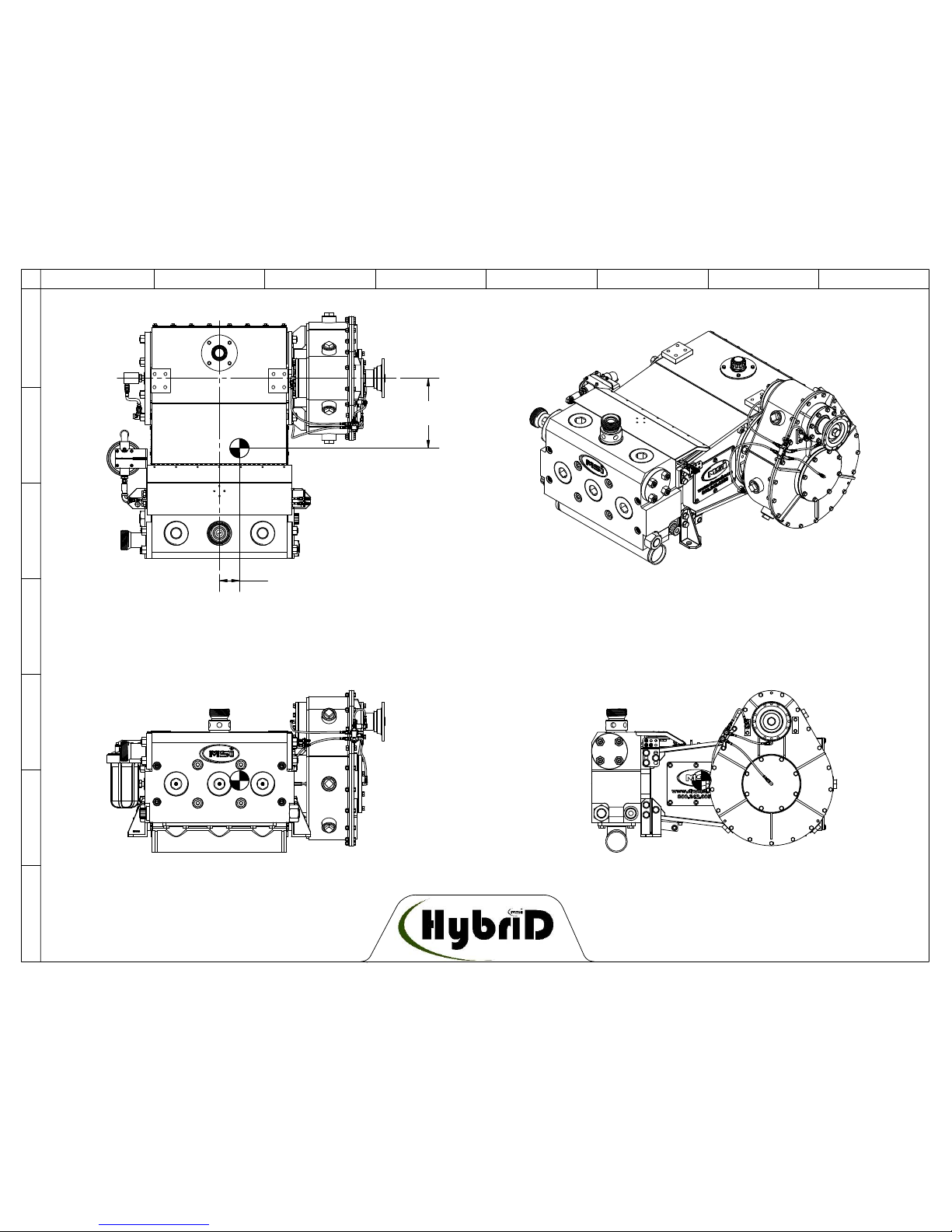

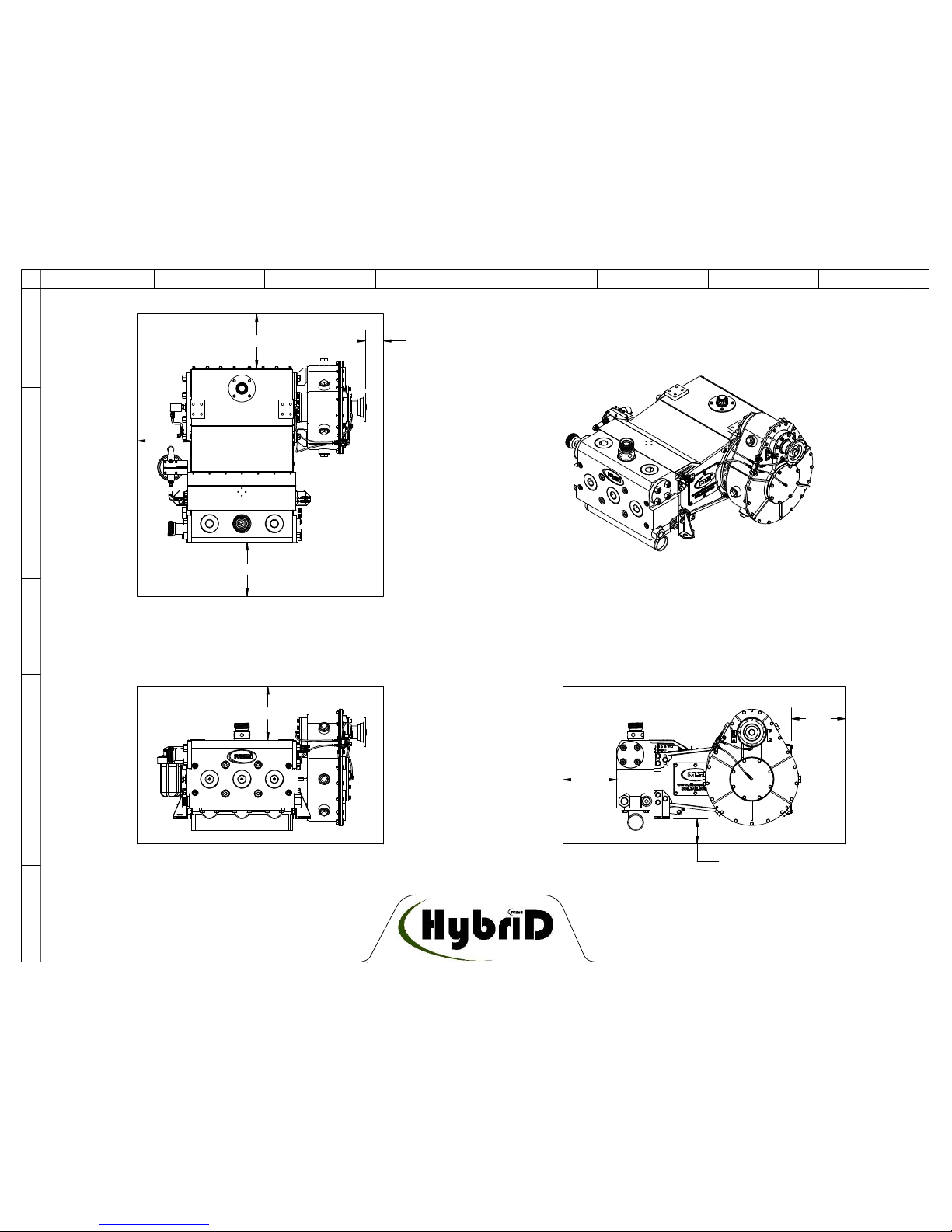

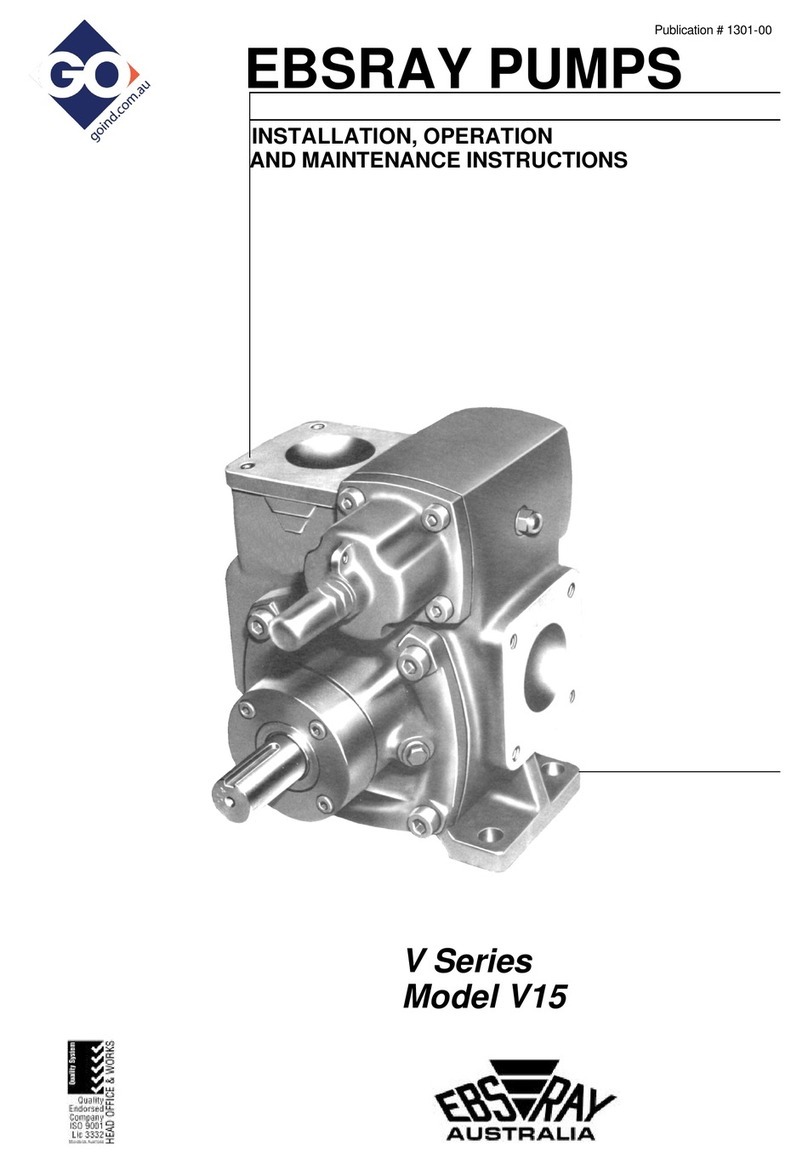

Well service pumps are used for fracturing, acidizing, cementing, well control, and circulating operations. The

MSI Hybrid™ Well Service Pump is a ‘compact’ well service pump. The pump length allows back-to-back

installation while still meeting the Department of Transportation’s (DOT) max highway load width limitation of

102". Other ‘compact’ style well service pumps also meet the DOT requirement; however, this is the first pump

which meets the DOT requirement, can be mounted back-to-back, and has separate fluid end and power end

sealing surfaces.

In other ‘compact’ well service pumps the plunger is a common sealing element for the fluid end and power

end. Approximately 2 linear inches of plunger surface crosses the seals in the fluid end and the seals in the

power end every full rotation of the pump. Over time, chemical attack and erosion from pumpage causes the

plunger surface to become relatively abrasive and continued operation in the condition will ultimately wear the

sealing edges of the packing. As a result of the worn packing, the roughened plunger surface carries pumpage

from the fluid end to the power end. In extreme cases, this ingress of contamination can destroy power end and

gear reducer bearings, lubrication pumps, and any other equipment in the lubrication circuit.

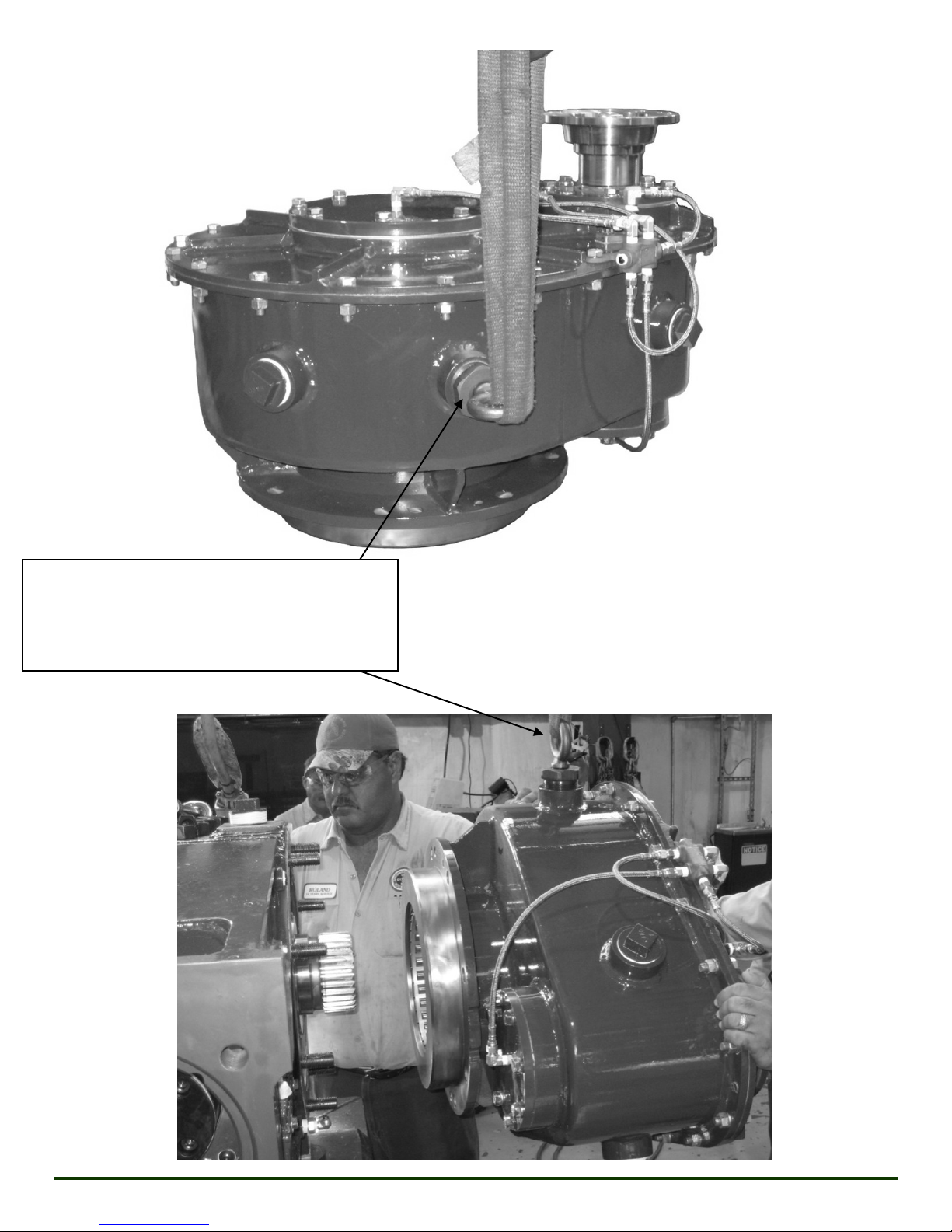

The MSI Hybrid™ Well Service Pump utilizes a power end plunger between the fluid end plunger and the

crosshead. The power end plunger cycles through the power end only, and the fluid end plunger cycles through

the fluid end only, no surface exposed to pumpage ever comes in contact with a power end seal. For all fluid

end plunger sizes the power end plunger is always larger in diameter. The manner in which this is

accomplished also improves the rigidity of the plunger stroke, thus reducing packing wear as a result of a

decrease in the slight orbiting motion of the fluid end plunger.

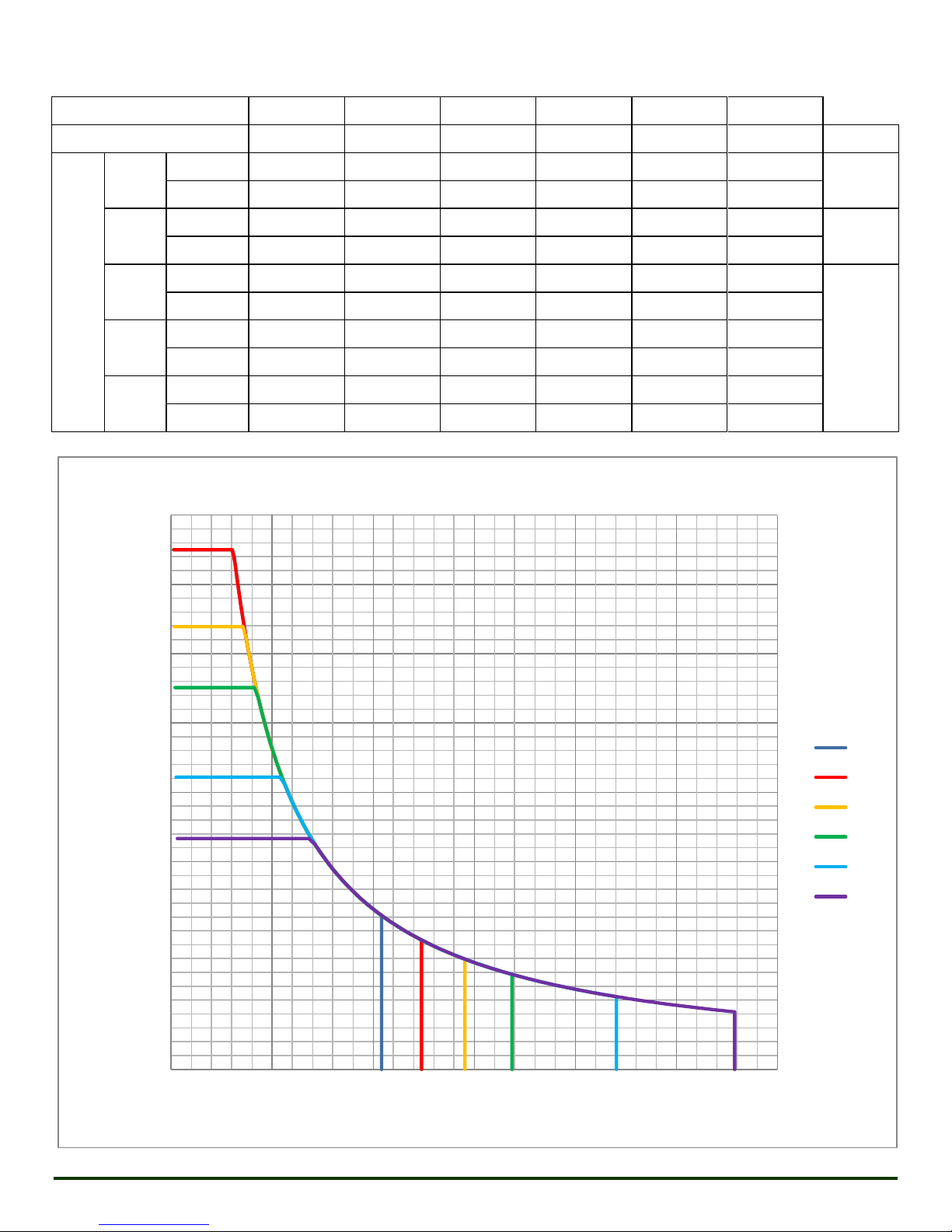

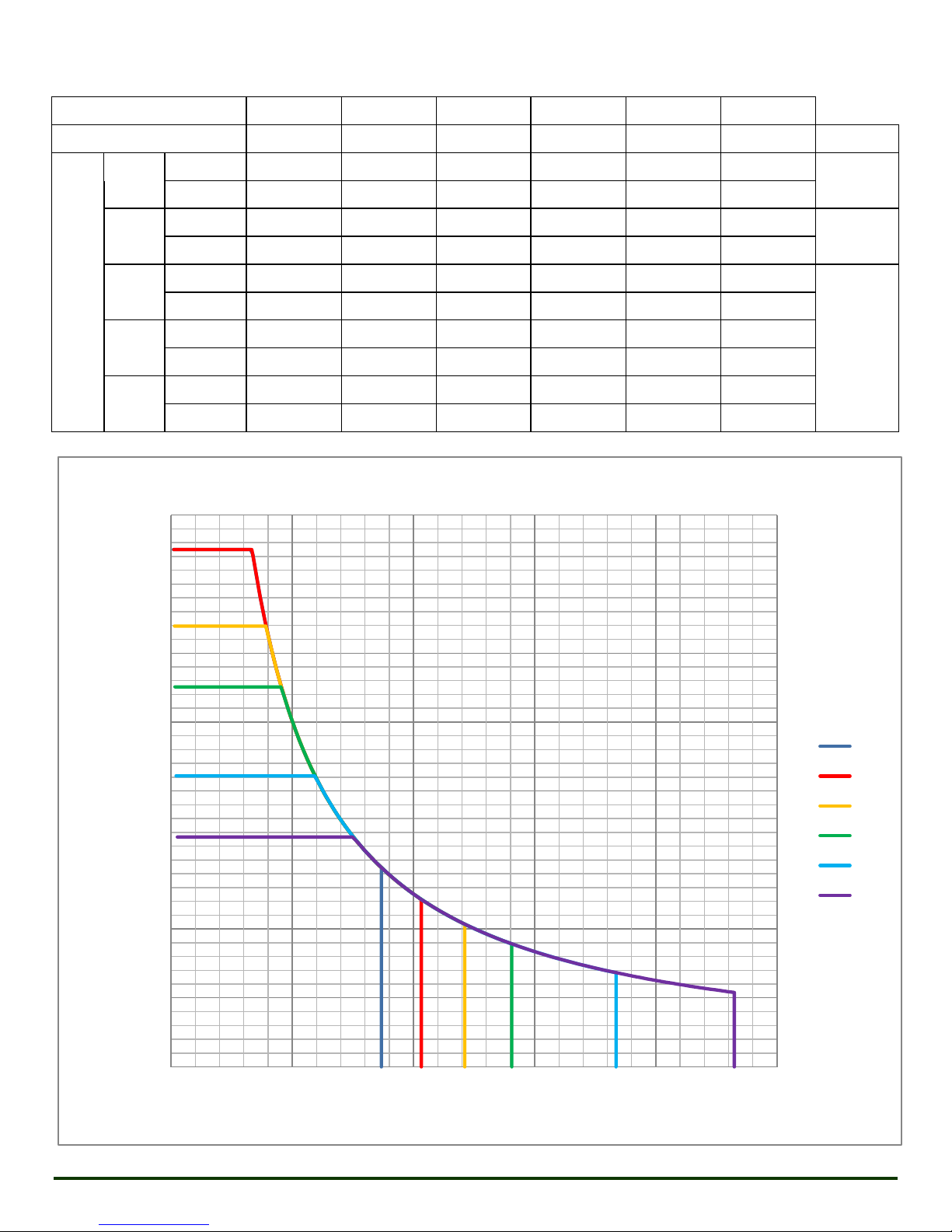

The MSI Hybrid™ Well Service Pump is rated for pumping fluids up to 15,000 PSI or at flow rates up to 929

GPM. With different materials it can handle many fluid types, including abrasive and corrosive fluids. Seals

are also available for low temperature and CO2applications.

2.2 Pump Specifications

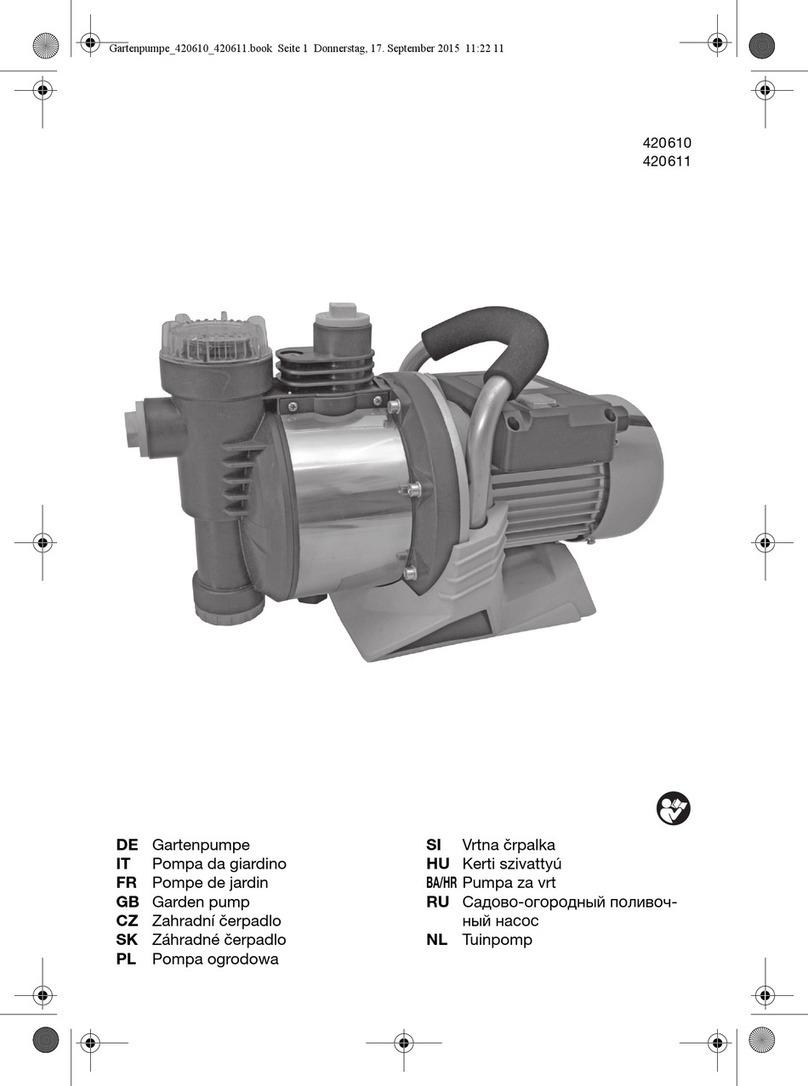

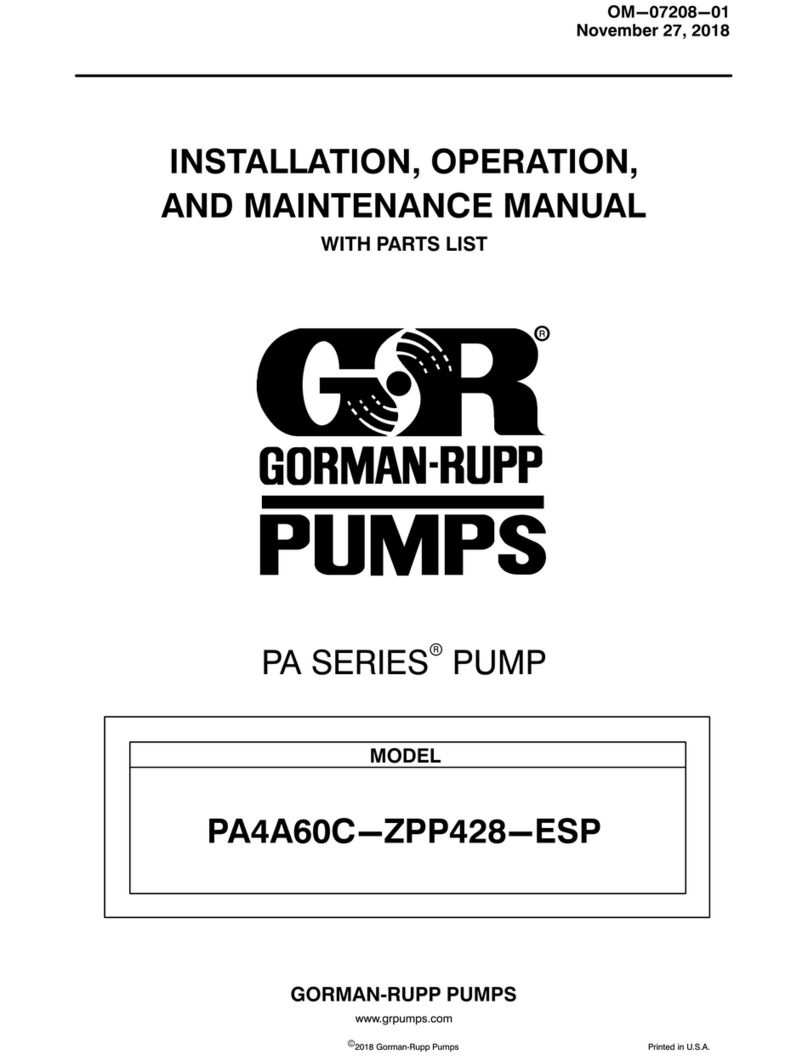

The MSI Hybrid™ Well Service Pump is a full 6" stroke, single acting reciprocating plunger pump available in

600 bhp triplex; and 1000 bhp or 1300 bhp quintuplex models. All models are rated for a 106,029 pound rod

load.

The Xtreme Service™ fluid end includes a patented system of tension bolts that reduces the stresses in the fluid

end. This reduction in stress increases the life expectancy of the fluid end thus substantially lessening costs

associated with replacing cracked fluid ends. The fluid end is machined from a one-piece, high-strength, steel

or stainless steel forging.

The MSI Hybrid™ Well Service Pump is equipped with a fluid end, power end, and a choice of gear reducers,

both with a 4.61:1 ratio. The standard gear reducer has a 13.00" center distance and a version is available with

a 16.50" center distance for driving over or under the pump. All gears are helical, precision ground and are

manufactured to AGMA #10 quality or better. The power end is a welded, high-strength steel frame that is

machined and line bored after stress relieving for accuracy.

The Hybrid™ Well Service Pump is designed to mount on a skid, a well service truck, or other rigid platform.

MSI - A Division of Dixie Iron Works, Ltd. All rights reserved.