7.4.2 Cylinder head cover – Removal and

installation 89

7.5 Injection Pump / HP Pump 90

7.5.1 Injection pump – Replacement 90

7.5.2 Injection pump – Removal and installation 91

7.6 Injection Valve / Injector 94

7.6.1 Injector – Replacement 94

7.6.2 Injector – Removal and installation 95

7.7 Fuel System 99

7.7.1 HP fuel line – Pressure pipe neck

replacement 99

7.7.2 Fuel – Draining 101

7.7.3 Fuel system – Venting 102

7.8 Fuel Filter 104

7.8.1 Fuel filter – Replacement 104

7.8.2 Fuel prefilter – Differential pressure check and

adjustment of gauge 106

7.8.3 Fuel prefilter – Draining 107

7.8.4 Fuel prefilter ‒ Flushing 108

7.8.5 Fuel prefilter – Filter element replacement 110

7.9 Charge-Air Cooling 112

7.9.1 Intercooler – Checking condensate drain line

for coolant discharge and obstruction 112

7.10 Air Filter 113

7.10.1 Air filter – Replacement 113

7.10.2 Air filter – Removal and installation 114

7.11 Air Intake 115

7.11.1 Contamination indicator – Signal ring position

check 115

7.11.2 Air-flow control flap – Ease of movement

check 116

7.12 Exhaust Flap with Actuator 117

7.12.1 Exhaust flow control flap – Ease of movement

check 117

7.13 Starting Equipment 118

7.13.1 Starter – Condition check 118

7.14 Lube Oil System, Lube Oil Circuit 119

7.14.1 Engine oil – Level check 119

7.14.2 Engine oil – Change 120

7.15 Oil Filtration / Cooling 121

7.15.1 Oil dipstick – Marking 121

7.15.2 Engine oil filter – Replacement 122

7.15.3 Centrifugal oil filter – Cleaning and filter-

sleeve replacement 124

7.16 Coolant Circuit, General, High-

Temperature Circuit 127

7.16.1 Drain and venting points 127

7.16.2 Engine coolant – Level check 132

7.16.3 Engine coolant – Change 133

7.16.4 Engine coolant – Draining 134

7.16.5 Engine coolant – Filling 135

7.16.6 HT coolant pump – Relief bore check 136

7.16.7 Engine coolant – Sample extraction and

analysis 137

7.17 Raw Water Pump with Connections 138

7.17.1 Raw water pump – Relief bore check 138

7.18 Belt Drive 139

7.18.1 Drive belt – Condition check 139

7.19 Battery-Charging Generator 140

7.19.1 Battery-charging generator drive – Drive belt

check and adjustment 140

7.19.2 Battery-charging generator drive – Drive belt

replacement 142

7.20 Engine Mounting / Support 143

7.20.1 Engine mounting – Checking condition of

resilient mounts 143

7.21 Universal Shaft 144

7.21.1 Universal shaft – Greasing 144

7.22 Wiring (General) for Engine/Gearbox/Unit 145

7.22.1 Engine wiring – Check 145

7.23 Accessories for (Electronic) Engine

Governor / Control System 146

7.23.1 Engine governor and connectors – Cleaning 146

7.23.2 Engine monitoring unit and connectors –

Cleaning 147

7.23.3 Start interlock limit switch – Check 148

7.23.4 Engine control unit plug connections – Check 149

7.23.5 Engine monitoring unit – Plug connection

check 150

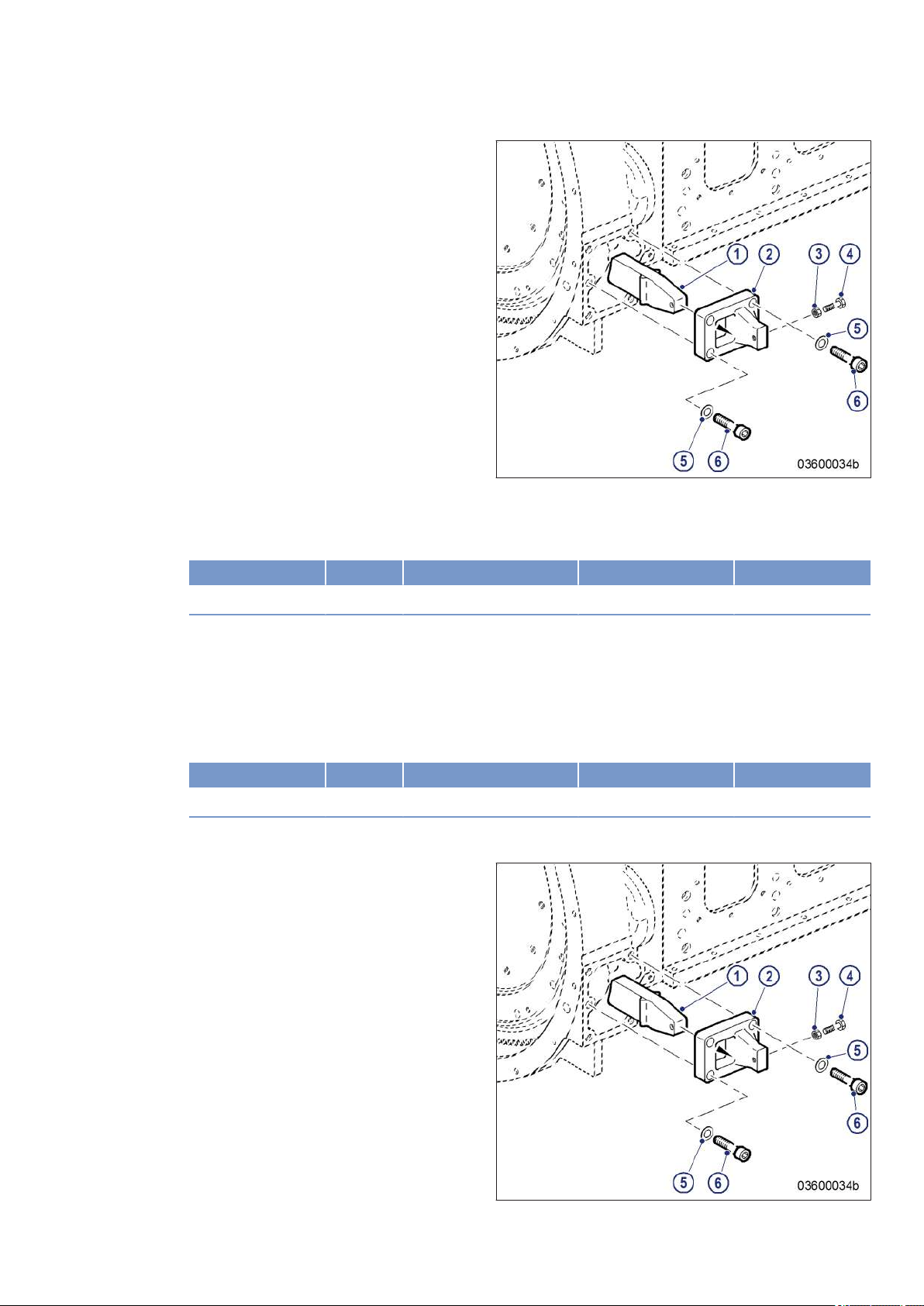

7.23.6 Engine control unit – Removal and installation 151

7.24 Emergency Instrumentation (Local

Operating Panel) 153

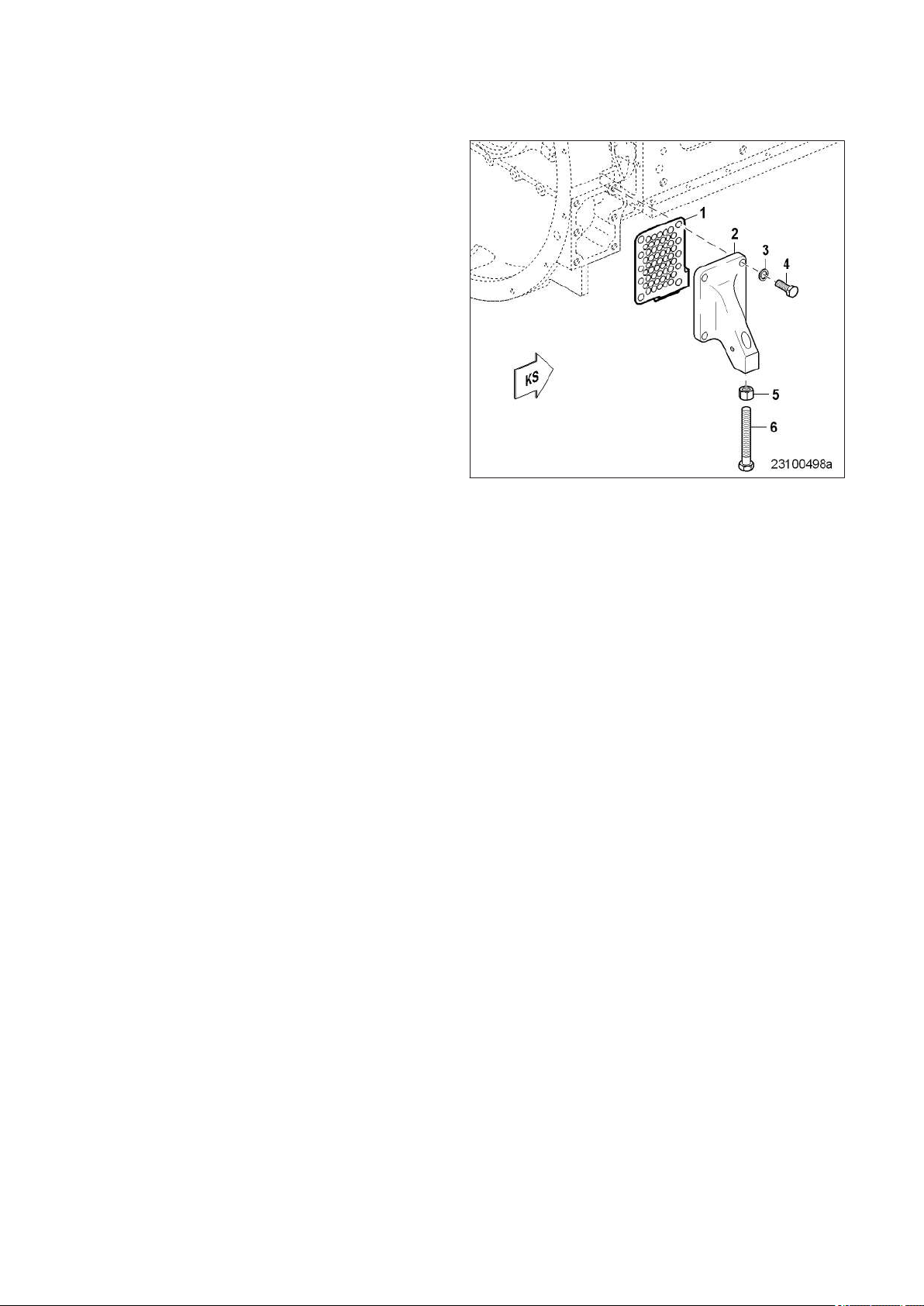

7.24.1 LOP and connectors – Cleaning 153

7.24.2 LOP – Visual inspection 154

7.24.3 LOP – Test procedures 156

8 Appendix A

8.1 Abbreviations 158

8.2 MTU contacts/service partners 161

9 Appendix B

9.1 Special Tools 162

9.2 Index 166

4 | Table of Contents | MW15407/14E 2012-02

DCL-ID: 0000015775 - 001