5

Disassembly / Reassembly Instructions

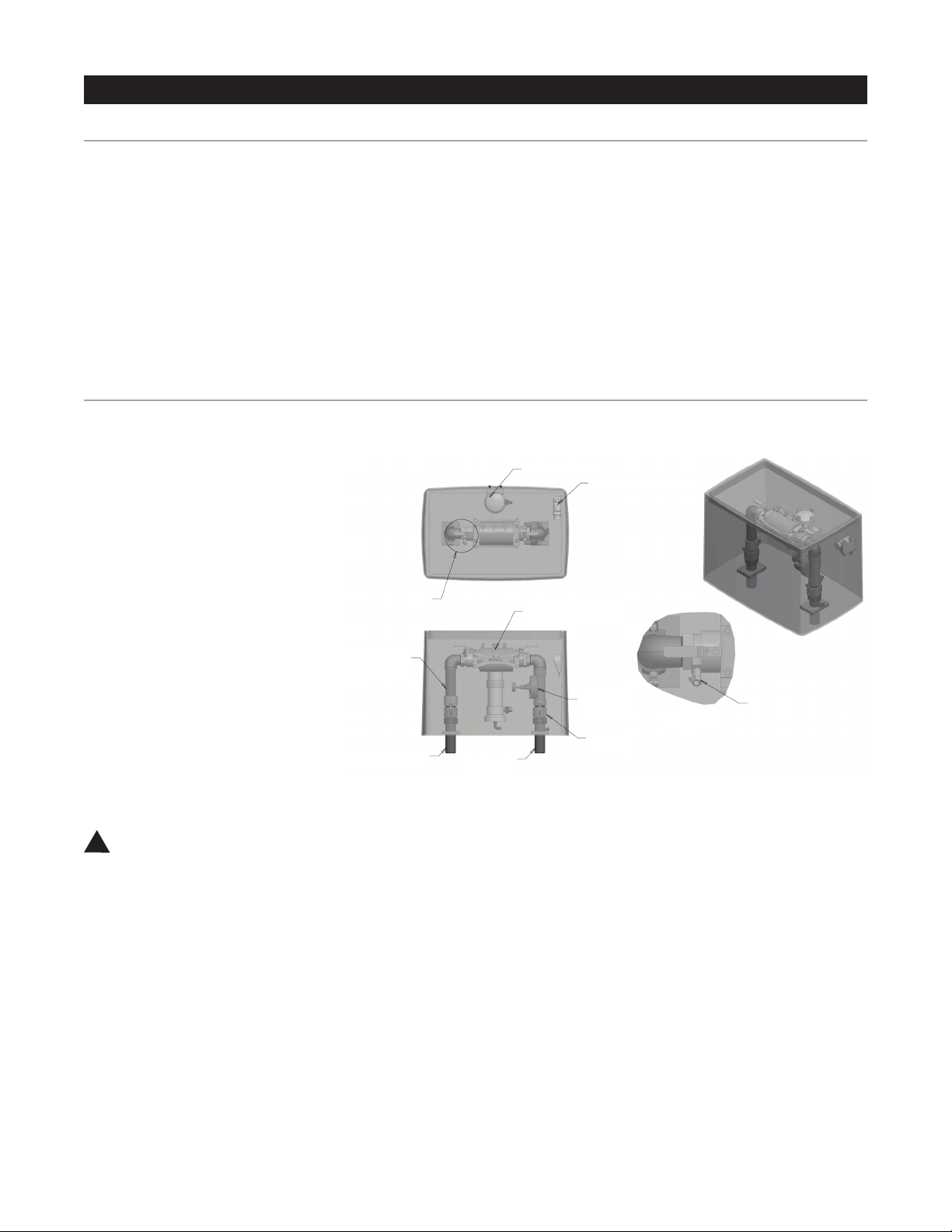

HG-8 WARM CLIMATE FLUSHING SYSTEM

TOOLS NEEDED: Philips screwdriver, at-head screwdriver, HG-20087 T-handle wrench

HG-8 DISASSEMBLY AND REASSEMBLY INSTRUCTIONS

4. To prevent the loss of the

solenoid plunger and spring, place

an object or have a finger over

the plunger of the solenoid. Allow

the plunger enough space to kick

out of the solenoid body into the

object or finger hovering over it.

5. If test is successful, return

the flush / meter assembly to its

operating position below grade.

6. Return insulation pad and cast

iron meter lid to their

proper positions.

If everything checks out, the

electrical system is in

working order.

Valve Disassembly and Check

1. Remove six (6) bolts from

top cover.

2. Slowly pull cover off the valve.

3. Remove rubber diaphragm and

inspect for holes or worn areas.

4. Be certain to avoid contacting

the EPDM rubber diaphragm with

pipe putty. Pipe putty can cause

the rubber to thin out and leak.

5. Remove the valve screen plug

on the lower half of the valve body.

Be careful not to exert too much

force when pulling plug out.

6. Check for debris in the valve

screen on the inlet side with the

lower half of the valve body by

removing the valve screen plug.

7. Return valve plug to its

proper location when debris screen

is cleared.

8. Replace the top cover back onto

the diaphragm – make sure to line

up the openings in both.

9. Match up the top cover of the

valve with the bottom portion.

The arrows have to align on both

portions.

10. Replace the bolts and

tighten down.

Although the Hydro-Guard HG-8

Warm Climate Sub-Surface

Unit was delivered completely

assembled, it may be necessary

and/or desirable to disassemble

portions of the Unit, or the Unit

in its entirety, in order to allow for

required service and maintenance.

If disassembly is necessary,

please follow the directions below.

Always close the curb stop before

working on the unit.

Disassembly

1. Shut off water supply to

the unit and remove the green

housing cover.

2. Remove the composite lid

of HG-8 protective ground

sleeve vault.

3. Backup to stress point then

push down on the camlock

release handles to disengage

the camlocks prior to lifting the

flushing components out of

the device.

4. Raise and remove the flushing

system assembly out of the

meter box.

5. Modular design of valve and

double check valve allow for

service to be completed without

removal of the devices’ bodies

from the piping assembly.

Electrical System Check

1. Pull internals of HG-8 out of

in-ground protective vault.

2. Unscrew solenoid from valve –

be careful to not drop the

solenoid plunger and spring into

in-ground housing.

3. Using the Bluetooth Controller,

run a 2 minute manual flush

seequence.

NOTE: Plunger inside solenoid

should be down when running and

up when off.

WARNING: Avoid overuse of

pipe sealant and never allow

sealant to come into contact with

EPDM rubber diaphram.

Reassembly

1. If any disassembly has been

conducted of the control valve and/

or double check valve, verify that all

bolts are properly tightened. Check

assemblies for leakage prior to

lowering flushing / metering assembly

back into position below grade.

2. Using lifting holes and/or lifting

strap on steel plate, lower flushing

assembly below grade by slowly

lowering the steel frame to the lower

part of the in-ground protective

housing (DO NOT apply excessive

force to assembly). Use Guide in

meter box to allign internols.

3. Once lowered back into the

pretective vault, lock the internals

in place by pulling up on camlock

handles.

4. Turn water supply to the unit

on. Using the controller, run a two

minute manual flushing procedure

to confirm all components

are operational.

5. Return insulation pad and lid to

their proper location.

!