Table of Contents

1SAFETY PRECAUTIONS...............................................................................................................................................................3

2SPECIFICATIONS..........................................................................................................................................................................4

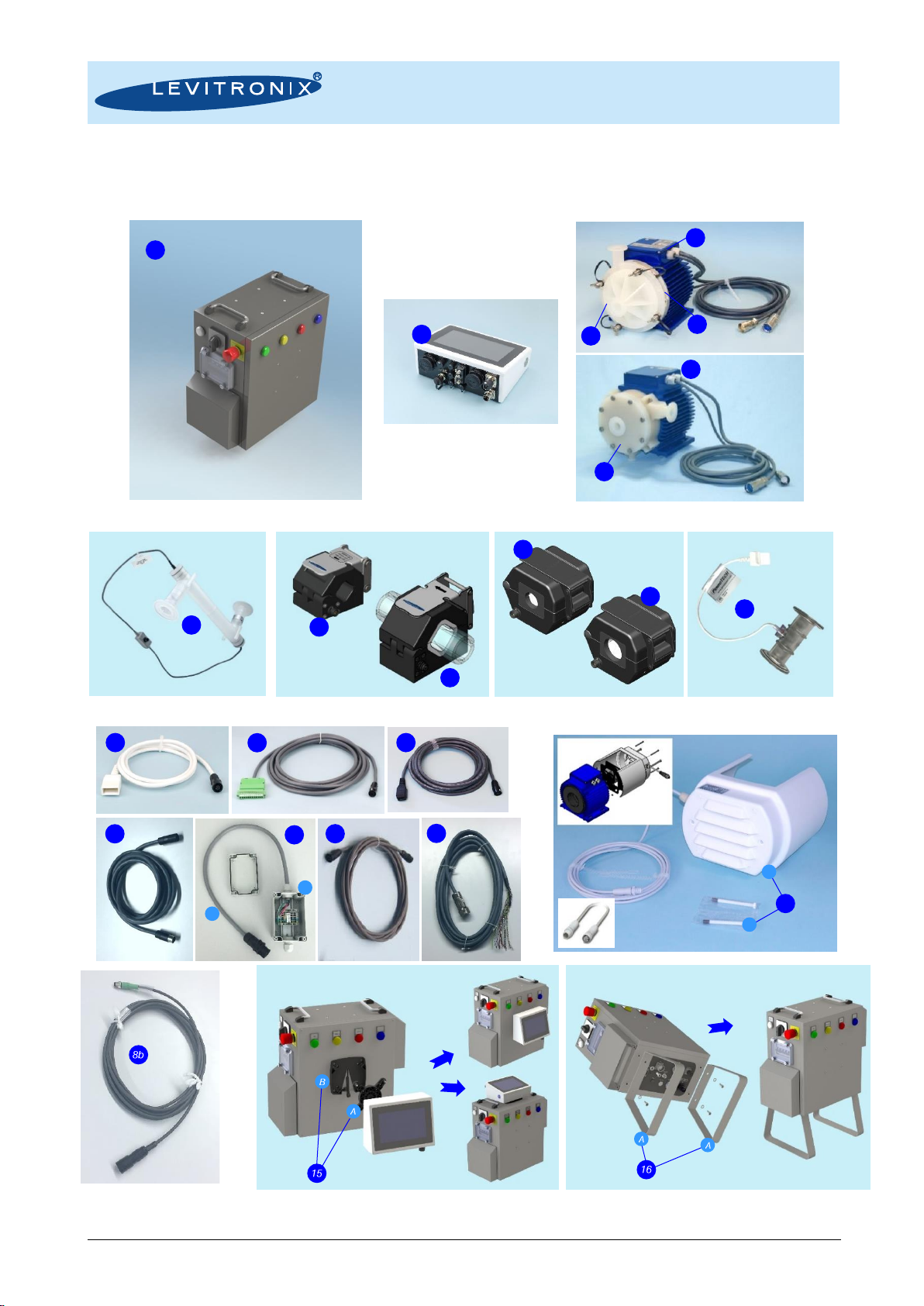

2.1 Specification of Console Components...................................................................................................................................4

2.2 System Overview and General Specification.........................................................................................................................6

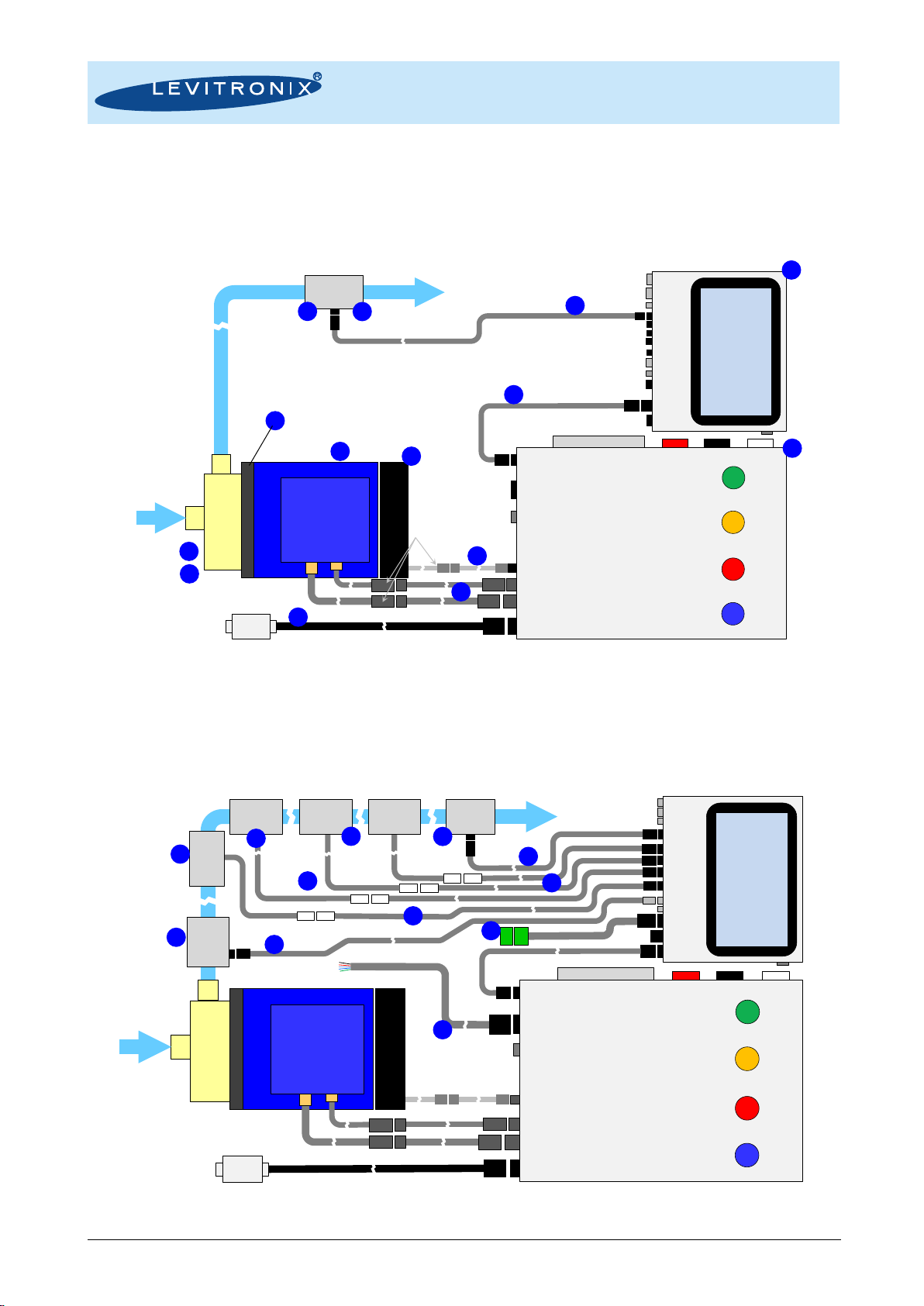

2.2.1 Basic Stand-Alone System Configuration with LCO-i100 .................................................................................................................................6

2.2.2 Extended System Configuration with LCO-i100................................................................................................................................................6

2.3 General Environmental Conditions........................................................................................................................................7

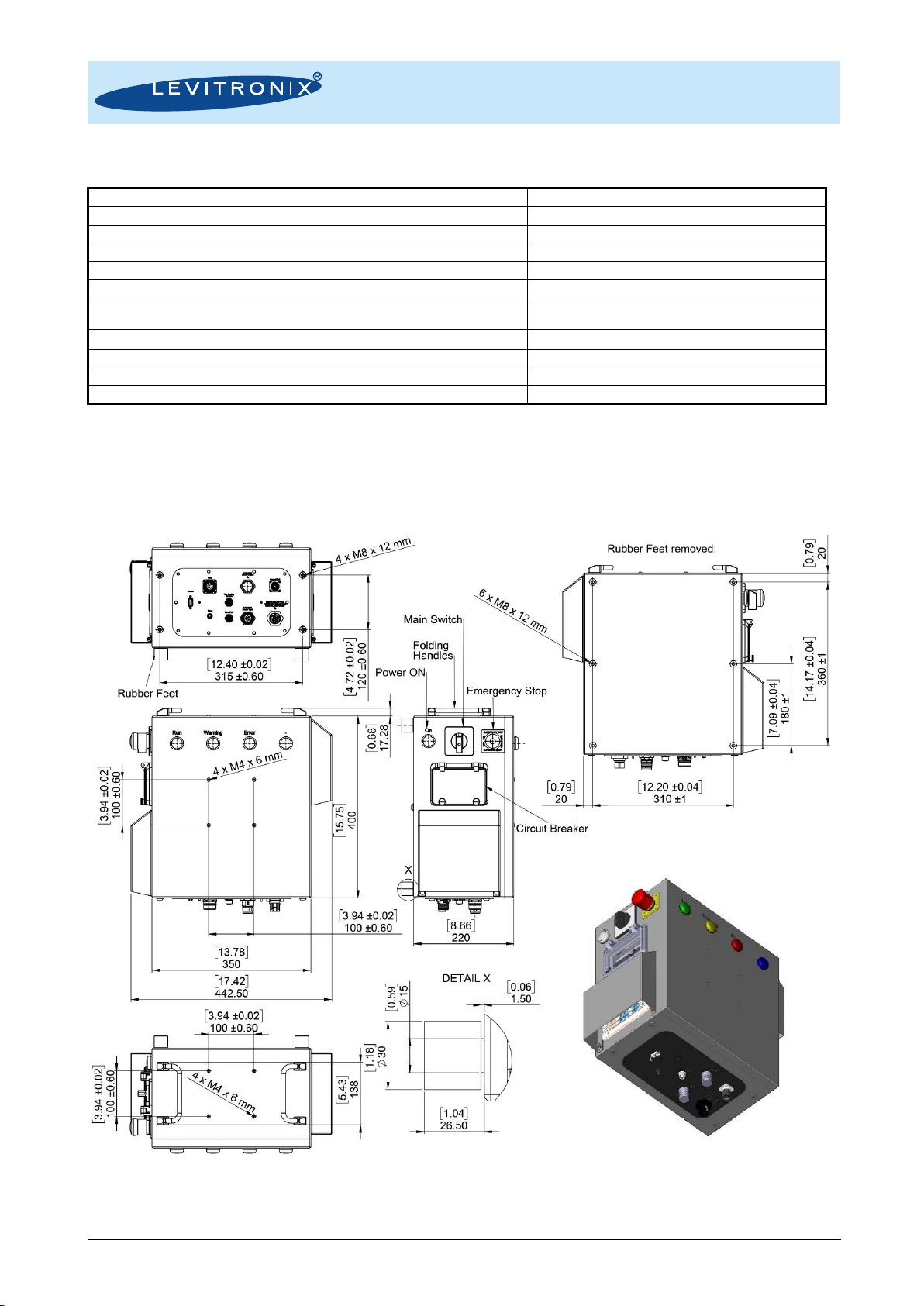

2.4 Basic Dimensions of Consoles..............................................................................................................................................7

3ENGINEERING INFORMATION.....................................................................................................................................................9

3.1 IP Rating...............................................................................................................................................................................9

3.2 Temperature Monitoring........................................................................................................................................................9

4INSTALLATION ...........................................................................................................................................................................10

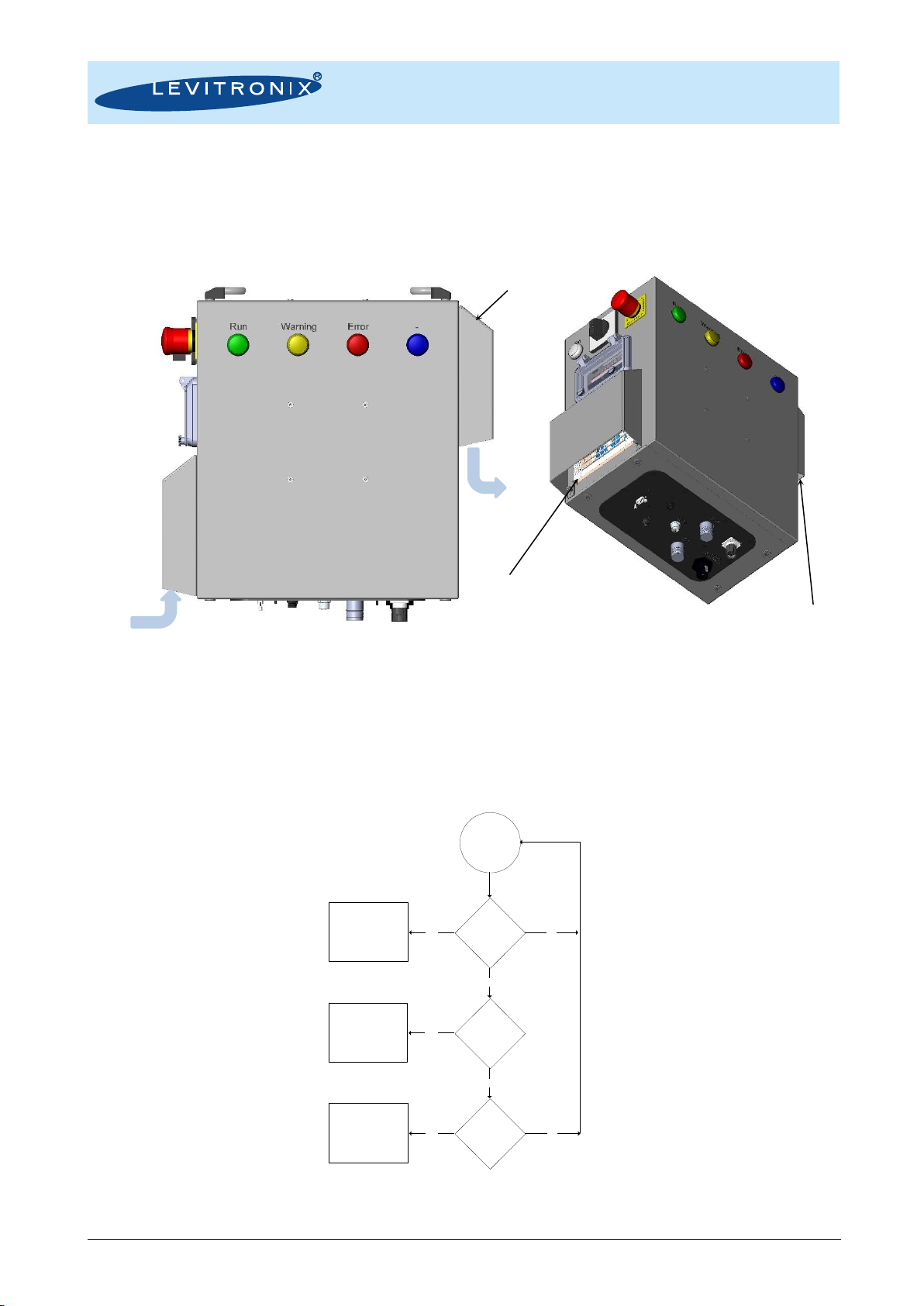

4.1 Mechanical Installation of LCO-2000...................................................................................................................................10

4.1.1 Mounting Positions...........................................................................................................................................................................................10

4.2 Mechanical Installation of LCO-i100....................................................................................................................................10

4.3 Electrical Installation of LCO-2000 ......................................................................................................................................11

4.3.1 Connection Overview.......................................................................................................................................................................................11

4.3.2 General Installation Instructions ......................................................................................................................................................................12

4.3.3 Installation of Motor Connectors to Console ...................................................................................................................................................14

4.3.4 RS232 Interface...............................................................................................................................................................................................14

4.3.5 PLC Interface...................................................................................................................................................................................................15

4.2 Electrical Installation of LCO-i100 .......................................................................................................................................16

4.2.1 Overview and Reference .................................................................................................................................................................................16

5OPERATION................................................................................................................................................................................17

5.1 Basic System Operation......................................................................................................................................................17

5.1.1 Start-Up............................................................................................................................................................................................................17

5.1.2 Power Down.....................................................................................................................................................................................................17

5.1.3 Auto-Resume Feature LCO-i100.....................................................................................................................................................................18

5.1.4 Software Update ..............................................................................................................................................................................................18

6MAINTENANCE...........................................................................................................................................................................19

6.1 Cleaning..............................................................................................................................................................................19

7TROUBLESHOOTING .................................................................................................................................................................19

8TECHNICAL SUPPORT...............................................................................................................................................................19

9APPENDIX...................................................................................................................................................................................20

9.1 Regulatory Status ...............................................................................................................................................................20

9.1.1 CE Marking ......................................................................................................................................................................................................20

9.1.2 IECEE CB Safety Certification.........................................................................................................................................................................20

9.1.3 NRTL/ETL Safety Certification and Marking ...................................................................................................................................................20

9.1.4 Disposal of Equipment –WEEE Directive 2012/19/EU...................................................................................................................................20

9.2 Symbols and Signal Words.................................................................................................................................................21