AFL Hyperscale SWR 1200 ODF User manual

SpiderWeb Ribbon®Optical Distribution Frame

SWR®1200 ODF

Installation Guide

2© AFL Hyperscale. All rights reserved

Safety Precautions

Laser Precautions

Warning: The laser light used to transmit information over optical ber cables can cause severe eye

damage. Because this light is invisible, it will not cause the iris of the eye to contract involuntarily as when

viewing a bright visible light, and no pain is felt as the retina is burned.

Never look into the end of a ber or connector which may have a laser coupled to it. Should accidental

eye exposure to laser light be suspected, arrange for an eye examination immediately.

General Precautions

Personnel must be thoroughly familiarized with all applicable Occupational Health and Safety (OH&S)

regulations, local regulations, and your company safety practices and policies.

Warning: To reduce the chance of accidental injury:

Before work begins, all personnel must be thoroughly familiar with the operation of all equipment

and procedures to be used during the installation.

Before use, all equipment, especially safety gear, must be inspected and tested for proper operation.

Replace and repair as necessary.

SWR®ODF 1200 Installation Guide

Before installing or adjusting this product, please read these instructions carefully.

Please keep this guide for future reference.

3

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

Contents

Component Overview

ODF Components

Moving the ODF

The ODF System Layout

Recommended Installation Methods

Feeding of Cable

Feeding of Ribbon Fiber Cable

Installing the U-Series Solution

Cassette Tail Routing

Patchcord Routing

04

10

21

06

11

13

08

17

09

20

4© AFL Hyperscale. All rights reserved

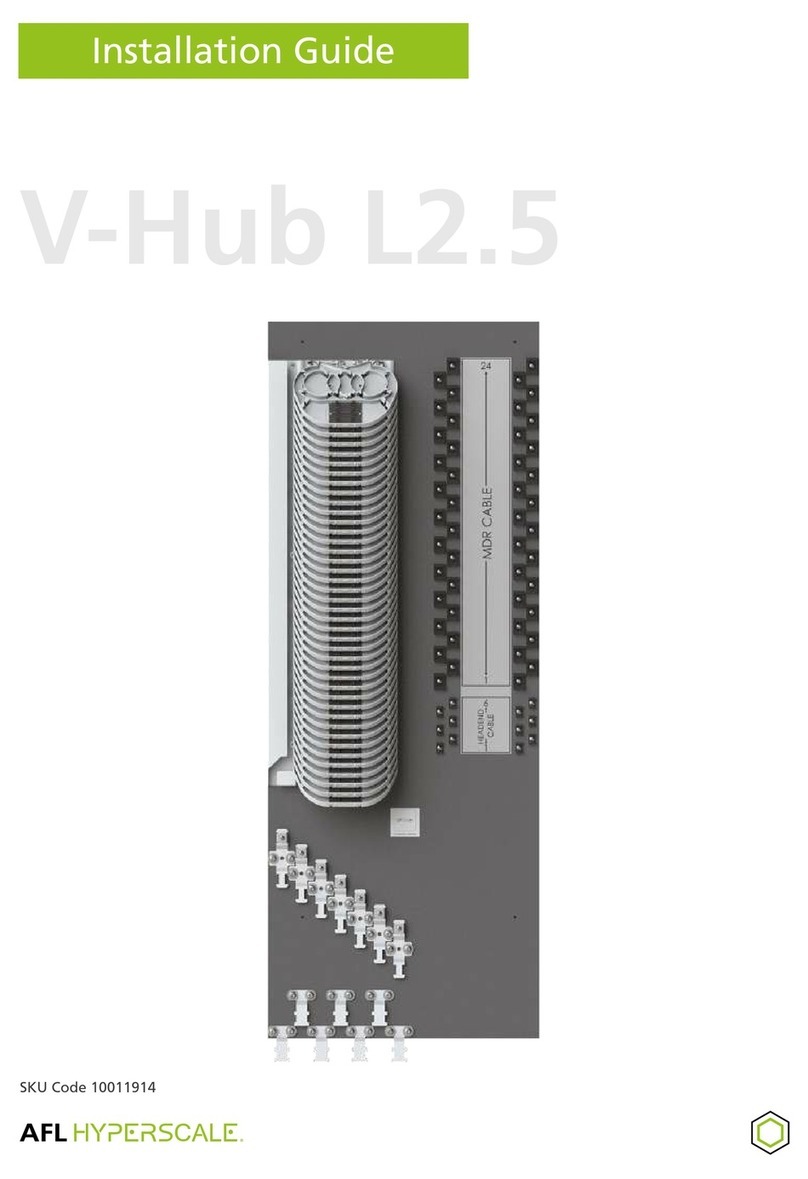

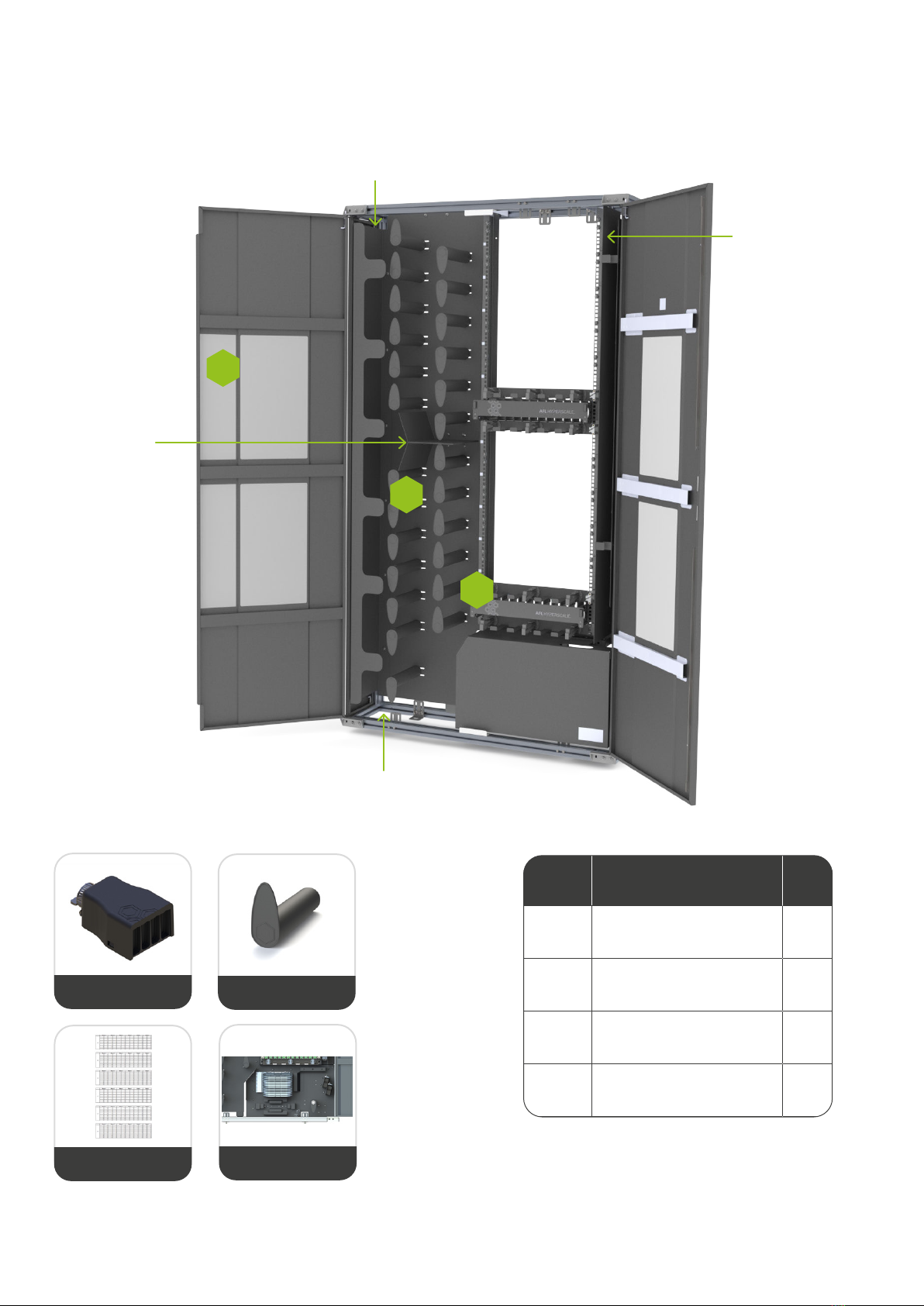

Component Overview

Internal

Distribution

Area

External

Distribution

Area

Core Kit

Area

A

BC

D

Item Item Qty

A Front access Frame 1

BU-Series 1RU front Access Fiber

Management 4

C U-Series 2RU Housing 2

DU-Series Front Access Cassette

(Not Supplied with frame) 0

(A) Front access Frame

(C) U-Series 2RU Housing (D) U-Series Front

Access Cassette

(B) U-Series 1RU front

Access Fiber Management

5

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

Internal

Distribution

Area

Exit Cable Point

Anchor Points

Patch cord

Separator

Top feed frame

and inbound

route divider

External

Distribution

Area

Core Kit

Area

H

F

G

Item Item Qty

E SWR Snap Fit Transition Box 2

F Spool 27

G Door Labeling 2

H Lockable splice area (Top Fed) 1

(G) Door Labeling

(E) SWR Snap Fit

Transition Box

(G) Lockable Splice Area

(Top Fed)

(F) Spools

Component Overview

6© AFL Hyperscale. All rights reserved

1. Entry Cable Point

2. 144 Fiber Ribbon Splice Tray

3. Slack Basket

4. SWR Snap Fit Transition Box Kit

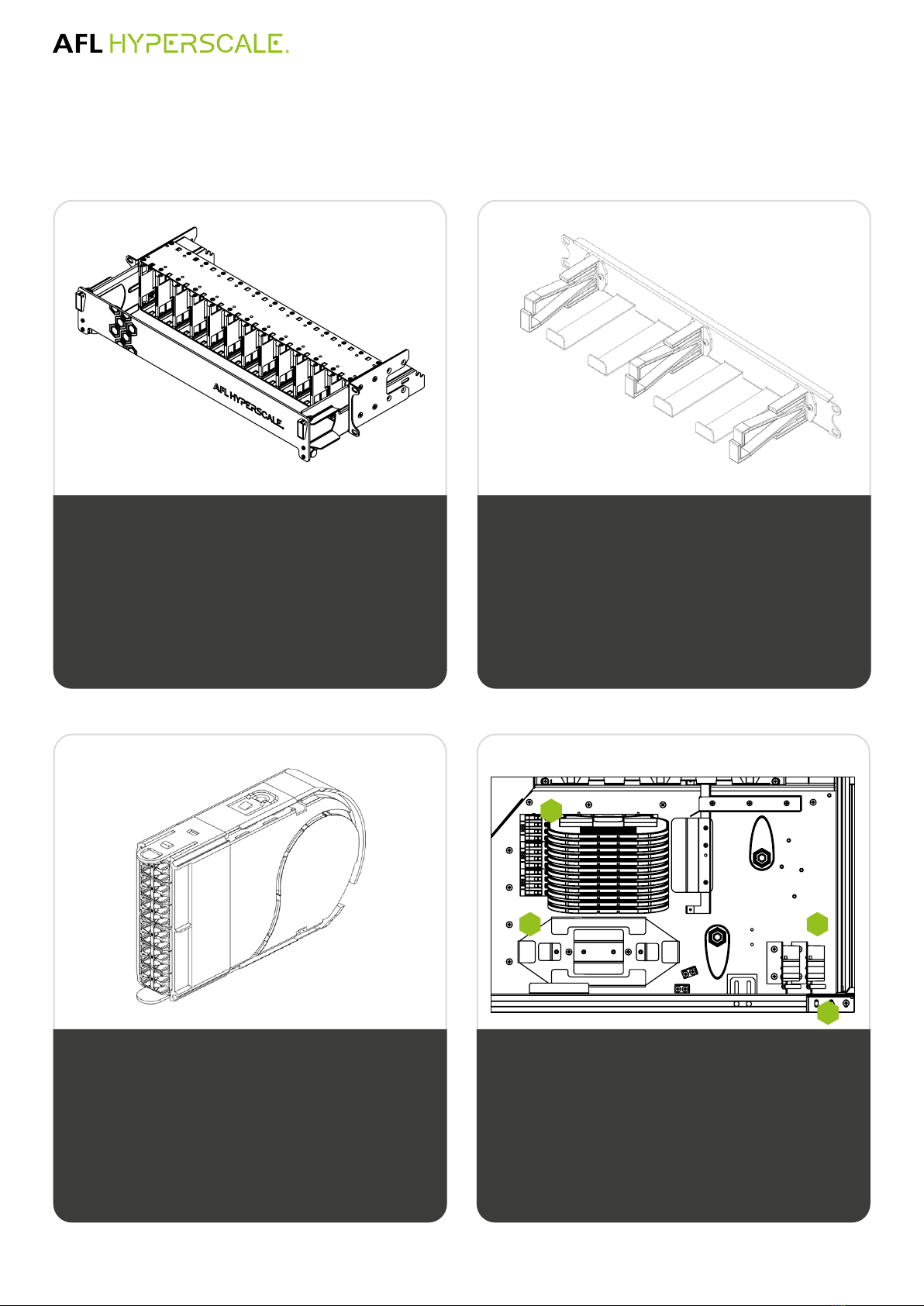

ODF Components

2

34

1

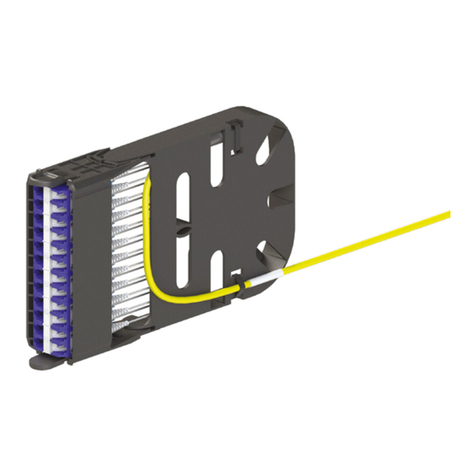

Front door: Front removable hinged door. Labelling

position on reverse for clear port identication and label

card included

Front and rear installation: Cassettes can be securely

installed and xed inside the chassis by an easy-access

latching mechanism. Each module can be installed from

the front or rear.

Cassette Slot: Up to 12 cassette in 2RU - 288 LC ports.

Front Management: Large cable management rings for

Outgoing Patch cord 2.0mm Cable.

Top/ Bottom Cable: Top and Bottom cable management

ring for Incoming 3.0mm cable.

Cable Support: Cable support for Outgoing Patch cord

2.0mm Cable.

U-Series 2RU Housing U-Series 1RU Fiber Management

Lockable Splice Area

Simplied Cassette Access

Convenient locking push latch for front and rear access.

Shuttered LC Quad Adapter

Shutter adapter for improved cleanliness and laser safety.

Cassette Tail: 24F 3.0mm cassette tail.

U-Series 24F

Tailed cassette

7

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

ODF Components

SWR Snap Fit Transition Box Kit

1. Transition Lid

2. Transition Base

3. Cable Fixing Point

4. 12 x 0.7 Meter 10MM OD Corrugate Tubing

5. Label Set

8© AFL Hyperscale. All rights reserved

Packaging/Handling of the ODF

The frame is packaged on a pallet vertically layout. Proceed to safely transport the unit to location using a forklift

or heavy lifting equipment.

1

Once in the desired position, continue by removing the packaging from the Frame, and release the bottom

anchor to free the unit. Proceed to remove the front and side doors of the frame by detaching the top and

bottom hinges on the door. Once done, lift the frame from its packaging close to the nal location.

2

CAUTION

CAUTION: The ODF

weighs approx.

112kg. Manual

handling training

and appropriate

equipment is required

for installation.

Side View ISO View Front View

9

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

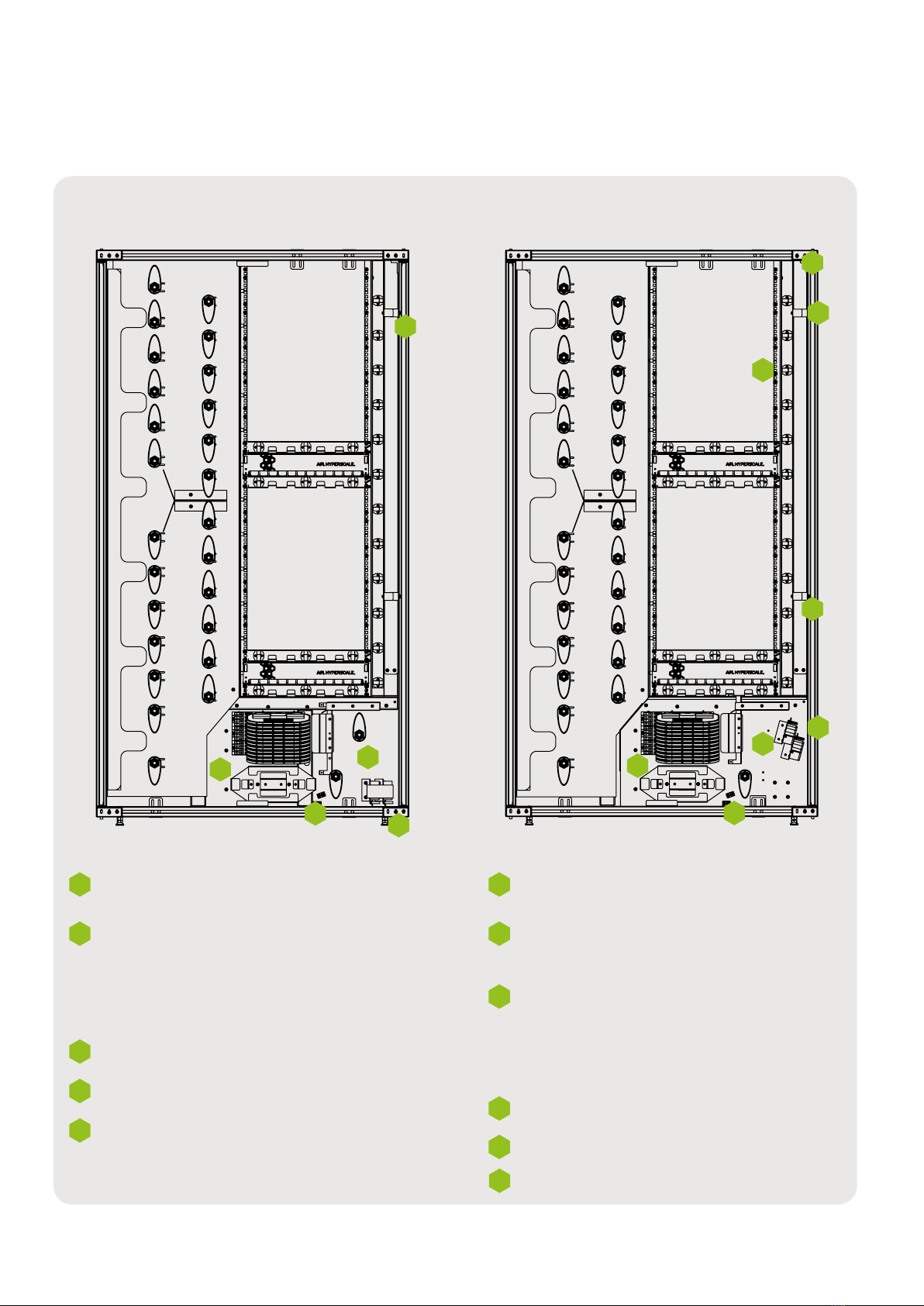

The ODF System Layout

WALL MOUNTED SIDE BY SIDE

BACK TO BACK END OF AISLE

600mm 1200mm

600mm

600mm

300mm

2400mm

600mm

600mm

300mm

1200mm

600mm

600mm

600mm

600mm

300mm 1200mm

10 © AFL Hyperscale. All rights reserved

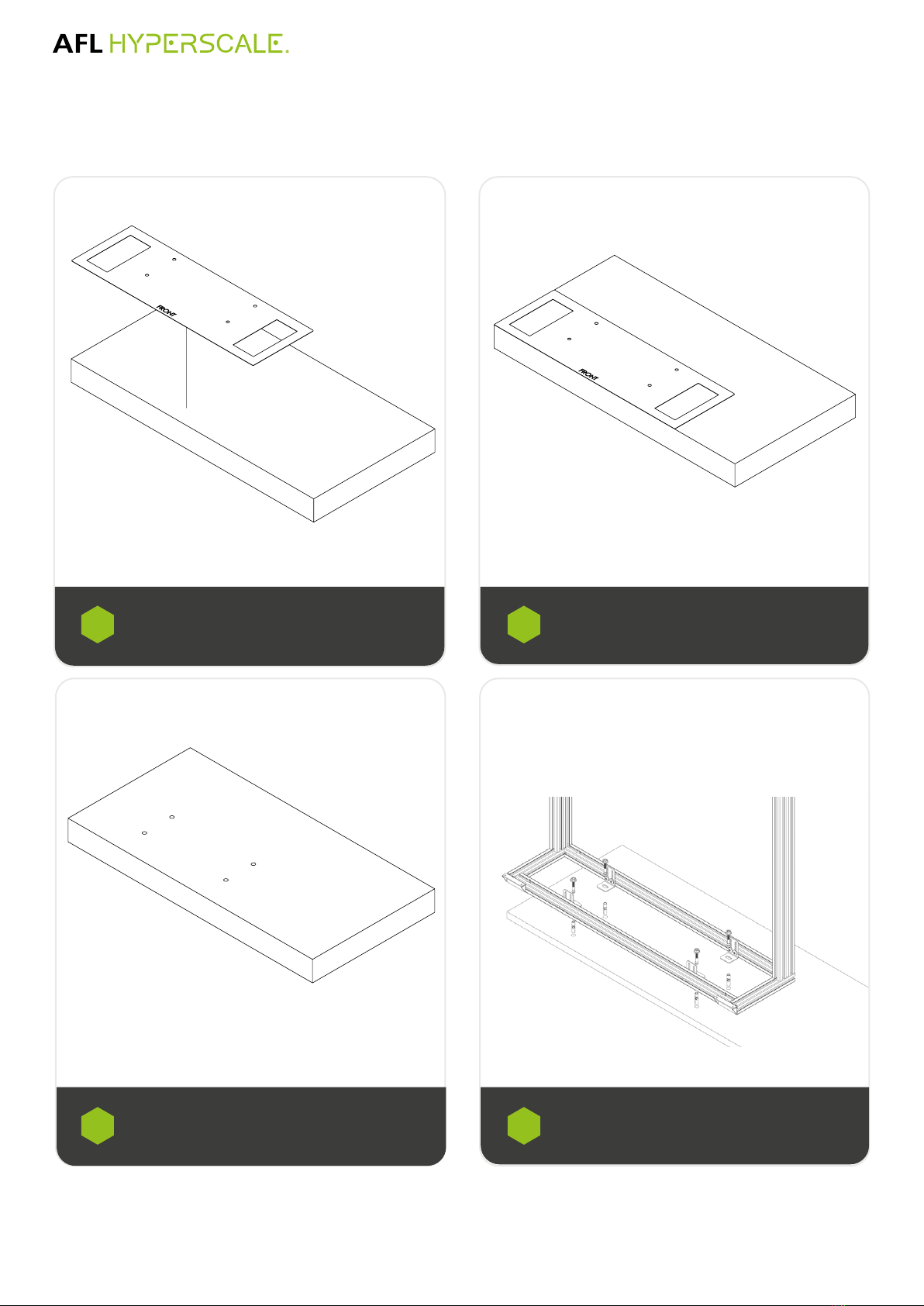

Recommended Installation Methods

Direct to Concrete Floor

Place the supplied template on the oor Mark out the holes

Drill the holes

Place the frame into position and remove the cover

for the splice area to gain access to the anchor points.

Once done, proceed to press in and tighten the M10

anchor bolt throught the base of the frame

1 2

3 4

11

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

Feeding of Cable

Bottom Feeding Cable Top Feeding Cable

Cable entry point at the bottom of the frame.

1

2

3

Support bracket for the cable SWR Snap

Fit transition box is placed at the lower

mounting position to support bottom

cable feeding. Note: The frame provides

two brackets for a total of four transition

positions.

Corrugate tie-point.

1

2

3

Cable entry point at the top of the frame

through dedicated cable through.

1

2

3

Dedicated through for outbound cable

from the cassette solution to the splice

area.

Support bracket for the cable and SWR

Snap Fit transition box is placed at the

top mounting position to support top

cable feeding. Note: The frame provides

two brackets for a total of four transition

positions.

4

1

2

3

4

1

6

5

6

5

4

4

Fiber slack loop.

5

Cable guard.

Corrugate tie-point.

5

Fiber slack loop.

6

Cable guard.

12 © AFL Hyperscale. All rights reserved

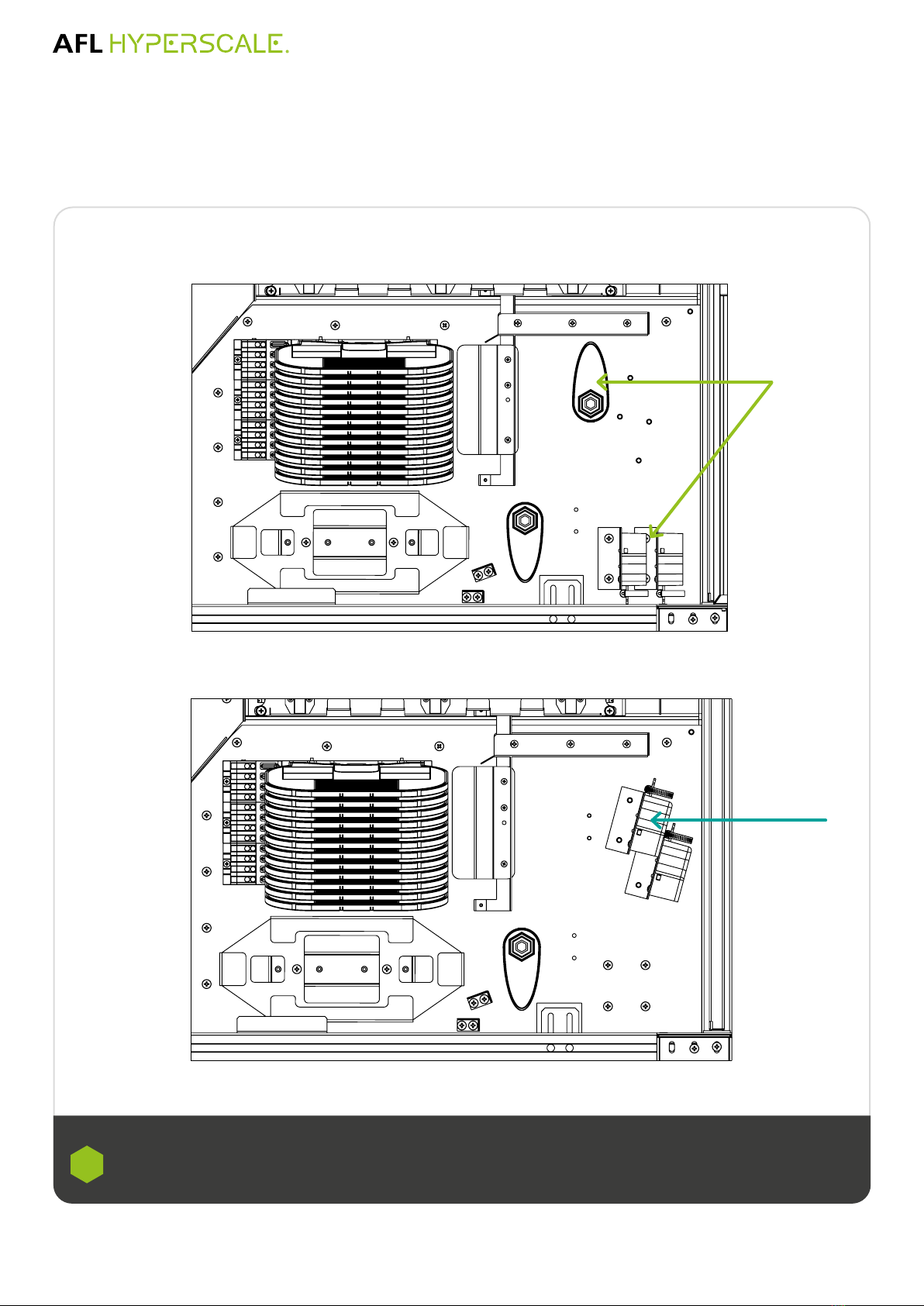

The frame is supplied by default with a bottom feed conguration. To change the conguration to a Top

feeding, the position of the cable landing brackets will need to change, and a spool will need to be removed.

To make the change, proceed to remove and unscrew the two brackets at the bottom and positions as indicated

on the image above. Once done, proceed to remove the spool indicated in the image above.

1

How to change the Conguration for

top/bottom feed

Bottom Feeding

Top Feeding

13

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

Feeding of Ribbon Fiber Cable

• Remove the top cover of the splice area at the bottom of the frame to access the splice tray and cable

support brackets.

• Once the Transition Box is xed on the bottom support bracket, address the corrugate tubing towards

the slack basket and secured the in the corrugate xing point. Proceed to address 1.8 meters of the ber

bundles coming from the corrugate in the ber slack basket

• Proceed to address the remain 1.5 meters of ber bundles into the trays starting from the bottom tray

• Remove the top cover of the splice area at the bottom of the frame to access the splice tray and cable

support brackets.

• Once the Transition Box is xed on the bottom support bracket, address the corrugate tubing towards

the slack basket and secured the in the corrugate xing point. Proceed to address 1.8 meters of the ber

bundles coming from the corrugate in the ber slack basket

• Proceed to address the remain 1.5 meters of ber bundles into the trays starting from the bottom tray

1a

1b

Bottom Feeding

12th Tray

1st Tray

Slack Basket

24f Cable

from

Cassette

Corrugate

tubing

Corrugate

xing point

Top Feeding

12th Tray

1st Tray

Slack Basket

24f Cable

from

Cassette

Corrugate

tubing

14 © AFL Hyperscale. All rights reserved

Feeding of Ribbon Fiber Cable

Top Feeding

Proceed to adjust the cable guard in the frame located at the top of the frame by releasing the two 2x M4 x 10

screws indicated. This will loose the bracket to allow the incoming cable from the top basket to be safely store

in the frame.

2

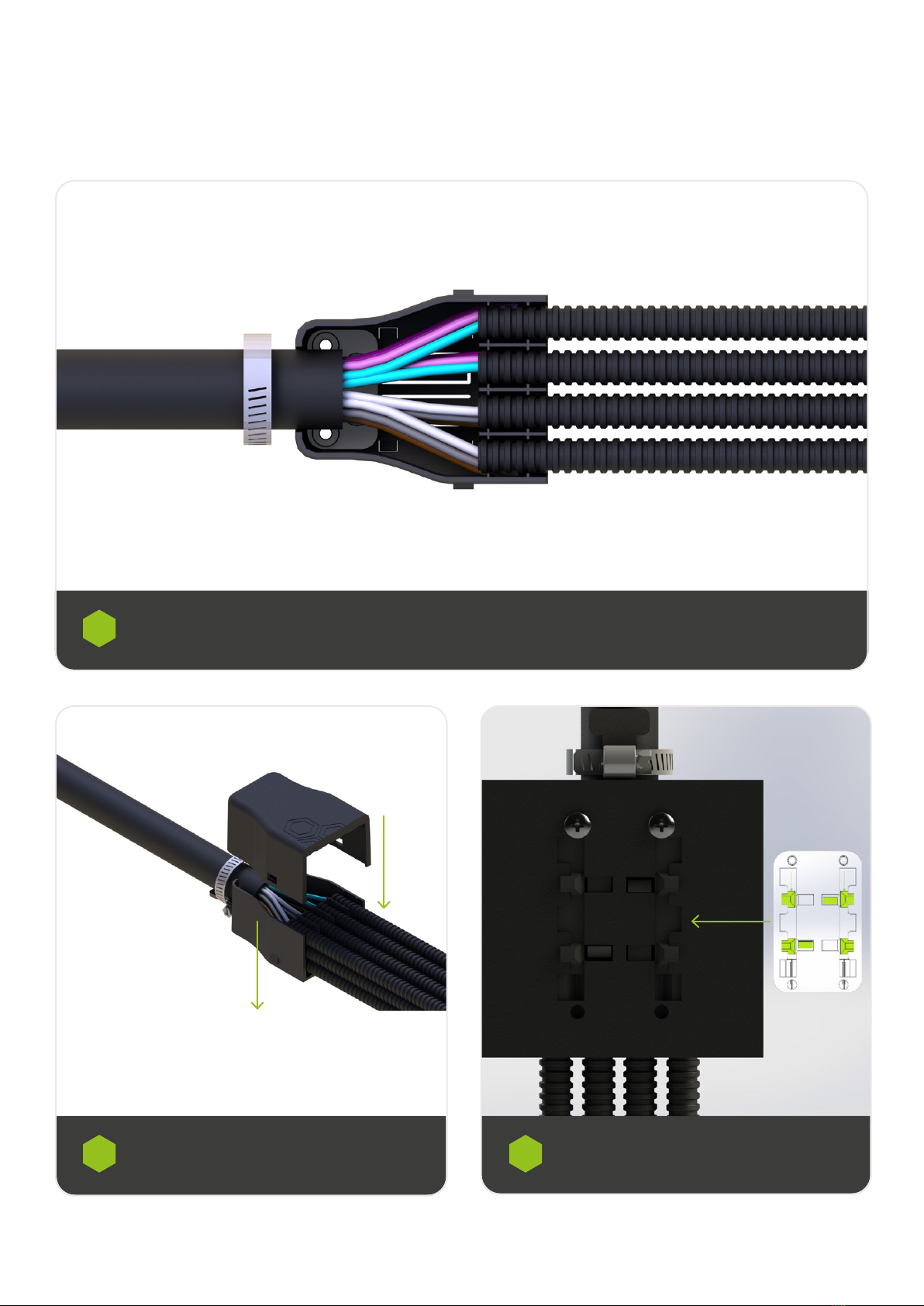

Slide hose clamps over cable and strip cable jacket

4m according to manufacturer’s guidelines.

Note: It is commended for top cable feeding to place

the cable in the incoming cable through before

proceeding with the stripping of the cable’s jacket.

Separate out and tape up 144f ber bundle ends

as per splicing schedule and feed into one of the

0.7meter 10mm OD corrugate tubing.

3 4

15

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

Feeding of Ribbon Fiber Cable

Repeat steps 3-4, ensuring all ber has been placed inside a corrugate tube. Once done, slide the corrugate tubing in the SWR

Snap Fit transition box’s grooves. Proceed to secure the transition on the cable using the hose clamp.

5

3

Attached the lid to the SWR Snap Fit Transition

Box body.

Slide SWR Snap Fit Transition Box onto the bracket

located inside of the splice area of the frame.

6 7

16 © AFL Hyperscale. All rights reserved

Feeding of Ribbon Fiber Cable

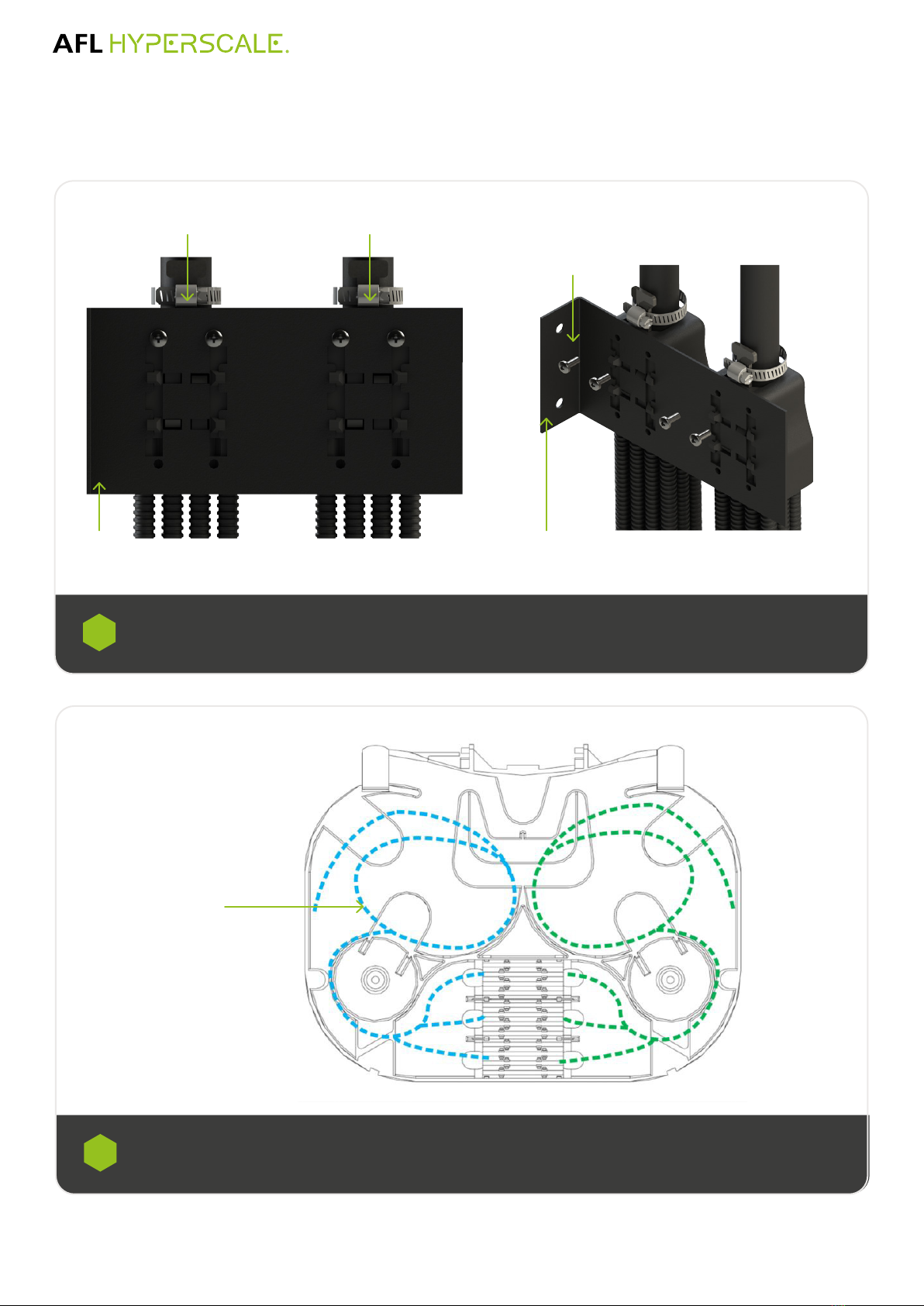

Each bracket in the frame provides two positions to secure the SWR Snap-Fit transition Box. Proceed to secure the rst transition

with 2x M4 x 10 screws (position “A”) and second or further expansions on following positions available.

Once the transitions are in installed, proceed to address the corrugate tubing and the bers as it is indicated in steps 1A or 1B

according to the conguration

7

Position A Position B

M4 x 10 Screws

Bracket holder

5 coils, approx., 1.5m

(both 144f ribbon

and 36f single

element)

Bracket holder

Route the incoming/ outgoing ber as per above image -up to 1.5 meters of 144f ribbon per side. Splice according to the splice

schedule.

8

17

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

Installing the U-Series Solution

Housing Installation:

Proceed to identify the required height in the frame. Once done, proceed to press in and tighten the M6 x16 Pozi-head screw

bolt through perforations located at each side of the frame to x the 1RU ber management in place.

1

Fiber Management:

Proceed to press in and tighten the M6 x16 Pozi-head screw bolt through perforations located at each side of the frame to x the

1RU ber management in place.

2

18 © AFL Hyperscale. All rights reserved

Cassette Installation:

Cassettes can be installed or removed from the front of the housing with no tools required.

When the release element is in the unlock position, you can remove/install the cassette by pulling.

4

Installing the U-Series Solution

The frame is supplied with am U-series 2RU Hosing installed at positions A1 at the bottom half for External distribution area

and B1 at the top Half for Internal Distribution Area. Additional units for expansion will need to be added on the next available

position, A2 for External Distribution or B2 for Internal Distribution.

3

First position at top

of frame

First housing position for

External Distribution Area

Locking push

latch

B6

B5

B4

B3

B2

B1

A6

A5

A4

A3

A2

A1

19

SWR®1200 ODF Installation Guide

© AFL Hyperscale. All rights reserved

A10 A11 A12

A8 A9

A6 A7

A4 A5

A2 A3A1

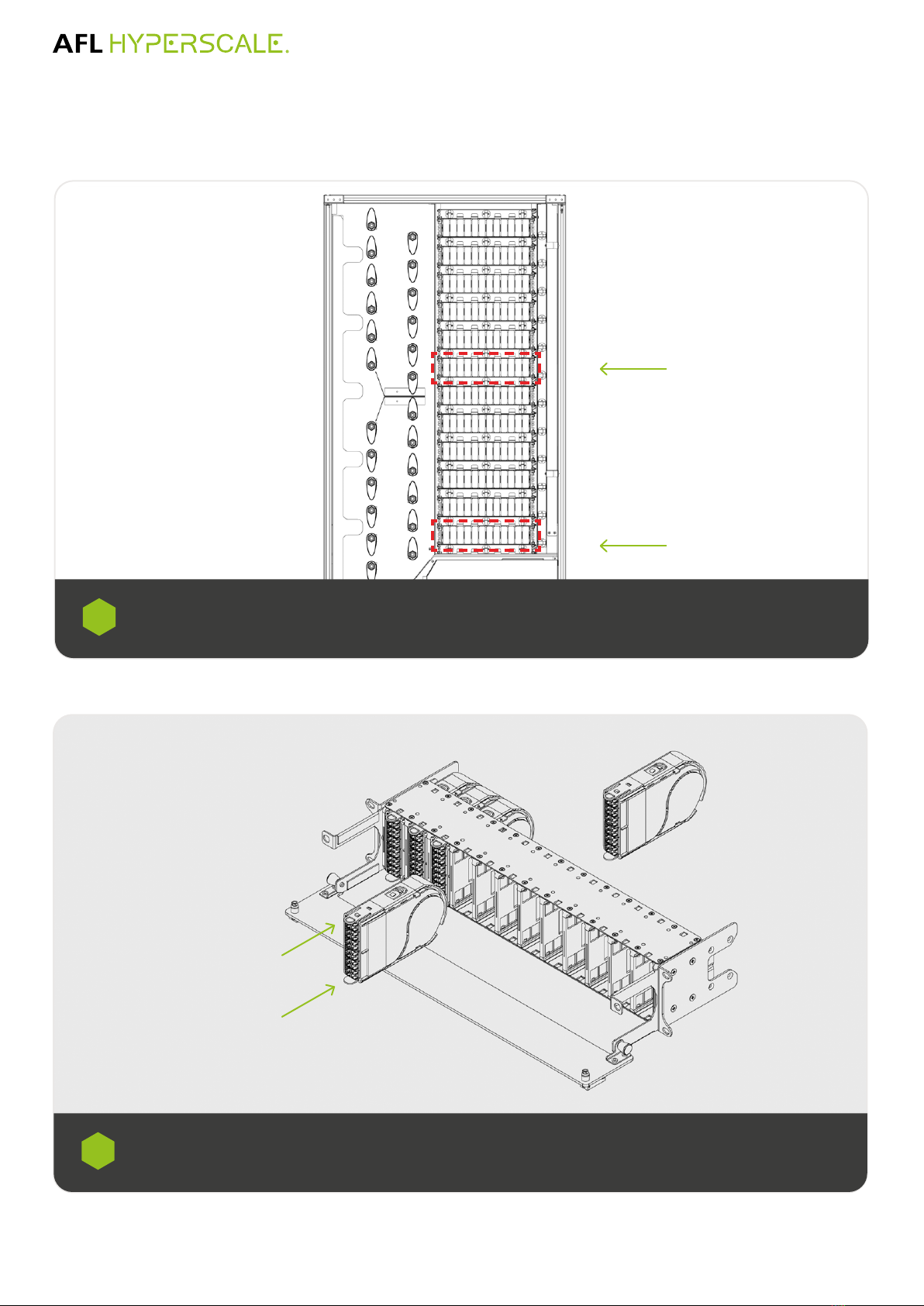

The recomened cassette installation used is position one from the bottom housing. It is recommended to instal the cassettes from

left to right.

5

Splice Cassette/Module Installation

in the U-Series 2RU Strat from the

left hand of the housing to right

Installing the U-Series Solution

The ber guide is assembled on right-hand side of the rack.

Proceed to lose the xing bolds on the 1RU U-Series Cable Management and slide the ber guide in between the head of the

bolts and the cable manager. Once done tighten the screws one more time

6

20 © AFL Hyperscale. All rights reserved

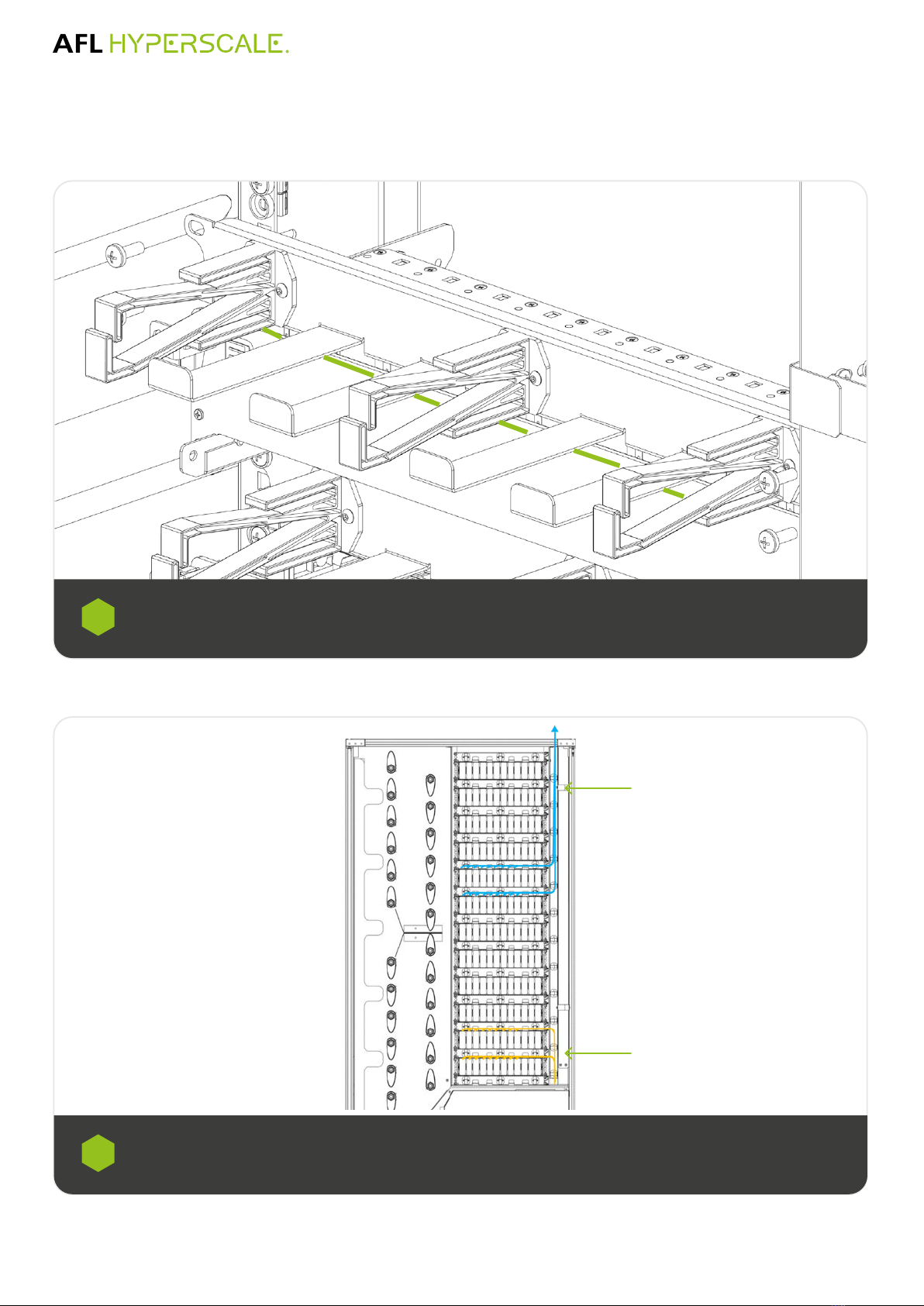

Cassette Tail Routing

Outgoing ber cable will need to be routed from the top of the cassette into the 1RU U-Series ber management passing

through the bottom hock. Once done the cable will go underneath the nger management of the 1RU U-Series ber

management toward the ber guides located at the right-hand side of the frame to be later route to the splice area.

1

Outgoing ber cables from the cassette presented in the External Distribution are addressed starting from the rst unit from the

top (Position A1) and routed to the splice area in bundles of 6 cables (144f) from the rst six cassette positions. Outgoing ber

cables from the cassette presented in the Internal Distribution Area are addressed starting from the rst unit at the top half and

routed in bundles of 6 cables (144f) from the rst six cassette positions to the cassette designated outside of the frame.

2

Bottom half for External

Distribution Area

Bottom half for Internal

Distribution Area

Table of contents

Other AFL Hyperscale Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIRIUS ACT 3SU19 operating instructions

Unitary products group

Unitary products group PT8 installation manual

Masterbuilt

Masterbuilt HITCH-HAUL HDMF Operation manual & safety instructions

Draco

Draco K5 manual

Siemens

Siemens SIMOVERT MASTERDRIVES 6SE70 C.87-2DA0 Series operating instructions

Ceriotti

Ceriotti C3000 Assembly instructions