Safety Info

Donot use thisapparatusnear water.

Clean only withlint free dry cloth.

Do not block any ventilationopenings.

Do not install near any heat sources such as

radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce

heat.

Do not defeat the safety purposes of the

grounding- type plug. A ground type plug has

two blades and a third grounding prong. The

third prong is provided for your safety.If the

provided plug does not fit in to your outlet,

consult anelectrician for replacement of the

obsoleteoutlet.

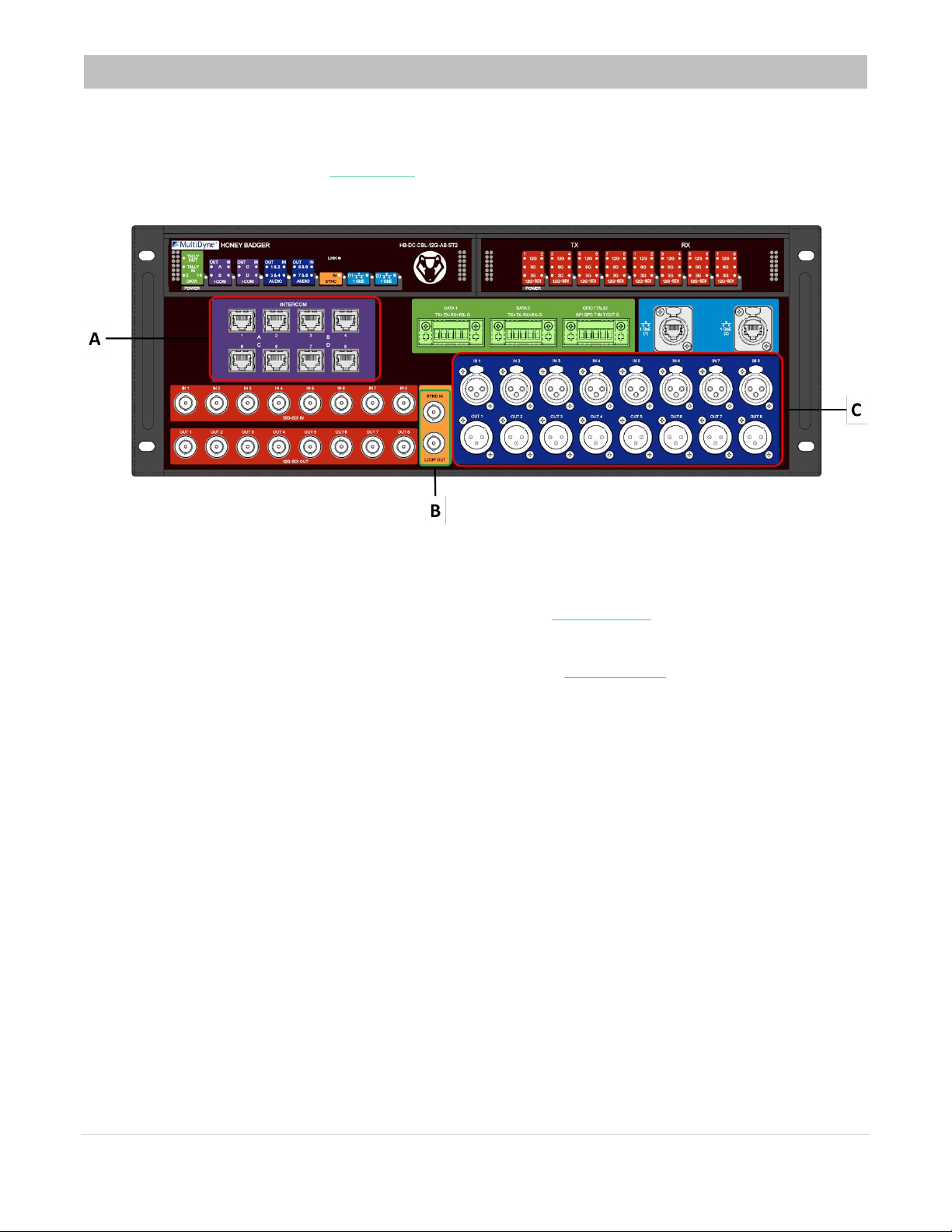

Install in accordance with the MultiDyne®

installationinstructions.

Install all peripheral equipment (cameras,

routers, etc.) in accordance with the

requirements.

Protect the power cordfrom being walked on or

pinching particularly at plugs, convenience

receptacles, and point where they exit from the

apparatus.

Only use attachments/accessories specified by

MultiDyne®.

Use only with the cart, rack, stand, tripod,

bracket, or table specified by MultiDyne®, or

sold with the apparatus. Whenacartisused,use

caution when moving the cart/apparatus

combination to avoid injury from tip-over.

FollowalllocalElectricalCodesforGrounding,Lightning

Arrestmentand SurgeProtection.Unplugthis apparatus during

lightningstorms or when unused for extended periods of time.

AllElectricalWorktothefacilitymustbe performedby a qualified Licensed Electrician.Alllocal ElectricalCodes must

be followedand, if necessary, must be inspected by a Local orState Inspector.

All servicing of MultiDyne equipment must be performedat the factory bya MultiDyne trained service technician or

engineer.

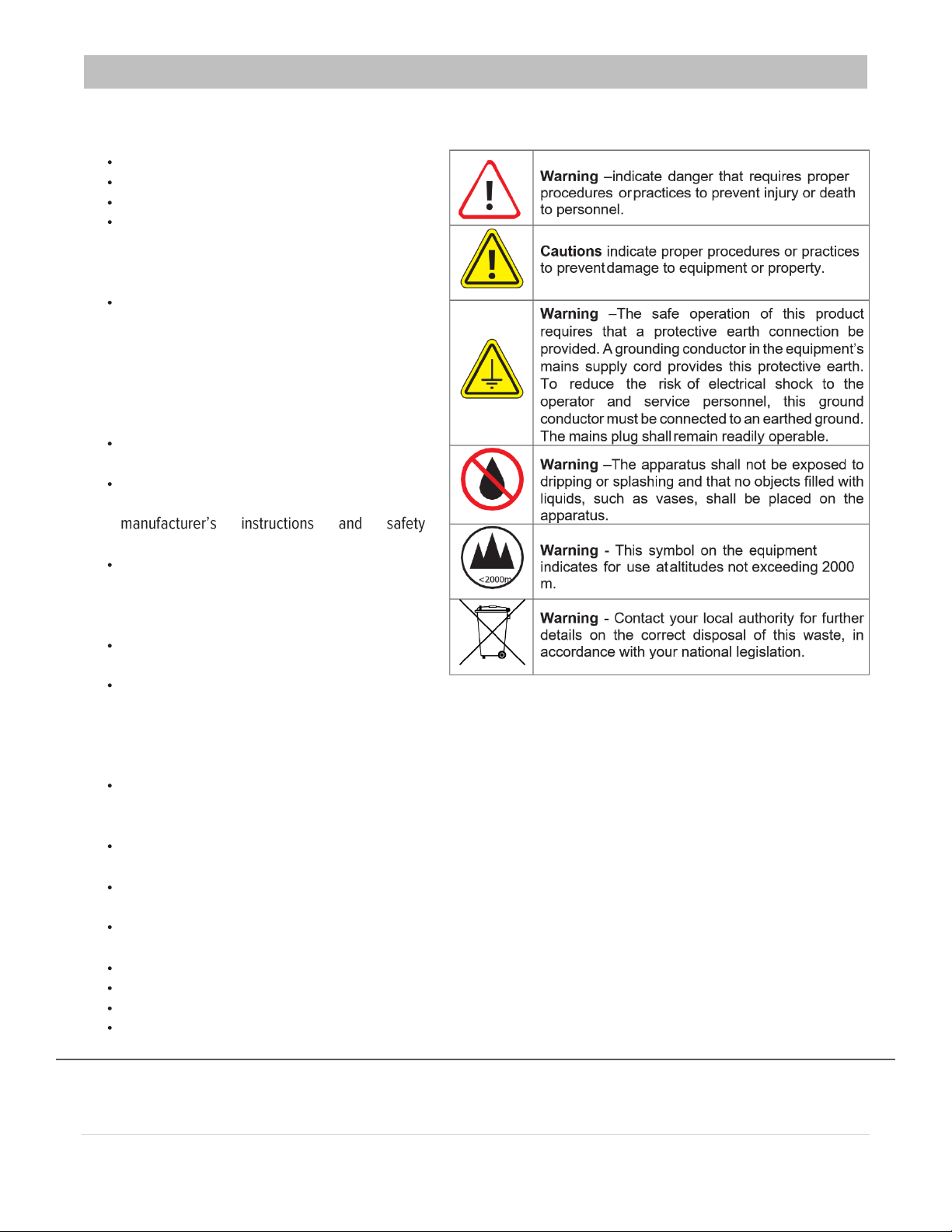

Throughoutthis manual, severalWarnings andCautions and Notesmay bepresentedto alert the user toimportant

safety oroperating information.

Always adhere to local building,safety and fire preventioncodes during the installationand operation of this product.

Use only power cords that were shipped with specified for this product and certified for the country of use.

Connect the unitonly to a power source withthe specified voltage rating.

Unless otherwise stated in the Installation Instructions, and in adherence to local Electrical Codes, MultiDyne®

Equipment should only be plugged into a standard 15-amp dedicated circuit.