MultiSmart Integrator Guide

Page 6 of 20 MultiSmart_Integrator_Guide_R01.doc

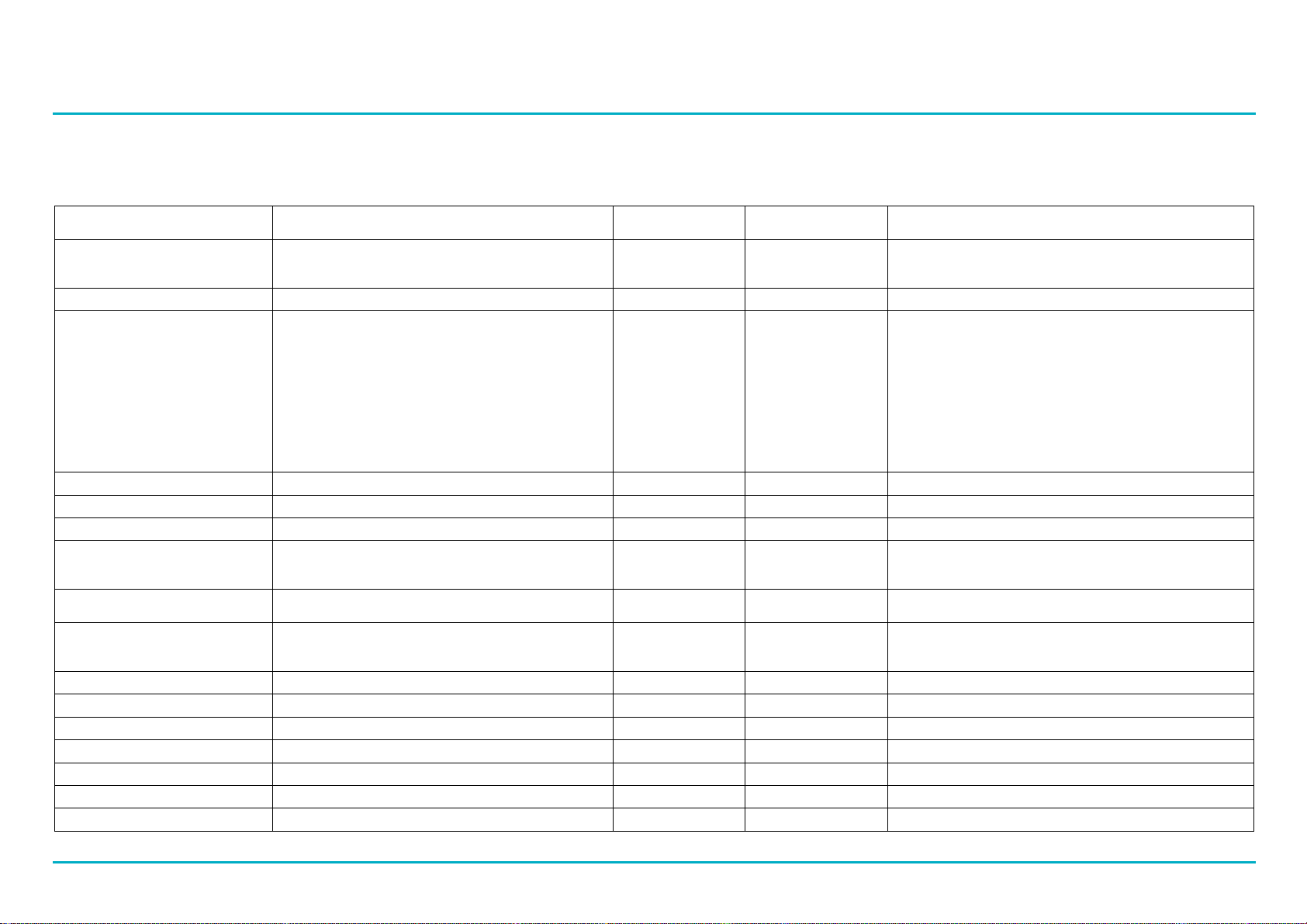

5.4 Basic 2-pump application (1 well) – 18 tags

Description Tag ID DNP ID (default) Modbus ID

(default) Comments

Pump 1 Running (called) PumpControl._1.Running Binary Input 70 Discrete Input 62 This means that the output control relay has been

asserted. Feedback from the contactor can be brought

back, details in section 5.5)

Pump 2 Running (called) PumpControl._2.Running Binary Input 130 Discrete Input 122

Pump 1 Unavailable PumpControl._1.FaultStatus.UnavailableActive Binary Input 73 Discrete Input 65

The pump can be unavailable when supply faults are

present as well as when pump faults exist.

A pump fault does not have to make the pump

unavailable, e.g. the default configuration for a seal

fault.

Any fault can be defined to be a display only fault, an

auto reset fault (pump becomes available when fault

condition clears), or a manual reset fault (pump only

becomes available when manual or SCADA reset takes

place)

Pump 2 Unavailable PumpControl._2.FaultStatus.UnavailableActive Binary Input 133 Discrete Input 125

Pump 1 Active Fault Fault.Pump._1.Active See note 1 See note 1

Pump 2 Active Fault Fault.Pump._2.Active See note 1 See note 1

Level PumpControl.Well._1.CurrentLevel or

PumpControl.Well._1.ScaledLevel Analog Input 10 or

Analog Input 12

Input Register 38 or

see Note 3 (section

5.5)

Currentlevel = level in %, ScaledLevel can be defined

by the user so it displays on the MultiSmart screen, e.g.

0-5m, 0-10ft

High Level alarm Faults.Well._1.HighLevel.Status.Active Binary Input 32 Discrete Input 30 There are 2 high level alarms available. High and High-

High. See Note 2.

Supply fault – Under-voltage

Over-voltage

Phase imbalance

Faults.Station.UnderVoltage.Status.Active

Faults.Station.OverVoltage.Status.Active

Faults.Station.VoltsPhaseImbalance.Status.Active

Binary Input 0

Binary Input 2

Binary Input 4

Discrete Input 0

Discrete Input 2

Discrete Input 4

Supply, phase AB IO.Unit._1.TopBoard.Vin._1.VoltsAb Analog Input 47 Input Register 113

Supply, phase BC IO.Unit._1.TopBoard.Vin._1.VoltsBc Analog Input 48 Input Register 114

Supply, phase CA IO.Unit._1.TopBoard.Vin._1.VoltsCa Analog Input 49 Input Register 115

Inflow Flow.InflowRate Analog Input 4 Input Register 21

Pump 1 Flow rate Flow.Pump._1.FlowRate Analog Input 21 Input Register 63

Pump 2 Flow rate Flow.Pump._2.FlowRate Analog Input 31 Input Register 93

Station volume Flow.VolumePumped Counter 4 Input Register 22

Lobley St SPS SP331 General (Electrical Manual (MPA) Multismart Manual Multitrode System Integrator Guide) General