Service Manual

Table of Contents

Part Ⅰ: Technical Information ............................................................ 3

1.Summary ...................................................................................................... 3

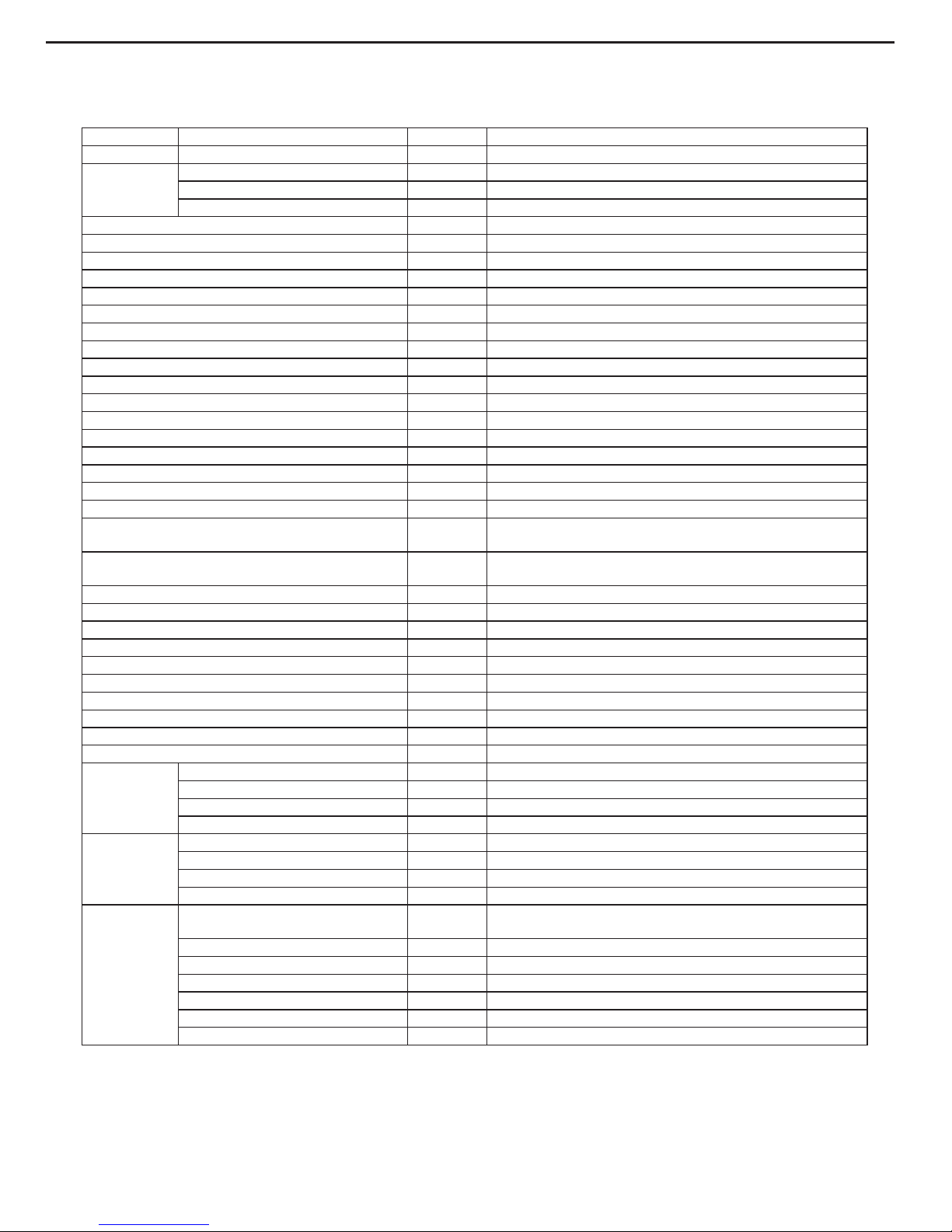

2.Specications ........................................................................................... 4

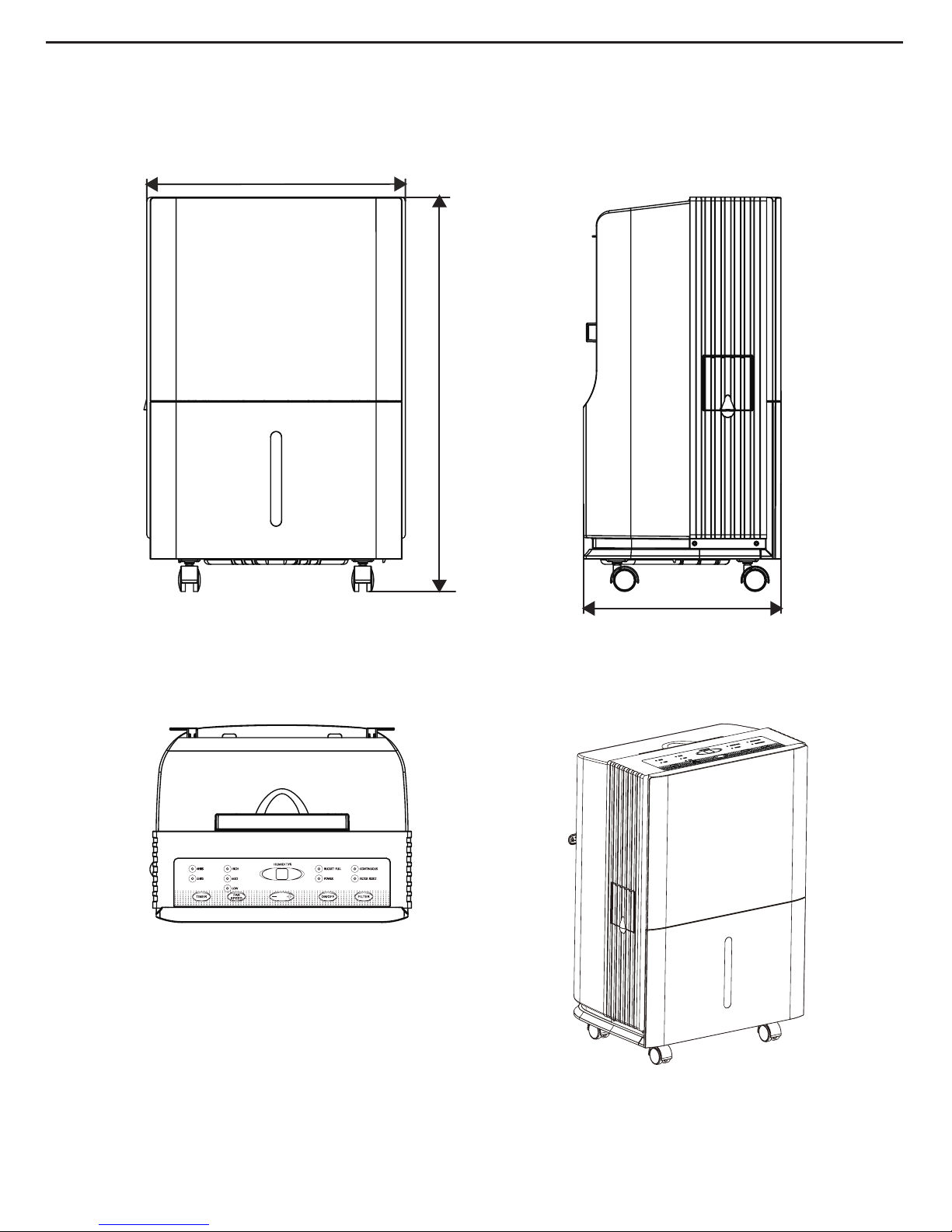

3.Outline Dimension Diagram .............................................................. 6

4.Refrigerant System Diagram ............................................................7

5.Electrical Part ............................................................................................8

5.1 Wiring Diagram ...........................................................................................8

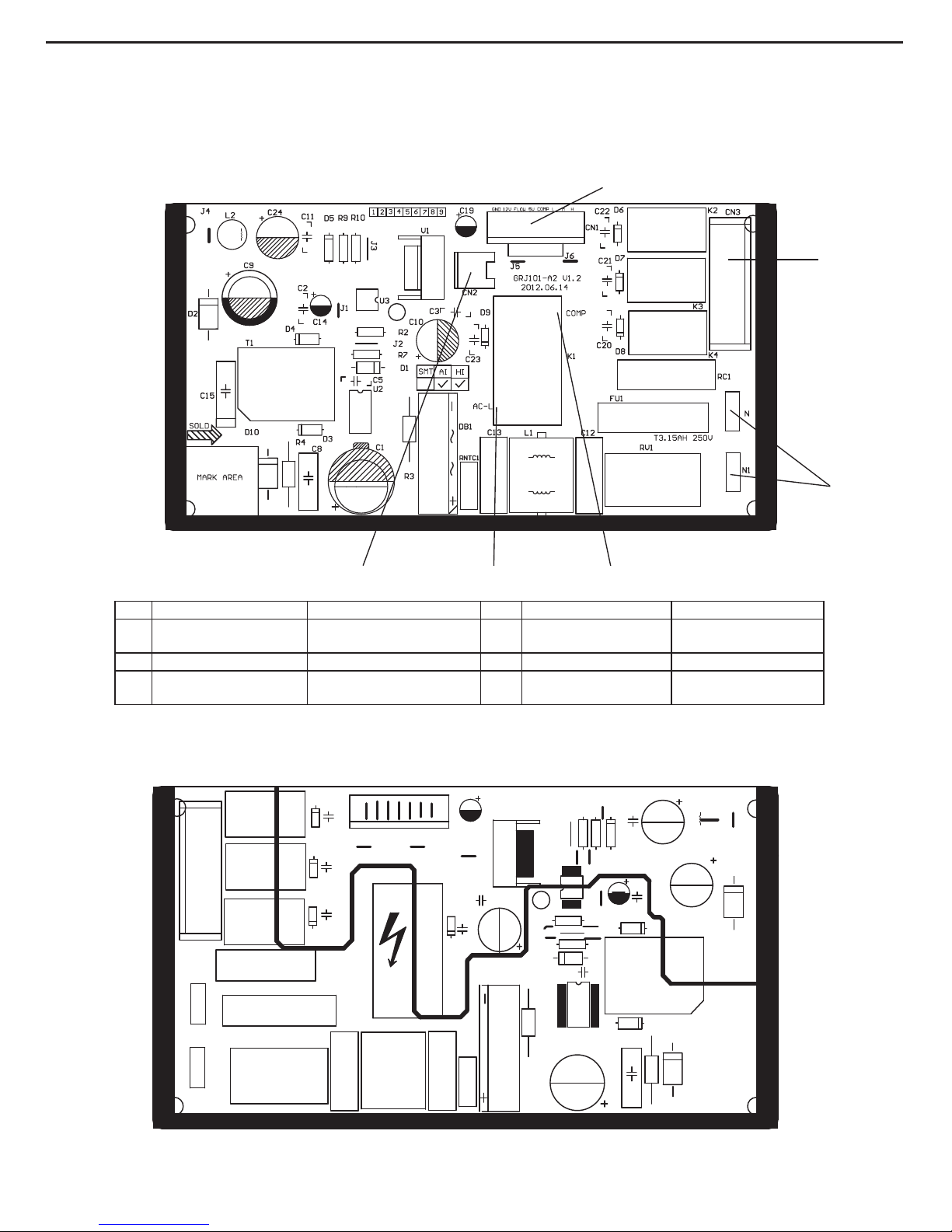

5.2 PCB Printed Diagram ..................................................................................9

6.Function and Control .......................................................................... 11

6.1 Control Panel Instruction ........................................................................... 11

6.2 Introduction of Basic Mode Function ......................................................... 12

Part Ⅱ: Maintenance ............................................................................ 14

7.Notes Maintenance .............................................................................. 14

8.Maintenance ............................................................................................. 15

8.1 Error Code ................................................................................................. 15

8.2 Malfunction Detection Flowchart ............................................................... 16

8.3 Maintenance Method for Common Malfunction ........................................ 18

9.Exploded View and Parts List ........................................................ 20

10.Removal Procedure ........................................................................... 23

Appendix: ...................................................................................................... 30

Appendix 1: Reference Sheet of Celsius and Fahrenheit ............................... 30

Appendix 2: Resistance Table of Temperature Sensor ................................... 31

Appendix 3: Resistance Value Table of Humidity Sensor ............................... 36

2