M2582, M5081, and M5180 Series

Electromechanical and Pneumatic, Fuel Gas Shut-

off Valves Installation and Operation Instructions

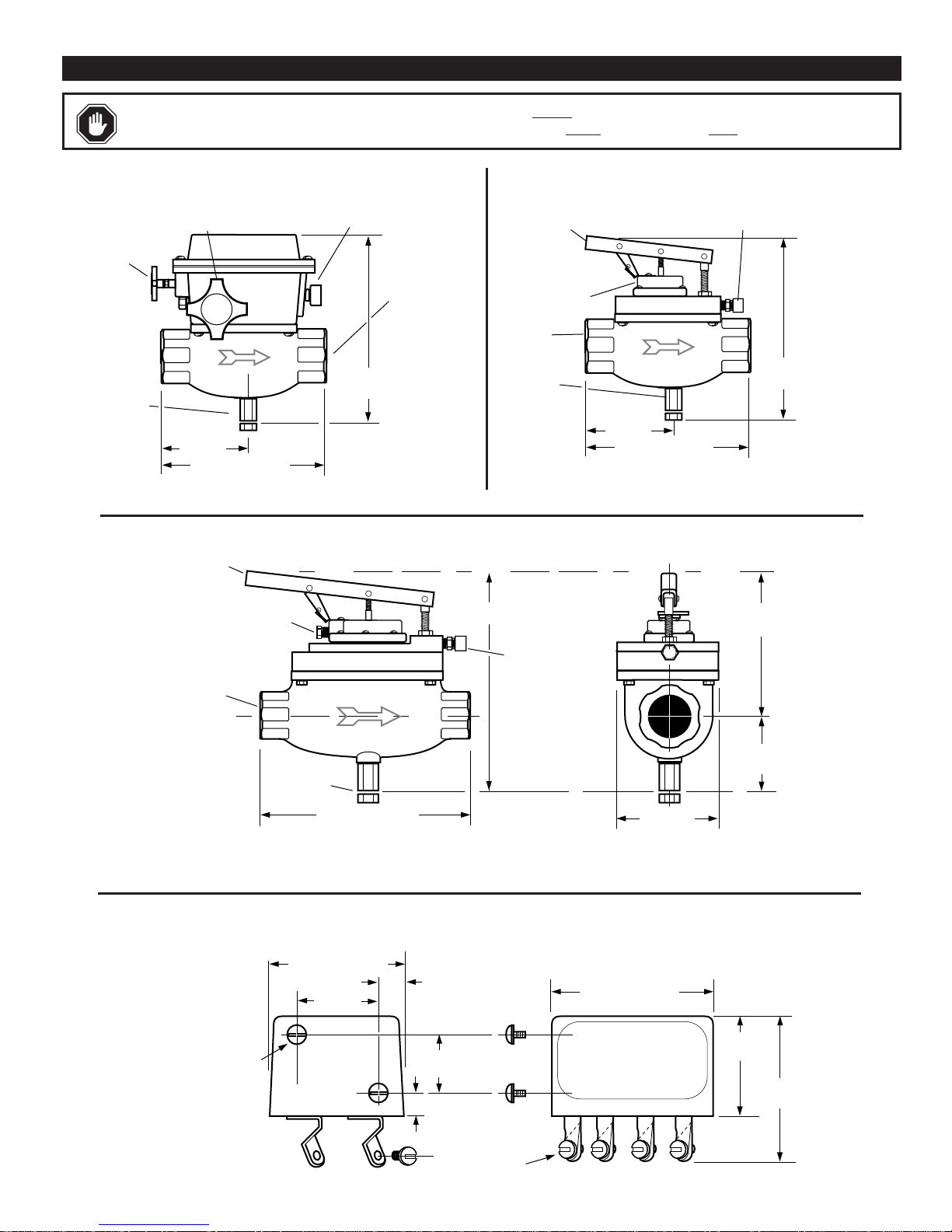

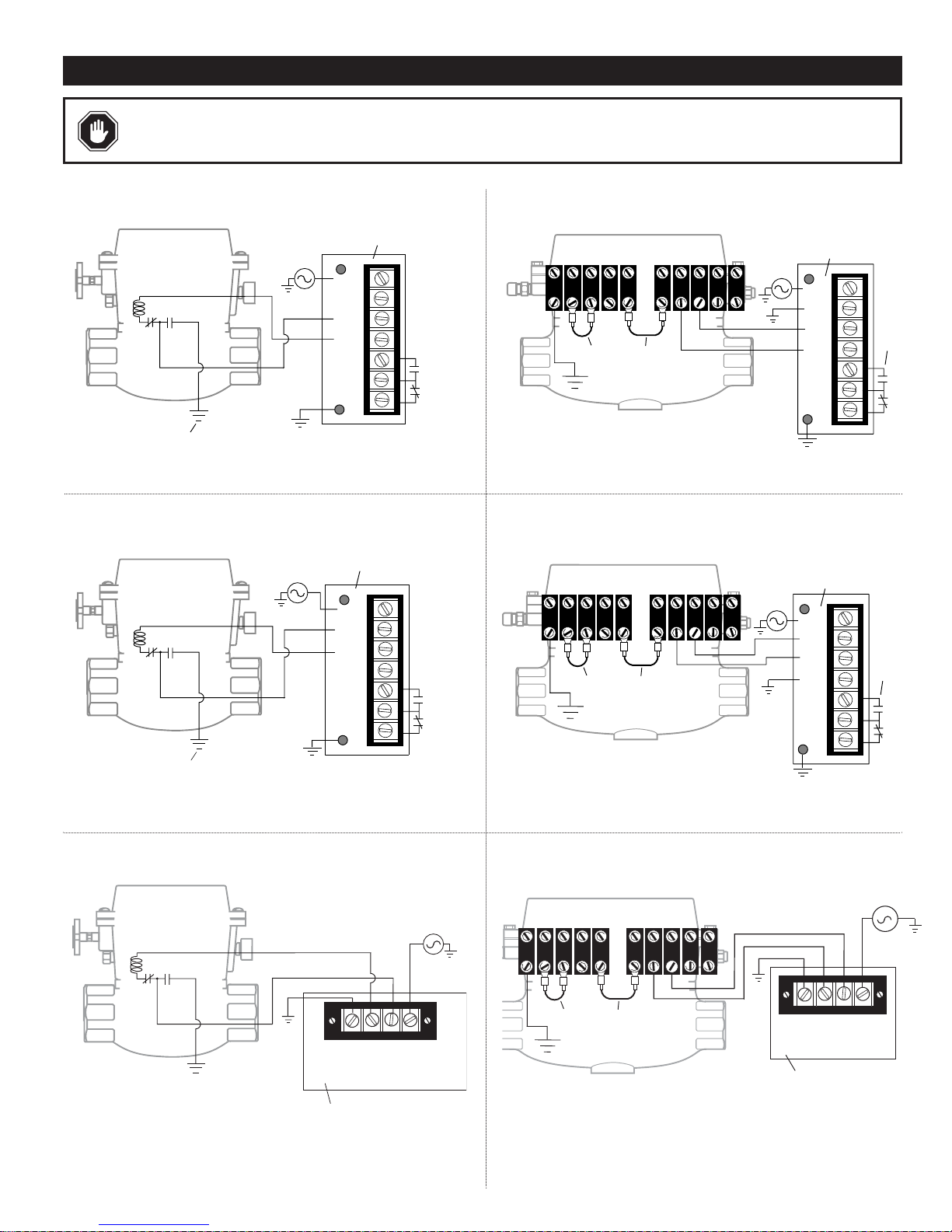

M2582 and M5081Series

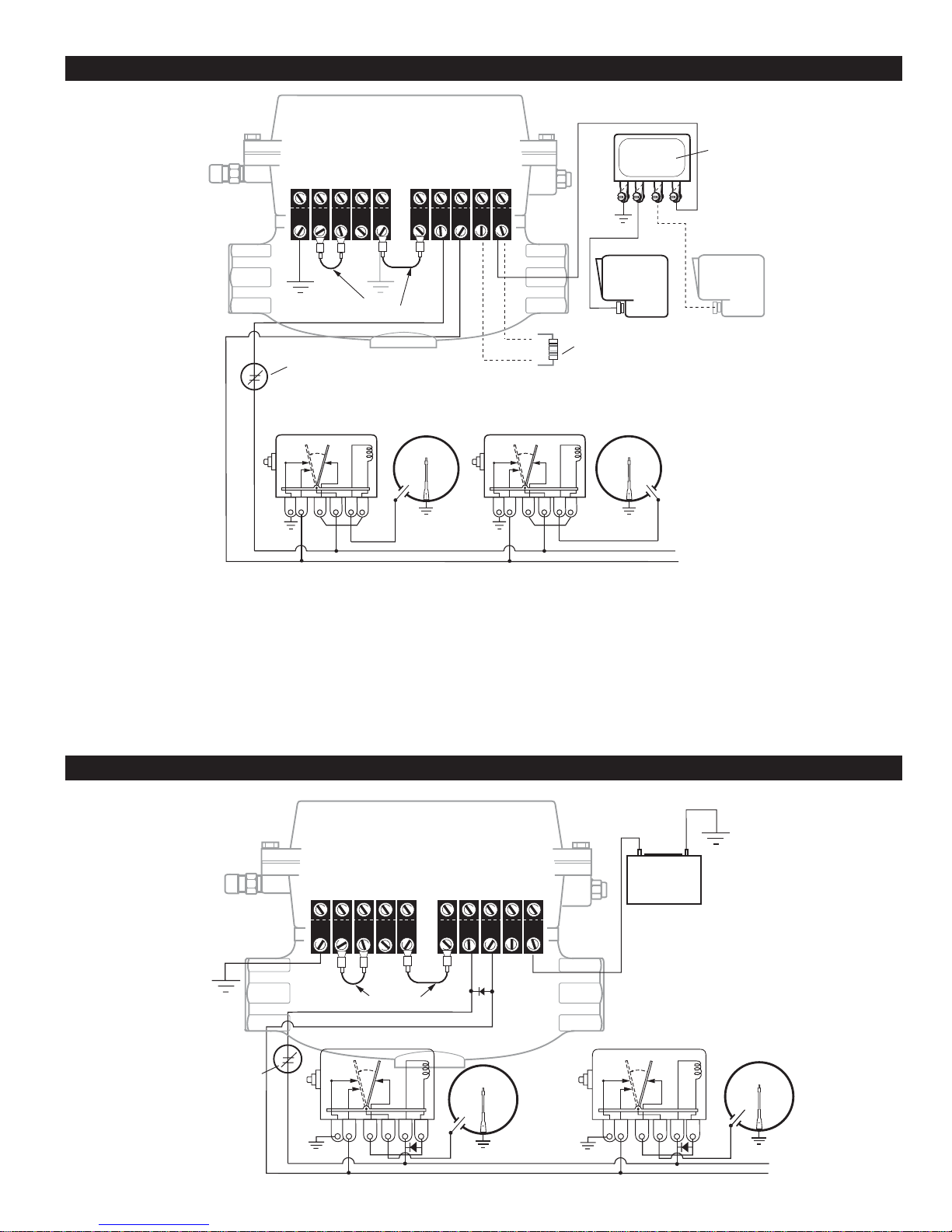

Tripping Power From Engine Ignition System or Battery

(Models available for magneto, CD ignition or 12/24 V battery)

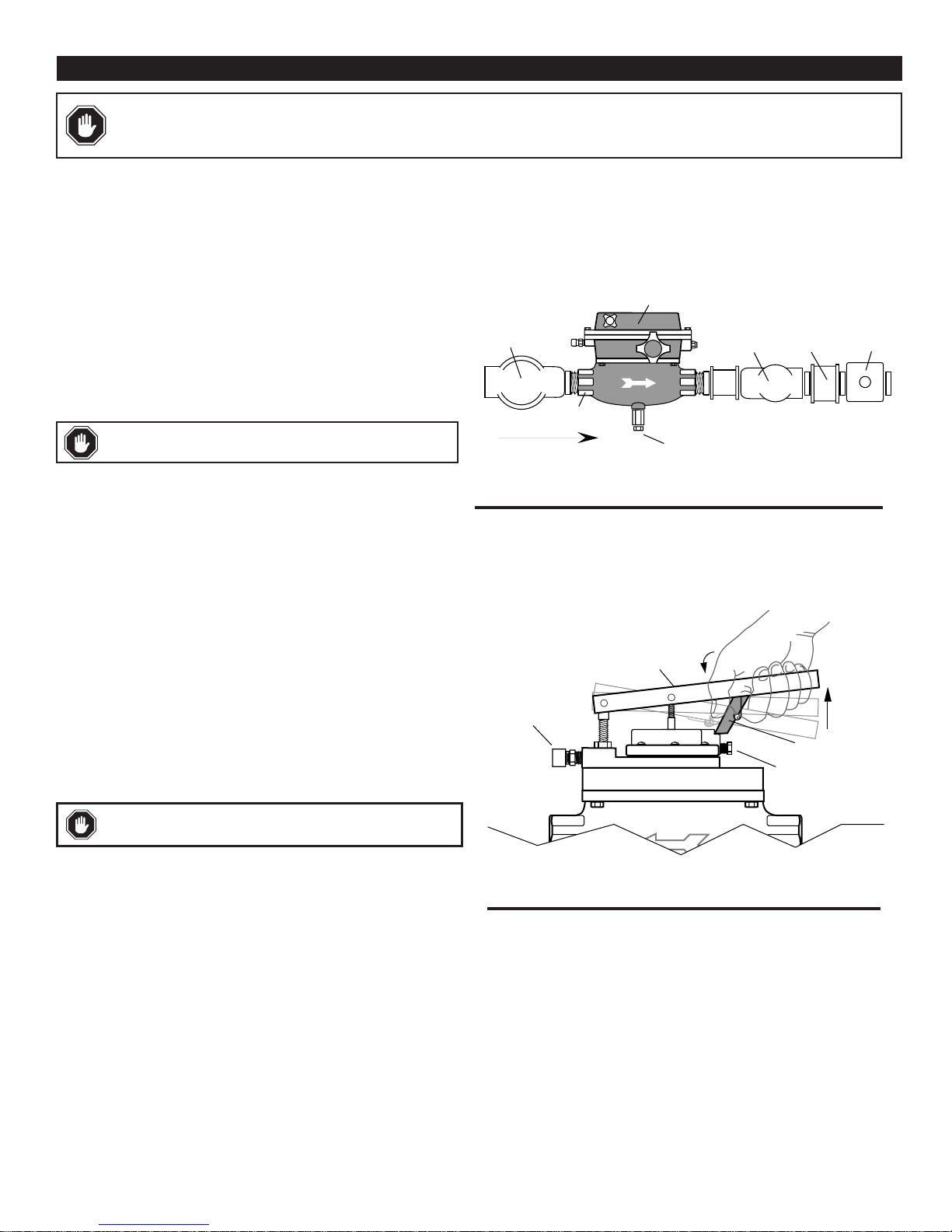

These fuel shut-off valves are semi-automatic devices for shutdown of

natural gas fueled engines. The standard valve opens by manual

operation of the reset handle. A latch in the upper body of the valve will

set and hold the valve open. At this point no electric power is used.

The electromagnetic coil is de-energized, the snap-switch(es) is SET.

If a SWICHGAGE®contact closes, a circuit is completed from power

through the snap-switch and coil. Now energized, the electromagnet

trips the latch, (latch can be tripped manually), the valve closes, and the

snap-switch resets. Power switches from the coil circuit to your choice

of an open line, an electrical ground, or an alarm. After tripping, the

vent seal opens, and on the M50 models, the open/close indicator (green

button) retracts to indicate that the valve is closed.

Valve body is sandcast aluminum. Optional cast steel for M5081 models.

M2582-P and M5180-P

MURPHY-NUMATIC™Pneumatic Version for Pressure

The M2582-P and M5180 pneumatically controlled valves can operate

from pressure, and are designed to open and close automatically or semi-

automatically (the supply can be air, oil or gas).

NOTE: If using oil as a pressure source, use a lightweight oil.

These valves will open on rising control pressure and close on

decreasing control pressure. M2582-P and M5180-P automatically open

at 2 psi (14 kPa) [0.14 bar] and fully open at 3 psi (21 kPa) [0.21 bar].

All models include a built-in lever to aid in opening the valve manually.

The M2582-P can be manually opened against inlet pressure of 80 psi

(552 kPa) [5.52 bar]. The M5180-P valve can be opened against inlet

pressure of 100 psi (689 kPa) [6.89 bar].

Standard models include an escape vent for gas trapped forward in the

line after shut-off.

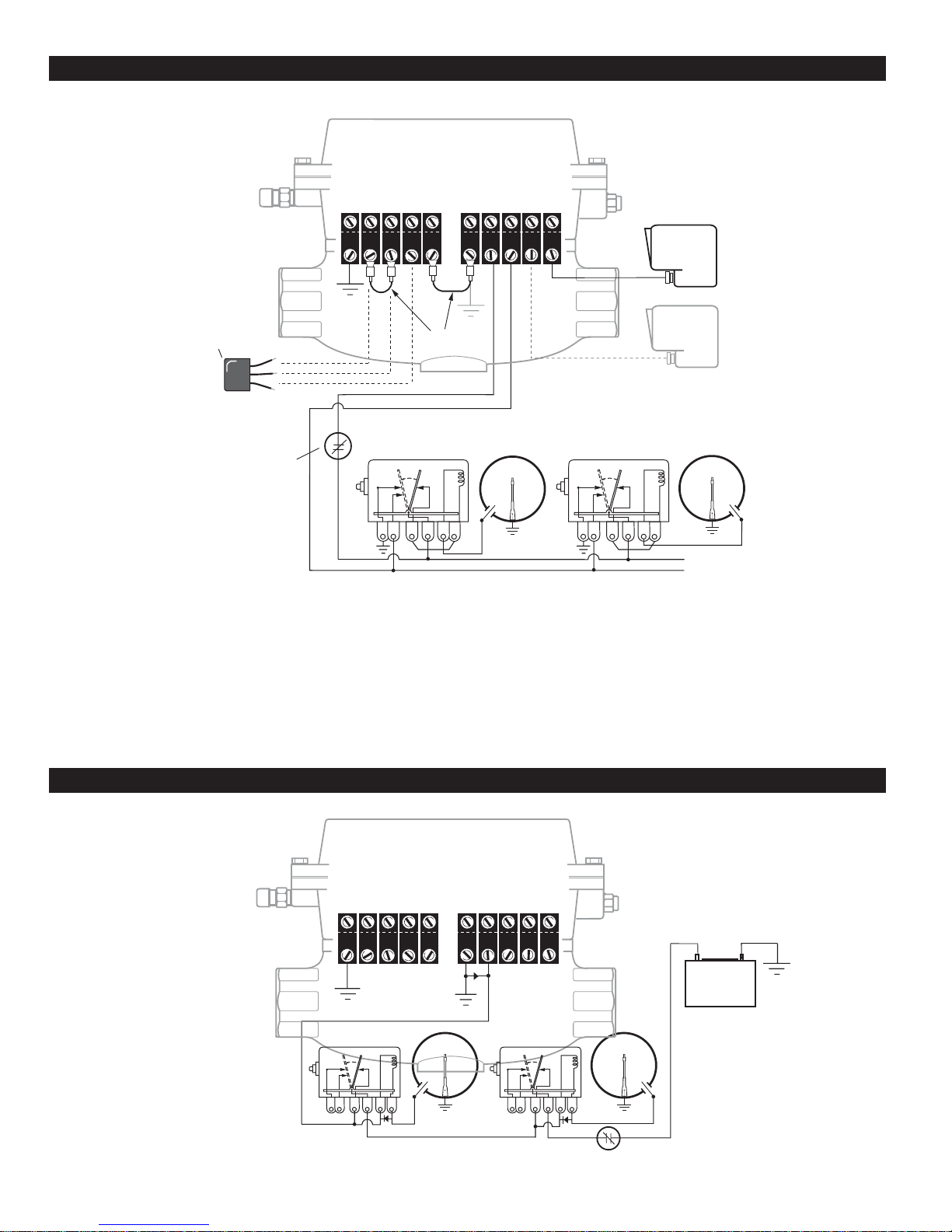

M5081FS

Normally Energized Circuit

The M5081FS is manually opened, electrically latched open and tripped

by interrupting the coil power circuit.

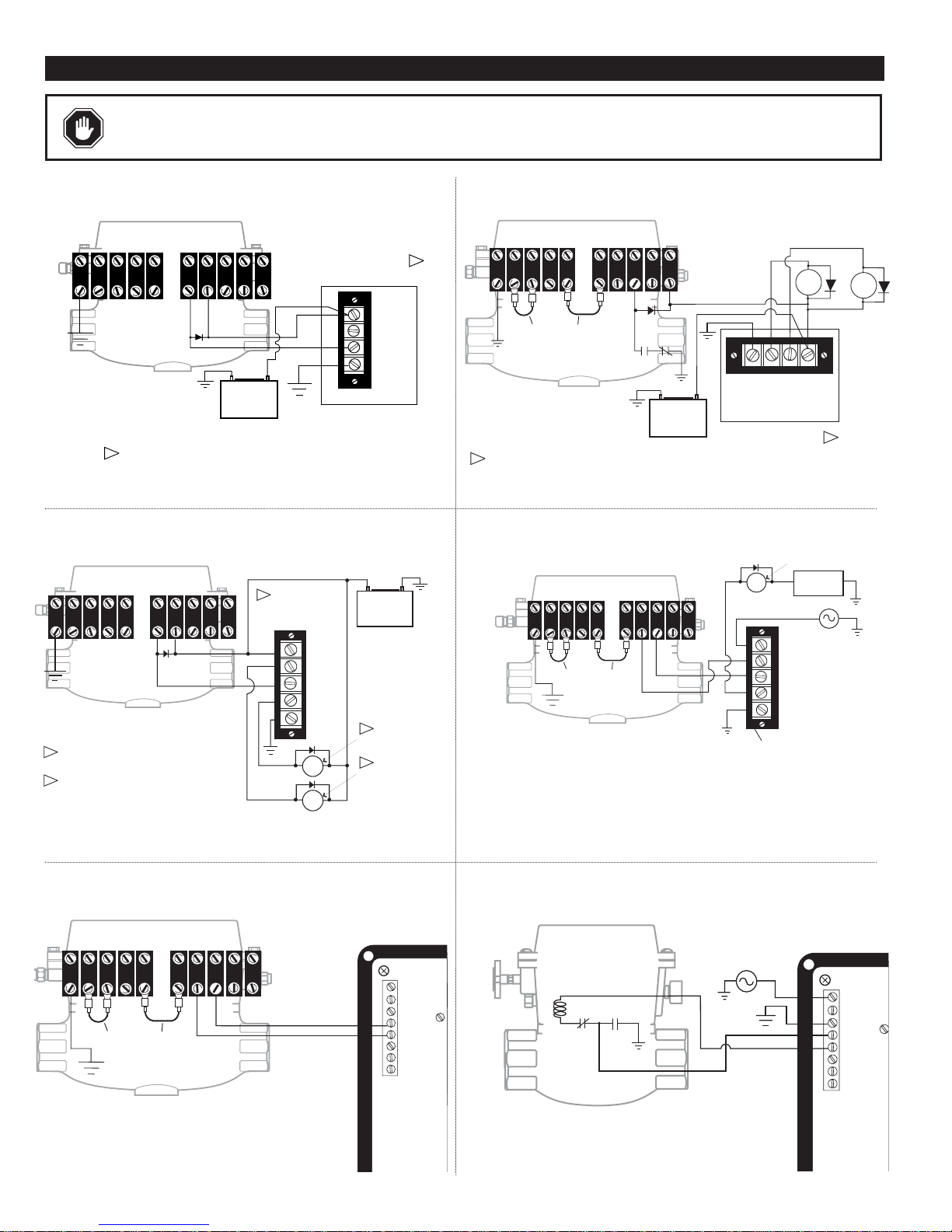

Magnetic Switch Adapter

As ignition systems wear from usage, their power output becomes less

and less. Ignition may not have the capacity to reliably trip the Fuel

Valve. Therefore, the use of a Magnetic Switch Adapter for CD

ignition systems is recommended. The Magnetic Switch Adapter is a

device that stores energy from the CD ignition to trip the Fuel Valve.

Three models are available:

65700053 (was 65020126): For use with negative ground ignitions

up to 240 VDC.

65700054 (was 65020127): For use with positive ground ignitions

up to 450 VDC.

65700055 (was 65020155): For use with negative ground ignitions

up to 450 VDC.

100 ohm, 2 watt Resistor

For Capacitor Discharge Ignitions that are specified to be grounded when

the valve closes, and a Magnetic Switch Adapter is in use. The resistor

must be connected in the system to prevent damage to the snap-switches

in the fuel shut-off valve (see typical wiring diagrams).

Diode Package

The Murphy diode package (65010065) is designed to allow the fuel shut-

off valve to be used with dual Magneto Ignition systems.

NOTE: All aluminum versions of the M5081 Series Fuel Valve carry

Canadian Registartion Number OC1476.2.

*M5081 model is CSA approved for Class I, Division 1, Groups C and D.

See Specifications on page 12.

GENERAL INFORMATION

Please read the following instructions before installing. A visual inspection of this product for damage during shipping is

recommended before mounting. It is your responsibility to have a qualified person install the unit and make sure installation

conforms with NEC and local codes.

M-7980N

Revised 11-02

Section 55

(00-02-0206)