Control Outputs

The following are provided:-

•Switched +ve RUN relay and START outputs, used for

controlling the engine fuel and starter motor circuits.

•A –ve DC (open collector transistor), common ALARM

output, used for remotely signalling a fault condition.

Fault protection and Alarm System

After the operator has started the engine and the fault

override timer has expired, the Keystart monitors for engine

and plant faults through remotely connected switch sensors.

Dedicated inputs are provided for Low Oil Pressure and

High Engine Temperature switch sensors. 1 or 2 additional

inputs may be used for general purpose ‘plant fail’ contacts.

Switches at the rear allow the inputs to be configured for

use with remote contacts which either open or close during

fault, with wiring polarity to either +ve or –ve DC.

The Keystart may optionally be fitted with an engine

overspeed trip, available in alternator sensing (generator

AC, 50/60Hz) or magnetic pickup sensing variants.

If any of the above faults occur, Keystart will:-

•turn off its RUN output (stopping the engine)

•indicate the fault on the appropriate front facia LED

•activate its Alarm output (to remotely signal that a

fault has occurred).

The automatic fault shutdowns operate on a first-up and

latching basis - subsequent faults are not indicated and the

displayed fault can only be cleared by switching the

Keystart to STOP.

Charge Fail Warning

A charge failure warning LED is provided for use with an

engine driven charge alternator. The charge alternator’s

WL terminal is connected to the Keystart, which will in turn

monitor the WL voltage and provide the alternator with

excitation current at engine start up.

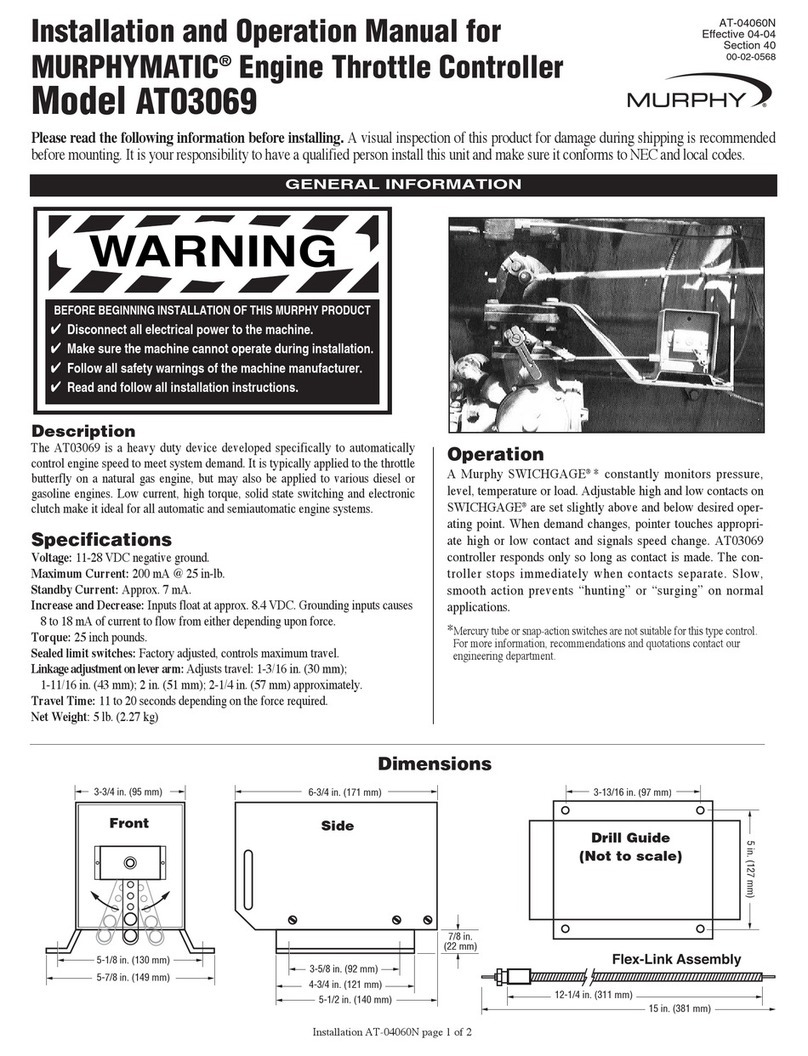

Installation

The Keystart uses a DIN standard 96 x 96 mm casing,

designed for mounting in a control panel cut-out (92 x 92mm

DIN). Electrical connection is through a pair of ‘two-part’

type terminal blocks at the rear of the unit, with 2 separate

¼” blade terminals on overspeed versions for the

tachometer or calibration meter.

Also at the rear is are 4 switches for the setting of the

supply voltage and alarm input configurations, and up to 3

potentiometers: one to set the fault ‘override’ time (all units),

and 2 more to set the speed calibration and overspeed trip

level, where fitted.

When ordering, please specify:–

a) Base unit type:-

Keystart 9700: no overspeed

Keystart 9701: magnetic pickup sensing overspeed

Keystart 9702: AC alternator (50/60Hz) overspeed

b) Options:-

‘A’: auxiliary control/preheat option

N.B: stock units are supplied with switch settings for 24VDC

power supply, inputs closing to –ve DC during fault.

Typical Connection Circuit

RPM/Calib.

Meter

L

N

30

29

Start

Emergency

Stop

Start

+

1

–

only)

15

63

Plant Fail

HET

LOP

2

5

–

+

WL

Generator AC

(KEY9702 only)

(KEY9701 only)

15

Rear Facia Settings & Electrical Connection

Charge fail input

+ve DC power supply

Aux. input ('A' option)

Mag. pickup input (KEY9701 only)

Alarm output: –ve DC, < 250mA

Aux./preheat output: +ve DC

('A' option only)

- No connection -

- No connection -

- No connection -

- No connection -

- No connection -

- No connection -

- No connection -

- No connection -

Note:–

Pin 5 is not used on models 9700 and 9702.

Pin 18 is not used on overspeed models 9701 and 9702.

Pins 29 and 30 are not used on models 9700 and 9701.

- No connection -

- No connection -

- No connection -

- No connection -

- No connection -

- No connection -

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

22

23

24

25

26

27

28

29

30

S1

Not

Used

Switch Settings(N.B. = up = down)

Fault Inputs:–

closed –ve

closed +ve

open –ve

open +ve

Supply:–

12 V DC

24 V DC

S2 S3S4

VR3: Fault override timer:–

< 10 to > 30 seconds

clockwise to increase

100 - 130% of nominal calibrated

speed, clockwise to increase

VR2: Overspeed trip level:–

With engine running at normal

speed, adjust VR1 until calibration

meter reads 0.75mA.

VR1: Nominal speed calibration:–

Tachometer/calibration output:–

0 – 1mA into 75 meter

VR1

+ve–ve

VR2

VR3

Input 1: Low Oil Pressure

Input 2: High Engine Temp.

Input 3: Plant Fail (9700 only)

Input 4: Plant Fail

Fuel output: + ve DC, 16A max.

Start output: + ve DC, 15A max.

Generator AC: 90 - 300 VAC

(KEY9702 only)

L

N

Since 1939

Frank W. Murphy Manufacturer

PO Box 470248, Tulsa, Oklahoma 74147, USA

Tel: + 1 918 627 3550 Fax: + 1 918 664 6146

web: http://www.fwmurphy.com

Frank W. Murphy Southern Division

PO Box 1819, Rosenberg, Texas 77471, USA

Tel: + 1 281 342 0297 Fax: + 1 281 341 6006

Incorporating Modex Automation

Church Road, Laverstock, Salisbury U.K.

Tel: + 44 1722 410055 Fax + 44 1722 410088

Pour service en Français, tél: + 44 1722 410697

web: http://www.fwmurphy.co.uk

1620 Hume Highway, Campbellfield, Vic. 3061 Australia

Tel: + 61 3 9358 5555 Fax: + 61 3 9358 5558

Murphy Switch of California

PO Box 900788, Palmdale, California 93590, USA

Tel: + 1 805 272 4700 Fax: + 1 805 947 7570

web: http://www.murphyswitch.com

Murphy de Mexico S.A. de C.V.

Blvd. Antonio Rocha Cordero 300, Fracción del Aguaje

San Luis Potosí, S.L.P. México 78384

Tel: + 52 48 206264 Fax: + 52 48 206336

Frank W. Murphy Pte, Ltd.

No. 2 Tuas South Street 2, Sprintecs Building

02-01/02, Singapore 637895

Tel: + 65 863 1398 Fax: + 65 863 0208

Frank W. Murphy Ltd. en France

Tel: +33 (1) 30 76 26 26 Fax: +33 (1) 30 76 39 89

Direct usine Tel: + 44 1722 410697