Summary

English

CHAPTER 1

Safety Instructions

1.1 Safety Notices in the Manual................................................5

1.2 Safety Notices on the Product..............................................5

1.3 Preliminary Recommendations.............................................5

CHAPTER 2

General Information

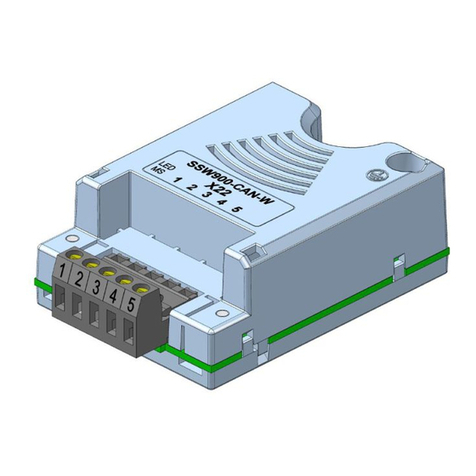

2.1 About this Manual ................................................................7

2.2 About the Soft-Starter SSW-07 ............................................7

2.3 Soft-Starter SSW-07 Identication Plate ............................8

2.4 Receiving and Storage .......................................................11

CHAPTER 3

Installation and Connection

3.1 Mechanical Installation .......................................................12

3.1.1 Environmental Conditions............................................12

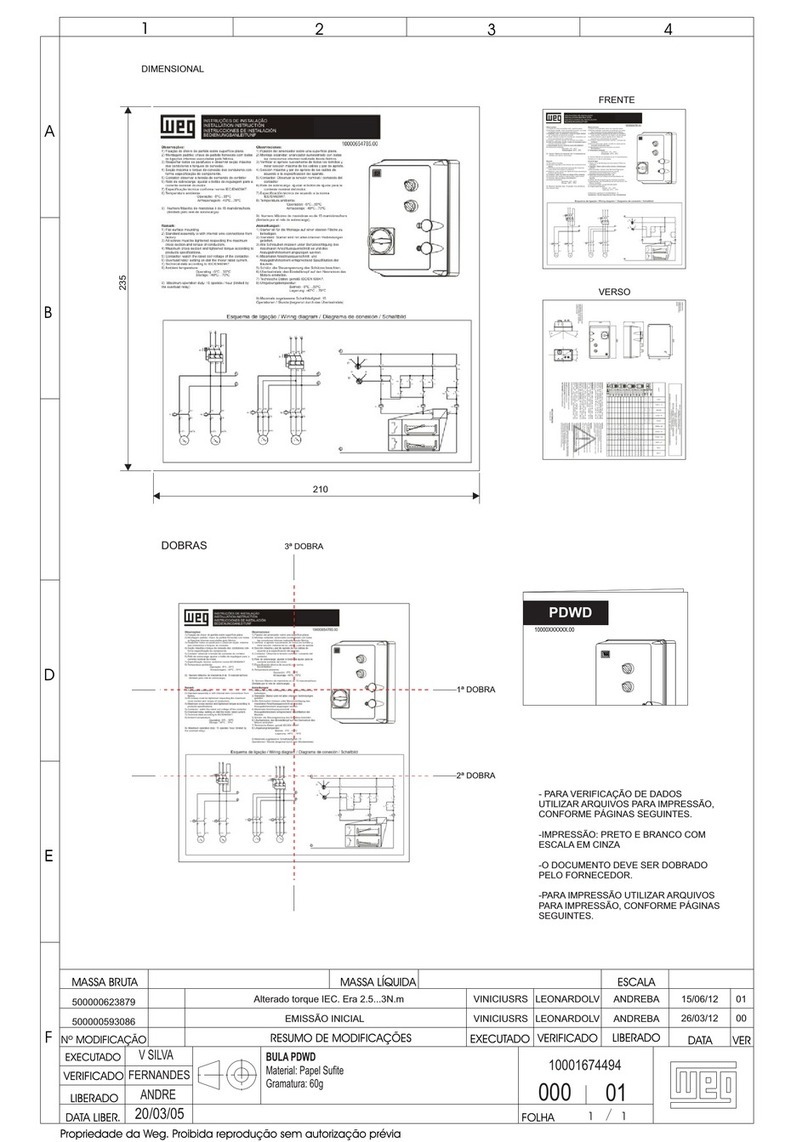

3.1.2 Soft-Starter SSW-07 Dimensions ................................12

3.1.3 Mounting Specications...............................................13

3.1.3.1 Mounting Inside a Panel .....................................14

3.1.3.2 Mounting on Surface ..........................................15

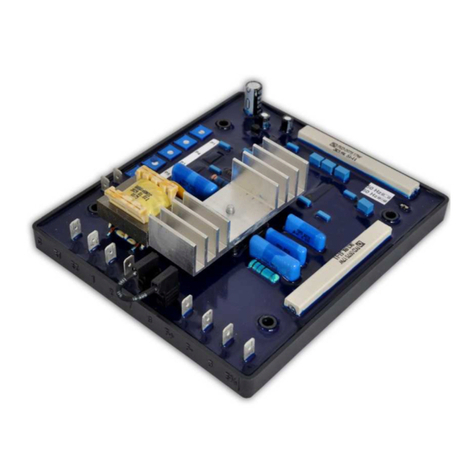

3.2 Electrical Installation...........................................................15

3.2.1 Power Terminals...........................................................16

3.2.2 Location of the Grounding, Control and Power

Connections..................................................................17

3.2.3 Recommended Power and Grounding Cables ............18

3.2.4 Power Supply Connection to the Soft-Starter SSW-0718

3.2.4.1 Short Circuit Capacity, Fuses, ................................

Circuit Breaker – UL............................................19

3.2.4.2 Input Circuit Breakers and Fuses – IEC..............20

3.2.4.3 Control Fuse........................................................21

3.2.5 Soft-Starter SSW-07 Connection to the Motor.............22

3.2.5.1 Standard Three-Wire Connection .......................23

3.2.6 Grounding Connections ...............................................23

3.2.7Control and Signal Connections...................................24

3.3 Recommended Set-ups......................................................25

3.3.1 Recommended Set-up with Command via Two-wire

Digital Inputs and Isolation Contactor..........................26

3.3.2 Recommended Set-up with Command via Three-wire

Digital Inputs and Circuit-Breaker................................26

3.3.3 Recommended Set-up with Command via Two-wire

Digital Inputs and Direction of Rotation .......................27

3.3.4 Recommended Set-up with Command via Two-wires

Digital Inputs and DC-Braking .....................................28

3.3.5 Symbols .......................................................................29