4Subject to modications

• 19, rue de Rennes • BP 83221 • F - 35690 ACIGNÉ

1. SAFETY INSTRUCTIONS

— The tractor – linkage combination must only be operated by trained and experienced personnel.

— When the tractor is tted with a front linkage and front-end loader, the user is required to unhitch the loader before using the MX front linkage (please refer

to the loader user manual for the unhitching procedure).

— CAUTION: before using of the front loader, please check the front linkage is locked (with the hydraulic tap), and the arms are folded or removed (see

chapter "folded arms position").

— Only operate the front linkage from the operators seat or by using the MX factory-supplied external controls. Keep controlling until movements stop.

— The controls for operating the front linkage must be of the "spring return" type with the exception of the oating position which may be held by a detent system.

— Do not leave the control station without stopping all control movements.

— You must ensure that nobody is in the area while the front linkage and tractor are in use.

— The transport or elevation of persons using the front linkage is forbidden.

— Before moving with a front implement tted, check and ensure that the tractor-front implement assembly is stable by tting a counter weight at the rear of

the tractor. This should ensure that 20% of the gross weight (tractor-front implement) remains on the rear axle of the tractor for optimum safety while

travelling and working.

— The maximum front axle loading specied by the tractor manufacturer must not be exceeded.

— The front tyres maximum safe load provided by the tyres’ manufacturer must not be exceeded.

— Check tyre pressures regularly.

— An implement hitched to the front linkage must be capable of being lifted through the full travel of the linkage. Any excess load impeding this travel is strictly

forbidden.

— Before any operation, the user must ensure that the front linkage is in proper working order and can be used in complete safety.

— When travelling on the road with a front implement, the front linkage must always be in a raised position and it is imperative that the regulations governing

use on the public highway be observed (size, implement markings, etc.).

— When driving on the road without a front implement, the front linkage must be set to the transport position (see "Setting the front linkage to transport

position" section).

— Whenever the tractor is stopped momentarily or for an extended period, the engine must be shut down and the linkage lowered.

— The tractor must never be towed from an anchoring point on the front linkage.

— Check periodically to ensure that safety pins and bolts are in place. Do not replace them with any other items, such as nails, wire, etc.

— Any work involving fault tracing (diagnostics) and/or disassembly of parts may only be undertaken by a skilled technician who will start with an assurance that

the work will be carried out in complete safety for himself and his surroundings.

Caution!

— The MX front linkage hydraulic system is designed to withstand a maximum operating pressure of 200 bar.

— Never make any changes to the hose connections.

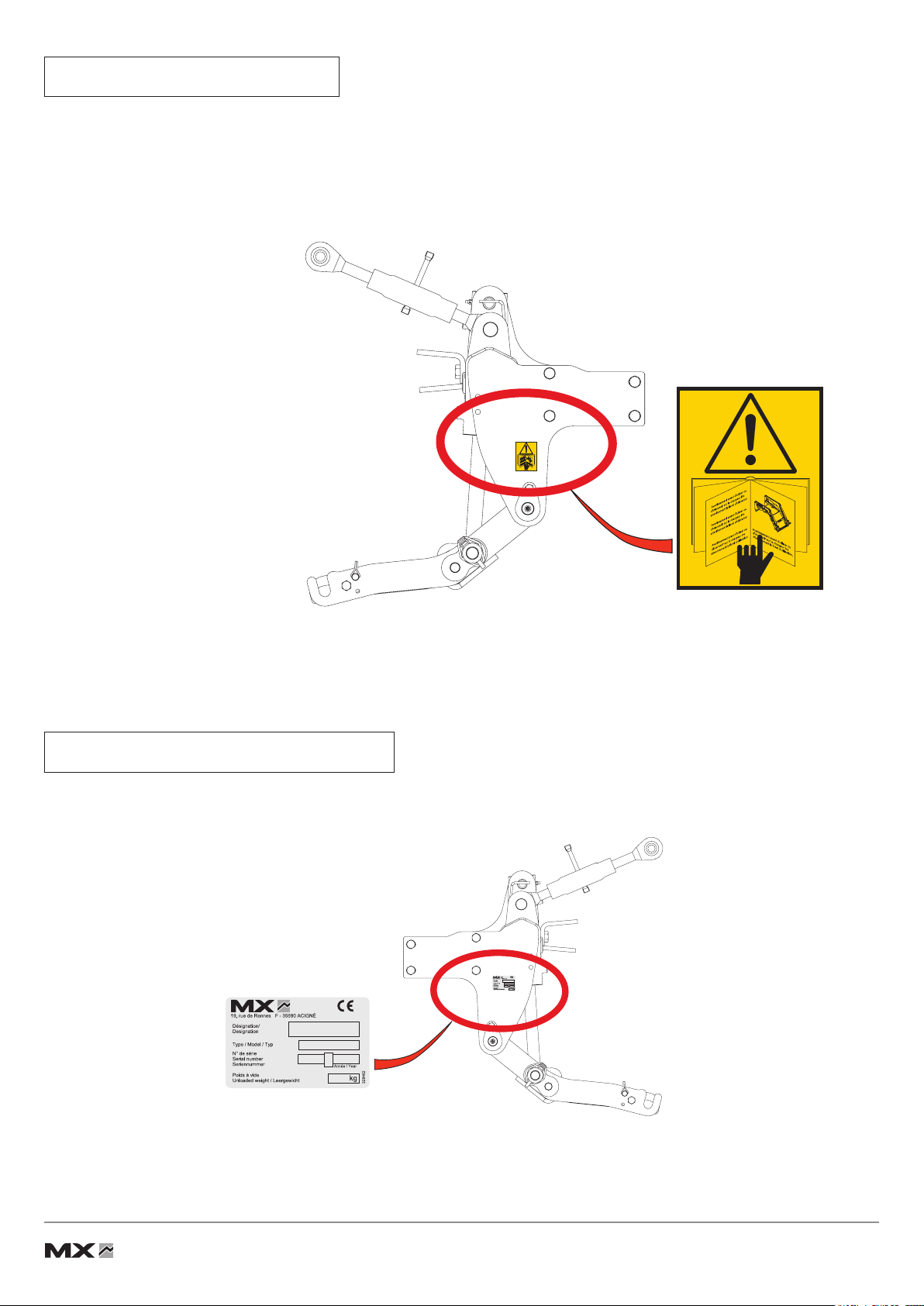

— Any instance of MX front linkage being tted which ignores the recommendations in the MX price list in force on the date of purchase will void MX warranty

on the entire MX supply.

— Any modication to any part of the MX supply (rams, arms, linkage frame, etc.) or usage of a component installed on the MX front linkage which has not

originated from MX will void MX the warranty and liability on the entire MX supply.

— Use only genuine MX spare parts. Do not modify your MX front linkage yourself or have it modied by anyone else, without applying for written authorisation

from MX in advance. Failure to comply these rules may make your MX front linkage hazardous. In the event of damage or injury, MX shall not be held

responsible in any way.

— Warranty cover will cease immediately in the event of failure to observe the standards and instructions for use and maintenance of the MX front linkage

as stipulated in the user manual.