SPECIFICATIONS

M9015SSE (12/19/12)

Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

© 2012 Pentair Ltd. All Rights Reserved.

MYERS®SX50/SX50H

USA

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.FEMEYERS.COM

PH: 888-987-8677 ORDERS FAX: 800-426-9446

CANADA

269 TRILLIUM DRIVE, KITCHENER, ONTARIO, CANADA N2G 4W5

PH: 5196065484 ORDERS FAX: 8004269446

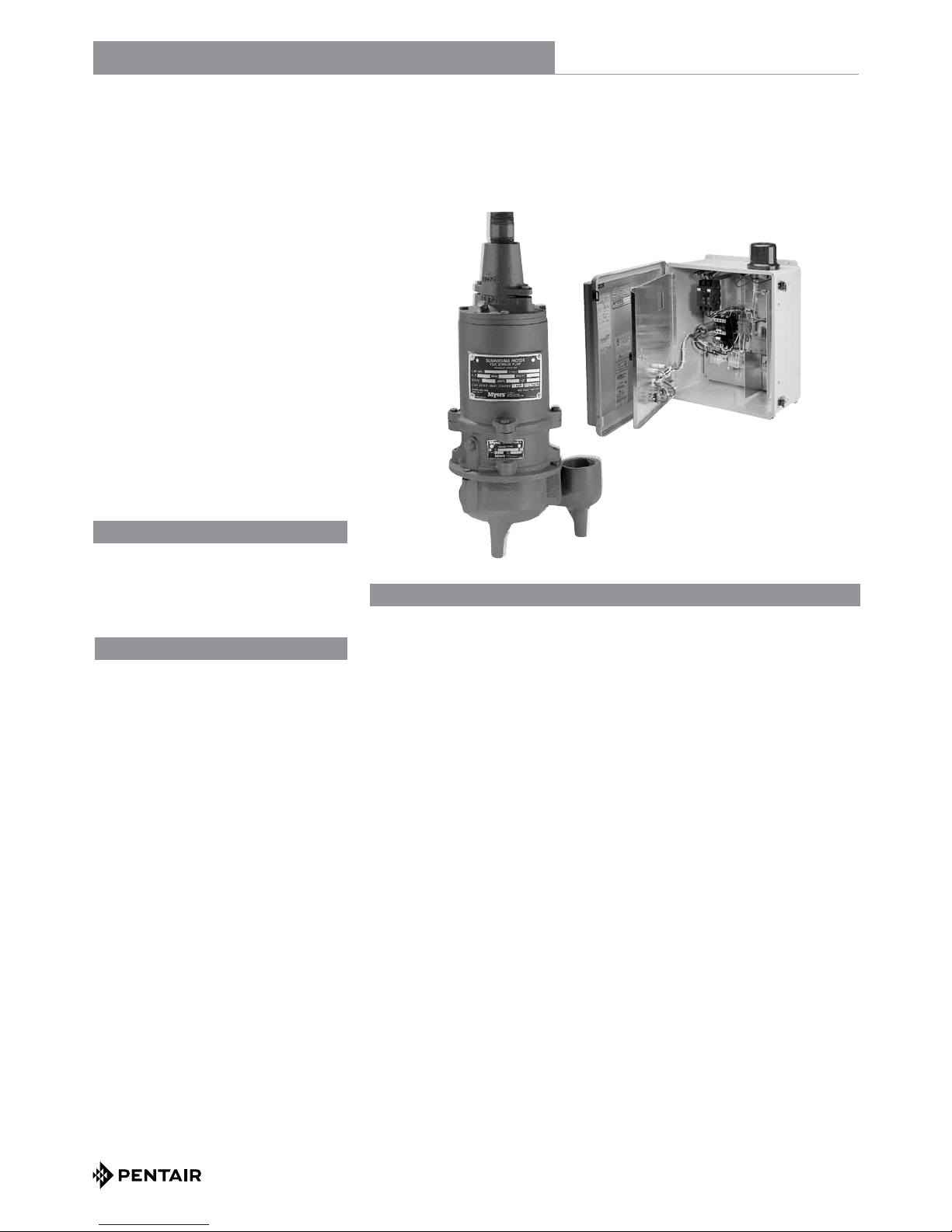

Pump Model – Pump shall be of the centrifugal type Myers model SX50/SX50H with an integrally built in submersible type motor.

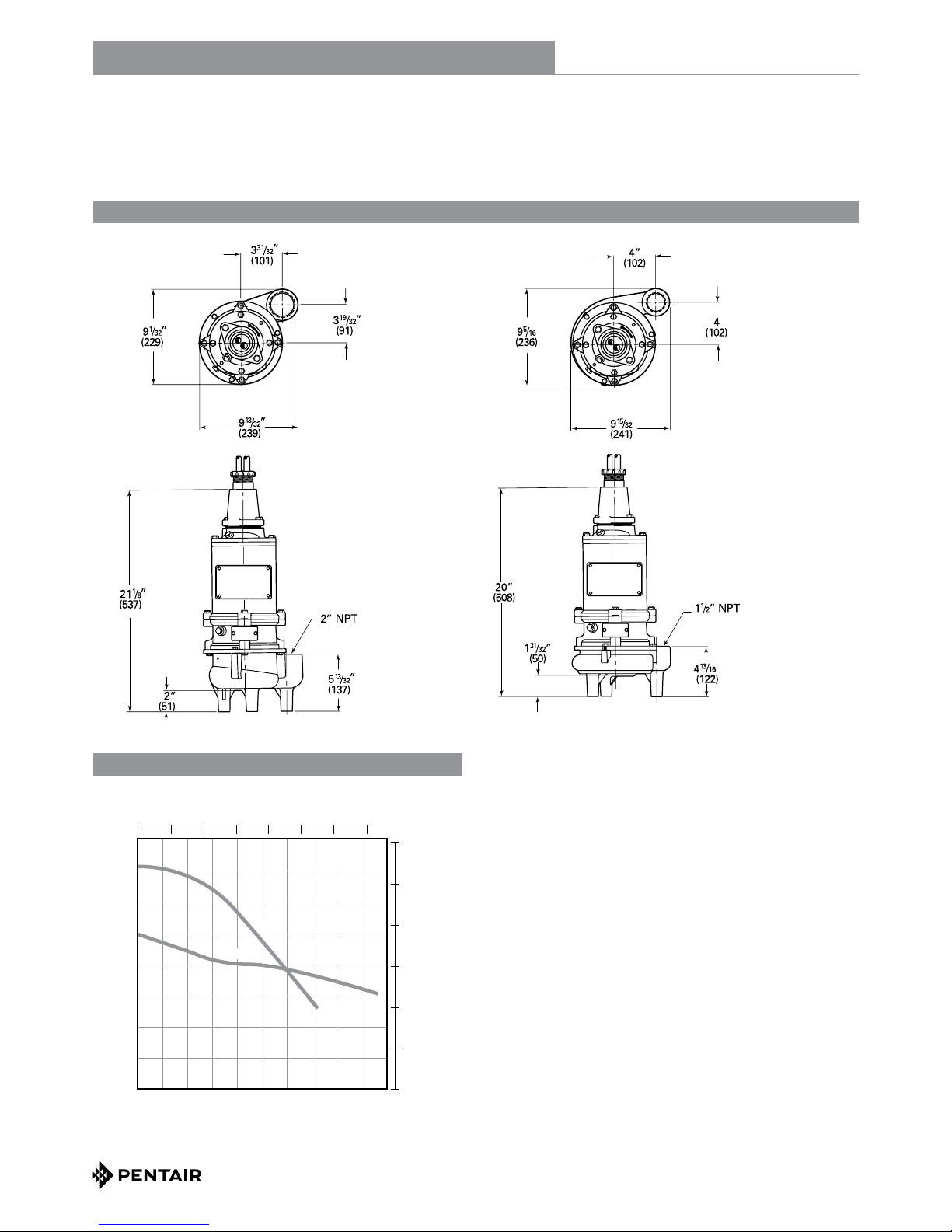

Discharge shall be 1-1/2” NPT_____ OR 2” NPT_____. Pump shall be capable of passing a full 3/4”_____ or 2”_____ diameter solid.

Motor shall be UL listed for Class 1, Div. 1, Group D.

Operating Conditions – Pump shall have a capacity of _______ GPM at a total head of _______ feet and shall use a 1/2 HP motor

operating at 1750 RPM.

Motor – Pump motor shall be of the submersible type rated 1/2 horsepower at 1750 RPM. Motor shall be for single phase 208

volts____, 230 volts____ or three phase 200 volts_____, 230 volts_____, 460 volts_____ or 575 volts_____. Single phase motors shall

be of P.S.C. type NEMA N type. Three phase motors shall be NEMA B type.

Stator winding shall be of the open type with Class B insulation good for 130°C (266°F) maximum operating temperature. Winding

housing shall be filled with a clean high dielectric oil that lubricates bearings and seals and transfers heat from windings and rotor

to outer shell. Air-filled motors which do not have the superior heat dissipating capabilities of oil-filled motors shall not be

considered equal.

Motor shall have two heavy duty ball bearings to support pump shaft and take radial and thrust loads and a sleeve guide bushing

directly above the lower seal to take radial load and act as flame path for seal chamber. Ball bearings shall be designed for 50,000

hours B-10 life. Stator shall be pressed into motor housing.

A heat sensor thermostat shall be attached to top end of motor winding and shall be connected in series with the magnetic contactor

coil in control box to stop motor if motor winding temperature reaches 221°F. Thermostat to reset automatically when motor cools.

Two heat sensors shall be used on 3 phase motors.

The motor pump shaft shall be of #416 stainless steel threaded to take pump impeller.

Seals – Motor shall be protected by two mechanical seals mounted in tandem with a seal chamber between the seals. Seal chamber

shall be oil filled to lubricate seal face and to transmit heat from shaft to outer shell.

Seal face shall be carbon and ceramic and lapped to a flatness of one light band. Lower seal faces shall be _______ carbide

(optional).

A double electrode shall be mounted in the seal chamber to detect any water entering the chamber through the lower seal. Water in

the chamber shall cause a red light to turn on at the control box. This signal shall not stop motor but shall act as a warning only,

indicating service is required.

Pump Impeller – The pump impeller shall be of the recessed Myers type to provide an open unobstructed passage through the volute

for solids. Impeller shall be of cast iron and shall be threaded onto stainless steel shaft.

Pump Case – The pump case shall be designed for a recessed vortex impeller and have unobstructed passageways

to handle full spherical solids. The pump volute shall be constructed of Class 30 gray cast iron.

Motor Castings – The motor housing castings shall be high tensile strength Class 30 gray cast iron.

Corrosion Protection – All iron castings shall be pretreated with phosphate and chromic rinse and to be

painted before machining and all machined surfaces exposed to the sewage water to be repainted. All fasteners

to be 302 stainless steel.

Bearing End Cap – Upper motor bearing cap shall be a separate casting for easy mounting and replacement.

Power Cables – Power cord and control cord shall be double sealed. The power and control conductor shall be single strand sealed

with epoxy potting compound and then clamped in place with rubber seal bushing to seal outer jacket against leakage and to provide

for strain pull. Cords shall withstand a pull of 300 pounds to meet UL requirements.

Insulation of power and control cords shall be type SOOW. Both control and power cords shall have a green carrier ground conductor

that attaches to motor frame.

SUBMERSIBLE SUMP PUMPS & CONTROL PANEL PACKAGES

4