1

TABLE OF CONTENTS

NOTE:The original installation and operating instructions were compiled in English. Any other available language is a translation of the original English version.

1. SAFETY INSTRUCTIONS AND INTENDED USE......................................................................................................................................................................................2

2. DELIVERY SCOPE......................................................................................................................................................................................................................................4

3. TOOLS NEEDED.........................................................................................................................................................................................................................................4

4. OVERVIEW OF GATE OPERATOR............................................................................................................................................................................................................4

5. MECHANICAL INSTALLATION....................................................................................................................................................................................................................5

5.1 Dimensions of Gate and Operator.........................................................................................................................................................................................................5

5.2 Determine the Position of the Post Bracket...........................................................................................................................................................................................5

5.3 Post Bracket Installation........................................................................................................................................................................................................................6

5.4 Operator Mounting and Travel Distance Adjustment...........................................................................................................................................................................6

5.5 Emergency Release Mechanism..........................................................................................................................................................................................................8

5.6 Control Board Installation and Motor Wiring........................................................................................................................................................................................8

5.7 Power Wiring.........................................................................................................................................................................................................................................8

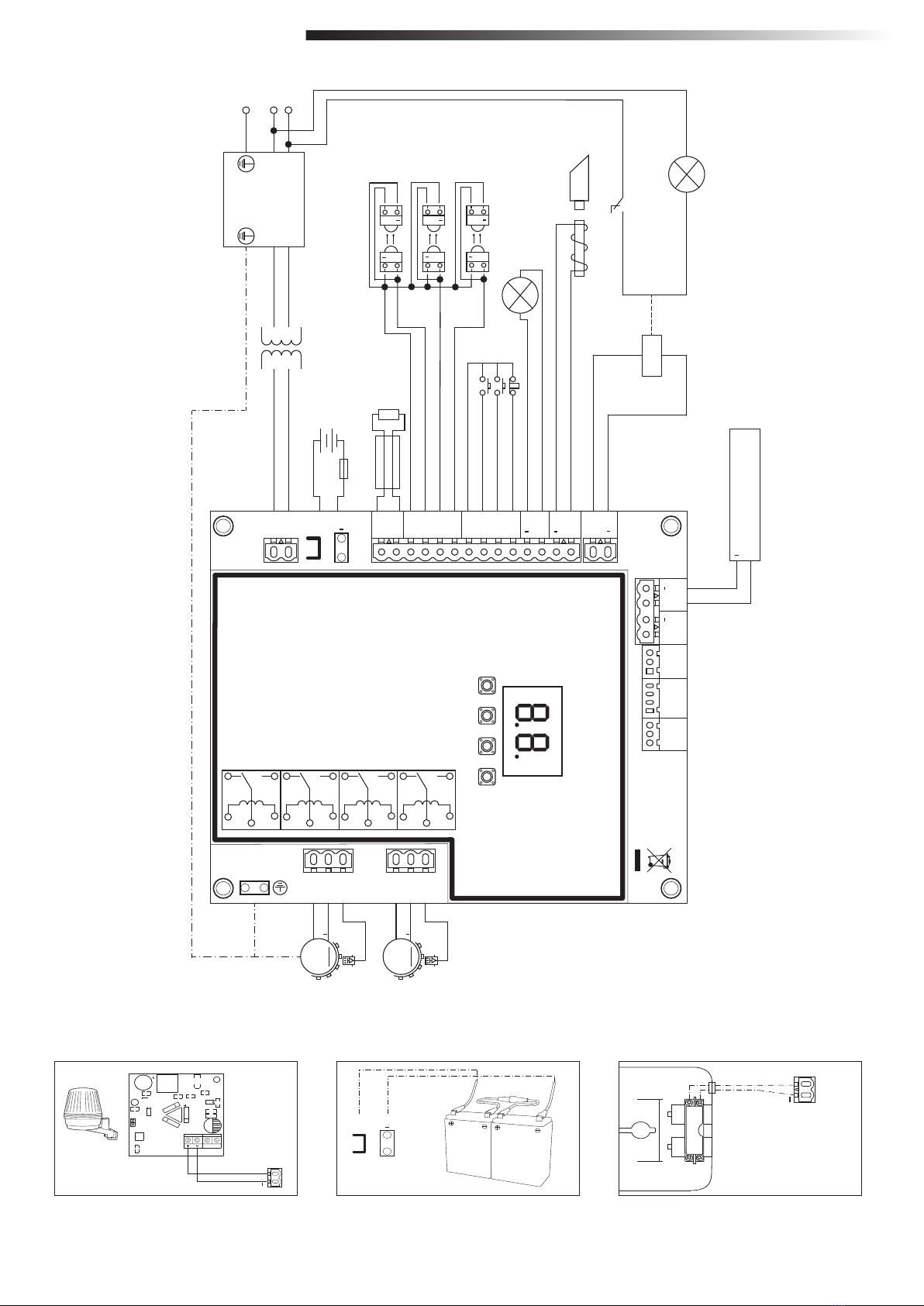

6. WIRING DIAGRAM......................................................................................................................................................................................................................................9

7. PROGRAMMING..............................................................................................................................................................................................................................................10

7.1 Display, Programming Buttons and Function Setting.........................................................................................................................................................................10

7.2 General Programming Overview..........................................................................................................................................................................................................10

7.3 Wing Movement Direction...................................................................................................................................................................................................................11

7.4 Basic Settings......................................................................................................................................................................................................................................11

7.4.1 Application Settings..................................................................................................................................................................................................................11

7.4.2 Direction Motor 1 Settings.........................................................................................................................................................................................................11

7.4.3 Direction Motor 2 Settings.........................................................................................................................................................................................................11

7.4.4 Limit Learning...........................................................................................................................................................................................................................11

7.5 Stand-by Mode....................................................................................................................................................................................................................................12

7.6 Programming and Erasing of Remote Controls, Radio Accessories and myQ Devices.......................................................................................................................13

7.7 Advanced Settings..............................................................................................................................................................................................................................14

7.7.1 Overview Advanced Settings....................................................................................................................................................................................................14

7.7.2 Transmitter Settings.................................................................................................................................................................................................................14

7.7.3 Infrared Photocells Settings......................................................................................................................................................................................................14

7.7.4 Input Settings...........................................................................................................................................................................................................................14

7.7.5 Partial Opening Motor 1.............................................................................................................................................................................................................15

7.7.6 Delay Motor 2 in Open Direction..............................................................................................................................................................................................15

7.7.7 Delay Motor 1 in Close Direction..............................................................................................................................................................................................15

7.7.8 Timer to Close..........................................................................................................................................................................................................................15

7.7.9 Reversal Time after Impact.......................................................................................................................................................................................................15

7.7.10 E-Lock / Mag-Lock Settings.....................................................................................................................................................................................................15

7.7.10a Relief Motor 1 for E-Lock.......................................................................................................................................................................................................16

7.7.11 Flashing Light Settings...........................................................................................................................................................................................................16

7.7.11a Pre-Flashing................................................................................................................................................................................................................................16

7.7.12 Special Contact Settings.........................................................................................................................................................................................................16

7.7.13 Start Speed in Open and Close Directions.............................................................................................................................................................................16

7.7.14 Maintenance Counter...............................................................................................................................................................................................................16

7.8 Factory Default Settings....................................................................................................................................................................................................................17

7.9 Finish and Exit...................................................................................................................................................................................................................................17

8. BATTERY BACKUP....................................................................................................................................................................................................................................17

9. ERROR CODES........................................................................................................................................................................................................................................17

10. TECHNICAL DATA....................................................................................................................................................................................................................................18

11. MAINTENANCE.......................................................................................................................................................................................................................................19

12. DISPOSAL.........................................................................................................................................................................................................................................19

13. WARRANTY.........................................................................................................................................................................................................................................19

14. DECLARATION OF CONFORMITY............................................................................................................................................................................................................19