Table of Contents

①User Guide...................................................................................................................................3

②System Requirements................................................................................................................4

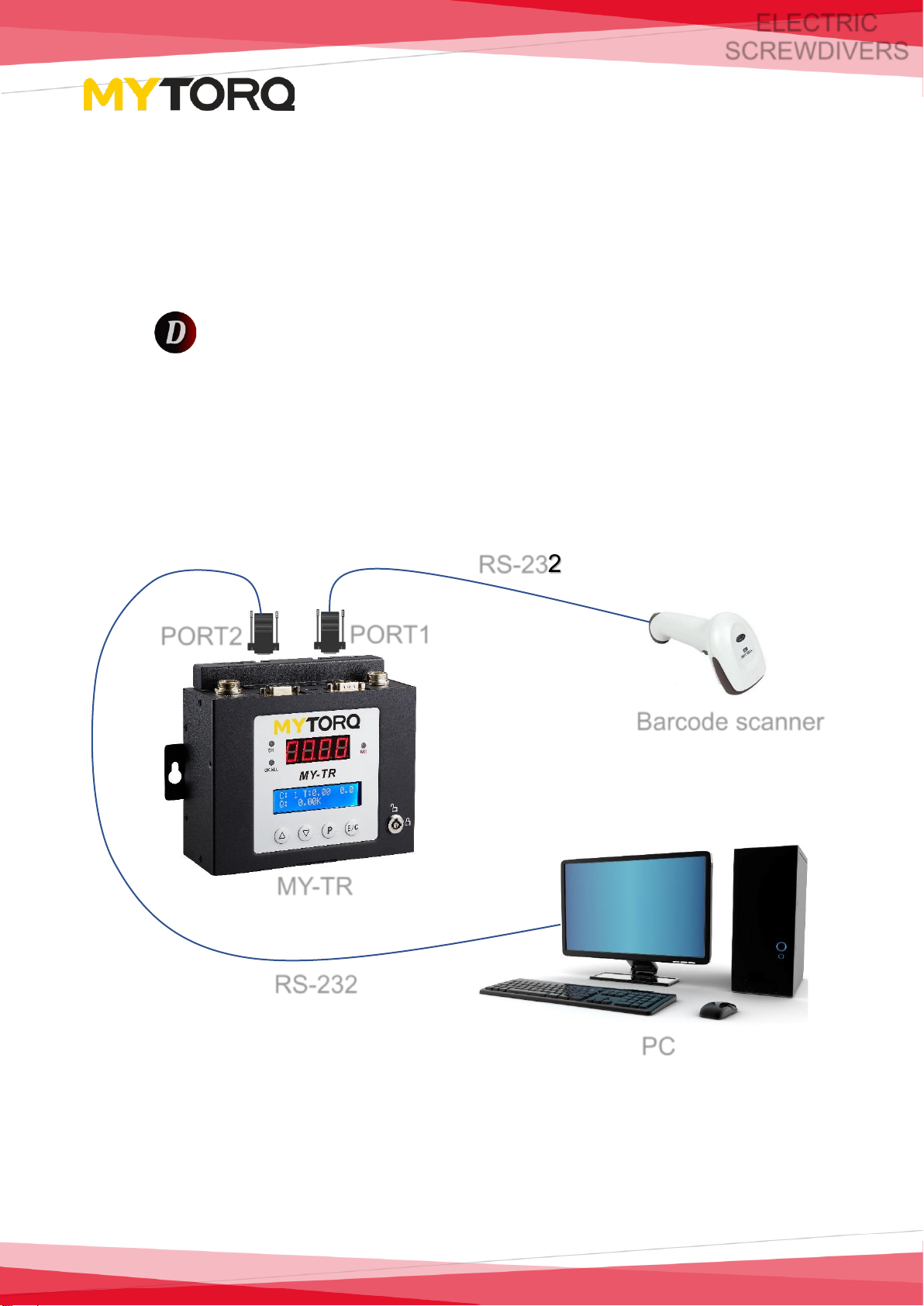

③Hardware......................................................................................................................................5

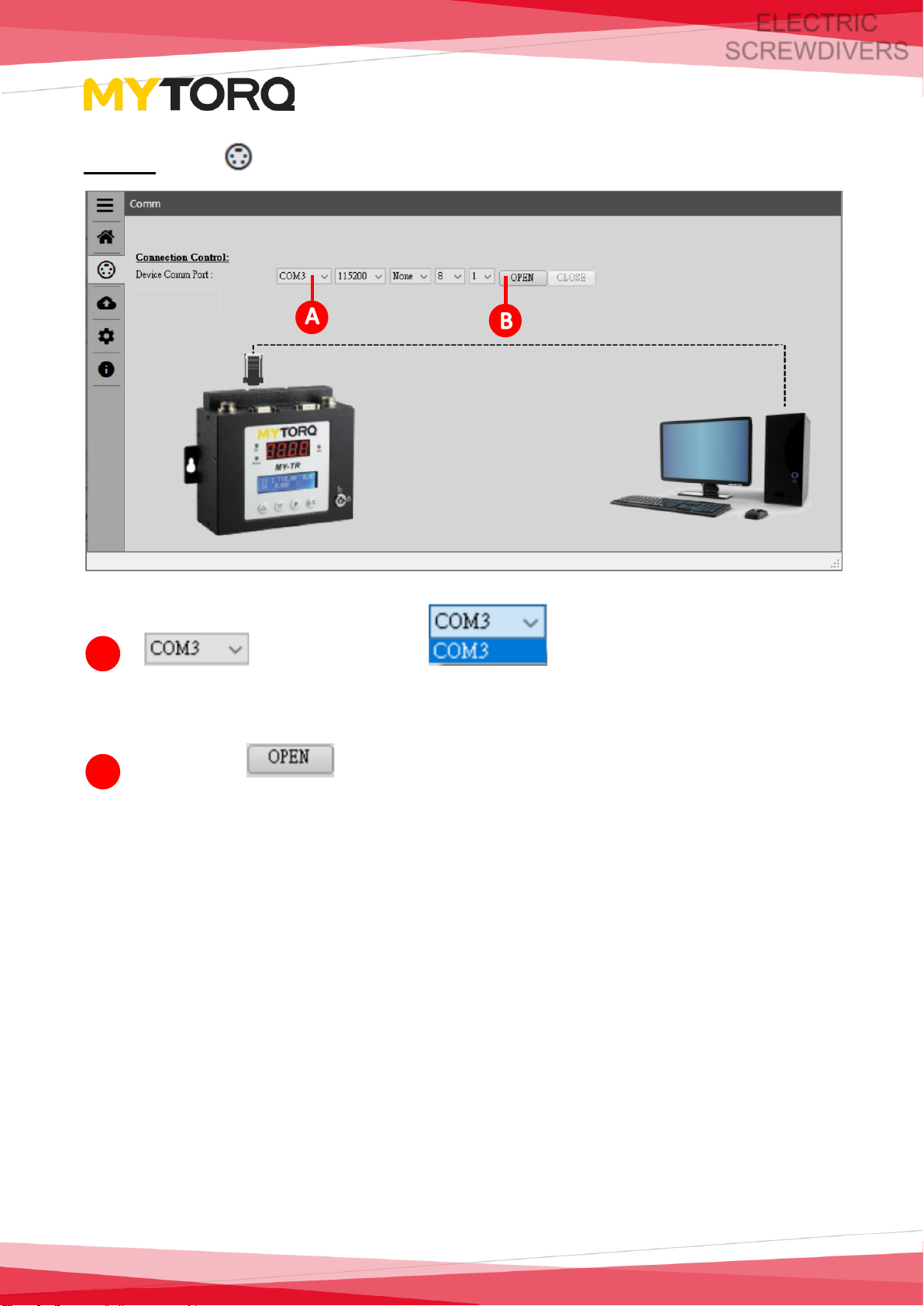

④System Connection.....................................................................................................................6

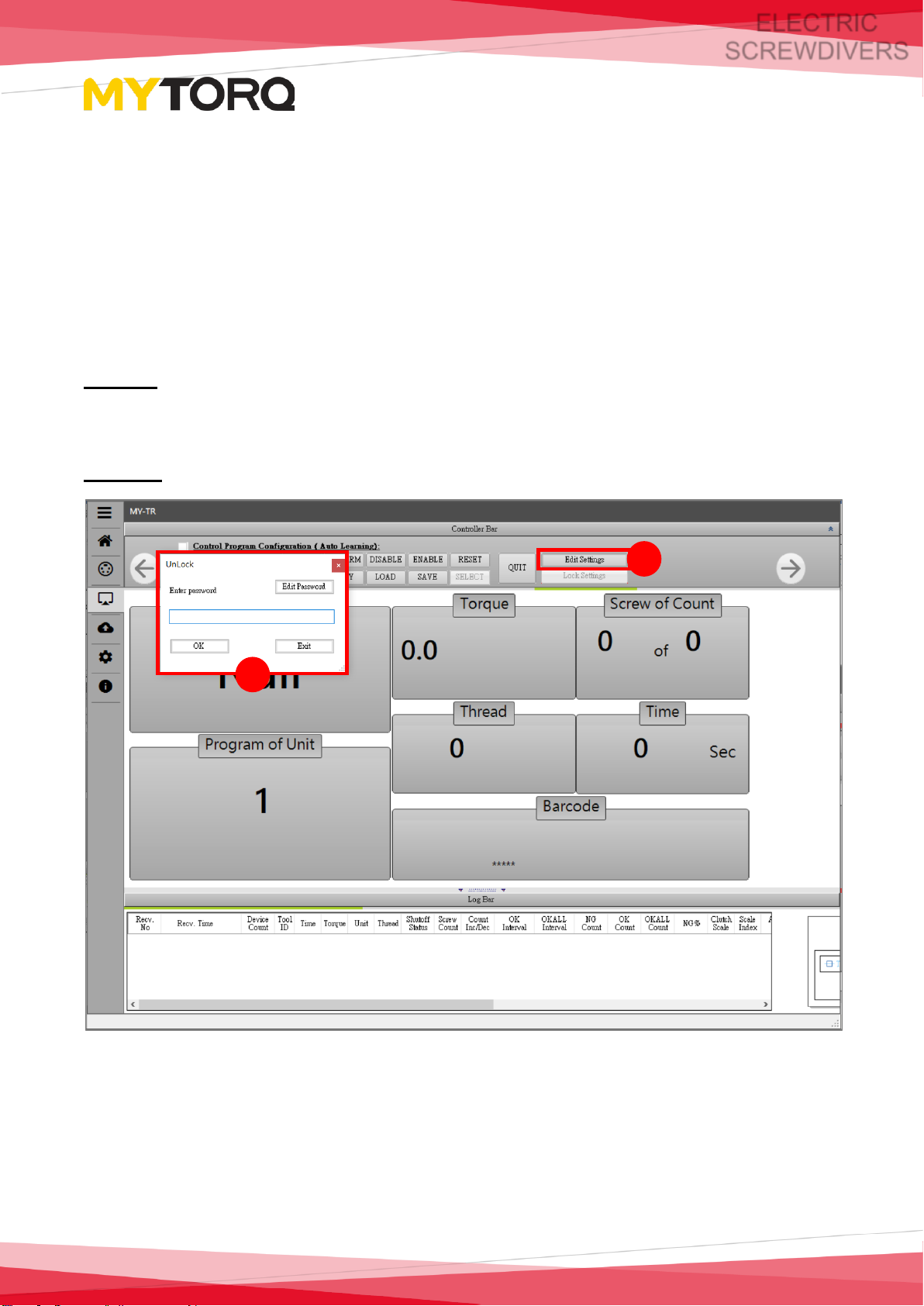

⑤System Screen Introduction ......................................................................................................9

➢Unlock Settings....................................................................................................................9

➢Password change setting method...................................................................................10

➢Restore default password ................................................................................................10

1. Product setup page...........................................................................................................11

2. Controller and Job setup page.........................................................................................28

3. Barcode Manager................................................................................................................32

4. Report and trend graph setup page.................................................................................34

5. Instant data display.............................................................................................................37

⑥Remote Screen..........................................................................................................................38

⑦System Function Setup............................................................................................................39

⑧Info Company Website.............................................................................................................41

⑨Example Description.................................................................................................................42

⑩Statement...................................................................................................................................46