N.KO PASOVEC 75 RUNNER User manual

1

MOBILE BELT GRINDER

PASOVEC 75 RUNNER

Purchase order No. 1300 – 400 V / 60 Hz

Purchase order No. 13001 – 480 V / 60 Hz

Purchase order No. 13002 – 220 V / 60 Hz

Operating manual

CHANGE RESERVED

2

Contents:

General information 3

Description of RUNNER machine 3

Identification data 4

Tests 4

Warranties 4

Safety regulations 5

Technical specification 7

Accessories 7

Device unpacking 7

Controls of RUNNER 8

Use 9

Maintenance and operation 10

Spare parts 11

List of spare parts 12

Wiring diagram 14

Basic dimensions 15

Always read the operating instructions carefully before use

3

1. General information

Thank you for purchasing one of our machines and we hope you will be fully satisfied

with it.

This manual contains all the instructions for installing, adjusting, operating and

maintaining the PASOVEC 75 RUNNER in accordance with applicable safety

standards.

The information and data in this manual may be subject to change as a

result of further machine upgrading. To resolve any doubts, please contact

N.KO Machines in case of discrepancies.

Never perform any operations on the machine before you read and understand the

instructions in the manual. Lots of accidents that occur at the workplace are caused

by not following the guidelines and recommendations contained in the manual.

Graphical symbols in this manual are used to highlight important information about

the safety and operation of the machine.

Attention:

Important information for the operator's personal safety.

Important:

Instruction to be followed to ensure the proper operation of the machine.

2. Description of the PASOVEC 75 RUNNER machine

The mobile belt grinder PASOVEC 75 RUNNER only is designed for the

following activities:

The mobile belt grinder PASOVEC 75 RUNNER is designed for grinding at a workshop

or a production hall.

This is a hand-driven machine. Only use the machine in an environment protected

from rain, snow and other adverse weather conditions.

Mobile belt grinder PASOVEC 75 RUNNER - Mobile sander PASOVEC 75

RUNNER – the special belt grinder developed for flat grinding applications.

Particularly for grinding of the welds in the material surface and further for removal

of the undesirable layer resulting from the rolling of metal sheets or after metal

sheet cutting by means of plasma or oxygen.

The machine has a stable chassis, a quick adjustment mechanism and a depth stop

for precise grinding depth adjustment.

4

• Continuous grinding depth adjustment

• System for the quick working mode deactivation

• The workplace of flat grinding of small workpieces

• Low operating costs

Purchase order No.

1300 – 400 V / 60 Hz

13001 – 480 V / 60 Hz

13002 – 220 V / 60 Hz

3. Identification data

The identification data of the PASOVEC 75 RUNNER mobile grinder are listed on the

label attached to the machine body.

4. Tests

The PASOVEC 75 RUNNER mobile grinder is tested in our technical testing room.

During this test the correct function of the machine is tested.

5. Warranties

The seller provides for the PASOVEC 75 RUNNER mobile belt grinder the warranty

that the goods will be free of any material and manufacturing defects for the period

of 12 months from the date of the goods delivery.

The warranty of the perfect operation of the goods and the used materials is 12

months from the date of the goods delivery.

The seller undertakes to remove any defects covered by the warranty free of charge

and without undue delay so that the buyer can properly use the goods. If the buyer

applies the rights of liability for defects not covered by the warranty, he shall pay to

the seller any costs associated with the warranty.

5

The manufacturer considers the warranty invalid in the case of:

• machine misuse.

• use contrary to national or international standards

• incorrect installation

• faulty power supply

• serious maintenance deficiencies

• unauthorized modifications or interventions

• Using other than original and factory-approved spare parts and accessories for

the model in question

• Complete or partial non-compliance with the instructions in this manual

• exceptional events, natural calamities, or others.

6. Safety regulations

Attention:

To avoid injury, observe the following

Before starting work make sure the machine is not mechanically or otherwise

damaged.

Only operate the machine if the power cord is not damaged. Regularly

check the condition of the machine and the supply cable. In the event of

damage, have it replaced immediately by a workshop authorized to carry out such

repairs. Contact your supplier.

The employer is obliged to inform operators about safety standards and make sure

that they are complied with. Make sure the work space is large enough and well lit.

"Operator" means a person who installs, operates, adjusts, maintains, cleans and

repairs the machine.

Attention:

Prior to work commencing the operator must become familiar with

the machine's features and must read this entire manual.

Attention:

When working with the machine, take increased care and wear safety aids for safe

work.

6

Operator (s) must always:

1. Make sure before the machine starts that all safety covers are mounted and

that the safety devices are functional.

2. Avoid wearing the type of clothing or jewellery that might be caught in

moving parts.

3. Wear approved safety clothing, such as footwear with non-slip sole, hearing

protectors, and safety goggles.

4. Apply safety standards, see that they are always upheld, and in case of any

doubts, look again in this manual before taking any action.

5. Contact the machine supplier if the defects that cause the machine to

malfunction cannot be remedied when the defects relate to faulty parts or

irregularities.

Safety device

The machine is equipped with an emergency button. It is red, and stops the

machine immediately before all other operations.

This emergency button is used:

• To turn off the machine

• In case of immediate danger or mechanical accident

Remaining risks

The machine has been designed and manufactured with all the equipment and

equipment to ensure the health and safety of the operator.

The machine is designed in such a way that the risk of contact with movable

parts is as low as possible.

7

7. Technical specification

PASOVEC 75 RUNNER

Voltage (V)

400 V (220 V, 480 V)

Frequency (Hz)

60 Hz

Motor(kW)

3 Kw

Belt speed (m/s)

30 m/s

Size of grinding belt (mm)

75X2000 mm

Weight (kg)

70 kg

W x H x L (mm)

610x944x1419 mm

8. Accessories

Purchase order No. BELT STANDARD ZK75X2000

Universal grinding belt 75x2000mm, grain optional 36, 60, 80 or 120 (package of 10

pcs)

Purchase order No. PAS top Quality XK75X2000

TOP Quality grinding belt is designed for grinding stainless steel 75x2000mm,

optional grain 36, 60, 80 or 120 (package of 10 pcs)

9. Device unpacking

Unpack the machine from a wooden box and check that everything is OK and the

machine is undamaged. If you have any questions, please contact your reseller.

Mobile belt grinder PASOVEC 75 RUNNER is supplied:

Belt grinder PASOVEC 75 RUNNER

Packed in the wooden box

1 pc of the grinding belt, grain 80

Operation manual

8

10. Controls of the mobile belt grinder PASOVEC 75

RUNNER

1. Securing the machine in the non-working position (transport

mode)

2. Power supply connection and ON/OFF control

3. Emergency switch

4. Belt centering mechanism

5. Removal adjustment mechanism

9

11. Use

Always unplug the power supply before adjusting the machine.

1. Release the mechanism lever to secure the machine in the transport position

(pos. 1)

2. Using the removal adjustment mechanism (pos.5), ensure that the contact

wheel with the abrasive belt is slightly touching the material. Set the removal

mechanism adjustment before using the machine to the position so that it has

sufficient power for subsequent removal adjustment.

3. Re-secure the machine lock lever in the transport position (pos.1)

4. Connect the appliance to the power supply (pos. 2). Before connecting to the

power supply (pos. 2), always make sure that the device is not damaged.

5. Press the green button to start the device

6. Set the desired removal depth. Hold the device behind the control handle to

prevent the machine from starting spontaneously. Start with the less removal

and gradually increase the value until the machining depth matches your

requirement or working with the machine is still comfortable.

7. Hold the control handle firmly and press the machine in front of you to start

the grinding process.

8. Adjust the size of the removal as required, see point number 2.

9. When finished, turn the appliance off with the red button and disconnect it

from the power supply.

Attention:

When adjusting, use gloves and other personal protective equipment. The

operations must be performed on the machine at rest and after

disconnection from the power supply.

10

12. Maintenance and operation

Pay attention to the maintenance of the drive and contact wheel. Monitor their wear

and weighing. Remove dirt. Regularly clean and maintain the cleanness of the

outside of the grinder and remove the shredded material and dust from the outlet

and the inside of the grinder.

Important:

Pay the increased attention to the wear of the graphite pad on the flat

grinding surface. In case of its wear, excessive friction occurs and

overloading and consequent damage to the machine may occur.

Belt replacement

We only can achieve satisfactory grinding results when using a completely clean

grinding belt. Otherwise, the belt must be replaced.

This can be done by unlocking the handle of the eccentric mechanism that tensions

the belt. After removing the grinding belt and replacing it with the new one return

the eccentric handle to its original position.

Proceed as follows:

- Switch off the machine.

- Make sure that the belt is completely at rest.

- Use the Allen key to open the side cover.

- Loosen the belt using the belt tension lever.

- Replace the belt.

- Check the condition of the graphite pad on the flat grinding surface

- Tension the belt using the belt tension lever.

- Close and secure the side cover.

- Before starting maintenance, disconnect the power supply from the socket

first. Adjustment, lubrication and maintenance must be carried out when the

machine is completely at rest.

11

13. Spare parts and accessories

Purchase orders for spare parts must contain the following information:

• Machine type

• Serial number

• Description of the required part and its number

• Quantity

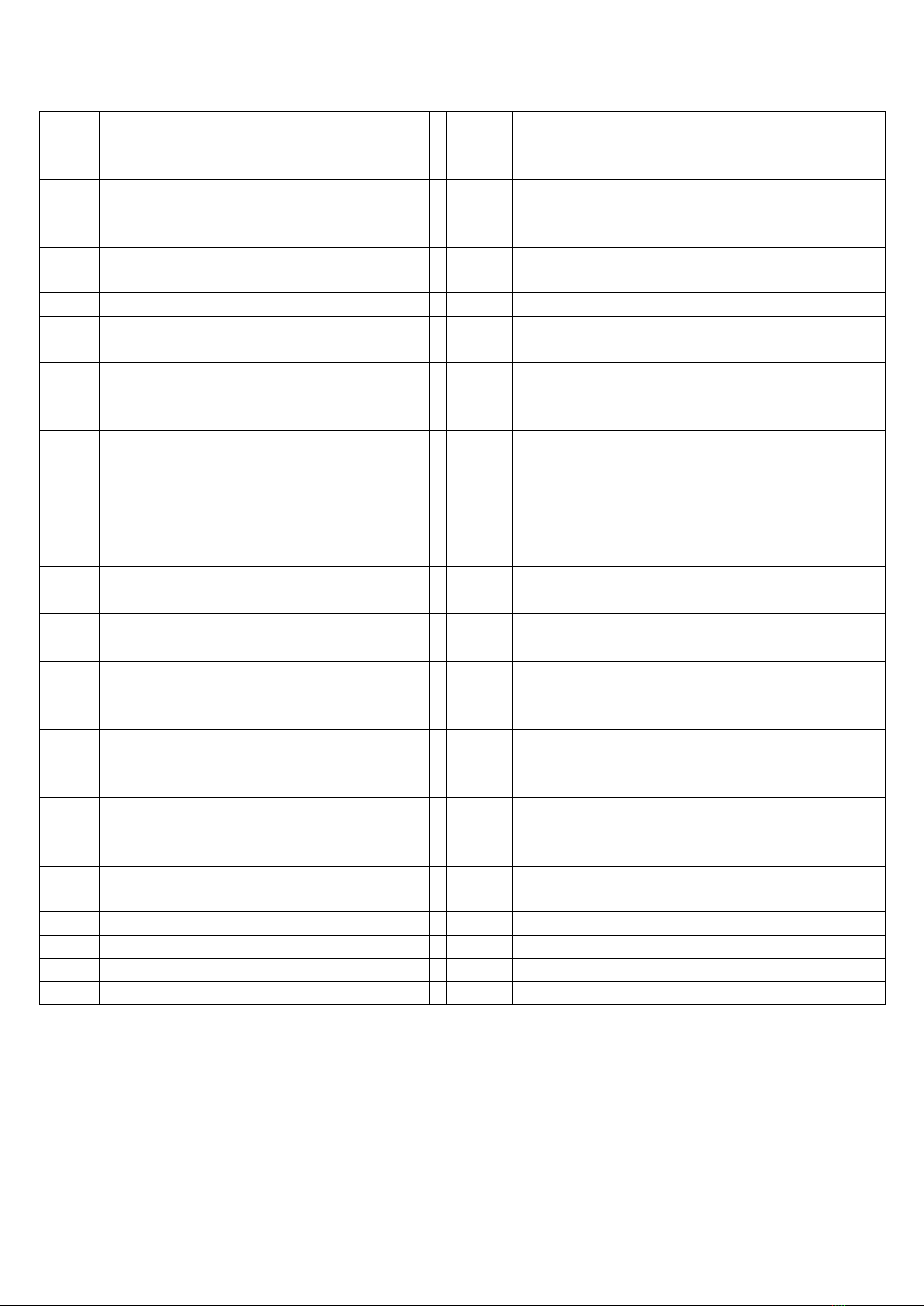

13.1 List of spare parts

12

PART

NO.

DESCRIPTION

QTY

Art. Nr.

PART

NO.

DESCRIPTION

QTY

Art. Nr.

1

SUPPORT

ASSEMBLY

1

1300_1

46

SUPPORTING

PLATE

1

1300_46

2

JOYSTICK

1

1300_2

47

BLACK LEAD

PLATE

1

307518/1

3

FIFTH WHEEL

1

1300_3

48

BEIVEN WHEEL

GUIDE

1

1300_48

4

HANDLE

1

1300_4

49

HANDLE

1

1300_49

5

HANGER

BEARING

1

1300_5

50

TAPER KNOB

1

1300_50

6

WHEEL

2

1300_6

51

SPRING

1

1300_51

7

WHEEL AXLE

1

1300_7

52

TENSION SPRING

2

1300_52

8

PULL RING

2

1300_8

53

SPRING

1

1300_53

9

REGULATING

PLATE

2

1300_9

54

HANDWHEEL

1

BS75X2000_22

10

MECANUMWHEEL

2

1300_10

55

WEDGE LOCK

1

BS75X2000_21

11

DISTANCE

SLEEVE

2

1300_11

56

DRIVEN GEAR

1

BS75X2000_11

12

GOBE

1

1300_12

57

ABRASIVE BAND

1

1300_57

13

MAIN SWITCH

1

1300_13

58

DRIVING WHEEL

1

BS75X2000_59

14

JUNCTION BOX

1

1300_14

59

HANDLE

CONNECTING

ROD

1

1300_59

15

HANDWHEEL

1

1300_15

60

BIANMENMEN

COVER

1

1300_60

16

FIXED PIPE

1

1300_16

61

LOCATING BUSH

2

1300_61

17

LIFTING PIPE

1

1300_17

62

PLATE

1

1300_62

18

SCREW M12

1

1300_18

63

HANDLE

1

1300_63

19

FIXED CASTER

1

1300_19

64

HINGE

4

1300_64

20

HANDLE

1

1300_20

65

GEARSHIFT

LEVER KNOB

1

1300_65

21

HEXAGON

HEADED BOLT

M10X120

1

1300_21

66

PATTERN

HANDLE

2

1300_66

22

WASHER Φ10

1

1300_22

67

HOLE CHECK

RING

2

1300_67

23

LOCKNUT M10

1

1300_23

68

WHEEL AXLE

1

1300_68

24

WASHER Φ14

6

1300_24

69

HINGE PIN

1

1300_69

25

NUT M14

4

1300_25

70

HEXAGON

SOCKET

COUNTERSUNK

HEAD

SCREWM8X16

4

1300_70

26

SCREW M6X50

1

1300_26

71

HEXAGON HEAD.

BOLT M8X12

2

1300_71

13

27

LOCKNUT M6

1

1300_27

72

HEXAGON

HEADED BOLT

M8X25

4

1300_72

28

SCREW M4X8

2

1300_28

73

HEXAGON

HEADED BOLT

M8X20

3

1300_73

29

WASHER Φ4

2

1300_29

74

BUTTON HEAD

SCREW M8X20

2

1300_74

30

NUT M4

2

1300_30

75

NUT M8

4

1300_75

31

SCREW M6X10

4

1300_31

76

BUTTON HEAD

SCREW M4X6

16

1300_76

32

HEXAGON

HEADED BOLT

M8X12

4

1300_32

77

INNER HEXAGON

SCREW M6X20

1

1300_77

33

WAD

16

1300_33

78

HEXAGON

HEADED BOLT

M6X14

1

1300_78

34

HEXAGON

HEADED BOLT

M8X30

4

1300_34

79

WASHER Φ35XΦ

8X3

1

1300_79

35

LOCKNUT M12

2

1300_35

80

SPRING WASHER

Φ8

9

1300_80

36

LOCKNUT M8

2

1300_36

81

COTTER PIN Φ

3X20

1

1300_81

37

HEXAGON

HEADED BOLT

M8X20

9

1300_37

82

INNER HEXAGON

SCREW M5X20

1

1300_82

38

SCREW

6

1300_38

83

DEEP GROOVE

BALL BEARINGS

6204

2

1300_83

39

THRUST

BEARING 51101

2

1300_39

84

WASHER Φ6

1

1300_84

40

HINGE

2

1300_40

85

NUT M6

2

1300_85

41

ELECTRIC

MACHINE

1

1300_41

86

LOCKNUT M6

1

1300_86

42

FUSELAGE

1

1300_42

87

43

WICKET DOOR

1

1300_43

88

44

TOP TABLE

1

1300_44

89

45

U -SUPPORT

1

1300_45

90

14

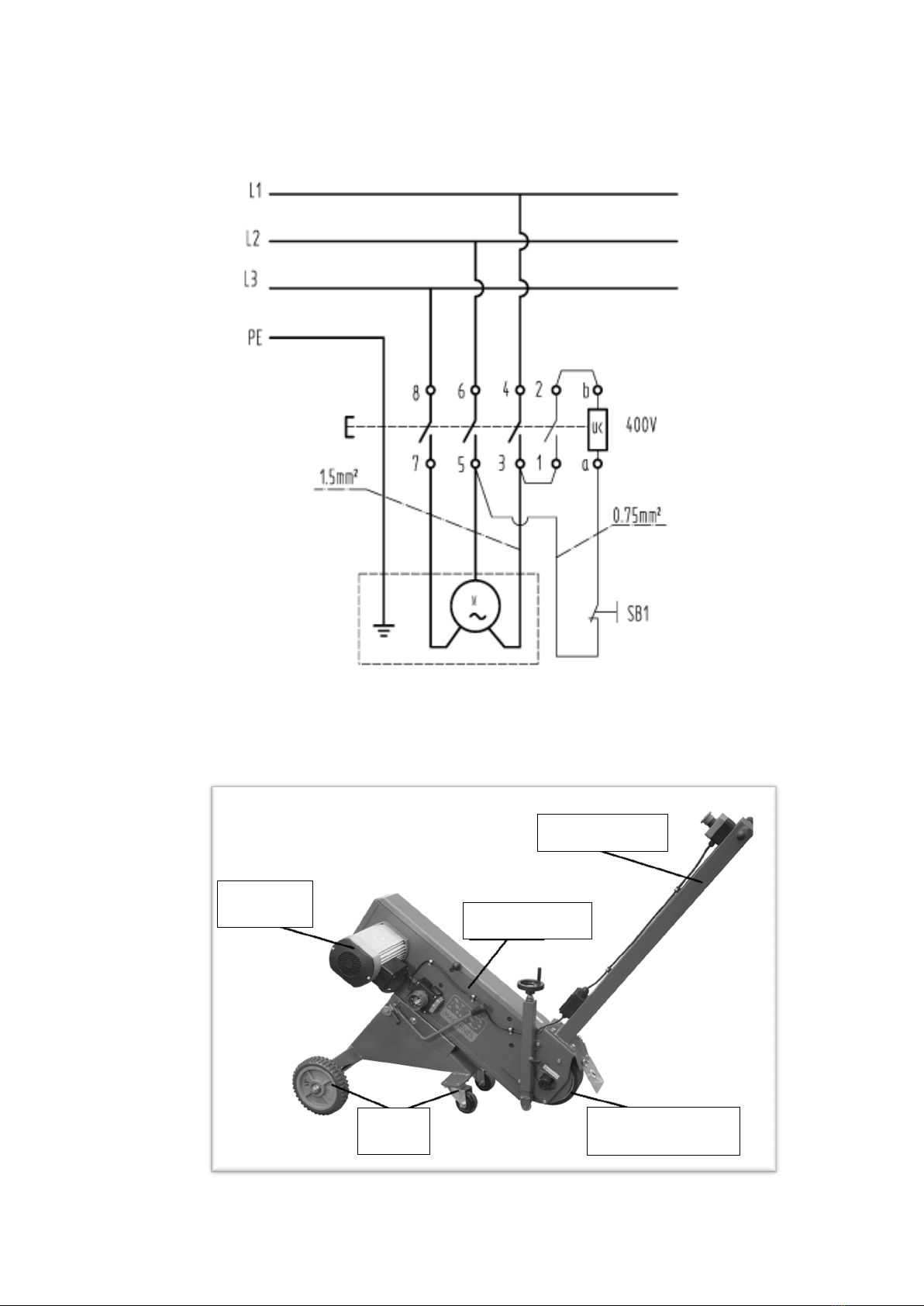

13.2 Wiring diagram

13.3 Basic dimensions and parts of the PASOVEC 75 RUNNER

mobile belt grinder

Control handle

Grinder body

Contact wheel

travel

Engine

15

A copy of this manual comes with each RUNNER machine.

All rights reserved.

No part of this publication may be reproduced without the prior consent of N.KO

N.KO spol. s r.o.

Táborská 398/22

293 01 Mladá Boleslav

The Czech Republic

phone: +420 326 772 001

BEVELER USA INC.

a Member of Richtr Group

producer of bevelling machines

328 14th Street

Ambridge, PA 15003

6538 Collins Avenue, #286

Miami Beach, FL 33141

Table of contents