MAINTENANCE / REPAIR TROUBLESHOOTING OPERATION ASSEMBLY / INSTALLATION SAFETY / SPECIFICATIONS GETTING STARTED

4

SAFETY RULES (CONTINUED)

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

• Focus your attention completely on your work. Looking

around, careless actions and other distractions can result in

serious injury.

Preparing the work area for your job

• Do not use this machine in dangerous environments. Do not

use it in damp or wet locations. Do not expose it to rain.

• Keep the work area clean. Cluttered work areas and work

benches invite accidents. Keep the area around the machine

clean of scrap metal, oil and grease.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

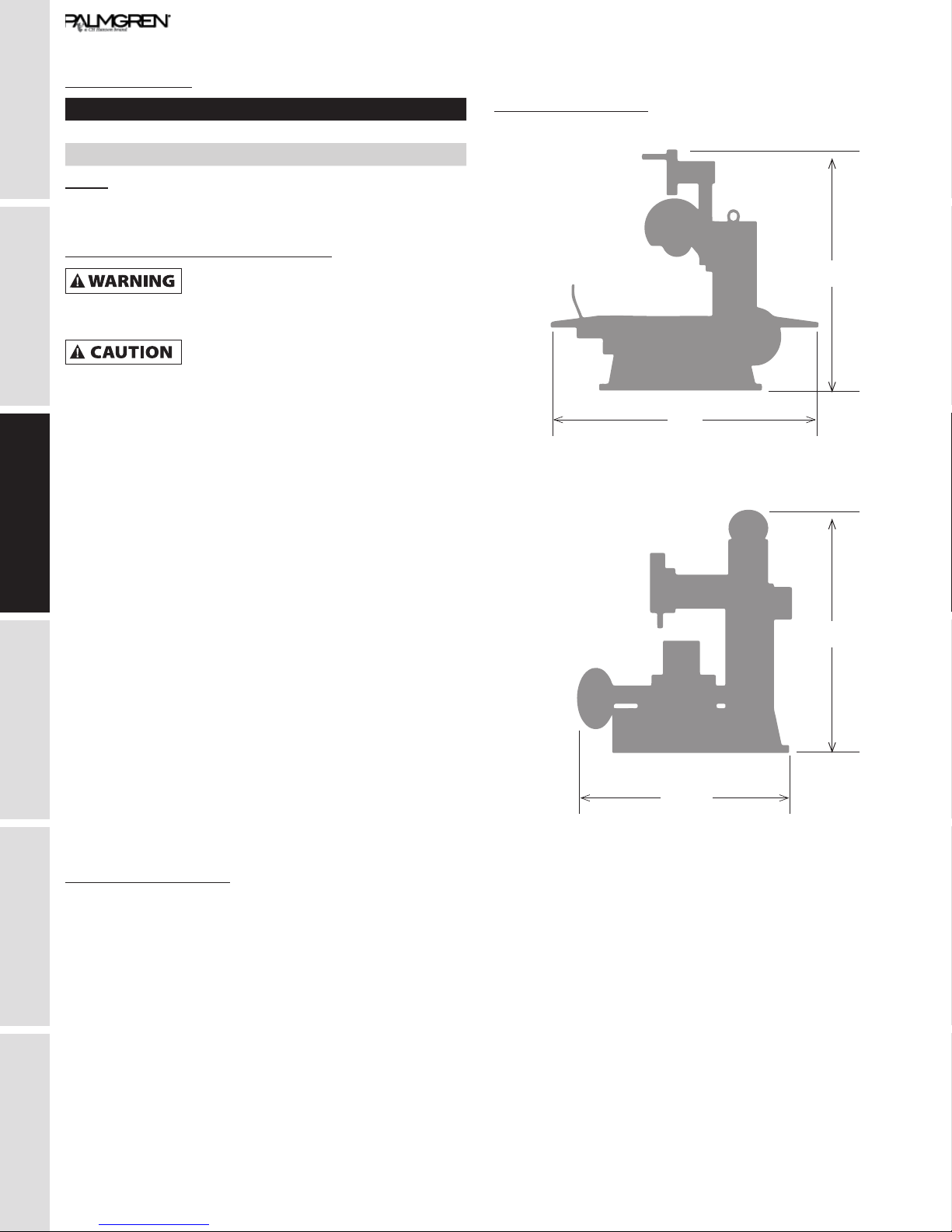

• Provide adequate space around the surface grinder and light

the area properly with non-glare, overhead lighting.

• Make certain the surface grinder is securely anchored to a

suitable base or floor stand before use.

Maintaining your tool

• Unplug and disconnect the tool completely from its power

supply before performing any service, maintenance, repair or

adjustments.

• Consult manual for specific maintenance and adjustment

procedures.

• Keep tool lubricated and clean for safest operation.

• Read and understand warnings posted on the machine and

in this manual. Replace the warning labels if they become

obscured or removed. Failure to comply with all of these

warnings can result in serious injury.

• Before turning on the machine, check for damaged parts.

Guards or other parts that are even slightly damaged should

be carefully examined to ensure they will function correctly.

Check for alignment of moving parts, binding, breakage,

mounting issues and any other conditions that may affect

the tools operation. Replace any guard or damaged part that

does not function properly before using the tool.

• Maintain this tool, its attachments the grinding wheel with

care.

Know how to use your tool

The operation of any power tool can result

in foreign objects being thrown into the

eyes, which can result in severe eye damage. Always wear

safety goggles complying with United States ANSI Z87.1.

before commencing power tool operation.

Think safety! Safety is a combination of operator

common sense and alertness at all times when tool

is being used.

• The Model 9682122 Surface Grinder is designed and

intended for use by properly trained operators. You must

be familiar with the proper and safe operation of a surface

grinder. Obtain proper training and knowledge before

operating this machine.

• Do not use the Model 9682122 Surface Grinder for any

use than its intended application. Improper use of this

tool revokes and voids any real or implied warranty. The

manufacturer is not responsible for any injury that may result

from improper use of the machine.

• Ensure the grinding wheel is solid and free from any flaws or

cracks. You can perform a ring test by holding the grinding

wheel with a wooden dowel rod through the arbor hole and

lightly striking it with a wrench or hammer. The wheel should

emit a clear “ping” sound. A damaged wheel will emit a dull

sound. If there is any doubt of a wheel’s condition, replace it

immediately.

• A damaged wheel is more likely to fly apart or explode

upon machine start up. Do not stand in line with the wheel’s

rotation upon start up.

• Grinding wheels operated at a speed faster than they are

rated for can fly apart or explode causing injury or death.

Before mounting a new wheel make sure the wheel’s RPM

rating is equal to or more than the machines RPM rating.

• Heavy impact with a workpiece or trying to make a very deep

cut can cause a wheel to break apart or explode. Do not jam

a workpiece into the wheel to reduce this risk.

• Make sure your workpiece is held tight on the chuck. If the

shape of the workpiece prevents it from laying flat, block the

ends with appropriate clamps or vises.

• Only use wheel grinding wheel flanges that come supplied

with the machine. Other flanges may not meet the required

specifications for safety.

• Do not force an attachment to do a job it was not intended or

designed for.

• Never work in an awkward position while using the machine.

Maintain your balance. Never lean against the machine, over

reach or use excessive force when working. You could tip or

fall into the machine causing serious injury.

• Remove adjusting keys and wrenches. Form a habit of

checking to see that keys and adjusting wrenches are

removed from the machine before turning it on.

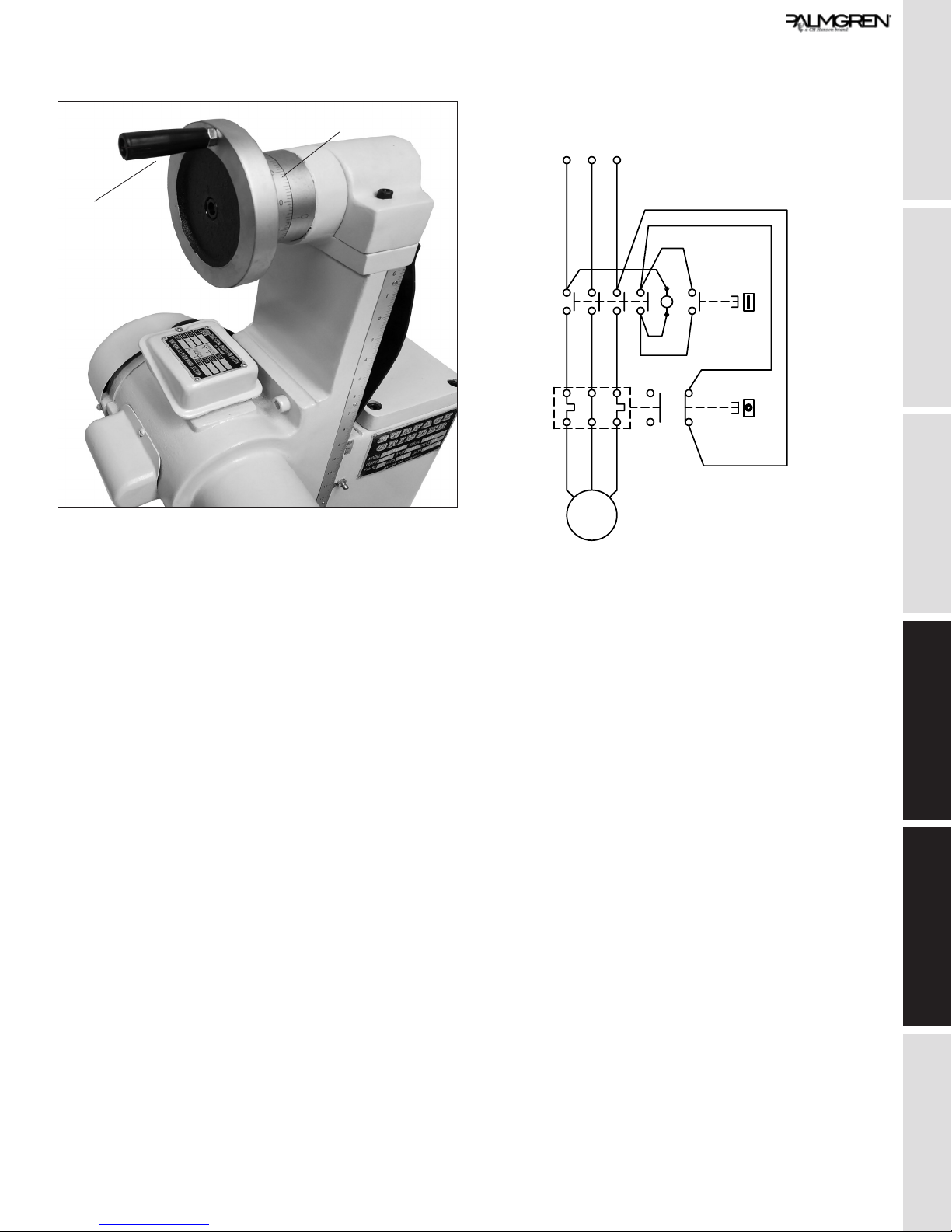

• Before connecting the machine to a power supply check to

ensure the switch is in the OFF position.

• The machine must be properly grounded.

• Safety guards must be in place and operate properly in

place at all times. If any guards, covers or safety devices are

removed for maintenance purposes they must be replaced

before using the machine.

• Never leave the machine running while it is unattended. Turn

off the power and stay with the machine until it comes to a

complete, full stop.

• Know your tool. Learn the tool’s operation, application and

specific limitations. Never force the machine to do a task it

was designed for.