E3

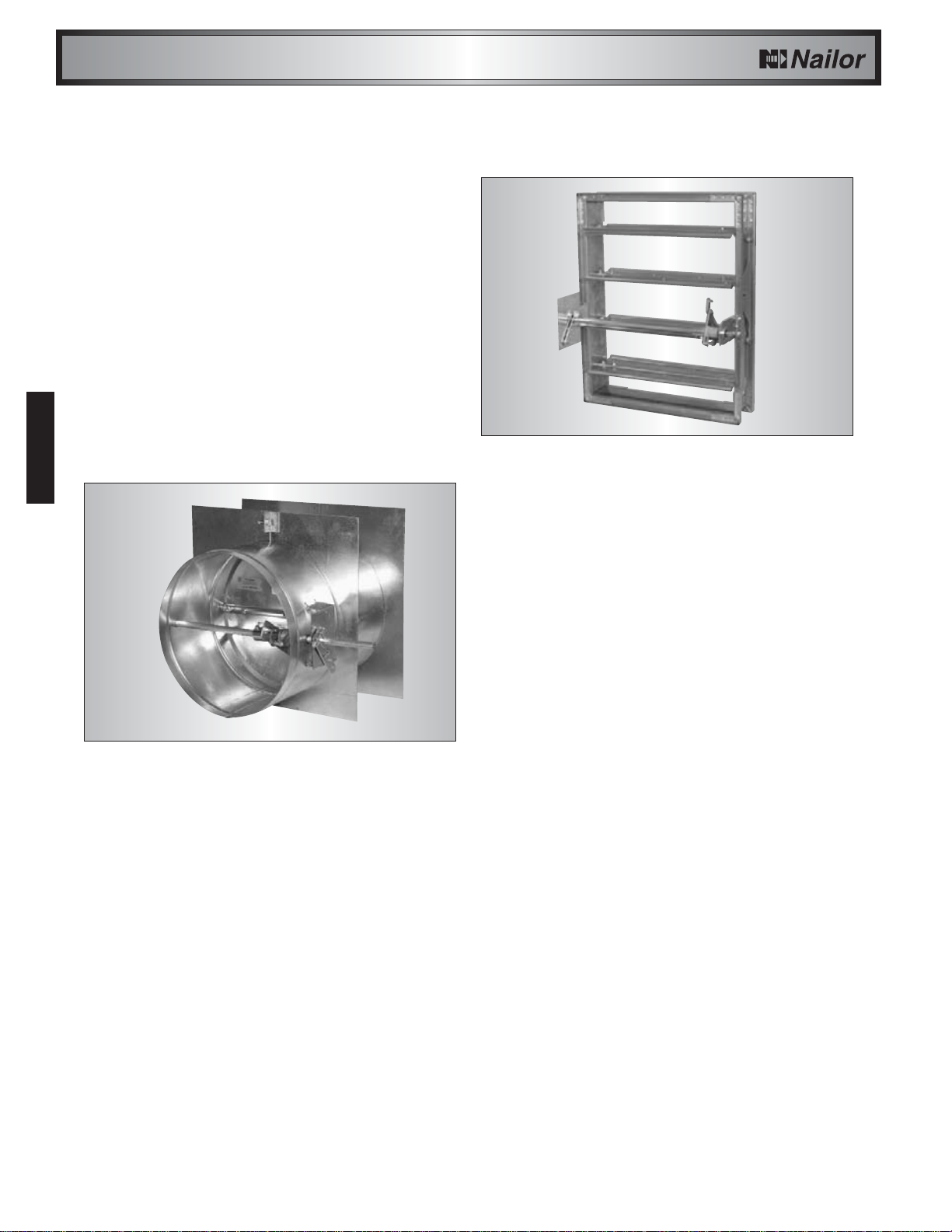

MULTI-BLADE FIRE DAMPERS

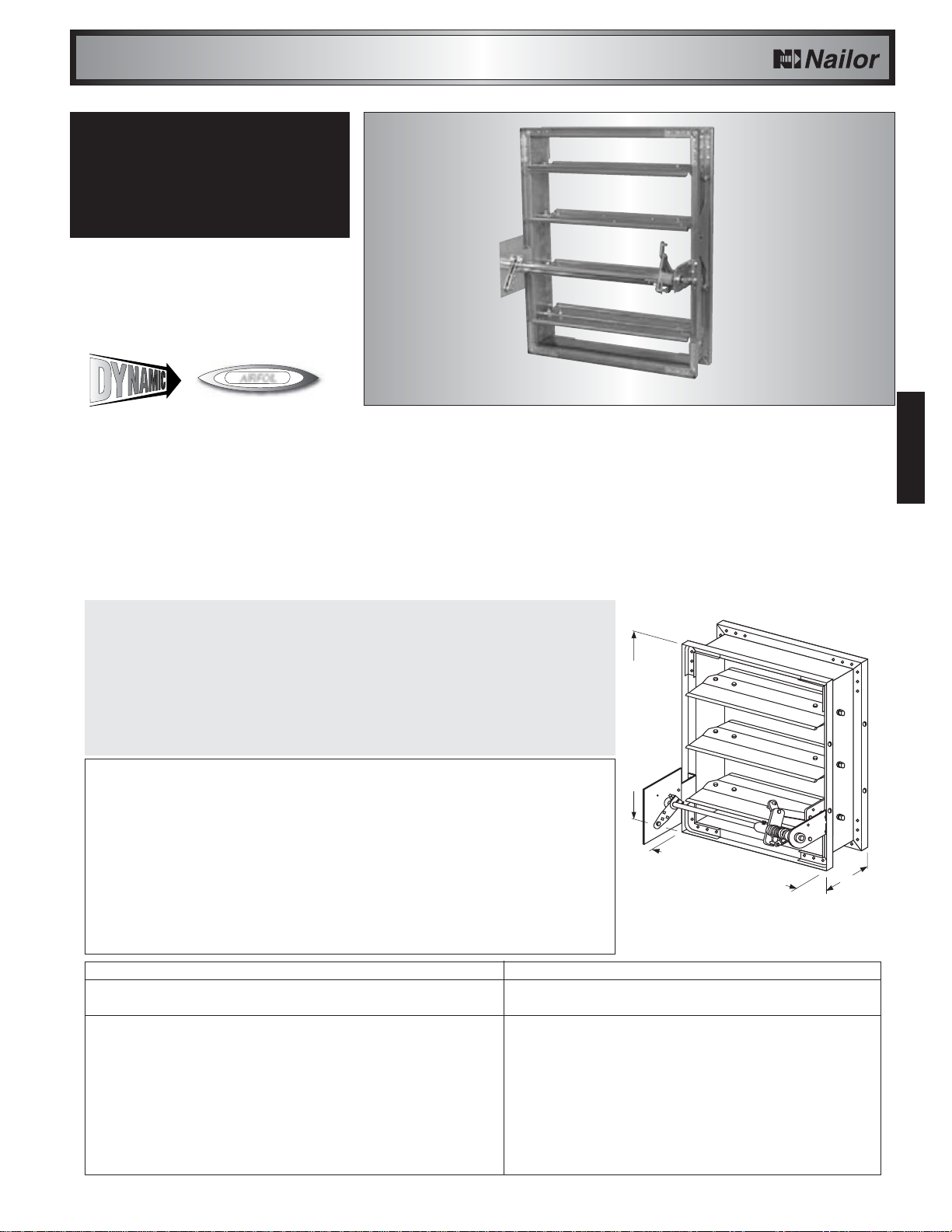

MODEL SERIES D1250

DYNAMIC FIRE DAMPER • VEE-GROOVE BLADE

Model Series D1250, with sturdy vee-groove style blades

and rugged mitered corner hat channel frame design that

virtually eliminates racking, provides 1 1/2 hour UL labeled

fire protection suitable for use where ductwork penetrates a

wall or floor with a fire resistance rating of up to 2 hours. The

over-center/knee lock with high torque spring fusible link

assures fail-safe closure during fire conditions. The D1250

series is also approved for use in both static or dynamic

HVAC system designs. Available with factory fitted sleeve

Model D1251, and choice of transition styles, the series is

supplied as standard with a manual locking quadrant, and is

a versatile and economical performer suitable for use in the

majority of today's applications.

GENERAL PRODUCT OVERVIEW

As today’s modern commercial and industrial building construction becomes increasingly life safety oriented, fire containment

and active smoke management systems are being utilized to a higher degree as more sophisticated technology is developed

and implemented into building codes. The development process begins with the understanding of fire and smoke behavior

through the research and study of real life emergency situations, and culminates in the design, testing of, and ultimate use

of new products to better control and manage the ravages of fire and smoke. Thus, resulting property damage is minimized

and occupant safety is maximized. Nailor Industries commitment to the development of new and existing fire and smoke

control technology has resulted in a comprehensive line of premium quality smoke, fire and combination fire/smoke dampers

and accessories, available at a reasonable cost and in a timely fashion. Nailor's ‘multi-blade’ type fire dampers are available

in several blade and frame styles including ‘true round’, to suit most applications.

E

E3

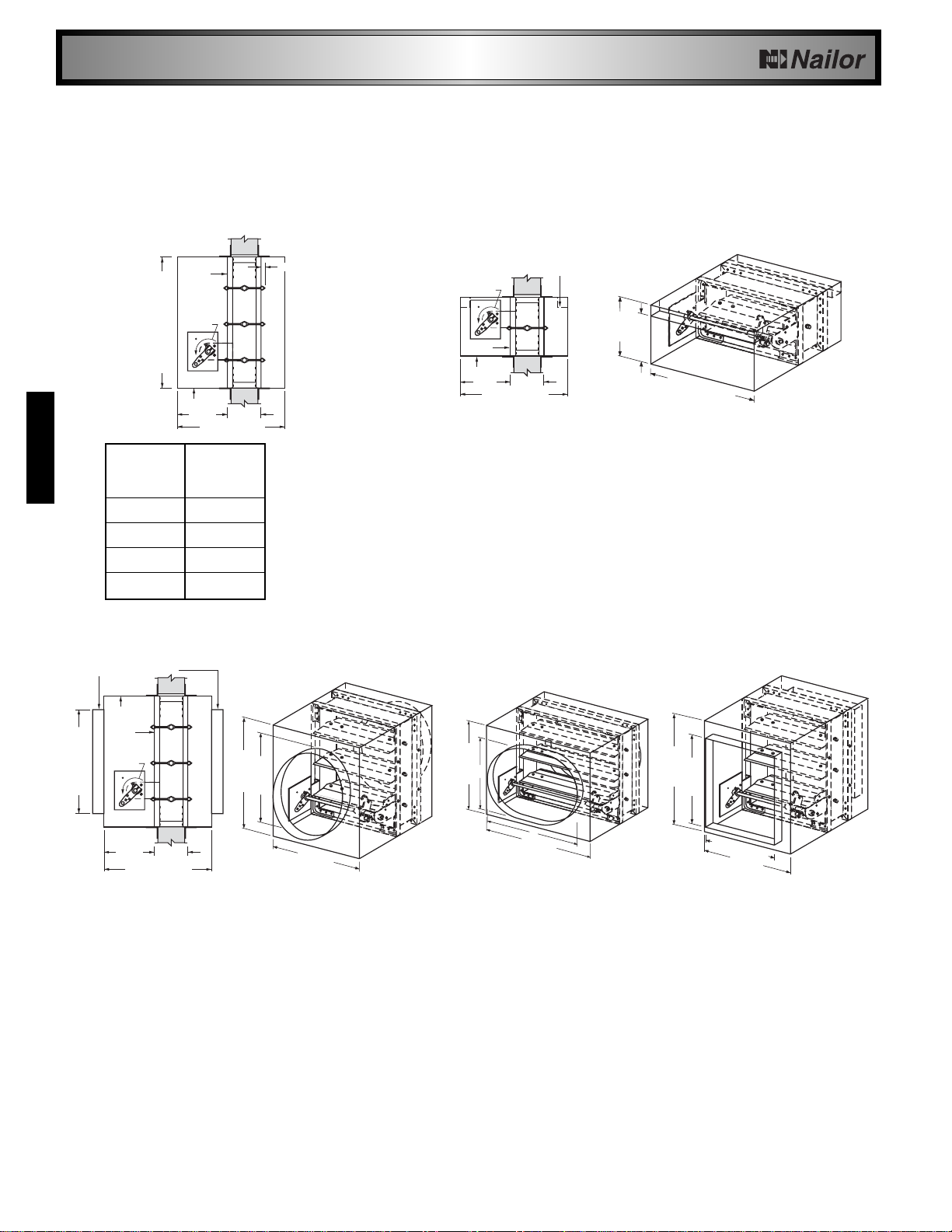

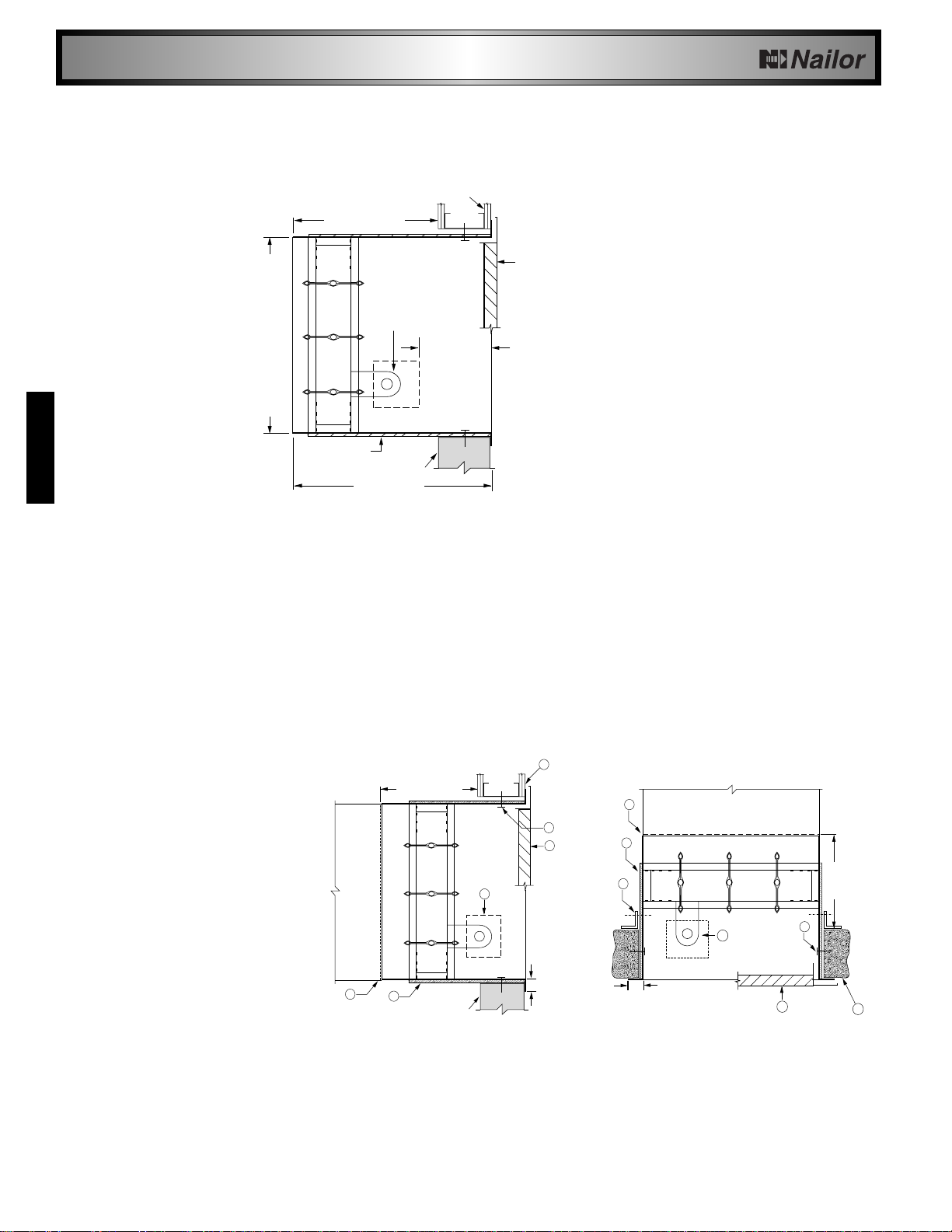

Model D1200

Model D1201-OW

MODEL SERIES D1200 AND D1200-3

DYNAMIC FIRE DAMPER • AIRFOIL BLADE

PREMIUM PERFORMANCE

Provides the ultimate in fire containment for both static and

dynamic HVAC systems. The D1200 Series utilizes an

innovative inter-locking double skin airfoil blade design that

maintains a complete barrier throughout the fire test with

absolutely no visible through-gaps. Amazingly, the D1200

Series fire damper gets tighter as it gets hotter! Ideal for use

where building codes require a fire damper for the protection

of ductwork penetrations in walls or floors. Premium

performance, versatility and assured closure make the

D1200 Series an excellent choice for the majority of today’s

applications.

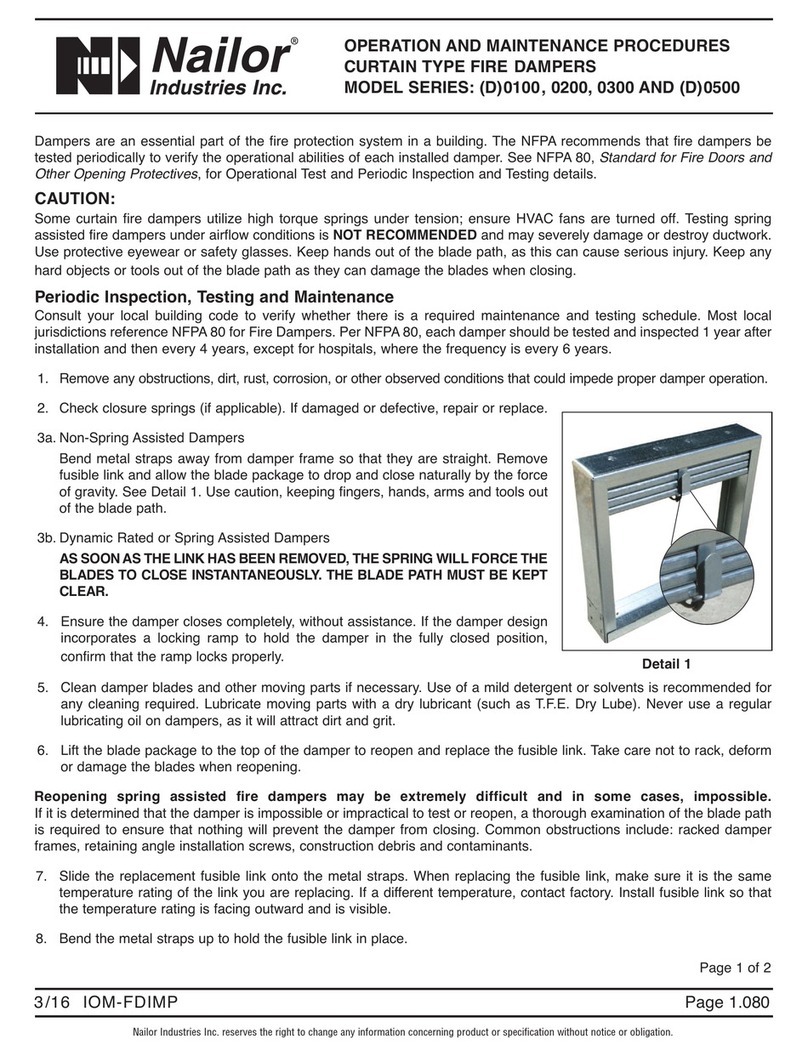

MODEL D1201-OW

DYNAMIC FIRE DAMPER • AIRFOIL BLADE

OUT OF WALL MOUNTING

Model D1201-OW is an "out of wall" high performance fire

damper. It is specifically designed for supply or return ducts

that terminate at a grille and provides through the grille

access to the damper. Standard sleeve length

accommodates most commercial supply and return

grilles/registers. It offers premium performance and a low

pressure drop well suited to the majority of commercial

applications. Unique, inter-locking double skin blade design

eliminates combustible seals and provides flame protection

under fire conditions at temperatures up to 2000°F. The

D1201-OW is supplied as standard with an internal locking

quadrant which holds the damper in the fully open position,

but may also be used for system balancing if required.

Model D1250

MULTI-BLADE FIRE DAMPERS