Page 6 3/21 IOM-ELECTRA-FLO-INST

Nailor Industries Inc. reserves the right to change any information concerning product or specification without notice or obligation.

1.4 Checking That You Received Everything

Carefully open the Airflow Measuring Damper shipping container(s)

and remove all equipment. Inspect equipment for any damage (if

damaged, contact Nailor and your freight company). Verify that

the following items have been shipped:

• (1) Control Damper in Sleeve with airflow measuring probes

• (1) Airflow G5 Transmitter

• (1) Installation Instructions

Verify that the configuration recorded on the factory set-up sheet

is correct for your application.

Please contact the Nailor Application Engineering Department if

you have questions.

1.5 Working Environment

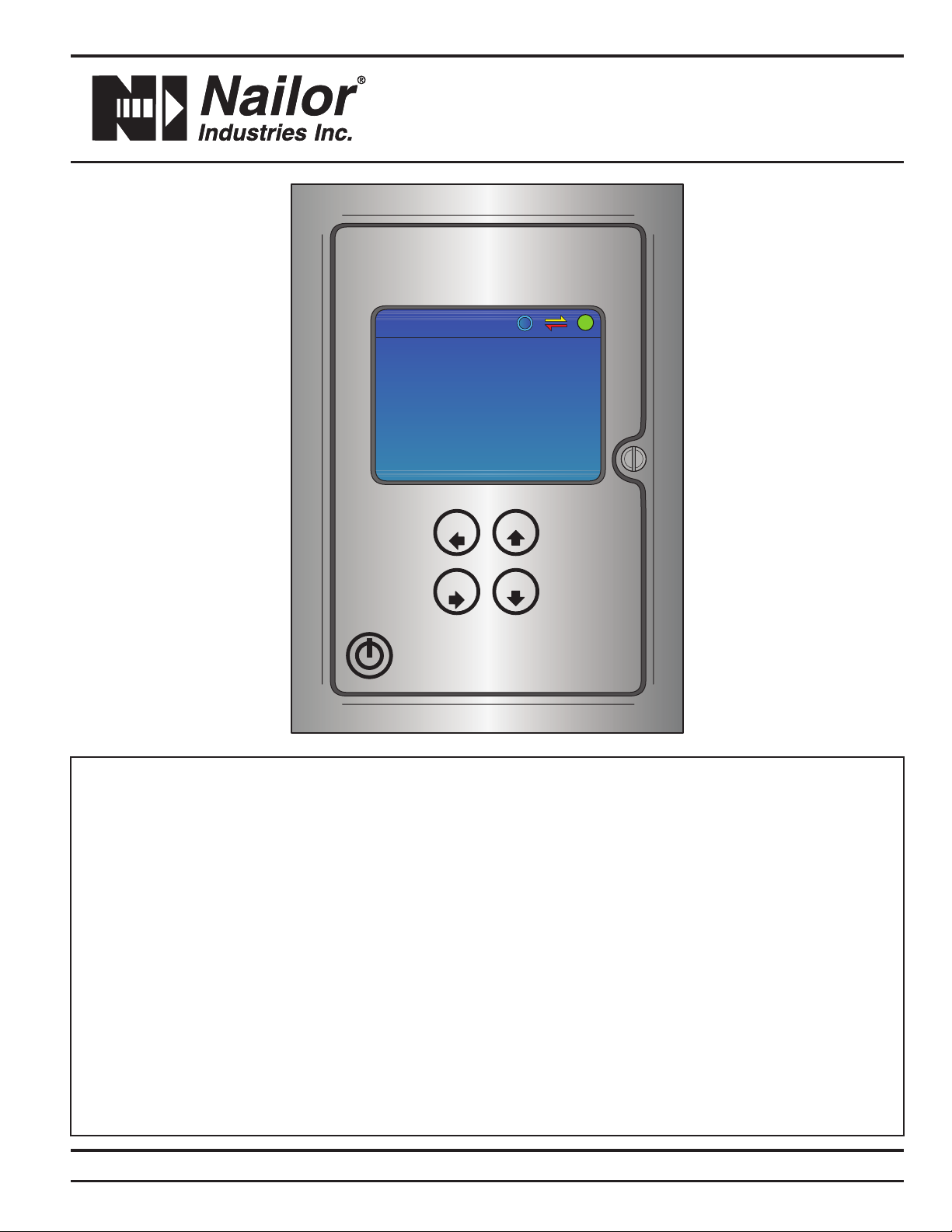

Airflow G5 transmitter enclosures are designed for use in indoor

installations that are free of condensing moisture. NEMA 4X

enclosures with display windows are designed for use in wet

indoor installations. Do not expose these transmitters to direct

sunlight, temperature extremes or excessive vibration.

The operating ambient air temperature range for both enclosures

is -20°F to 140°F (-29°C to 60°C).

Airflow G5 transmitter enclosures without windows are designed

for indoor or outdoor use. Do not expose these transmitters to

excessive vibration. Whenever possible, avoid exposure to direct

sunlight. The operating ambient air temperature range is -20°F to

140°F (-29°C to 60°C).

1.6 Serial and Sales Order Number

The serial number of your Airflow G5 transmitter is located

outside of the enclosure. The serial number and the sales order

number are a unique identifier for your product. Please have them

available when contacting Nailor for assistance regarding your

product.

The Nailor Airflow Measuring Control Damper should be installed

by experienced HVAC technicians and others with related

knowledge and experience with airflow systems. The installer

should use good trade practices and must adhere to all state and

local building codes.

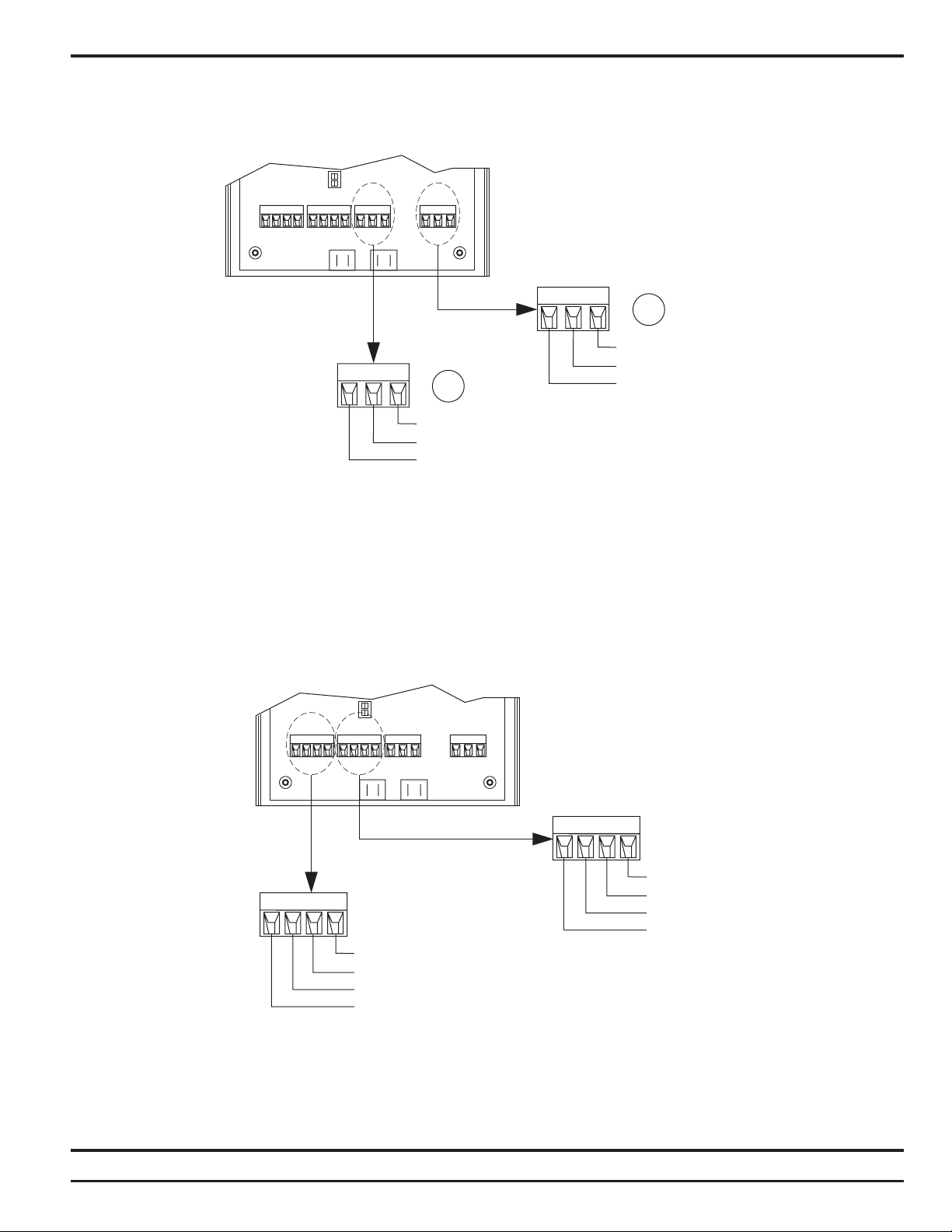

Each unit is individually calibrated, configured and programmed

using customer specific application data.

Configuration and programming parameters are recorded on

the Factory Set-Up Information Sheet provided with the unit.

Review this information and verify that the set-up is correct for

your application. If any problems or discrepancies are detected,

contact Nailor’s Application Engineering Department prior to

proceeding.

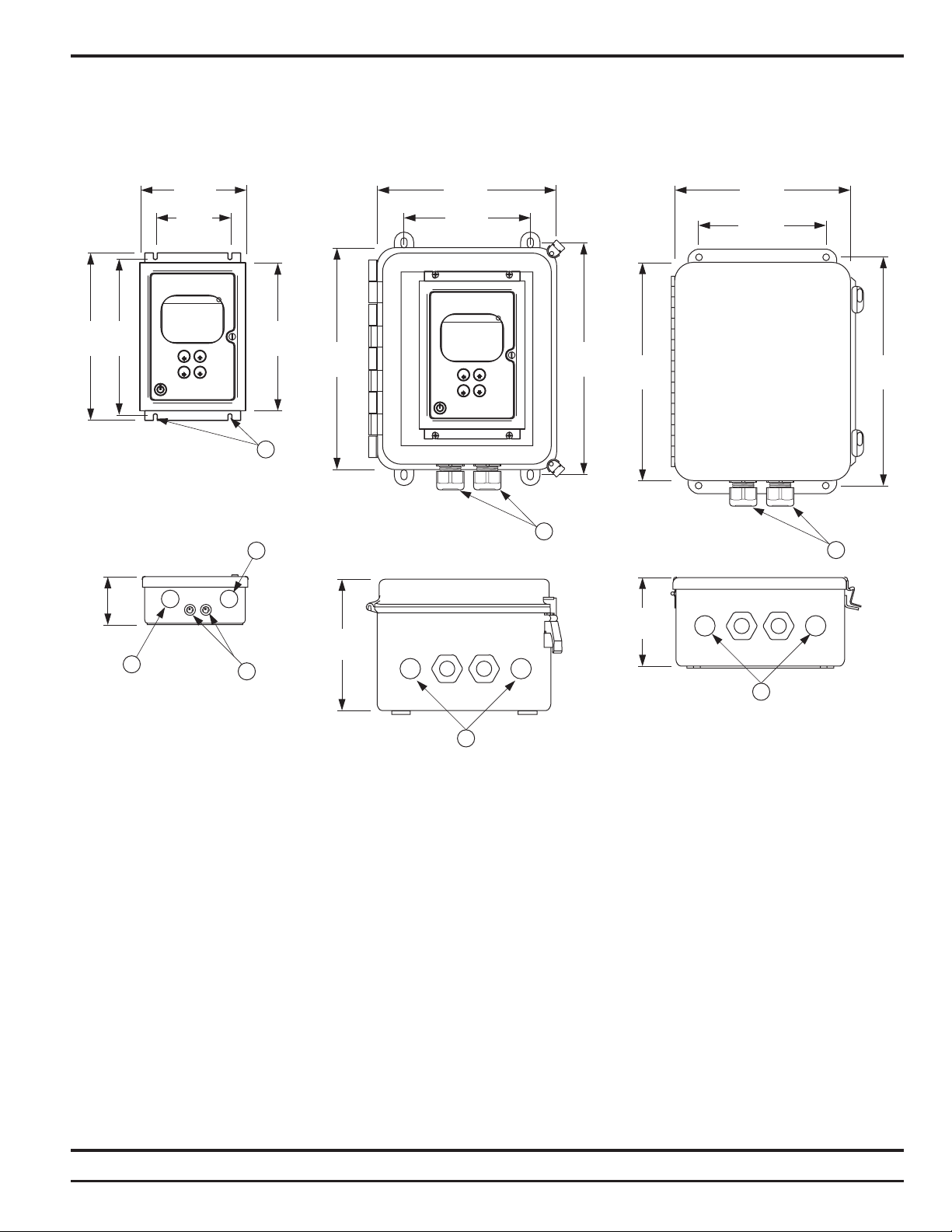

2.1 Site Selection

Careful attention to the site selection for the system components

will help the installers with the initial installation, reduce start-up

problems, and make future maintenance easier. For example,

do not install the unit where it will be difficult for personnel to

perform periodic maintenance. When selecting a site for mounting

the system components, consider the criteria under Section 1.5:

WORKING ENVIRONMENT.

SECTION 2.0 INSTALLATION