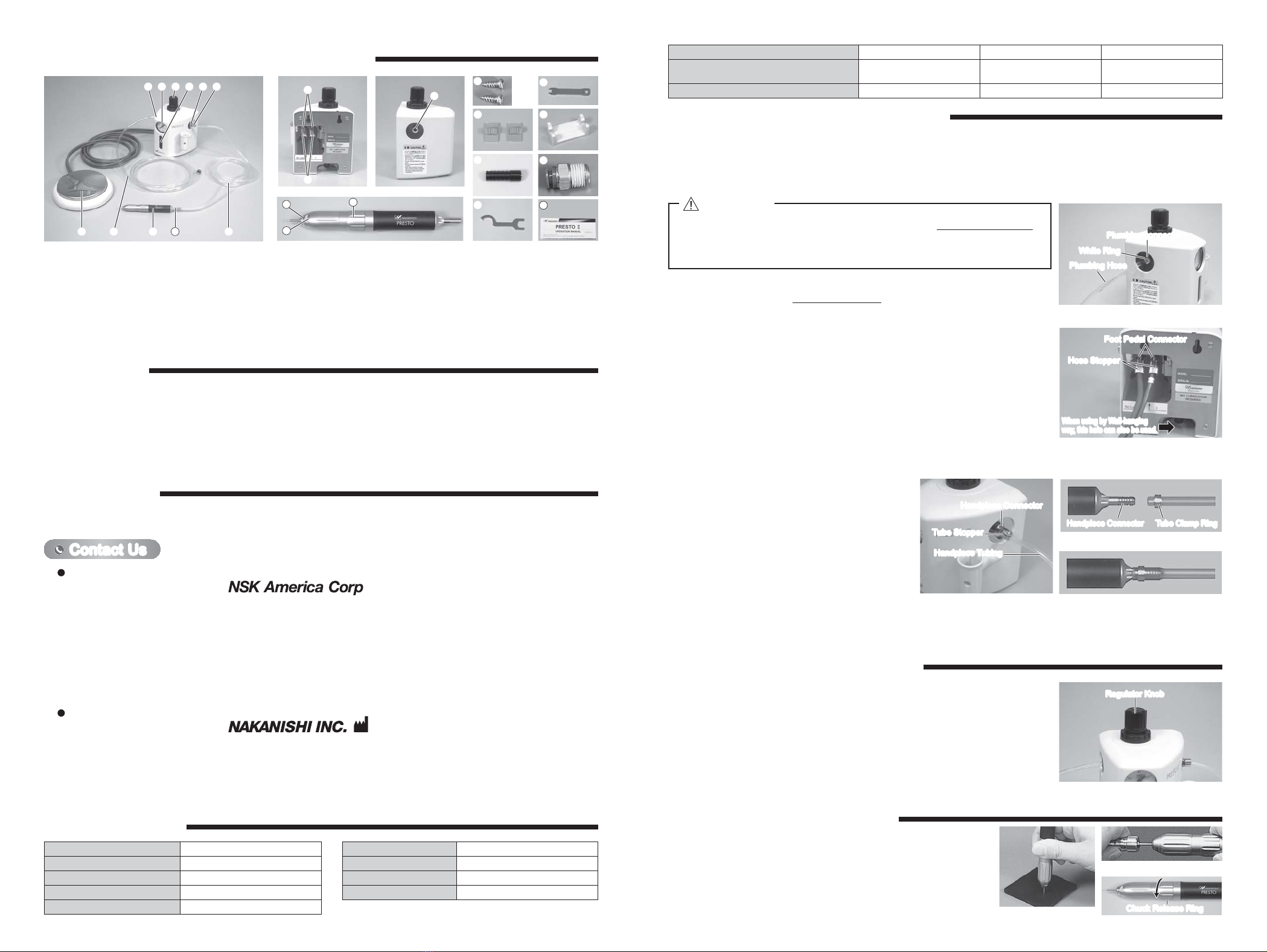

①PRESTOϩControl Unit ⑧Plumbing Hose ⑮Handpiese Tubing Clamps ㉒Wrench Flats

②Pressure Gauge ⑨PRESTO Handpiece ⑯Bur Push-in Tool ㉓Chuck Release Ring

③Regulator Knob ⑩Handpiece Tubing ⑰Cartridge Wrench ㉔Tube Clamp Ring

④Filter Inspection Window ⑪Foot Pedal Connector ⑱Rotor Shaft Nut Wrench ㉕Operation Manual

⑤Handpiece Connector ⑫Hose Stopper ⑲Handpiece Stand

⑥Tube Stopper ⑬Plumbing Connector ⑳Air Supply Connector

⑦Foot Pedal ⑭Unit Mounting Screws ㉑Cartridge

speed 320,000min-1 (rpm)

Recommended Air Pressure 0.2 - 0.25MPa (29 - 36.3psi)

Handpiece Dimensions ȭ16.6 (D) x 130 (H) mm

Handpiece Weight 71g

Noise Level at 1m distance Less than 70dB (A)

6 - 1 Mounting of the Control Unit

The Control Unit can be secured on a wall, on a work-bench, or under a work-bench.

When securing on a wall surface, etc., x the Control Unit with unit xing screws in the two screw holes on its back.

Control Unit Dimensions W120 x D102 x H165 (mm)

Control Unit Weight 720g

Proper Air Pressure 40Nℓ/ min

Inside Diameter ȭ1.6mm Bur Only

6 - 2 Installation of Plumbing Hose

WARRANTY3.

COMPONENT NAMES AND BASIC PACKAGE

2.

We provide a limited warranty for our products. We will repair or replace the products if the cause of failure is due to the following

manufactures defects. Please contact us or your local distributor for details.

①Defect in manufacturing.

②Any shortage of components in the package.

③Where damaged components are found when initially opening the package.

(This shall not apply if the damage was caused by the negligence of a customer.)

CONTACT US4.

For your safety and convenience when purchasing our products, we welcome your questions.

If you have any questions about operation, maintenance and repair of the product, please contact us.

Company Name

Business Hours

U.S. Toll Free No.

Telephone No.

Fax No.

Web Address

:

Industrial Div.

: 8:30am to 17:00pm (CST)

(closed Saturday, Sunday and Public Holidays)

: 800-585-4675

: 847-843-7664

: 847-843-7622

: www.nskamericacorp.com

Contact UsContact Us

For U.S. Market

Company Name

Business Hours

Telephone No.

e-mail Address

:

: 8:00am to 17:00pm

(closed Saturday, Sunday and Public Holidays)

: +81 (0) 289-64-3520

For Other Markets

SPECIFICATIONS5.

Temperature Humidity Atmospheric Pressure

Operation Environment 0 - 40°CMAX.75%

(No condensation) 700 - 1,060hPa

Transportation and Storage Environment -10 - + 50°C 10 - 85% 500 - 1,060hPa

Push the plumbing hose into the plumbing connector located at the regulator on the left-

hand side of the Control Unit until it is securely set to make connection as shown in Fig. 1.

Check if the hose is securely installed by tugging it after connection.

Connect the other end of the plumbing hose to the air line. At this time, use the attached

connector if necessary.

Plumbing connectorPlumbing connectorPlumbing connector

Plumbing HosePlumbing Hose

White RingWhite Ring

Fig. 1

SYSTEM ASSEMBLY PROCEDURES6.

・

Push the plumbing hose into the plumbing connector until it is securely set.

Otherwise, air may leak.

・

Pushing the white ring, on the plumbing connector, gently remove the tube.

CAUTION

6 - 3 Installation of foot Pedal

Loosen and remove the hose stoppers (two) from the foot pedal connectors on the back

of the Control Unit, and insert them into the foot pedal hoses. At this time, insert the hose

stoppers so that their screws come outside (Control Unit side) (Fig. 2)

. For wall-hanging

use, pass the hoses through the hole shown in Fig. 2.

Insert the "1" - marked end of each hose according to the instructions on the label. After

insertion of both hoses, securely tighten the hose stoppers.

Foot Pedal ConnectorFoot Pedal Connector

When using by Wall-hanging

way, this hole can also be used.

Hose StopperHose Stopper

When using by Wall-hanging

way, this hole can also be used.

Fig. 2

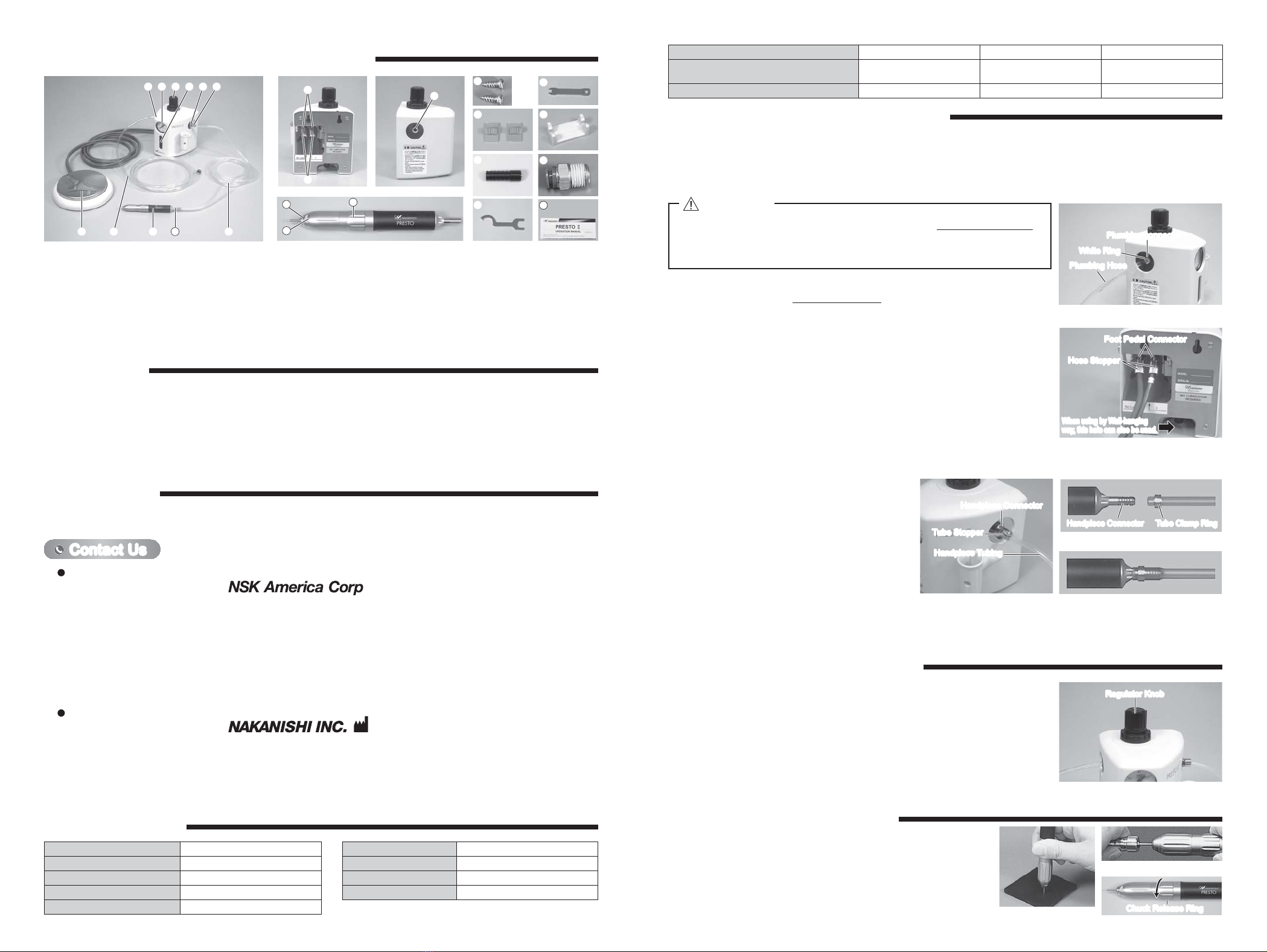

6 - 4 Installation of Handpiece

Loosen and remove the tube stopper from the handpiece

connector on the right-hand side of the Control Unit, and insert

it into the handpiece tubing. At this time, insert the tube stopper

so that its screw comes outside (Control Unit side) (Fig. 3).

Insert the handpiece tubing into the handpiece connector, and

securely tighten the tube stopper.

Insert the tube clamp ring into the other end of the handpiece

tubing as shown in Fig. 4, and insert it into the handpiece

tubing socket as shown in Fig. 5.

Handpiece ConnectorHandpiece Connector

Handpiece Tubing

Handpiece Tubing

Tube Stopper

Tube Stopper

Fig. 3 Fig. 5

Handpiece ConnectorHandpiece Connector Tube Clamp Ring

Tube Clamp Ring

Fig. 4

6 - 5 Installation of Handpiesce Tubing Clamps

Locate a Handpiece Tubing Clamp (two pieces supplied) at a proper location to conveniently position the handpiece tubing.

7 - 1 Set the Drive Air Pressure

Supply air, and adjust to 0.25MPa (36.3psi) by pulling the Regulator Knob upward and turning.

When adjustment is made, push the knob down to lock (Fig.6).

7 - 2 Operation

Stepping on the Foot Pedal starts rotation.

7 - 3 For Finishing Work

Close the main air valve.

Regulator KnobRegulator Knob

Fig. 6

OPERATION OF CONTROL UNIT

7.

①As the chuck of the PRESTO handpiece is a push-in type, set the

ȭ1.6mm burs and push in as shown in Fig.7.

If the end of the bur is tapered push in using the provided bur-

inserting wrench as shown in Fig.8.

②When removing the bur, turn the chuck release ring in the direction

of the arrow in Fig.9. Fig. 7 Chuck Release RingChuck Release Ring

Fig. 9

Fig. 8

OPERATION OF HANDPIECE

8.

① ② ③④⑤⑥

⑦⑧ ⑨ ⑩

⑪

⑫

⑬

23 25

21

24 22

⑭

⑮

⑯

⑰

⑱

⑲

⑳