M

FC - 300 (

M

Type6Type)

90° Mini-Angle Attachment

Thank you for purchasing the 90° Mini-Angle Attachment " MFC - 300 ". This Attachment

designed for small hole ID ¿nishing and deburring.

The Emax EVOlution Control Unit, Brushless Motor or ROTUS Air Motor / Air Line Kit are

required to drive this Attachment. Read this and all the associated component Operation

Manuals carefully before use. Always keep this Operation Manual in a place where a user

can referred to for reference at any time.

OPERATION MANUAL 003

CAUTIONS FOR HANDLING AND OPERATION

Class Degree of Risk

WARNING A safety hazard could result in bodily injury or

damage to the device if the safety instructions are

not properly followed.

CAUTION A hazard that could result in light or moderate

bodily injury or damage to the device if the safety

instructions are not followed.

1.

■Read these warnings and cautions carefully and only use in the manner intended.

■These warnings and cautions are intended to avoid potential hazards that could result

in personal injury to the operator or damage to the device. These are classi¿ed as

follows in accordance with the seriousness of the risk.

①This Attachment is designed for hand use. Never install this Attachment or

any hand cutting tool on a machine such as a special purpose machine, NC

lathe or mill.

②Do not exceed the " Maximum Motor Rotation Speed " (Refer to " 6 - 1

Speci¿cations ").

③Be sure to connect the reducer to the Attachment when using the

Attachment.

When not connecting the reducer to the Attachment may cause damage to

the inside components and short life of the Attachment.

④Do not touch the cutting tool while it is rotating. It is very dangerous.

⑤Wear safety glasses, dust mask, and use a protective cover around the

Attachment whenever the Attachment is rotating.

⑥When installing a cutting tool, tighten the collet correctly and check again

the collet before use. Do not over-tighten the collet. This may cause

damage to the spindle.

⑦Do not use grindstones with an outside diameter over ₥40mm.

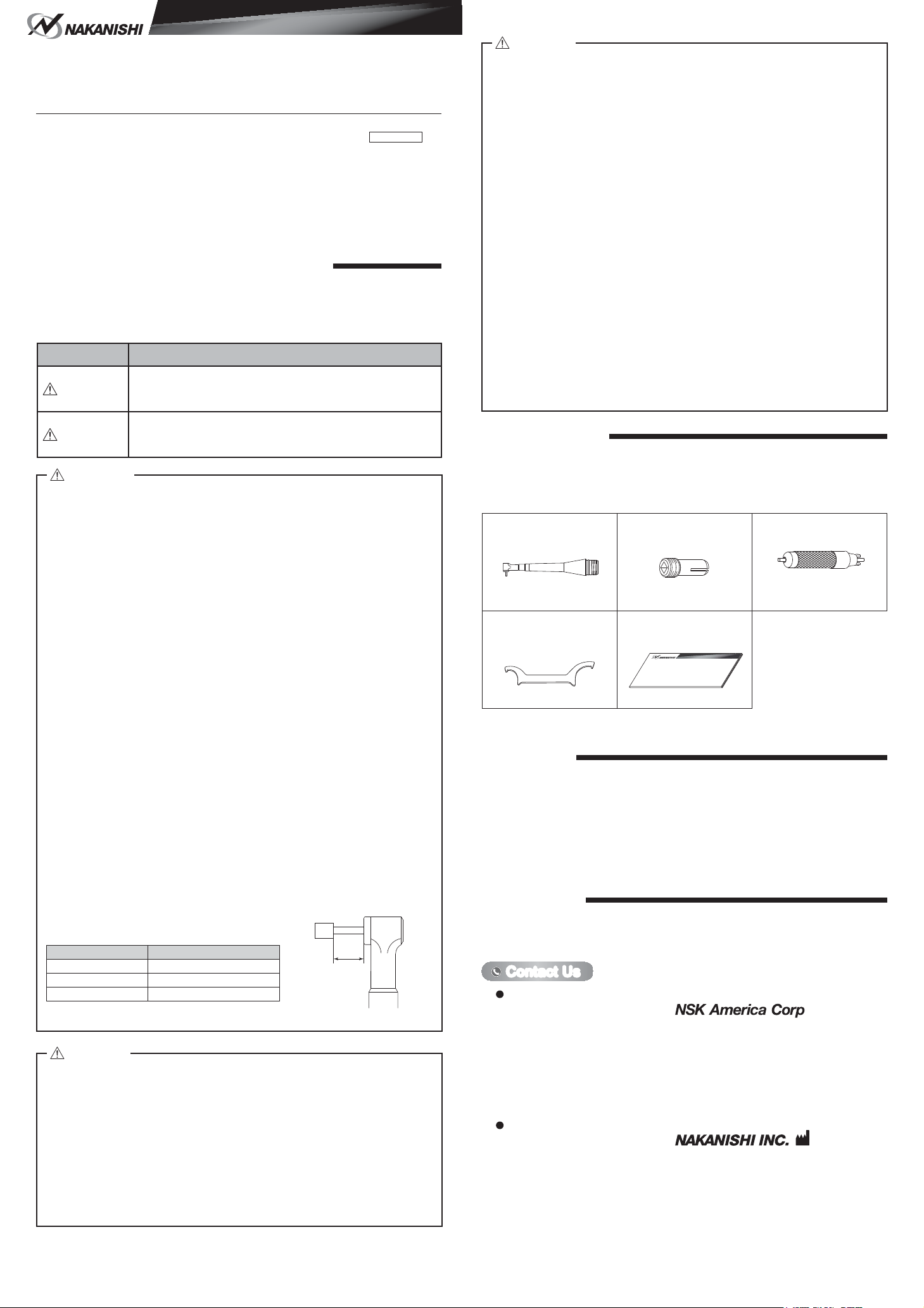

⑧Do not exceed 13mm of overhang for mounted grindstones as shown

in Fig. 1. If the overhang must exceed 13mm, reduce the motor speed in

accordance with Table 1.

⑨Do not use bent, broken, chipped, out of round or sub-standard cutting

tools as they may cause shatter or explode.

The cutting tool with cracked, bended may cause some injury to operator.

When using a new cutting tool, rotate it in a low speed and increase speed

gradually for safety.

⑩Always operate cutting tools within the cutting tool manufacturer's

recommended speed limits. Use of a cutting tool higher than the

manufacturer's recommended speed limits could cause damage to the

spindle and injury to the operator.

⑪Do not apply excessive force. This may cause cutting tool slippage, cutting

tool damage, injury to the operator, loss of concentricity and precision.

WARNING

Table. 1 Overhang and Speed

Overhang (mm) Max. Speed (min-1) (rpm)

20 N x 0.5

25 N x 0.3

50 N x 0.1

*N = Max. Operating Speed with 13mm overhang.

13

Fig. 1

①Do not drop or hit this Attachment, as shock can damage to the internal

components.

②Be sure to clean the collet, the spindle taper and threads before replacing

the cutting tool. If ground particles or metal chips stick to the inside of

spindle or the collet, damage to the collet or spindle can occur due to the

loss of precision.

③When cleaning an Attachment, stop the motor and remove dirt with a

brush or a cloth. Do not blow compressed air into the Attachment. Foreign

particles or cutting chips may get into the ball bearings.

④Always clean the cutting tool shank before installing the cutting tool in the

spindle.

CAUTION

⑤When sizing the correct collet size to the cutting tool shank diameter, a

tolerance of +0 〜

-

0.01mm is strongly recommended.

A cutting tool shank within the +0 〜

-

0.1mm range is mountable, however,

this may cause poor concentricity and or insuf¿cient cutting tool shank

gripping force.

⑥Select suitable products or cutting tools for each application. Do not

exceed the capabilities of the Attachment or cutting tools.

⑦Keep everything in order not to place the rag which could be caught near

the hand tool.

⑧Stop operating immediately when abnormal rotation or unusual vibrations

are observed. Immediately, please check the content of section

" 11. TROUBLESHOOTING ".

⑨Always check if the cutting tool, collet is damaged before and after

operating.

⑩If the collet show signs of wear or damage, replace it before a malfunction

or additional damage occurs.

⑪No lubrication is required because grease impregnated ball bearings are

used.

⑫After installation, repair, initial operation, or long periods of non operation,

please carry out break-in as follow. Start rotating slowly and over a short

period of 5 - 10 minutes, increase speed gradually until allowable maximum

speed.

⑬Do not disassemble, modify or attempt to repair the Attachment. Additional

damage will occur to the internal components. Service must be performed

by NSK NAKANISHI or an authorized service center.

CAUTION

2. BASIC PACKAGE

3. WARRANTY

4. CONTACT US

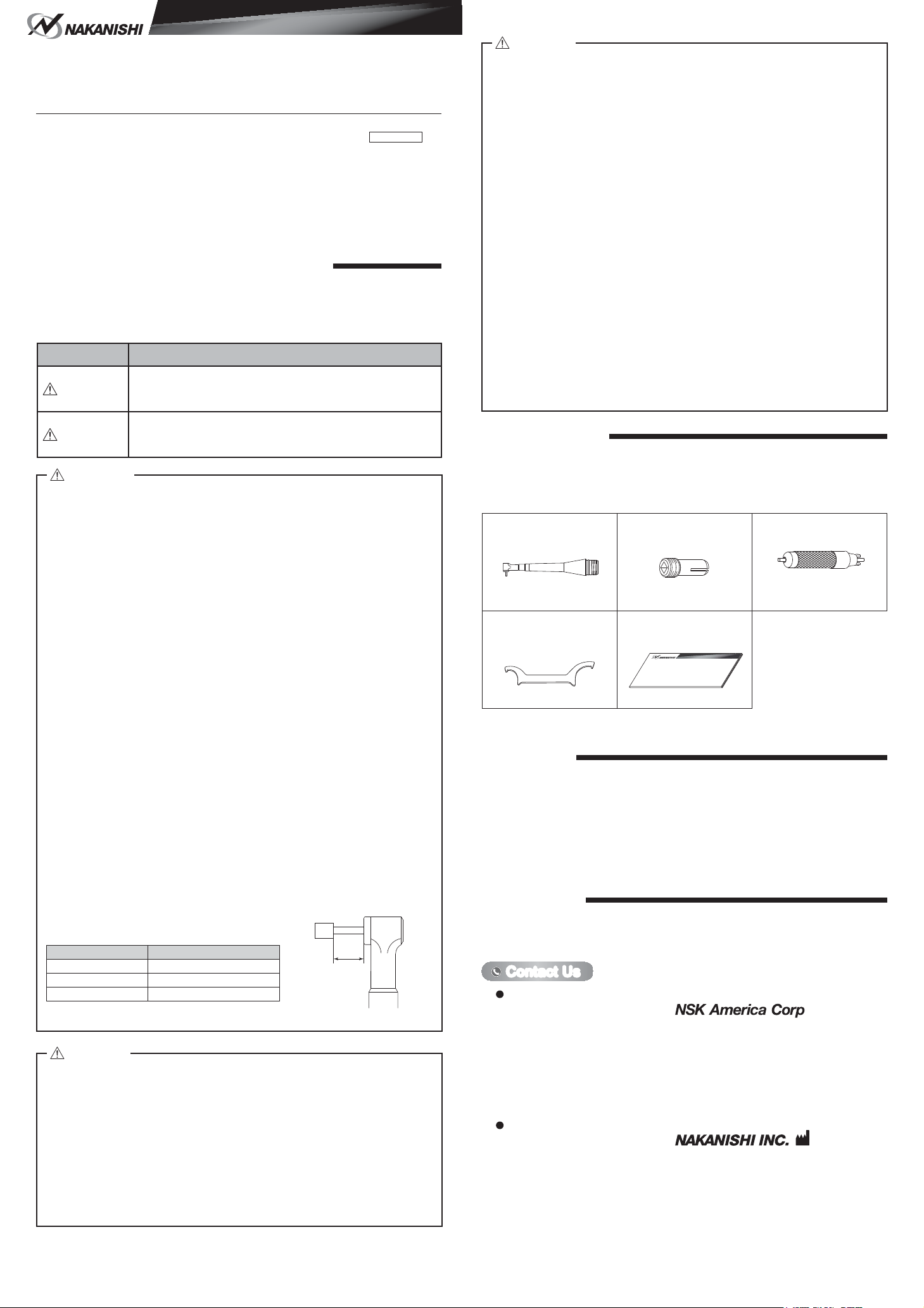

When opening the package, check if it includes all items listed in " Table. 2 Packing List

Contents ". In the event of any shortage, please contact either NAKANISHI (see the

" 4. CONTACT US " section) or your local dealer.

We provide a limited warranty for our products. We will repair or replace the products if the

cause of failure is due to the following manufactures defects. Please contact us or your

local distributor for details.

For your safety and convenience when purchasing our products, we welcome your questions.

If you have any questions about operation, maintenance and repair of the product, please

contact us.

* M Type : ȭ1.6mm (K - 253)・・1pc. S Type : ȭ1.6mm (K - 252)・・1pc.

The collet is attached to the Attachment.

Table. 2Packing List Contents

Attachment・・1pc. Collet* Chuck Wrench

(K - 232)・・1pc.

Pin Wrench

(K - 233)・・1pc. Operation Manual

・・1set

ྲྀᢅㄝ᭩

OPERATION MANUAL

①Defect in manufacturing.

②Any shortage of components in the package.

③Where damaged components are found when initially opening the package

(This shall not apply if the damage was caused by the negligence of a customer).

Company Name

Business Hours

U.S. Toll Free No.

Telephone No.

Fax No.

Web Address

:Industrial Div.

: 8:30am to 17:00pm (CST)

(closed Saturday, Sunday and Public Holidays)

: 800-585-4675

: 847-843-7664

: 847-843-7622

: www.nskamericacorp.com

Contact UsContact Us

For U.S. Market

Company Name

Business Hours

Telephone No.

e-mail Address

:

: 8:00am to 17:00pm

(closed Saturday, Sunday and Public Holidays)

: +81 (0) 289-64-3520

For Other Markets

OM-K0195E