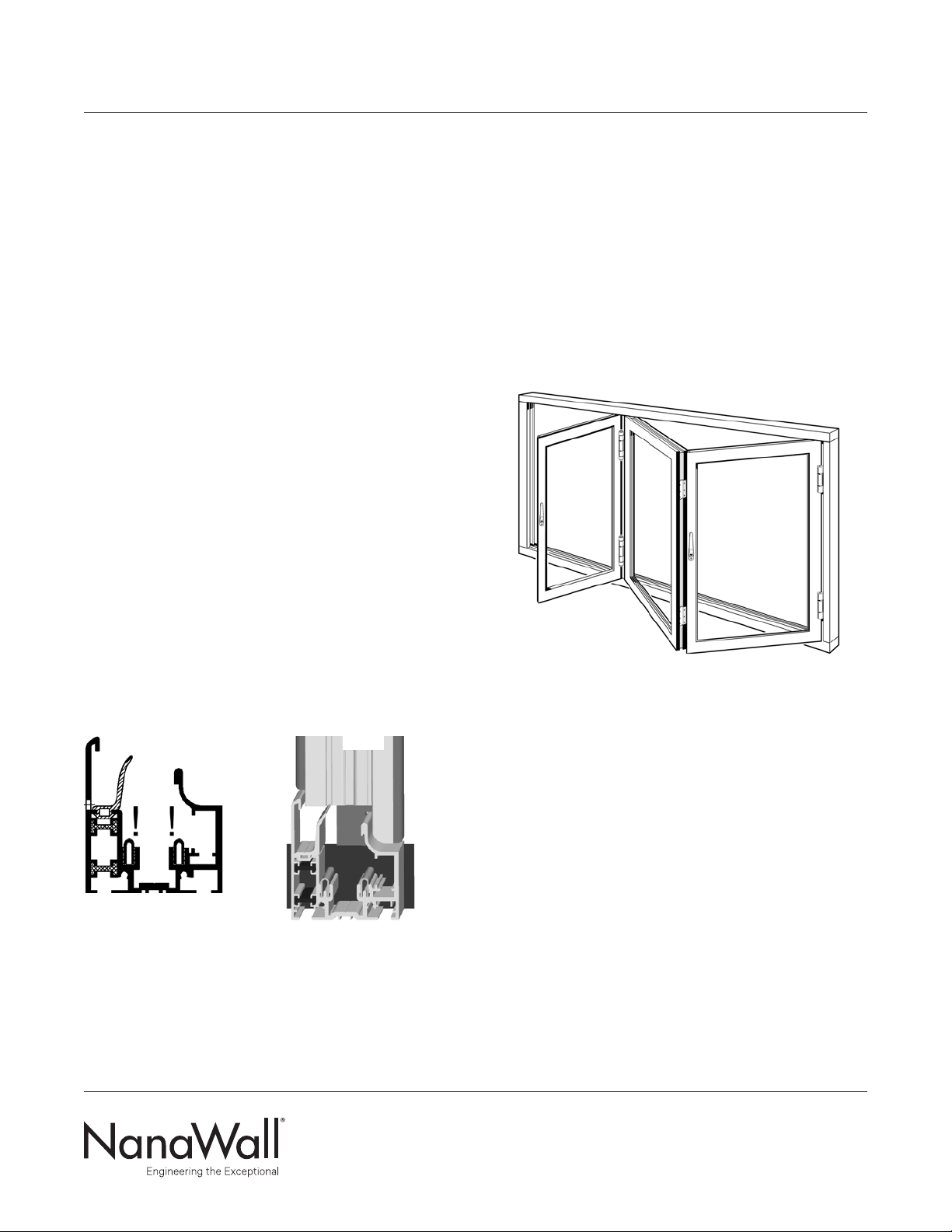

NANAWALL WD66 OWNER’S MANUAL

2

Installation Instructions

The installation of the WD66 System requires a working

knowledge and experience in the use of tools, equipment

and methods necessary for the installation of aluminum

doors, windows, storefronts,and/or partitions. This

practice assumes a familiarity with preparing a proper

and structurally sound opening, proper anchorage,

waterproofing, caulking,and sealing and assumes

an understanding of the fundamentals of building

construction that affect the installation of large door

systems.

Highly recommended is using an independent NanaWall

Certified Installer, if available, or, at least, an installer

who has some experience in installing NanaWall

systems.

IMPORTANT: READ COMPLETE INSTRUCTIONS

BEFORE BEGINNING INSTALLATION. INSTALL AS

RECOMMENDED; OTHERWISE, THE UNIT MAY

NOT FUNCTION PROPERLY AND ANY WARRANTY,

WRITTEN OR IMPLIED, WILL BE VOID.

CAUTION:

As regulations governing the use of glazed windows,

doors, storefronts and/or partitions vary widely, it is the

responsibility of the building owner, architect, contractor

or installer to insure that products selected conform to all

applicable codes and regulations, including federal, state,

and local. NanaWall Systems, Inc. can assume no

obligation or responsibility whatsoever for failure of the

building owner, architect, contractor or installer to

comply with all applicable laws and ordinances and

safety and building codes.

The WD66 system is shipped with all necessary

components. However, not included are screws, bolts,

shims, etc. to anchor the unit to the rough opening.

The frame is shipped knocked down and needs to be

assembled. Panels are pre-assembled with or without

glass, ready to be attached to the installed frame. In most

cases, all hinges, weather stripping, multiple locking, and

flat handles are pre-attached to the panels and frame

components.

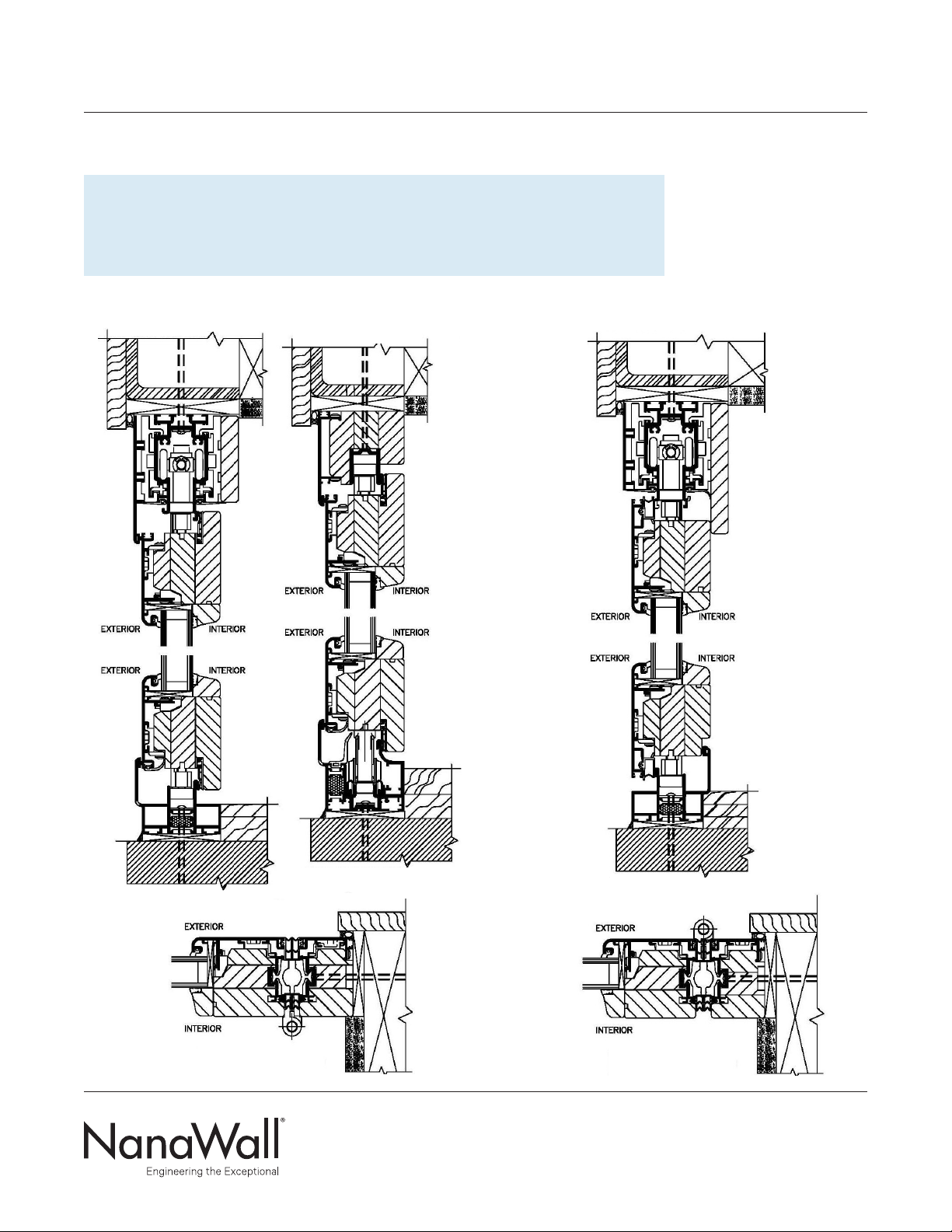

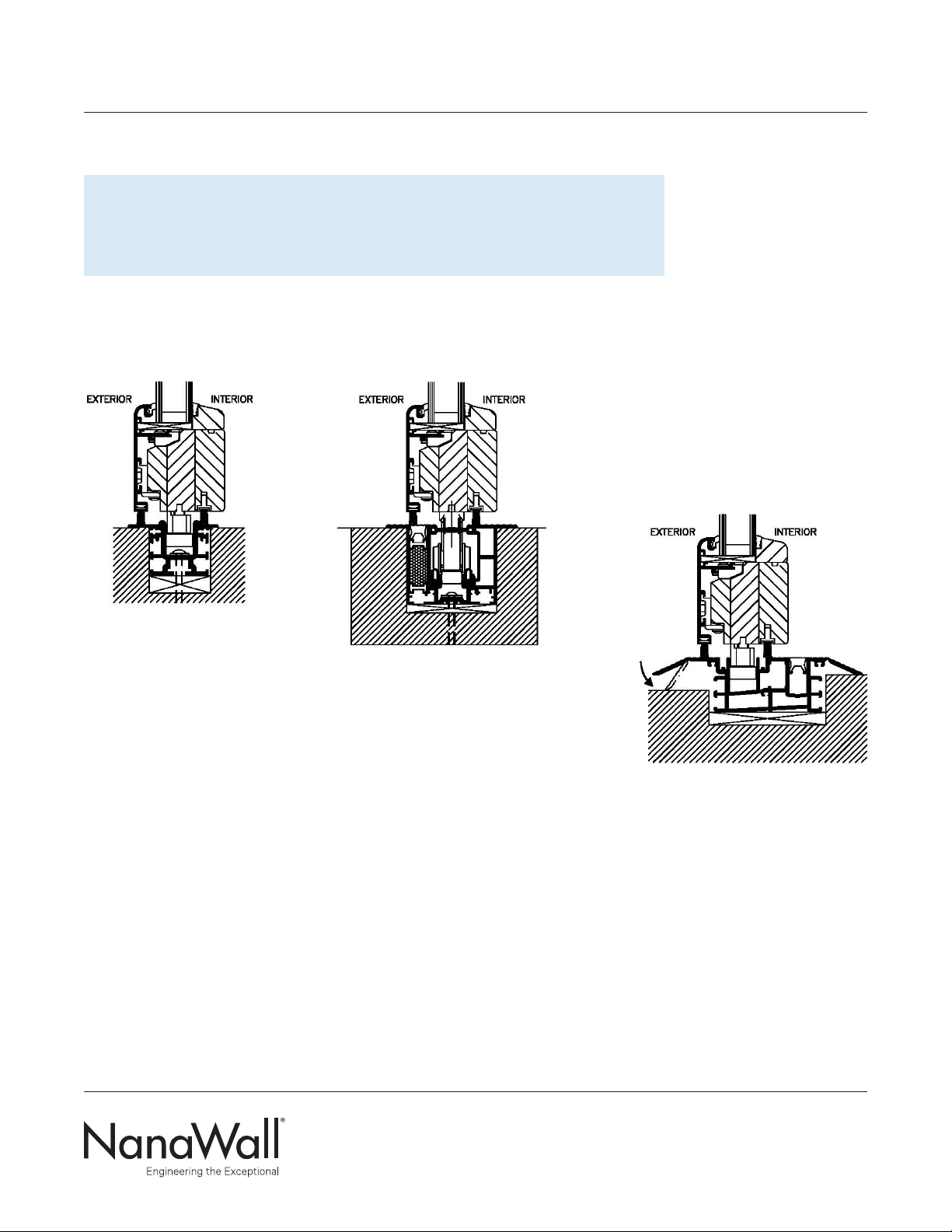

DESCRIPTION OF SUPPLIED PARTS

Check all parts carefully before assembly. Depending

on the model, some of these parts may already be pre-

installed on the panels. Check that the sizes of the frame

components and panels match with what was ordered.

In the cardboard box attached to the frame components

that contains hinge pins and various hardware, inspect

the elevation drawing, indicating size, configuration, and

labeling of the unit ordered. Confirm whether the unit

ordered is WD66/o, top-hung or WD66/u, floor supported.

For orders with multiple units, do not mix and match

panels and frames, even if two units are exactly the same.

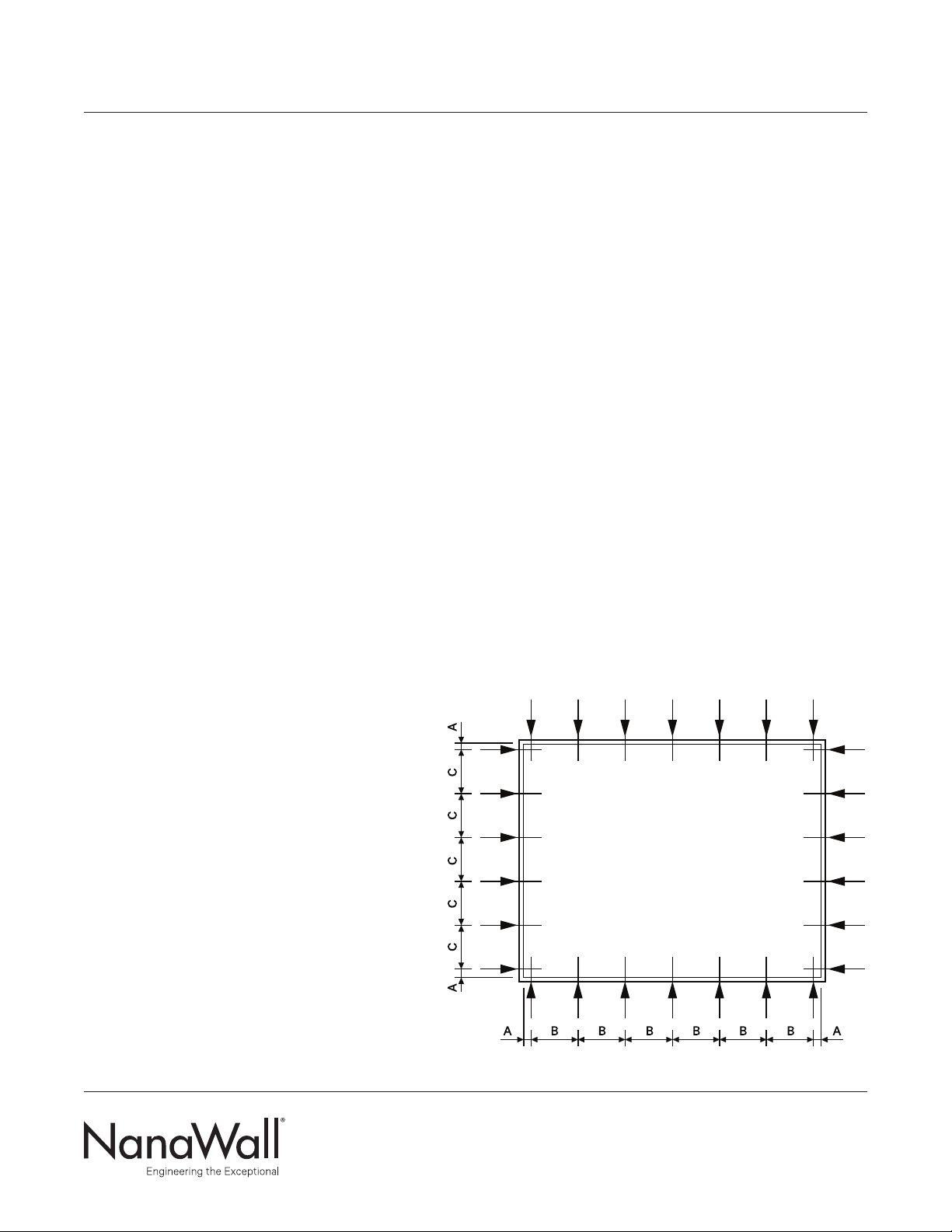

Below is a list of supplied parts.

Always looking from inside.

• Left side jamb, labeled L, and right side jamb,

labeled R.

• Head jamb, labeled O, and sill, labeled U. (In some

instances the head jamb and sill may be in segments.)

• Pre-assembled panels, that means locking

mechanism with flat handles are installed on the

panels. The number of panels depends on the model

ordered. The sequence of labeling of panels starts

from the left with the left most panel labeled Panel 1.

If supplied unglazed, panels have to be glazed before

being installed in the opening. See Appendix A: Glass

Installation and Glazing.

• For certain configurations with even number of

panels on a side, separate running posts.