Page 10

7. SERVICE ‘A’ INSTRUCTIONS

(Every 6,000 hrs or 12 months)

1. Ensure the dryer is shutdown and

fully depressurized before aempng any

maintenance work.

Refer to: CH. 6.MAINTENANCE GUIDELINES

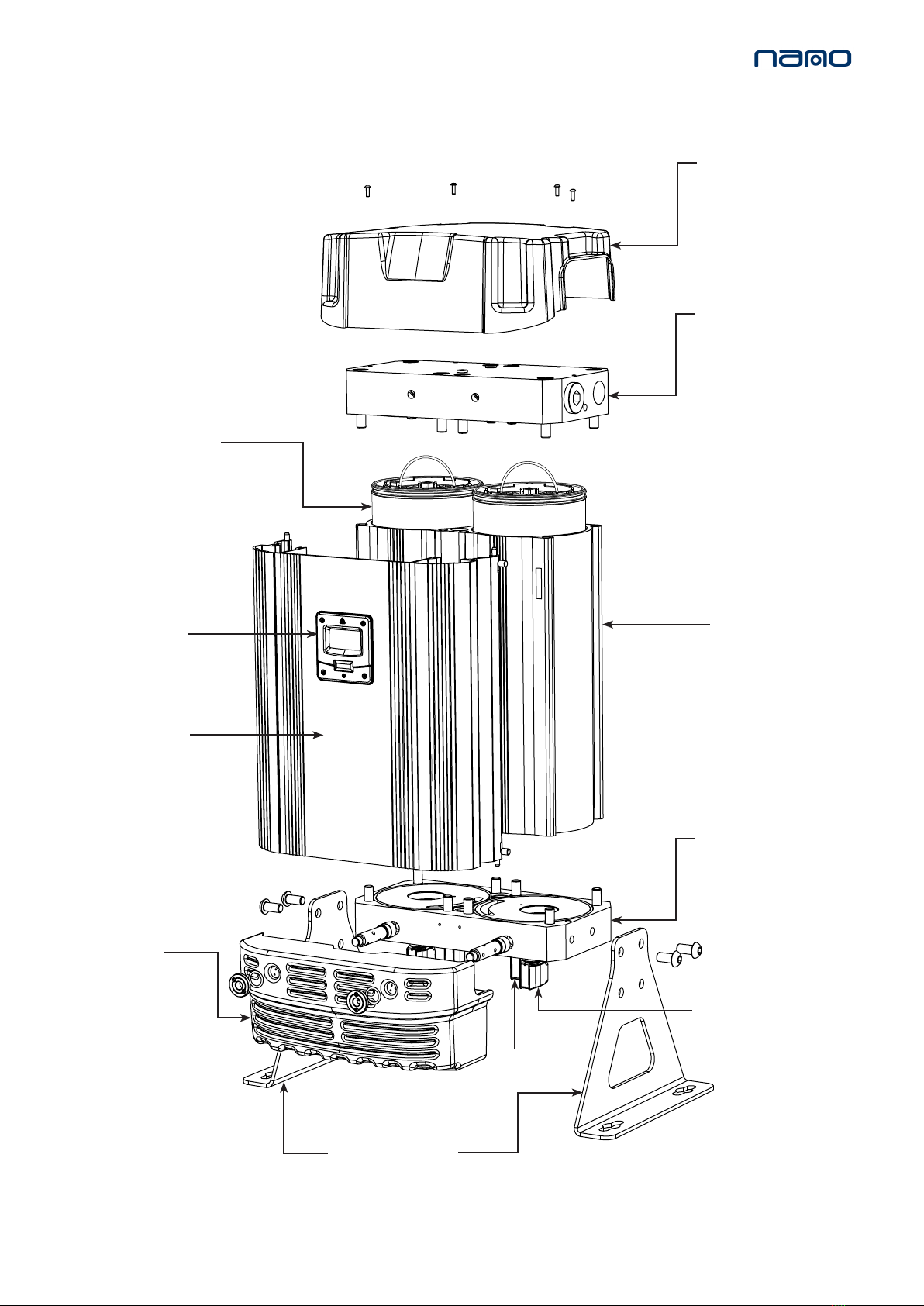

2. Remove the 4x M5 screws as shown to

remove the dryer top cover.

3. Remove the 8x M12 cap head screws and 8x

washers to remove the top manifold from the

dryer column and support front shroud.

4. Discard the gasket seal.

5. Li the wire handle and remove the

cartridge from the dryer column.

6. Check and clean the top manifold and dryer

column as required, paying parcular aenon to

the gasket sealing faces.

7. Remove the new cartridges and gasket seal

from the service kit provided.

8. Insert 2x new desiccant cartridges and press

them down unl they stop and the cartridge is

below the top surface of the dryer column.

9. Insert the new gasket seal placing it into the

gasket groove in the top manifold ensuring it is

fully retained.

10. Ensure both handles are folded at.

11. Replace the top manifold and secure with the

8x M12 cap head screws ghtening to a torque

seng of 80Nm.

NOTE: Refer to:

CH.

14. MANIFOLD TIGHTENING SEQUENCES

and

follow the correct ghtening sequence.

12. The seal between the dryer column and top

manifold should be checked for leaks prior to

ng the top cover and operang the dryer.

13. Replace the dryer top cover and secure with

the 4x M5 screws. These screws should be hand

ghtened only or ghtened to a torque seng of

less than 1Nm.

If service A is complete reset the dryer,

Refer to: NOTE: Care must be taken when removing the

desiccant cartridges not to damage the top face of

the dryer column. This is a sealing face!

(Sealing face shown as the shaded area)

GASKET SEAL

TOP MANIFOLD

8x M12 CAP HEAD

SCREWS

TOP COVER

DESICCANT CARTRIDGES

4x M5 SCREWS

MODELS: NBA-070, 090, 110, 120

DESICCANT CARTRIDGE REPLACEMENT

NBK-060, 080, 110, 120

Figure 1.

CH. 13. RESETTING DRYER CONTROLLER