L00049 1.0 08/2015 3

Table of Contents

PART A –WARNINGS, INSTRUCTIONS AND INTRODUCTION........................................................4

SECTION A1: IMPORTANT WARNINGS, LABELS and SYMBOLS .....................................................4

A1.1 Labels and Symbols ...............................................................................................................4

A1.2 Instructions .............................................................................................................................5

A1.3 Warnings.................................................................................................................................5

SECTION A2: INTRODUCTION TO THE TROPHON EPR ...................................................................6

A2.1 Intended Use ..........................................................................................................................6

A2.2 Disinfection Process...............................................................................................................6

A2.3 Disinfection History Log..........................................................................................................6

A2.4 Validated Probes and Disinfectants........................................................................................6

A2.5 Training...................................................................................................................................6

A2.6 Environment and User Profile.................................................................................................6

A2.7 Accessories ............................................................................................................................6

PART B –OVERVIEW OF TROPHON FEATURES AND INSTALLATION GUIDE.............................7

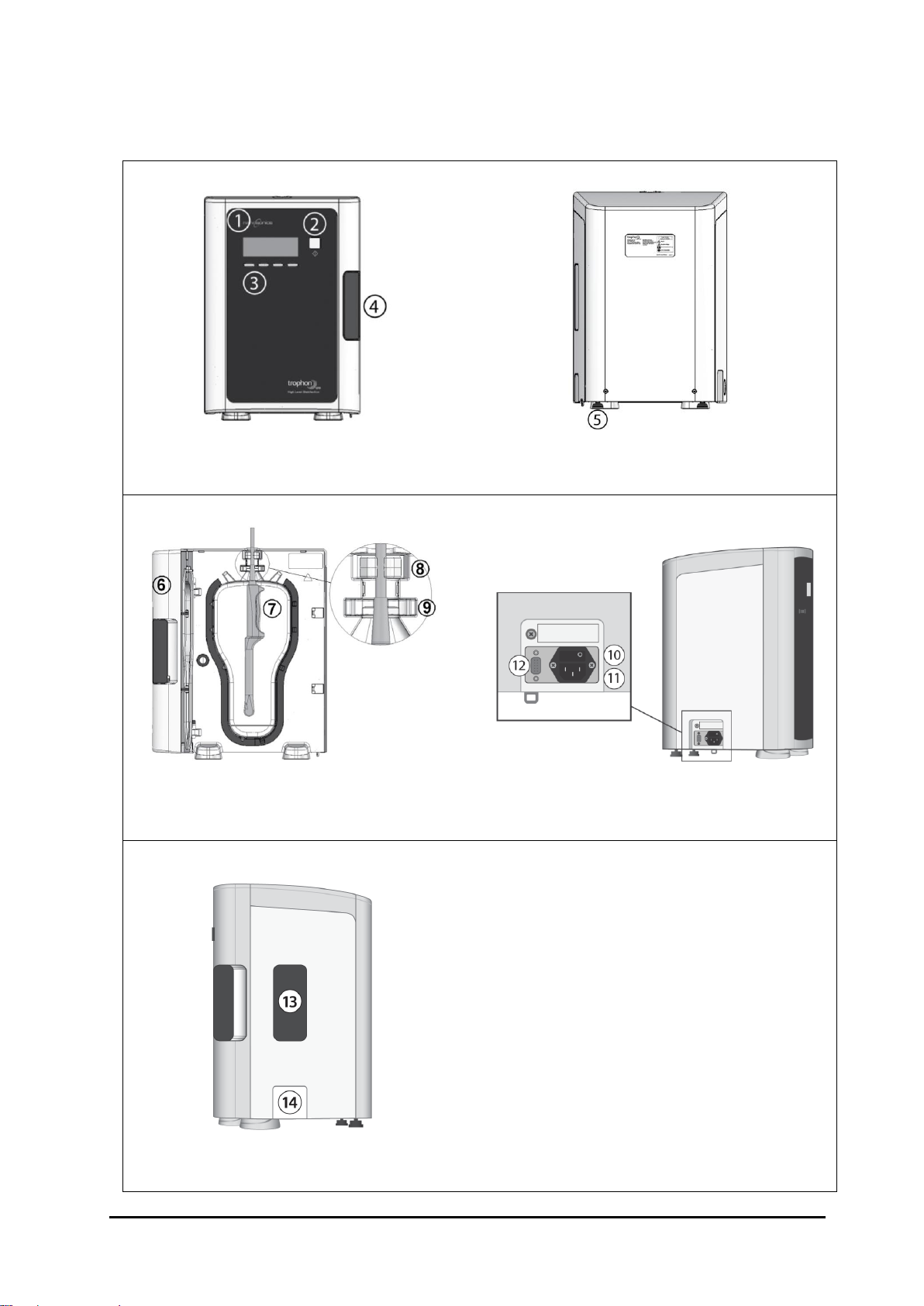

SECTION B1: TROPHON FEATURES ..................................................................................................7

SECTION B2: INSTALLATION GUIDE...................................................................................................8

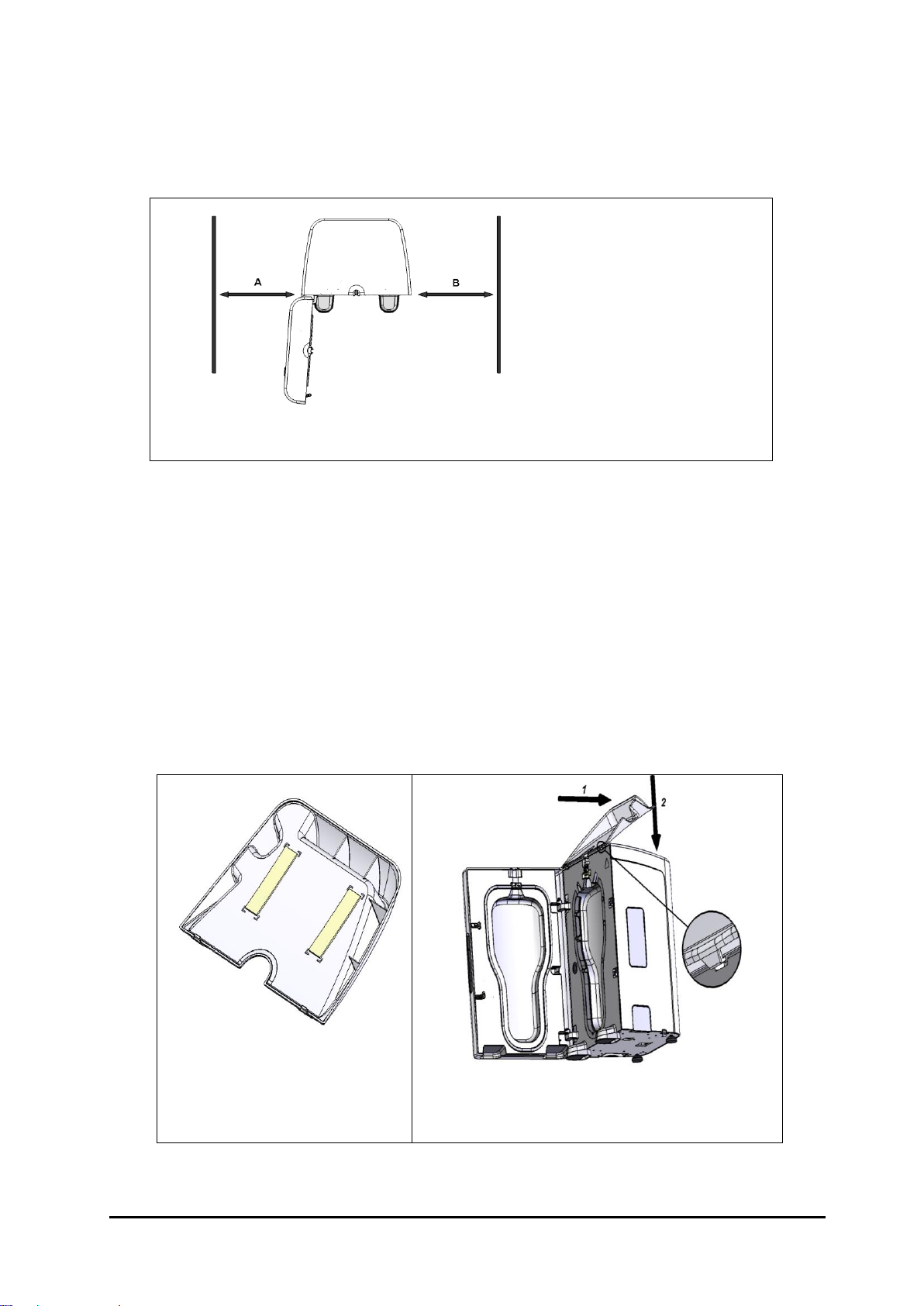

B2.1 Positioning your trophon.........................................................................................................8

B2.2 Cable Management System Installation.................................................................................8

B2.3 Powering On...........................................................................................................................9

B2.4 Basic Settings.........................................................................................................................9

B2.5 Warm-up Cycle.......................................................................................................................9

PART C –ROUTINE USE, MAINTENANCE AND CARE ...................................................................10

SECTION C1: LOADING THE DISINFECTANT CARTRIDGE ............................................................10

SECTION C2: ROUTINE HIGH LEVEL DISINFECTION CYCLE ........................................................10

C2.1 Preparing the Probe .............................................................................................................10

C2.2 Inserting the Chemical Indicator...........................................................................................10

C2.3 Positioning the Probe ...........................................................................................................10

C2.4 Closing the Chamber Door...................................................................................................12

C2.5 Disinfecting the Probe ..........................................................................................................12

C2.6 Removing the Probe.............................................................................................................12

C2.7 Sleep Mode and Shutdown Procedures...............................................................................13

SECTION C3: PURGE CYCLE.............................................................................................................14

C3.1 When to Run a Purge Cycle.................................................................................................14

C3.2 How to Manually Run a Purge Cycle....................................................................................14

C3.3 Transporting the trophon......................................................................................................14

SECTION C4: INCOMPLETE OR FAILED CYCLES ...........................................................................14

C4.1 Mains Power Failure.............................................................................................................14

C4.2 Cycle Fault............................................................................................................................14

C4.3 Manual Door Lock Override .................................................................................................15

SECTION C5: ROUTINE CARE AND MAINTENANCE .......................................................................15

C5.1 Regular Cleaning..................................................................................................................15

C5.2 Service..................................................................................................................................15

SECTION C6: DISPOSAL OF TROPHON ...........................................................................................15

PART D –TROUBLESHOOTING........................................................................................................16

PART E –SERVICE AND WARRANTY ..............................................................................................17

APPENDIX 1: TROPHON EPR TECHNICAL SPECIFICATIONS, N00010, N00020, N03000 &

N04000..................................................................................................................................................17

APPENDIX 2: PRODUCT WARRANTY TERMS AND CONDITIONS ................................................18