333 Bayview Avenue, Amityville, New York 11701

For Sales and Repairs, (800) 645-9445

For Technical Service, (800) 645-9440 or visit us at Tech.NapcoSecurity.com

(Note: Technical Service is for security professionals only)

Publicly traded on NASDAQ Symbol: NSSC

WI2485ALF 01/23

PAGE 1 of 2

INSTALLATION AND MAINTENANCE INSTRUCTIONS

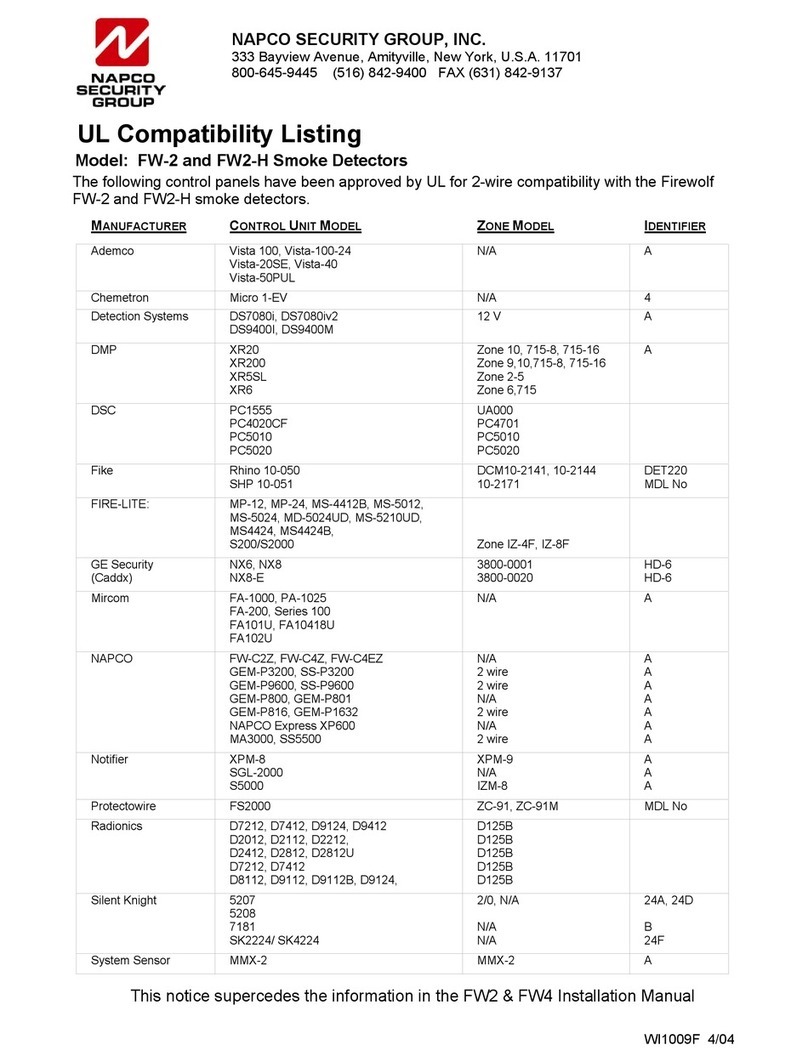

Connect these detectors only to a Napco listed-compatible control panel: Series GEM-P816, GEM-P1632, GEM-

P1664, F-64, Series GEM-P3200, GEM-P9600, GEM-X255, Series GEMC-32, GEMC-96, GEMC-128, GEMC-255, Series

FL-32FACP-xxxxx, FL-96FACP-xxxxx FL-128FACP-xxxxx, FL-255FACP-xxxxx, Series XP-600, GEM-P800, GEM-P801.

Refer to the control panel installation manual for additional instructions. Smoke detectors are not to be used with

detector guards unless the combination has been evaluated and found suitable for that purpose.

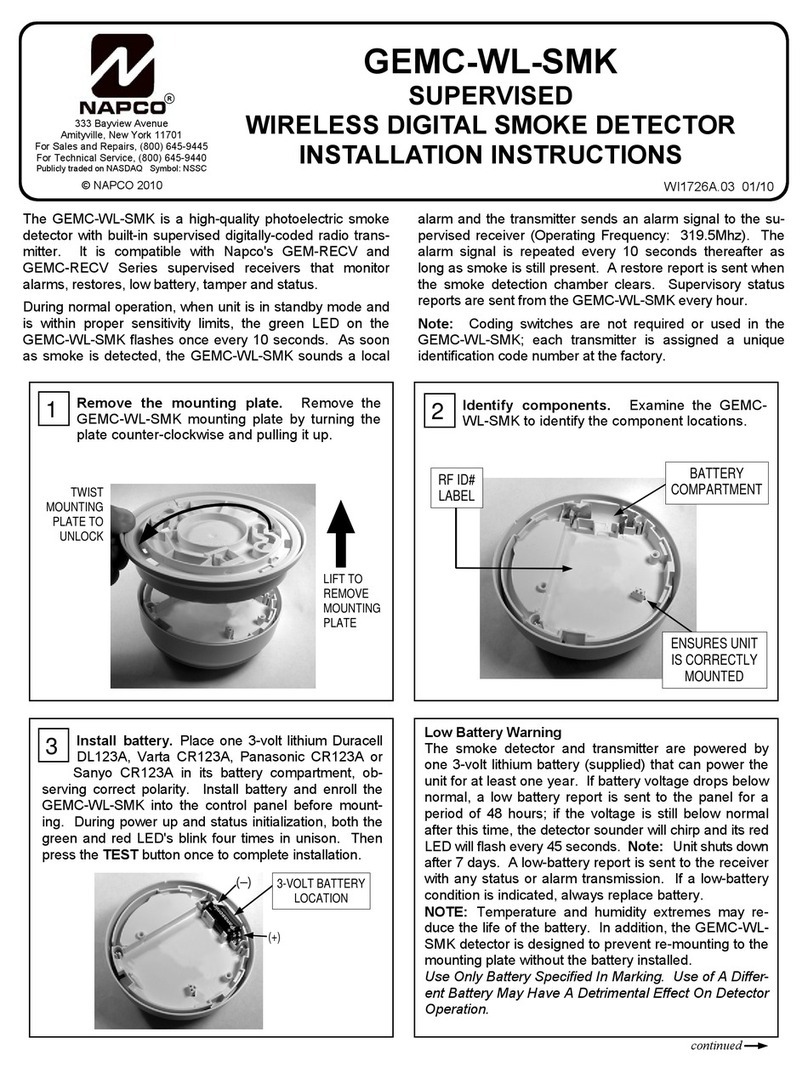

FW-2-E Conventional Photoelectric Smoke Detector and Base

Sensing Element Smoke IR LED, Blue LED, Photodiode

Blue LED enhances the photoelectric smoke sensor to reduce sensitivity

to false alarms and increase sensitivity to fire conditions.

Supply Voltage Operating Voltage Range 8 –35VDC

Maximum Voltage Ripple 8200mVAC

Current Consumption Standby Current 59A

Alarm Current 5mA (Min), 150mA (Max)

Startup Cold Start Time 25s (Max)

Alarm Verification Restart

Time

20s (Max)

Current 160A (Max)

Included Separable Base FW-2-EH6-BASE (HB-55) 6 inch diameter base

Included Separable Head FW-2-E-HEAD (Detector ID HD-3) Smoke Detector

Temperature UL Listed Ambient: 32F ~ 120F, Storage: -22F ~ +140F

Operating Humidity <95%RH at 104F, <80%RH at 120F

FW-2-H-E Conventional Photoelectric Smoke and Heat Detector and Base

Sensing Element Smoke IR LED, Blue LED, Photodiode

Blue LED, thermistor enhance the photoelectric smoke sensor to reduce

sensitivity to false alarms and increase sensitivity to fire conditions.

Heat Thermistor

Heat Sensitivity Range 135F

Supply Voltage Operating Voltage Range 8 –35VDC

Maximum Voltage Ripple 8200mVAC

Current Consumption Standby Current 59A

Alarm Current 5mA (Min), 150mA (Max)

Startup Cold Start Time 25s (Max)

Alarm Verification Restart

Time

20s (Max)

Current 160A (Max)

Included Separable Base FW-2-EH6-BASE (HB-55) 6 inch diameter base

Included Separable Head FW-2-H-HEAD (Detector ID HD-3) Smoke and Heat Detector

Temperature UL Listed Ambient: 32F ~ 117F, Storage: -22F ~ +140F

Operating Humidity <95%RH at 104F, <80%RH at 120F

SEPARABLE BASE SPECIFICATIONS

MODEL Base ID Alarm Current Mounting Box

FW-2-EH6-BASE HB-55 150mAlimit by panel @15.0 - 33.0V max 4”Octogonal / 4”Square

CAUTION

Install this and all life safety devices in accordance with applicable NFPA standards, local codes, and the authorities

having jurisdiction. Failure to follow these instructions may result in failure of the detector to initiate an alarm condition.

Napco Security Systems, Inc. and the original equipment manufacturer, are not responsible for detectors that have been

improperly installed, tested, or maintained.