W415-0372 / B / 04.24.06

6

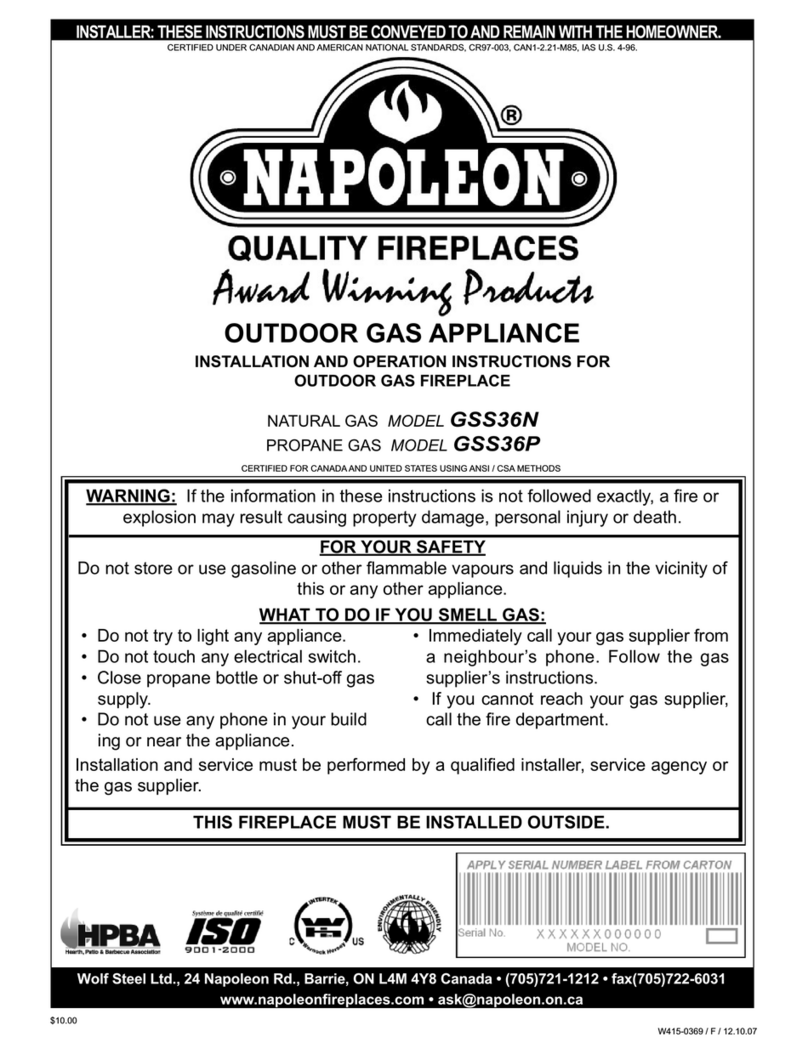

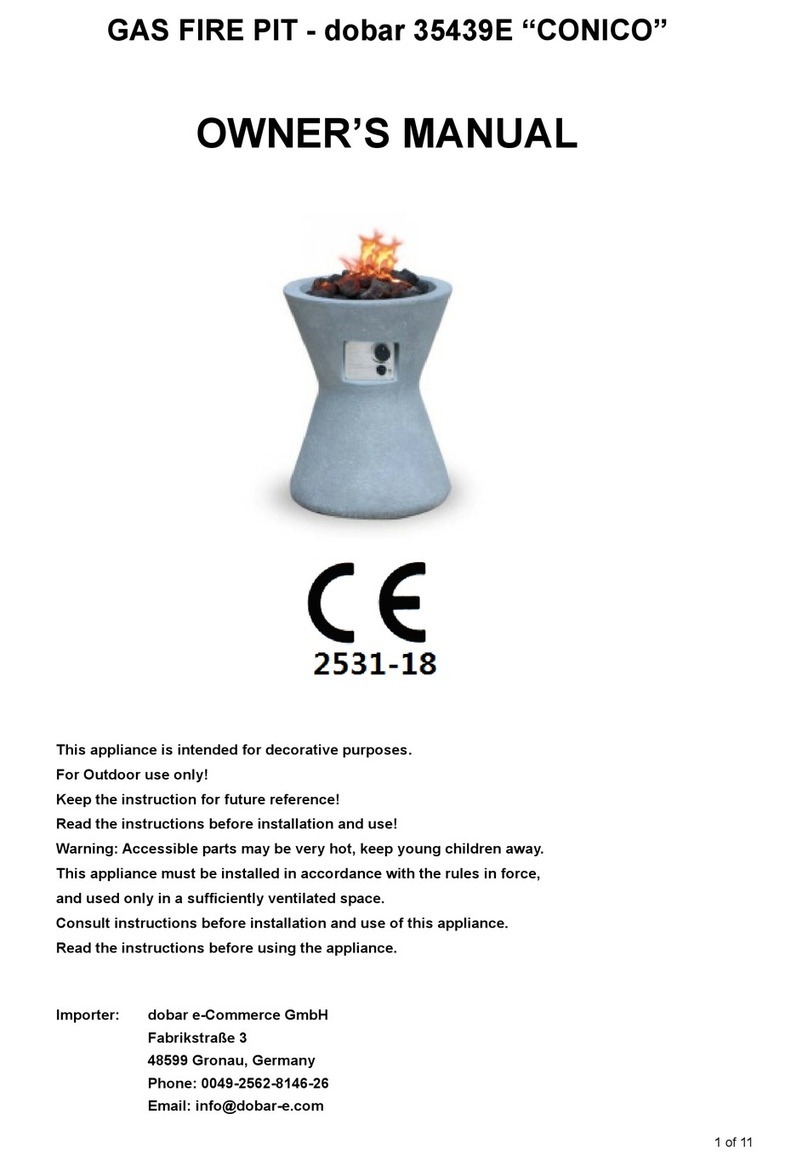

Natural Gas

Supply Line

(not supplied)

Propane Regulator

Hose Manual Gas

Valve (on/off)

QCC1

Tank Retaining

Bracket

INSTALLATION

The log set and the burner assembly are shipped together.

Remove the gas log set and burner assembly and check for

damage.DONOTinstalldamaged components.Thelogs are

fragile use care when handling.

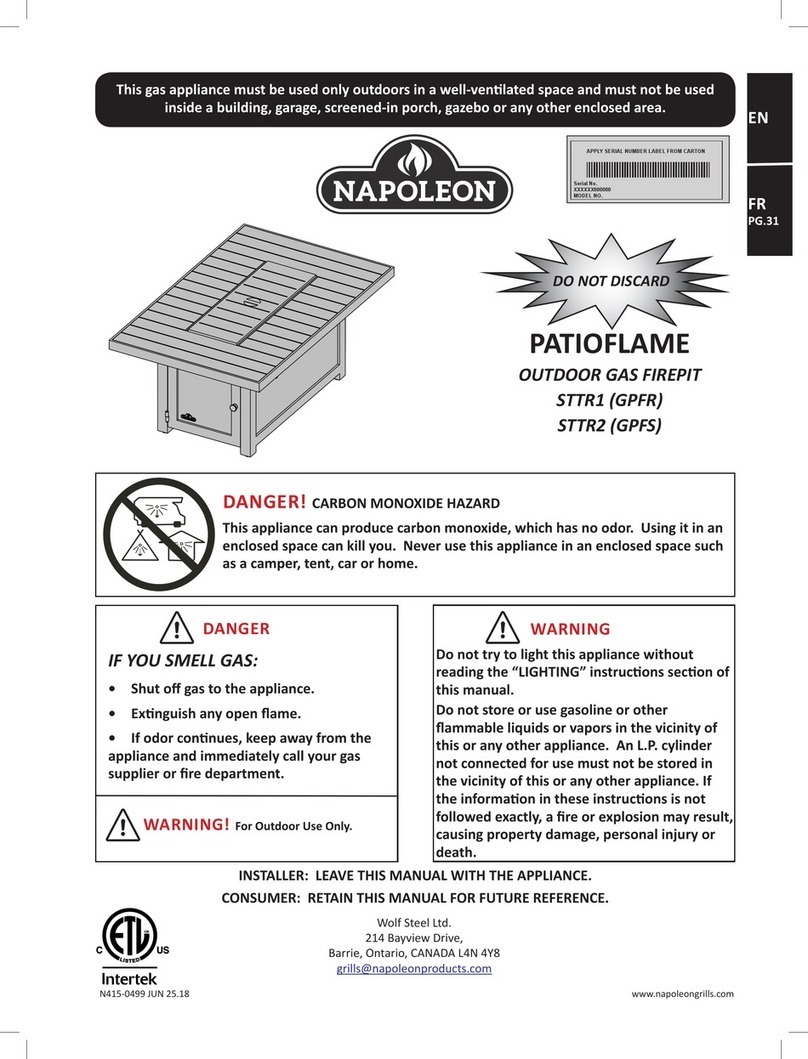

Place the Patioflame on a level/secure surface in desired

location. This location must be adjacent to the gas supply

line or cylinder.

NOTE:Minimumclearances to combustibleconstruction must

be maintained. ( See Page 5)

You must have clear and easy access to the on/off valve

AFTER the appliance is installed and connected to the gas

supply in order to safely turn off the burner.

THE ON/OFF GAS VALVE IS USED TO TURN THE

BURNER ON AND OFF.

Connect the incoming gas supply line to the on/off gas valve

ofthe appliance.Make certainALLgas connections are tight,

turn the on/off valve at the unit slowly to the on position and

use soap water to test for leaks.

DO NOT USEAN OPEN FLAME.

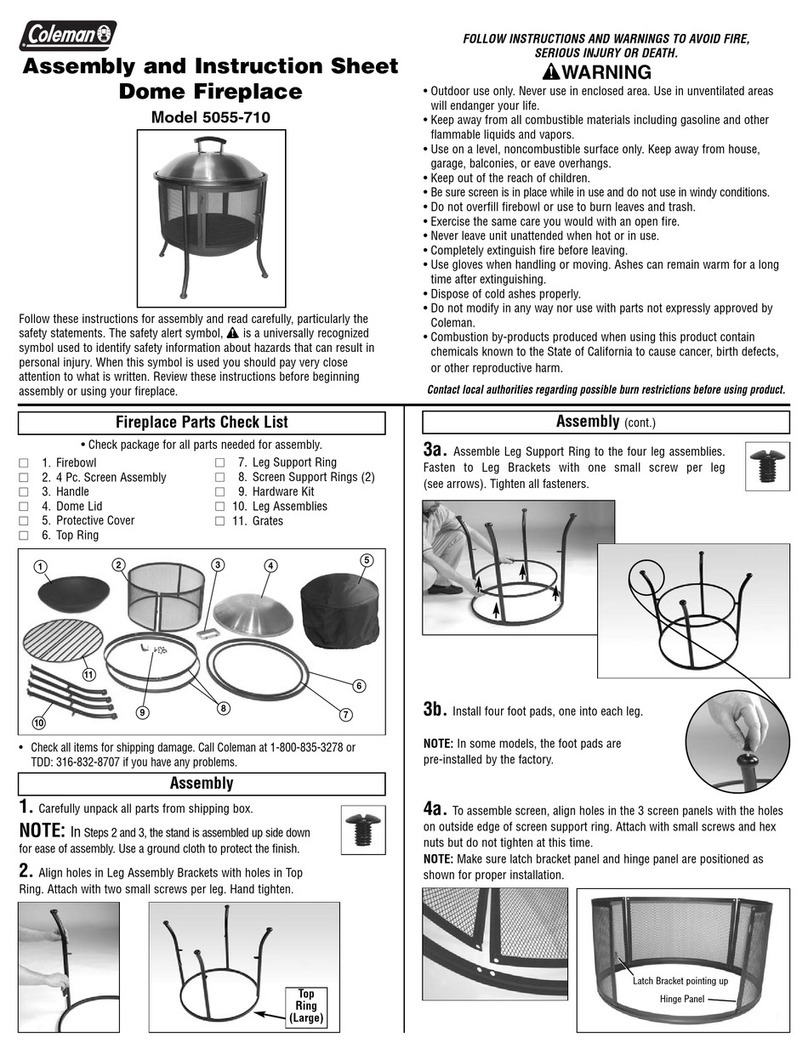

1. Attach tank retaining bracket supplied to the base of the

cylinder. Then secure to the surface to which it sits. Cylinder

should be on a level surface.

2. Make sure tank valve is in its full off position. (Turn clock-

wise to stop).

3. Check tank valve features to ensure it has proper external

mating threads. (Tank Valve Marked: USE WITH TYPE 1)

4. Inspect hose shipped with the unit for damage. Never at-

tempt to use damaged or plugged equipment. See your local

LP Gas Dealer for repairs.

5.Afterinspecting the LP hoseshipped with the unit, connect

the end with the female fitting on the hose to the male fitting

on the on/off gas valve at the end of the flex tube. Tighten

fittings using 2 wrenches.

6. When connecting regulator assembly to the tank valve,

hand tighten black QCC1 nut clockwise to a positive stop.

DO NOT use a wrench to tighten. Use of a wrench may dam-

age the quick closing coupling nut and result in a hazardous

condition.

7. Locate the hose out of pathways where people may trip

over it or in areas where the hose may be subject to acci-

dental damage.

8. Open tank valve fully (counter-clockwise). Turn the on/off

valve at the unit slowly to the on position and use a soapy

water solution to check all connections for leaks before at-

tempting to light the appliance. If a leak is found, turn tank

valve off and do not use the appliance until repairs can be

made.

NATURAL GAS

LP GAS

ENCLOSURES FOR LP GAS SUPPLY

SYSTEMS

If you build an enclosure for an LP gas cylinder, follow these

recommended specifications. You must also follow local

codes.

Enclosures for LP gas supply cylinders shall be ventilated by

openings at the level of the cylinder valve and at floor level.

The effectiveness of the opening(s) for purposes of ventila-

tion shall be determined with the LP gas supply cylinder(s) in

place. This shall be accomplished by one of the following:

1. One side of the enclosure shall be completely open;

or

2. For an enclosure having four sides, a top and bottom:

a) At least two ventilation openings at cylinder valve level

shall be provided in the side wall, equally sized, spaced at

180 degrees (3.14 rad), and unobstructed. Each opening

shall have a total free area of not less than ½ square inch per

pound(3.2 sq. cm/kg)ofstored fuelcapacityand notlessthan

a total free area of 10 square inches (64.5 sq. cm).

b) Ventilation opening(s) shall be provided at floor level and

shall have a total free area of not less than ½ inch per pound

(3.2 sq. cm/kg) of stored fuel capacity and not less than a

totalfree areaof 10square inches(64.5 sq.cm). Ifventilation

openingsat floorlevelare ina side wall,there shallbe atleast

two openings. The bottom of the openings shall be at floor

level and the upper edge no more than 5 inches (127mm)

above the floor. The openings shall be equally sized, spaced

at 180 degrees (3.14 rad) and unobstructed.

c) Every opening shall have minimum dimensions so as to

permit the entrance of a 1/8 inch (3.2mm) diameter rod.

3. Cylinder valves shall be readily accessible for hand opera-

tion. A door on the enclosure to gain access to the cylinder

valve is acceptable, provided it is non-locking and can be

opened without the use of tools.

4. There shall be a minimum clearance of 2 inches (50.8mm)

between the lower surface of the floor of the LP gas supply

cylinder enclosure and the ground.

5. The design of the enclosure shall be such that (1) the LP

gas supply cylinder(s) can be connected, disconnected and

the connections inspected and tested outside the cylinder

enclosure;and(2)thoseconnections which couldbedisturbed

when installing the cylinder(s) in the enclosure can be leak

tested inside the enclosure.

6. Be certain to mount or set the LP gas cylinder on a flat

surface and restrain it to prevent it from tipping.

Purge the gas supply line of any trapped air prior to the first

firing of the unit.

WARNING: During the initial purging and subsequent

lightings, NEVER allow gas valve to remain in the

"Open" position without first placing and igniting the

firestarter.