7

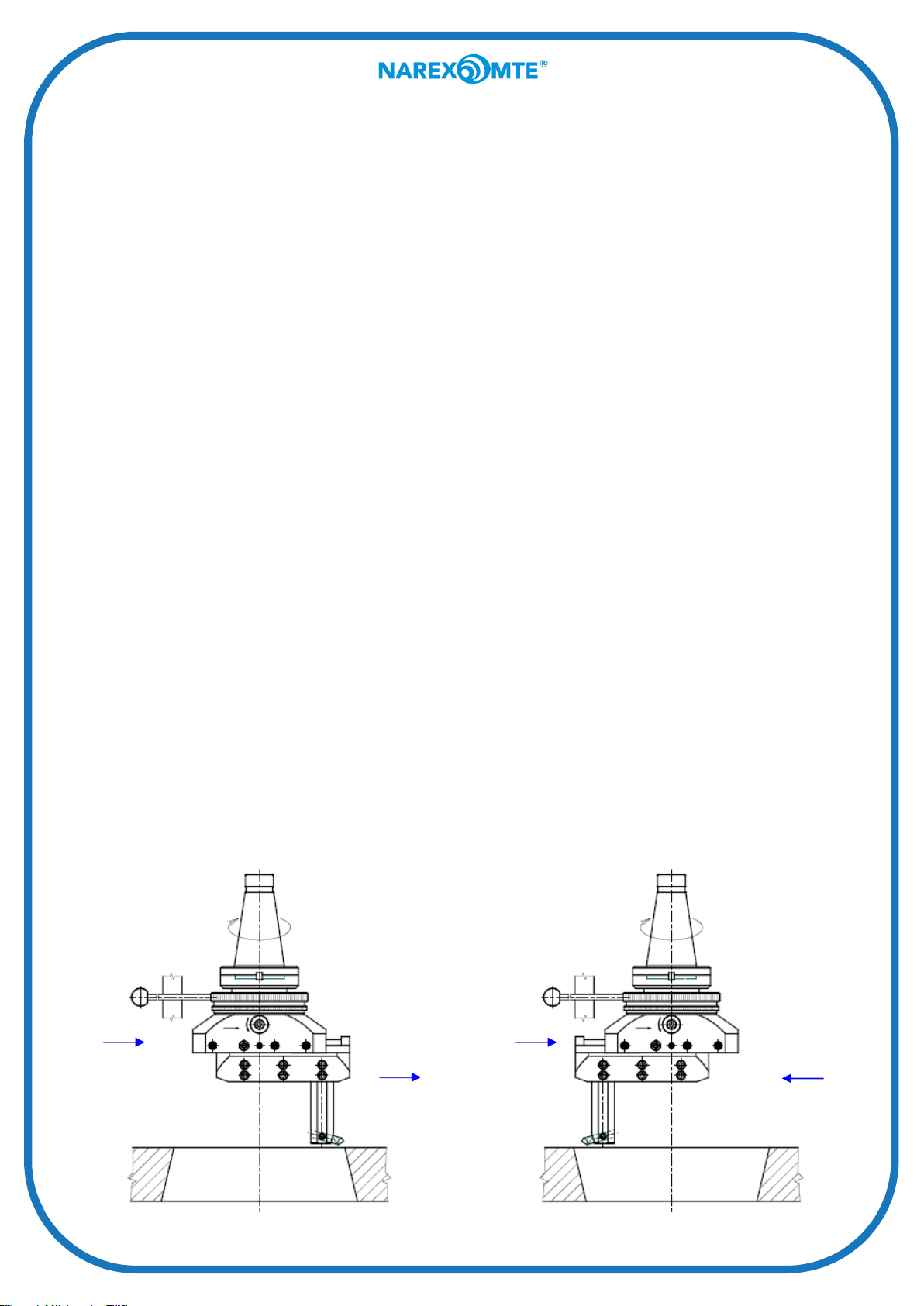

e) By slowing down of the control ring (3), when the head is turning to the right, the tool slide (5)

moves in the direction of both arrows situated on the tool slide side near the fine feed setting

dial (4); when the head is turning to the left, the tool slide moves against the direction of the

arrows.

f) An automatic disengagement of the transverse feed takes place when one of the trip dogs (10)

strikes the trip dog pin (11) or when the cutting resistance increases due to a large cut,

blunting or chipping of the tool. The sensitivity of the clutch disengagement (15) can be

adjusted by the adjusting screw (14) which compresses or relieves the spring of the clutch

(15). In case of excessive screwing-in of the clutch adjusting screw (14) try to disengage the

clutch by means of screw driver (as shown in Fig. No. 12). If the clutch cannot be completely

disengaged, the spring coils bear on each other and the clutch adjusting screw (14) must be

slightly loosened; then repeat the disengagement of the clutch (15) by the described method.

g) Adjustment of trip dog for disengagement on accurate diameter. The trip dog (10) must be

adjusted and secured so as to disengage the transverse feed at the moment the tool cutting

edge reaches a certain diameter. The disengagement of the clutch (15) must be therefore

adjusted so that the disengagement pressure between the trip dog and trip dog pin (11) be as

small as possible, i. e. the clutch adjusting screw (14) must be screwed in as little as possible.

In spite of this, however, there will be a certain overtravel exceeding the required dimension.

This overtravel is within the tolerance of the recess diameters for lock rings. A more accurate

adjusting for precision jobs can be attained by the following trip dog adjustment:

A) The trip dog (10) must be adjusted and firmly tightened so as to disengage shortly

before the required diameter will be attained, e. g. by turning the fine setting dial (4)

reverse the tool slide by approx. 0,008 inch push the trip dog (10) against the trip dog

pin (11) and secure firmly by screws.

The difference between the required and actual diameter will be measured after a

trial disengagement.

B) Now, the trip dog should be adjusted as follows:

a) Do not loosen the trip dog (10) but reverse the tool slide (5) so that a feeler gauge of

any type, for example 2 mm, can be slipped between the trip dog and trip dog pin

(11).

b) Secure the tool slide (5) against moving by means of the tool slide lock screw (9) so

that its position can be changed when displacing the trip dog (10).

c) A new slip gauge will be assembled as follows:

1. If the actual diameter which has been attained after a trial disengagement is

larger than the required diameter, the new feeler gauge must be smaller by

50% of the ascertained difference.

2. If the actual diameter is smaller than the required one, the new feeler gauge

must be enlarged by 50% of the ascertained difference.