CONTENTS

1. ACCESSORY DETAILS ............................................................................................................ 3

1.1. Accessory Identification ................................................................................................ 3

1.2. Dimensions ................................................................................................................... 3

1.3. Accessory Description .................................................................................................. 4

1.4. General Characteristics ................................................................................................ 4

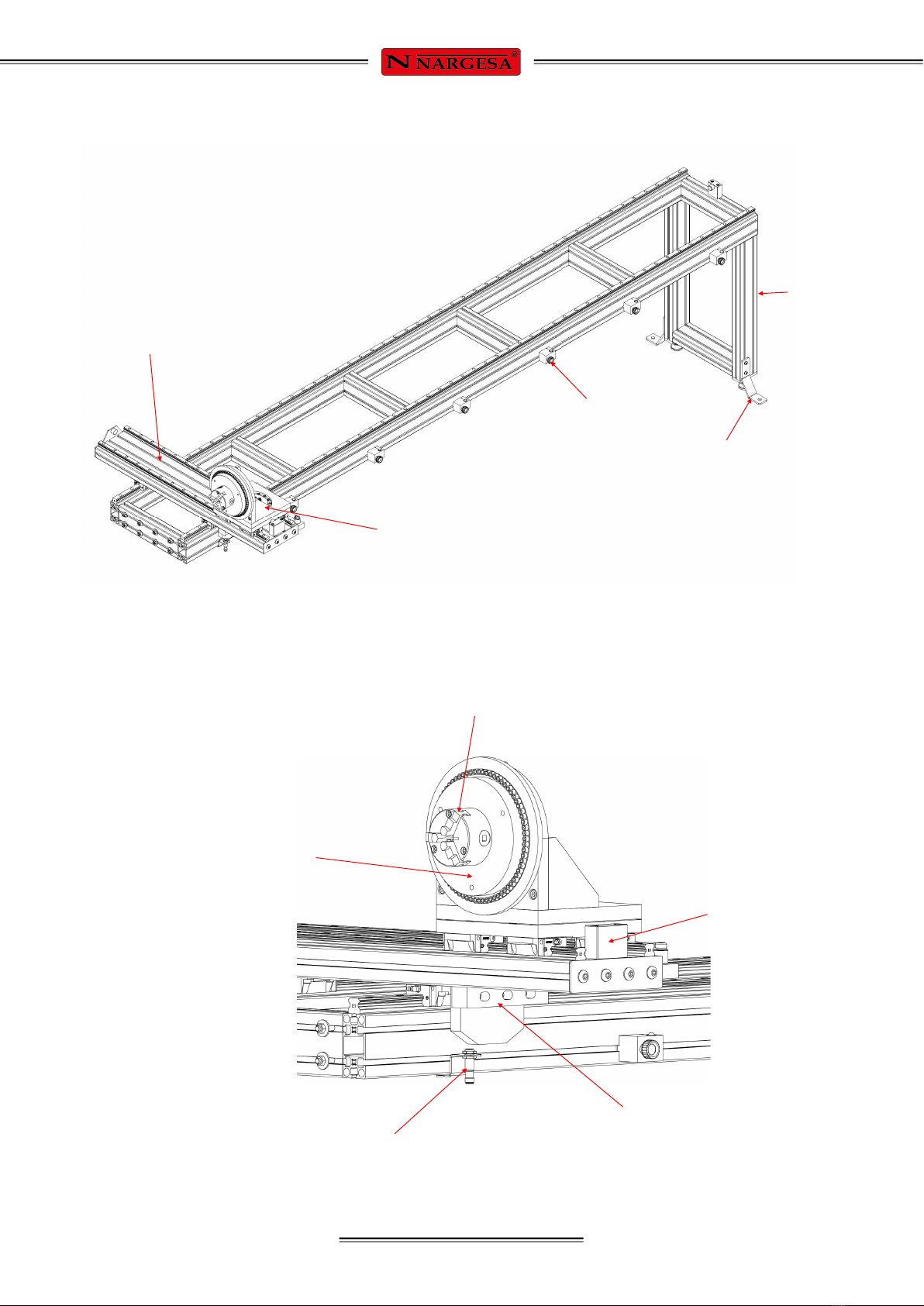

1.5. Machine Parts ............................................................................................................... 5

2. TRANSPORT AND STORAGE ................................................................................................. 6

2.1. Transport ....................................................................................................................... 6

2.2. Storage Conditions ....................................................................................................... 6

3. MAINTENANCE ......................................................................................................................... 7

3.1. Greasing the Moving Parts ........................................................................................... 7

4. LIMIT LOCATION AND INSTALLATION .................................................................................. 8

4.1. Limit Location ................................................................................................................ 8

4.2. Dimensions and Work Area ......................................................................................... 8

4.3. Acceptable External Conditions .................................................................................... 8

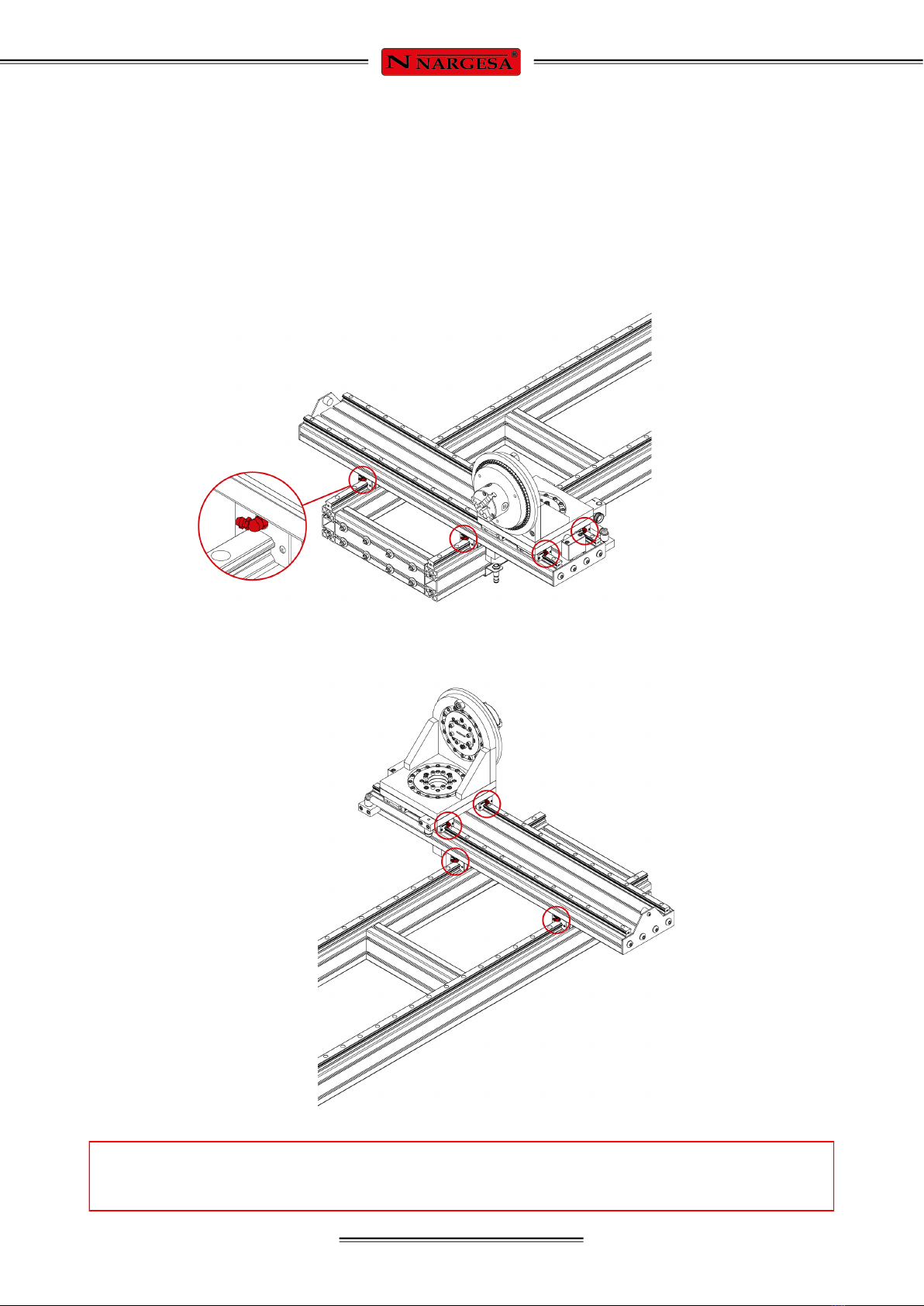

4.4. Installing the Limit ......................................................................................................... 9

4.5. Adjusting the Limit ....................................................................................................... 17

5. INSTRUCTIONS FOR USE ..................................................................................................... 20

5.1. Limit Features and Use ............................................................................................... 20

5.2. Securing the Pipe to the Limit ..................................................................................... 20

5.3. Installing the Through Pipe ......................................................................................... 20

5.4. Adjusting the Longitudinal Limits ............................................................................... 21

5.5. Adjusting the Cross Limit ............................................................................................ 22

5.6. Adjusting the Pipe Rotation Angle .............................................................................. 23

TECHNICAL ANNEXES