Foreword 5

1 Foreword

Congratulations,

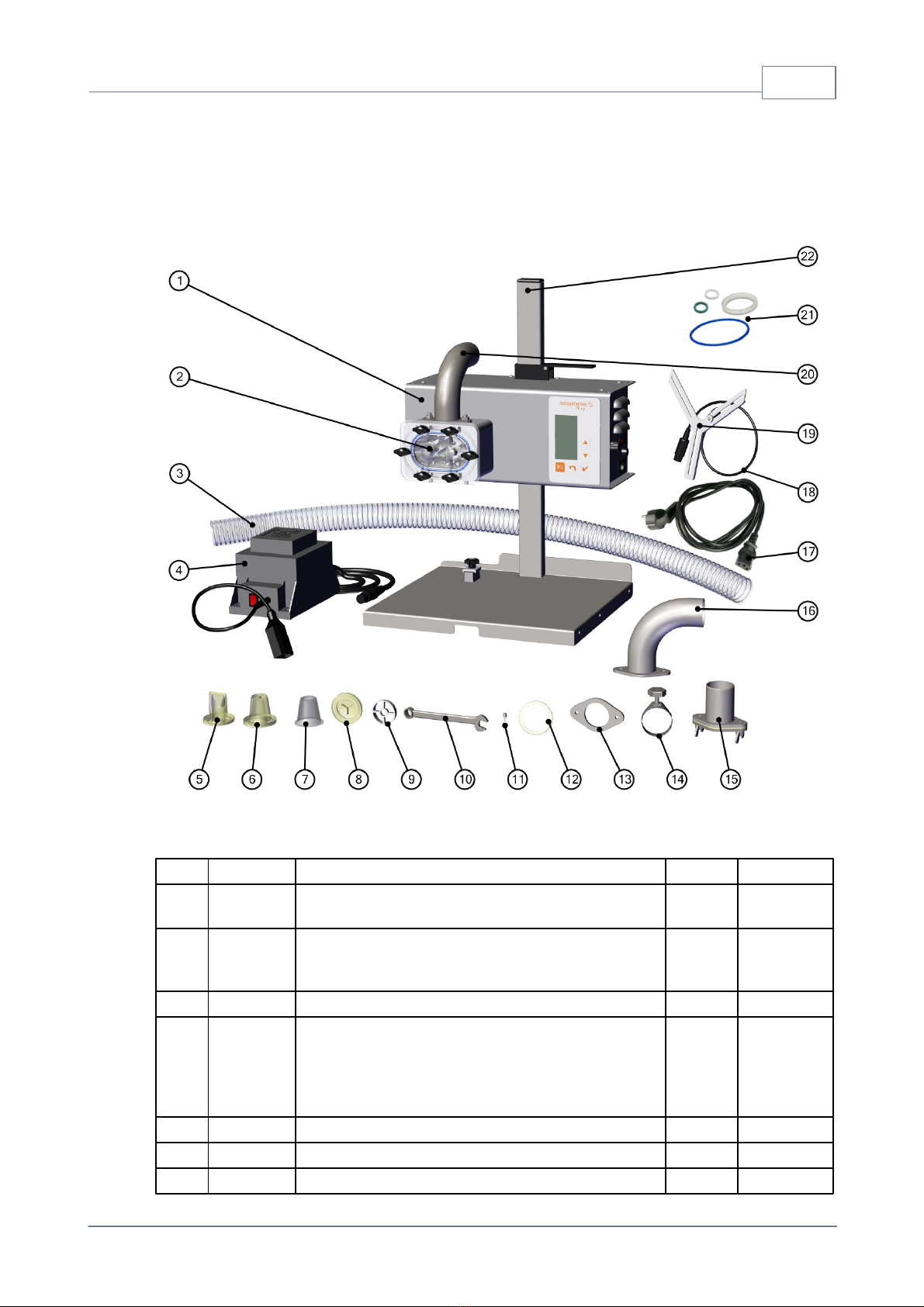

with the FILL-Systems product Fill up 2 you have chosen a proven and robust machine

from our high-quality product line for filling technology. The decision to include a

machine from FILL-Systems in your equipment fleet will facilitate the filling of your

products significantly and measurably increase productivity.

For many years now, all machines and devices bearing the NASSENHEIDER®product

brand name have been developed, designed and built exclusively by us in Dresden with

an international team. With passion and specialist engineering expertise, we adhere to

high quality objectives for our unique products and consistently integrate all the

current requirements set forth by the safety and environmental regulations into our

manufacturing processes. On the basis of quality, reliability and closeness to our

customers, we have developed into a leading global technology company with great

innovative strength and enjoy a high level of trust.

Sustainability and maximum efficiency are two of our most important principles.

All our machines are extremely energy-efficient and work without compressed air-

supported systems that unnecessarily increase energy consumption. Any maintenance

and extension of the machines can be very easily implemented due to our intelligent

modular system. When production volume increases, your machine park grows through

meaningful system extensions and extension options from FILL-Systems without any

problems.

Should a defect occur, each machine part can be repaired or replaced promptly and

with pinpoint accuracy. Likewise, the durability of our machine designs on the basis of

the long-term supply guarantee for spare parts has shown itself to be effective

thousands of times and all over the world. Moreover, we have the necessary

components / parts manufactured by partners in the region according to our quality

standards. This means that transportation routes are short while we are simultaneously

strengthening regional economic cycles.

In the interests of maximum functionality of our developments we do not use

unnecessary or superfluous features, in order to maintain the serviceability and

reliability of our products at the highest possible level.

Our website will provide you with all product-related information and a variety of

options relating to enhancements and innovations. We are also available for personal

consultation.

We thank you for your confidence in us and look forward to a long and happy

collaboration with you, wishing you every success with your new FILL-Systems

product.

Your FILL-Systems team from Dresden.