2

Index

1. MIDA Solar Introduction.................................................................................................................................................... 3

2. Safety Instructions............................................................................................................................................................. 4

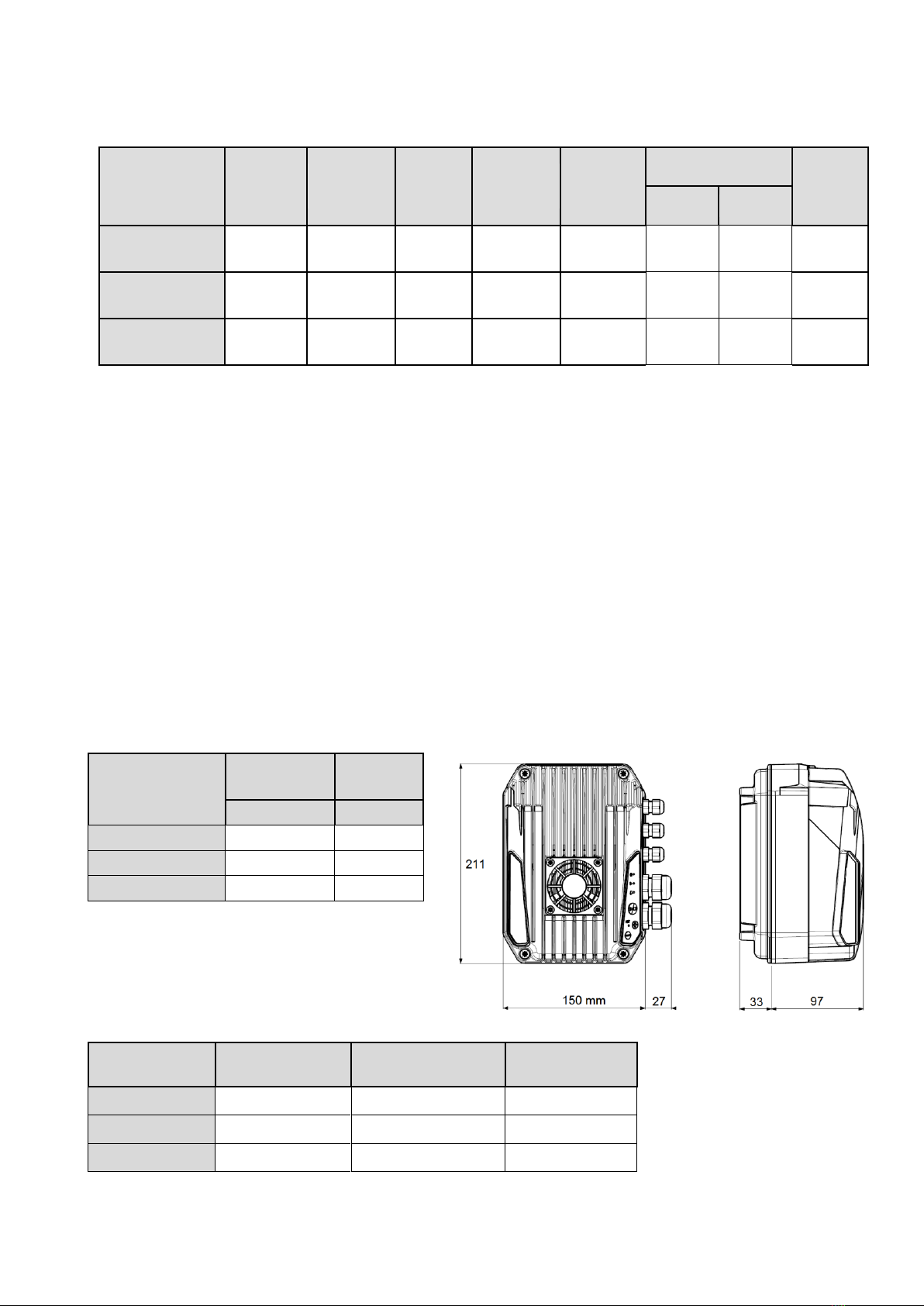

3. Technical Characteristics ................................................................................................................................................... 5

3.1 Performance ............................................................................................................................................................................ 5

3.2 Weight and dimensions .......................................................................................................................................................... 5

3.3 Cable entries ............................................................................................................................................................................ 5

4. MIDA Solar installation...................................................................................................................................................... 6

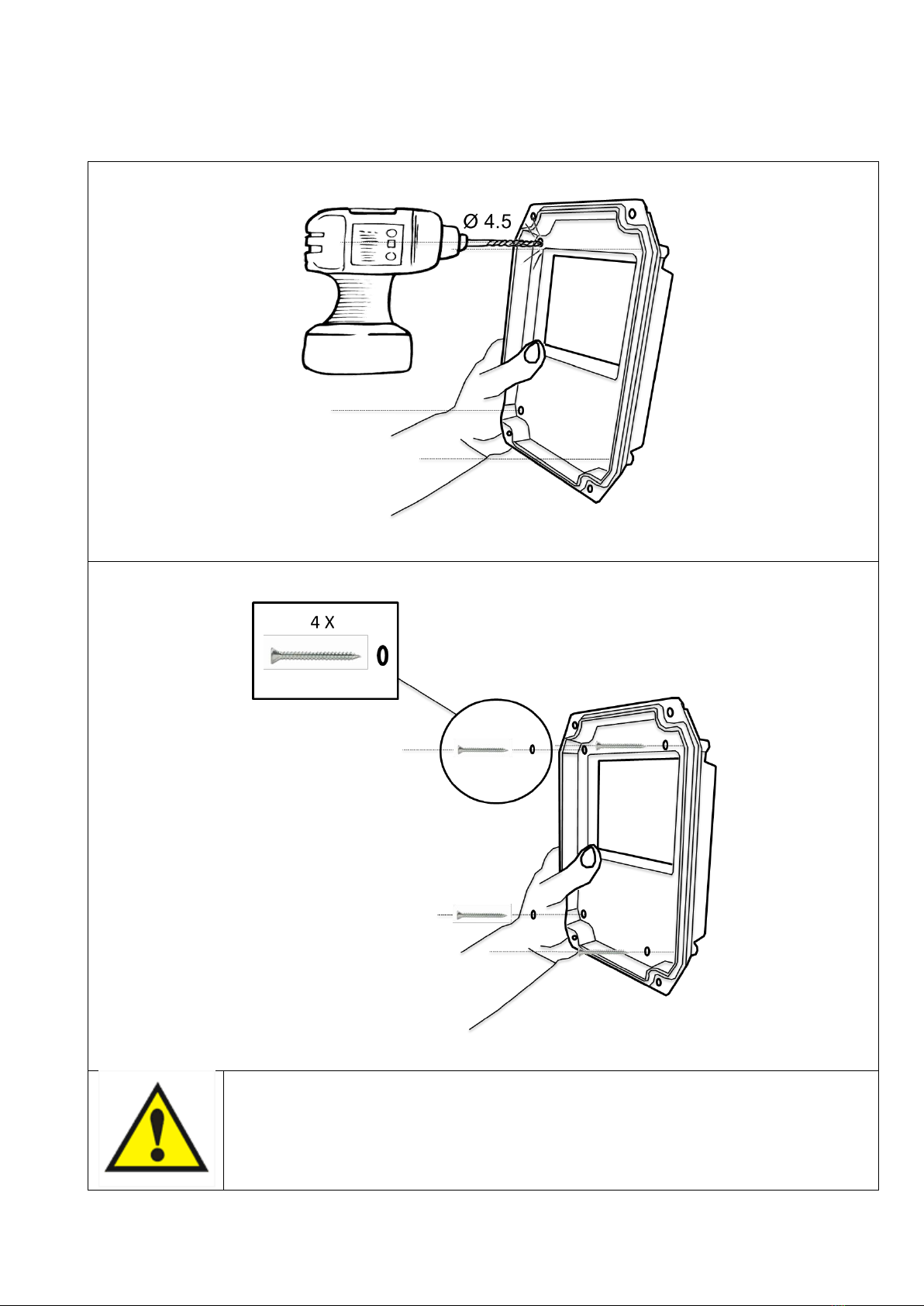

4.1 Mechanical installation ............................................................................................................................................................ 6

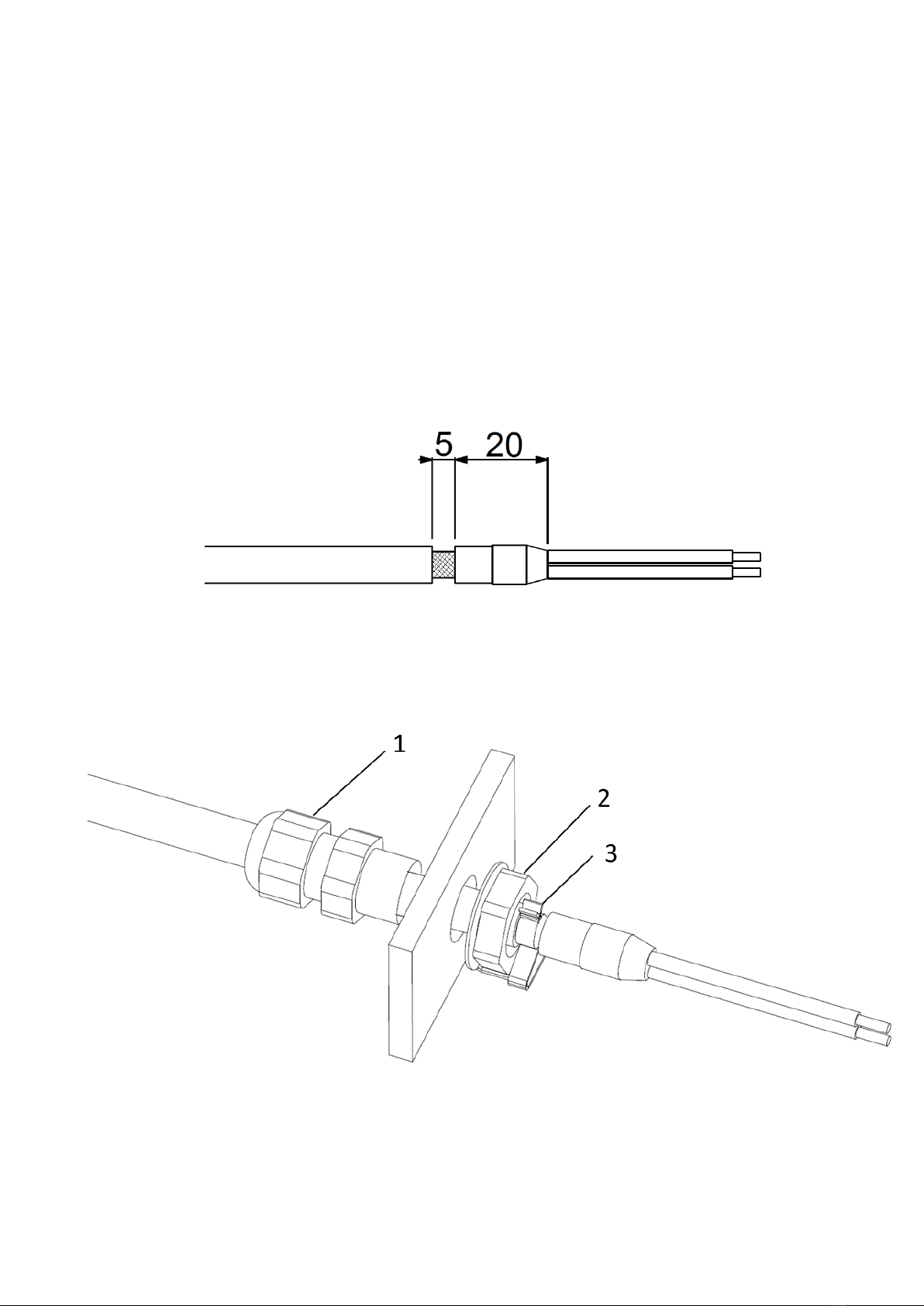

5. Electric wiring.................................................................................................................................................................... 8

5.1 Protections............................................................................................................................................................................. 11

5.2 Electromagnetic compliance.................................................................................................................................................. 11

5.3 Installation with long motor cables ....................................................................................................................................... 11

6. MIDA Solar use and programming ....................................................................................................................................12

6.1 Monitoring and programming............................................................................................................................................... 13

6.1.1 Monitoring ................................................................................................................................................................. 13

6.1.2 Programming.............................................................................................................................................................. 14

6.1.3 FOC motor control ...................................................................................................................................................... 23

7. Protections and alarms.....................................................................................................................................................25