26

Installation Guide for Comfort Pack (CPG) Units

Inspect the Heat Exchanger

Remove the heat furnace baffle panel (see page 29). Remove any

dirt or dust accumulation. Visually check the heat exchanger for

cracks and holes. If a crack or hole is observed, replace the heat

exchanger. Thorough inspection of the heat exchanger can be

done with furnace slid out of the cabinet. (See pages 29 & 30)

Burner Service

Inspect the burner/control compartment annually to determine

if cleaning is necessary. Open the burner/control compartment

and on the burner housing, clean the compartment and follow

the instructions below to remove and clean the burner.

Instructions for Burner Removal

Note: Components may be more easily accessed with the

furnace removed from cabinet. (See page 29 & 30)

1. Shut the gas supply off ahead of the combustion valve.

2. Turn off electric supply.

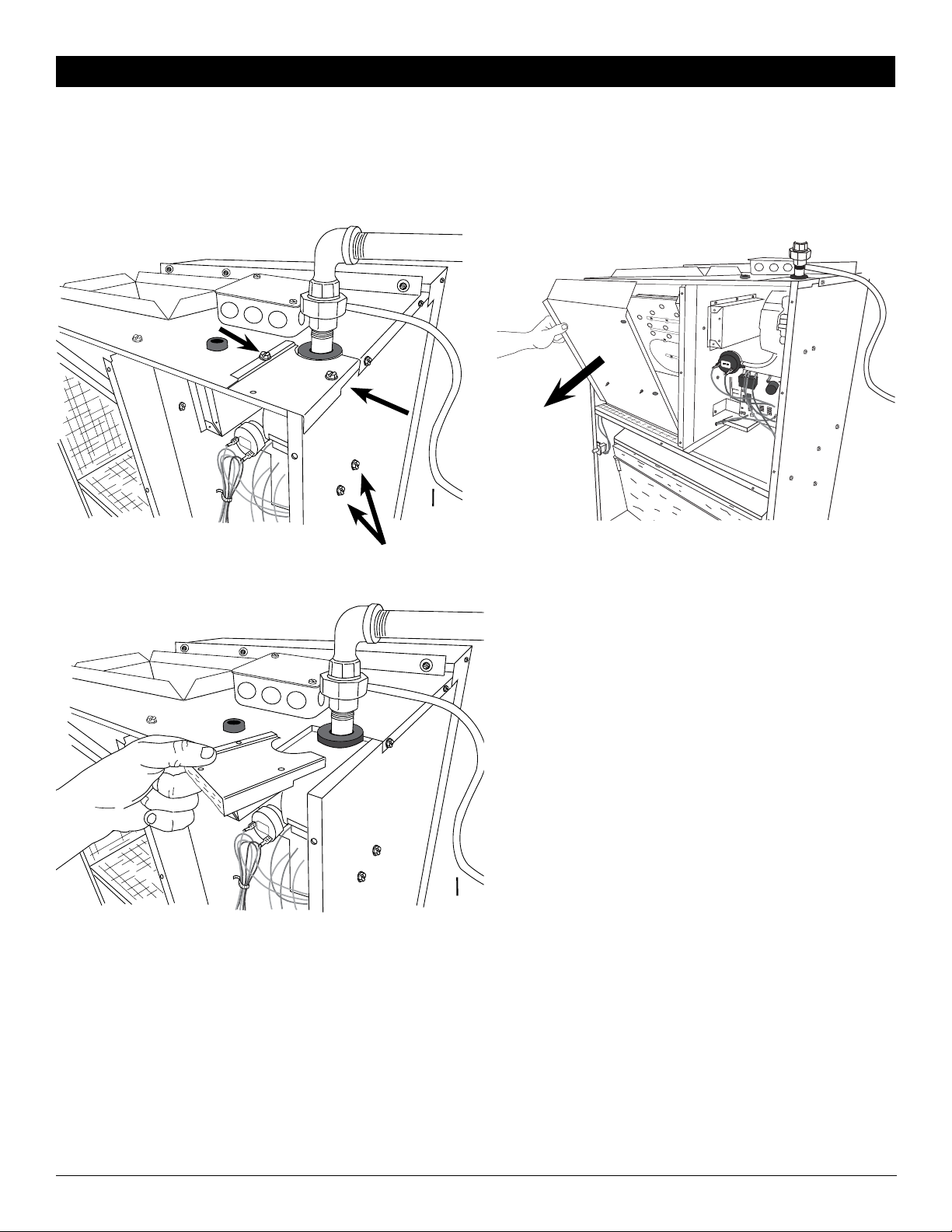

3. Remove the upper cabinet panel to expose the heat exchanger

section and the burner/control compartment (see Figure 2).

4. Carefully loosen and remove the gas valve and gas train from

the side panel and burner orifice bracket.

5. Mark and disconnect the pressure switch wires. Disconnect

the tubing and remove the pressure switch.

6. Locate the secondary air shield end cap. Remove the four

screws holding it to the air shield and remove the end cap.

7. Locate the upper burner brackets (one on each side). Remove

the two screws (one on each side) that attach the burner

assembly to the secondary air shield assembly.

8. Tilt the burner assembly slightly and lift it free from the

retaining track under the burner assembly. Remove the burner

assembly from the cabinet.

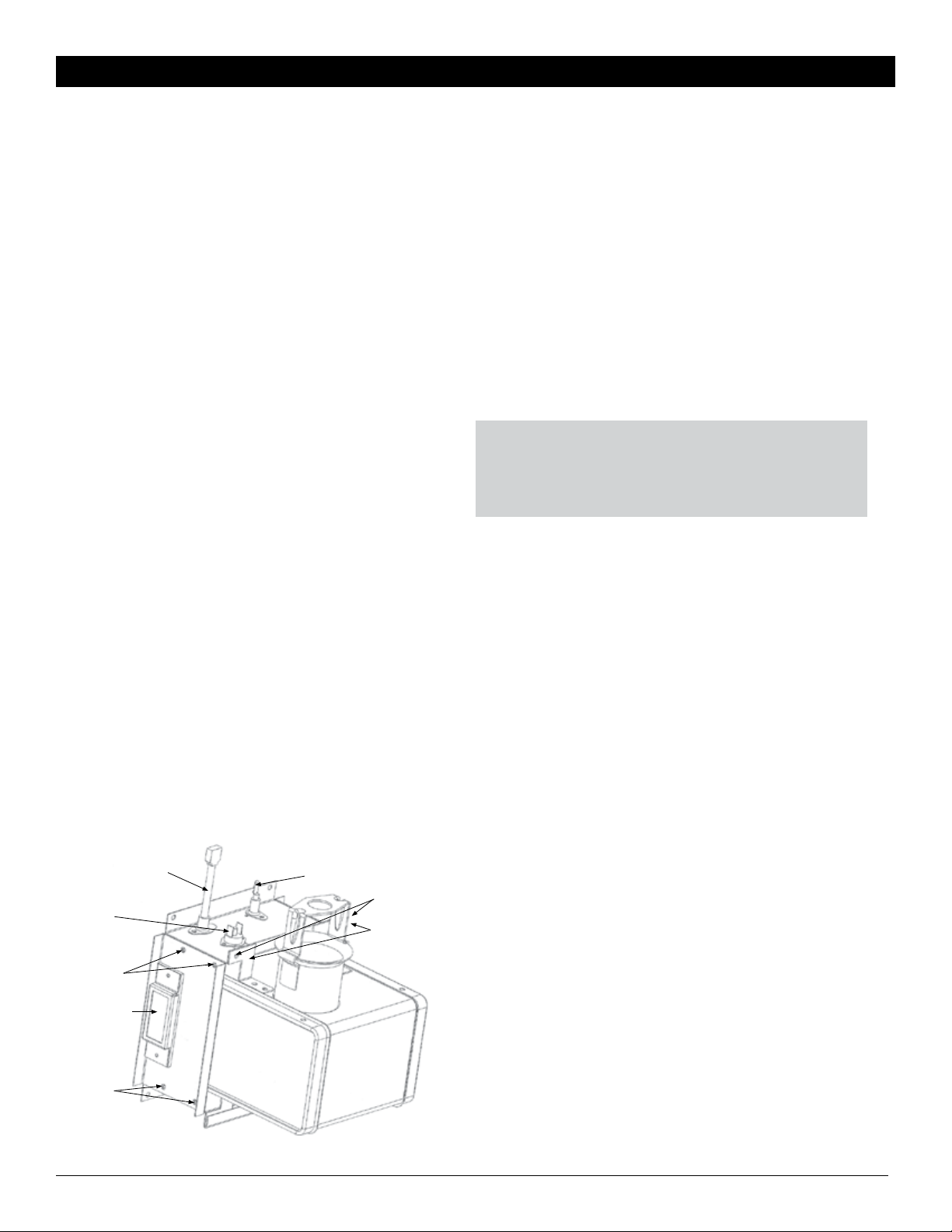

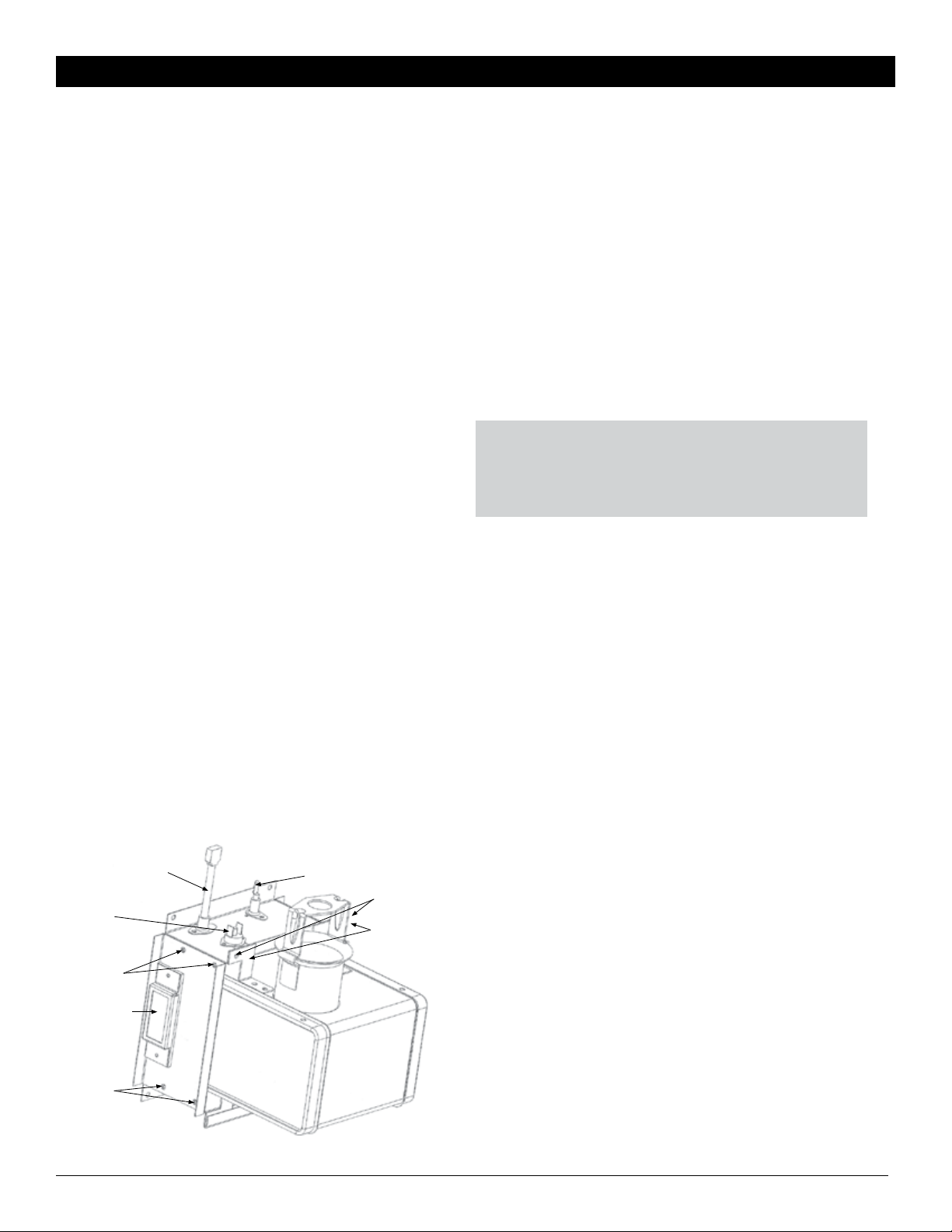

Figure 6A

Flame Rollout Switch

Ignitor

Remove screws

Sight Glass for

Flame and Ignitor

Secondary Air

Shield Assembly

Remove screws

Flame Sensor

Upper Burner Bracket

(one on each end) -

Loosen burner assembly by

removing only the two screws

indicated.

Burner Assembly

Secondary Air

Shield End Cap

Remove secondary air shield end cap

by removing four screws indicated.

Remove screw

(one on each end)

Inspect and Clean the Burner

With the burner assembly removed, shine a flashlight on the

burner ribbons. Look for carbon buildup, scale, dust, lint, and/

or anything that might restrict flow through the spaces between

the burner ribbons. Holding the burner assembly so that any

foreign material will fall away from the burner, use a stiff bristle

brush to loosen and remove any foreign material(s). If the burner

is excessively dirty, refer to Figure 6A and remove one of the

burner end caps. Remove the four screws that hold the end cap

to the burner housing. Lightly tap the end cap to remove it.

Clean all foreign material from the burner and venturi. After the

burner is thoroughly clean, replace the end cap making certain

that it is tight against the burner housing.

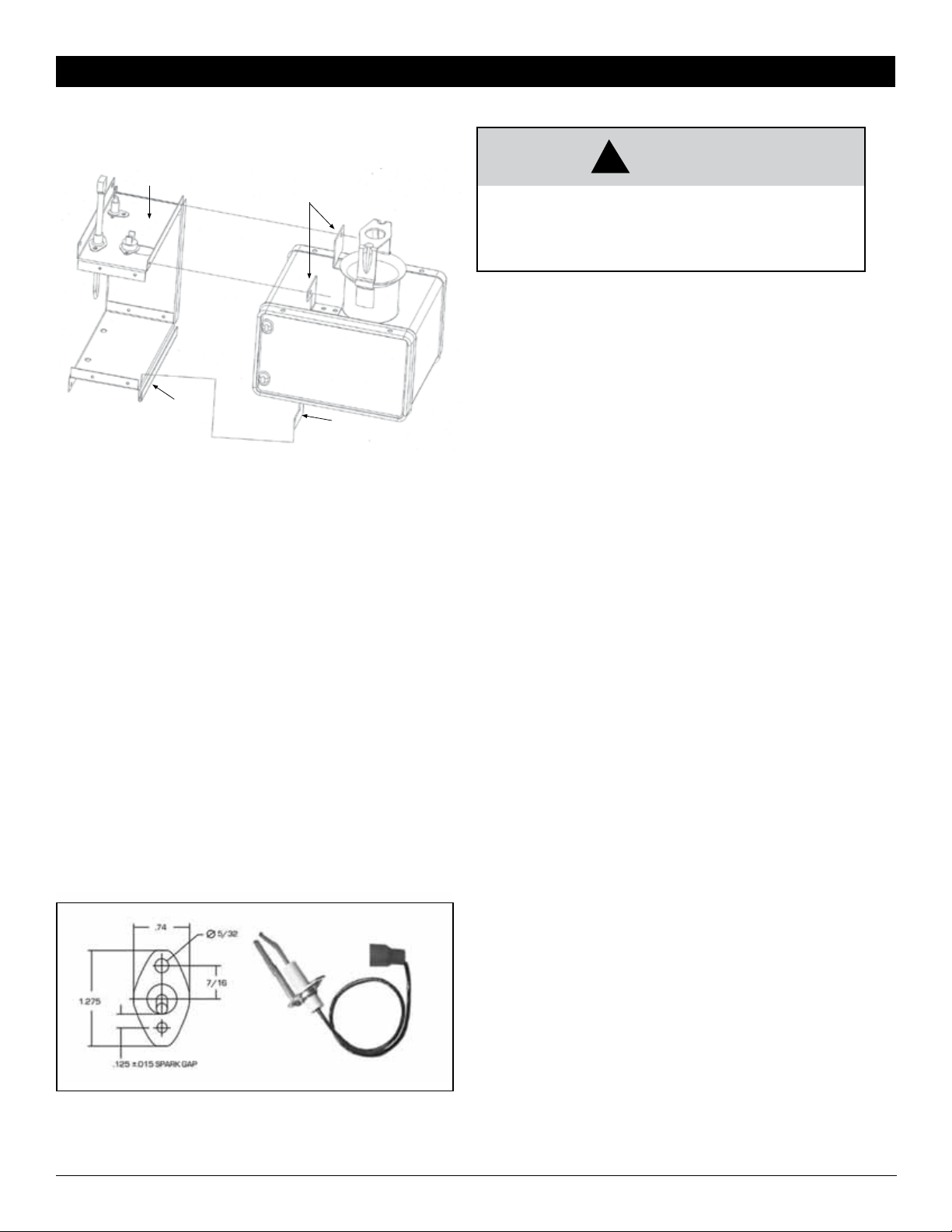

NOTE: IF ANY OF THE BURNER COMPONENTS

ARE DAMAGED OR DETERIORATED, REPLACE

THE BURNER ASSEMBLY.

Inspect the Lower Portion of the Heat Exchanger (with burner

assembly removed)

At the burner flame entrance of each tube, shine a bright light

into each heat exchanger section. If any light is observed,

replace the heat exchanger.

Instructions for Burner Installation

1. With lower burner brackets going inside the retaining track,

set the fully assembled, clean burner in the unit.

2. Secure the upper burner brackets to the secondary air shield

assembly.

3. Replace the secondary air shield end cap.

4. Attach and reconnect the pressure switch.

5. Reinstall the gas train and gas valve to the burner orifice

bracket and side panel.

6. Turn on the electric and the gas. Operate the furnace. Check

gas supply lines with a liquid leak detector or soap solution.

After it has been determined that there are no gas leaks and

the burner is operating satisfactorily, replace the cabinet panel

and the burner/control compartment panel.