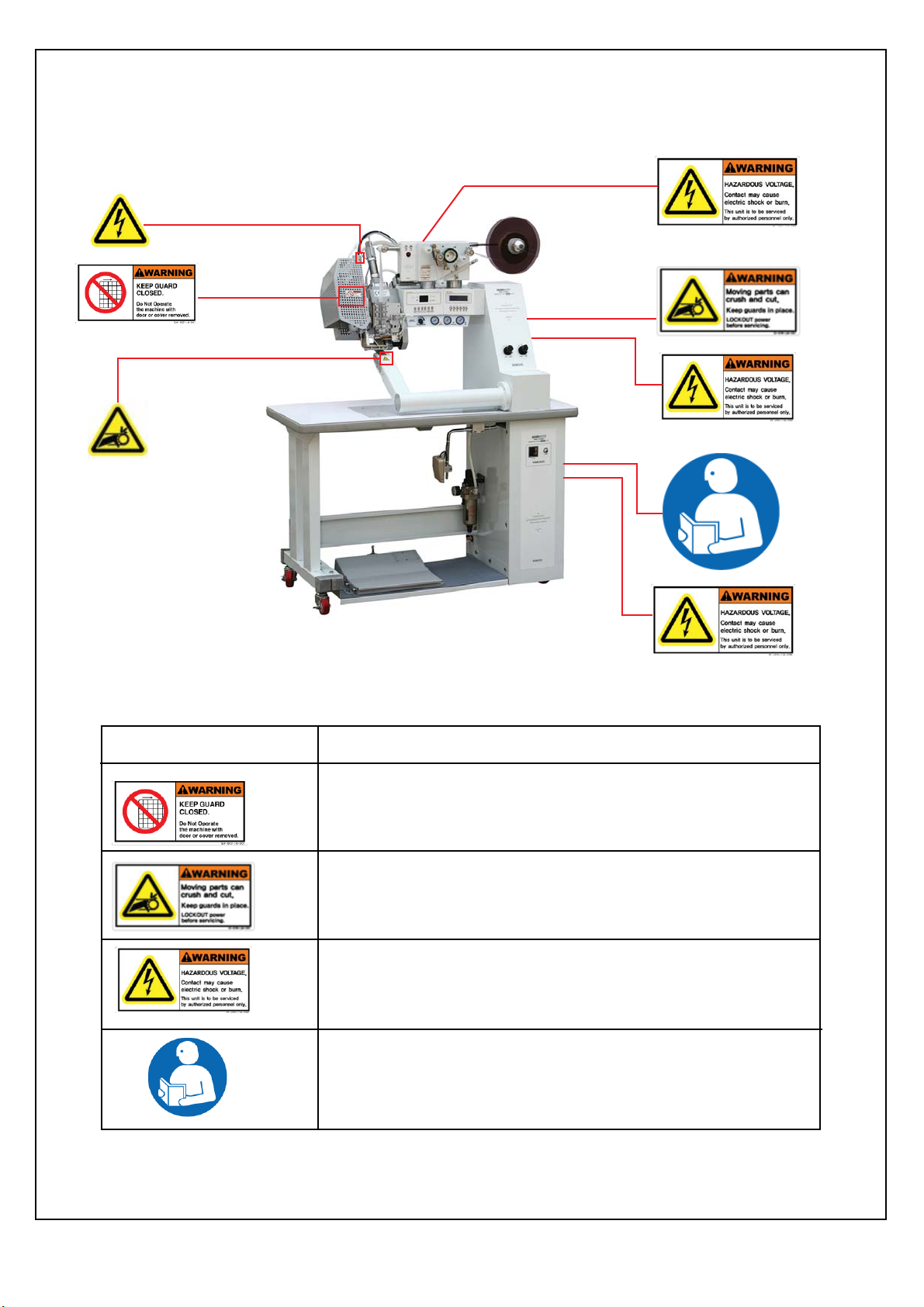

(1) Safety

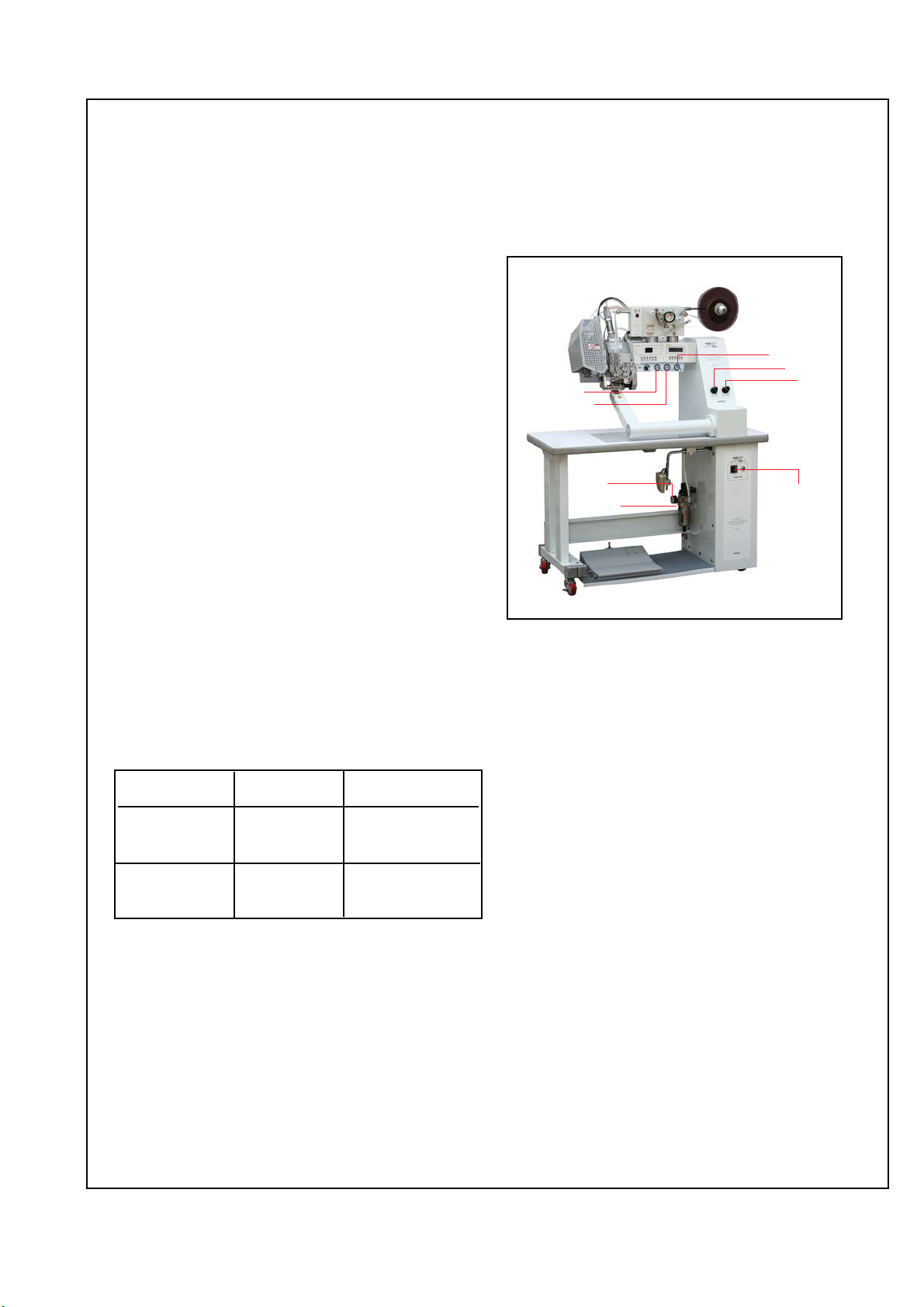

1. Outline

For seam sealing machine, a proper condition should be maintained

in transportation, installation, and maintenance & repair.

A supervisor should take good care of things in the processes above

for safe and decent management of machine.

Otherwise, a problem could occur.

This manual includes, safety, transport method, installation,

how to operate parts, and repair.

All operators and supervisor should be well informed of this manual

and follow the instructions.

However, this manual can’t cover all unexpected circumstances at

work place.

Therefore, operators should always watch out to prevent all possible

accidents with their experience and knowledge.

2. Installation and Transport Guide

□ All transport, installation, operation, and maintenance related safety

information should be well noticed before using the machine.

□ An exporter should control all processes from transport to installation

which have a direct influence on the safety of machine and operator.

□ When the equipment is transported by a forklift, an operator should

watch out several power cords on the floor. Besides, an operator should

be careful not to have the machine dropped on the floor.

□ Operators should be correctly informed of this manual (operation,

application, and management) and watch out all possible occupational

hazard and risk factors.

□ If necessary, safety equipment can be installed for operators’ safety.

A supervisor should carefully examine the equipment and machine to

prevent any accident caused by outdated machine.

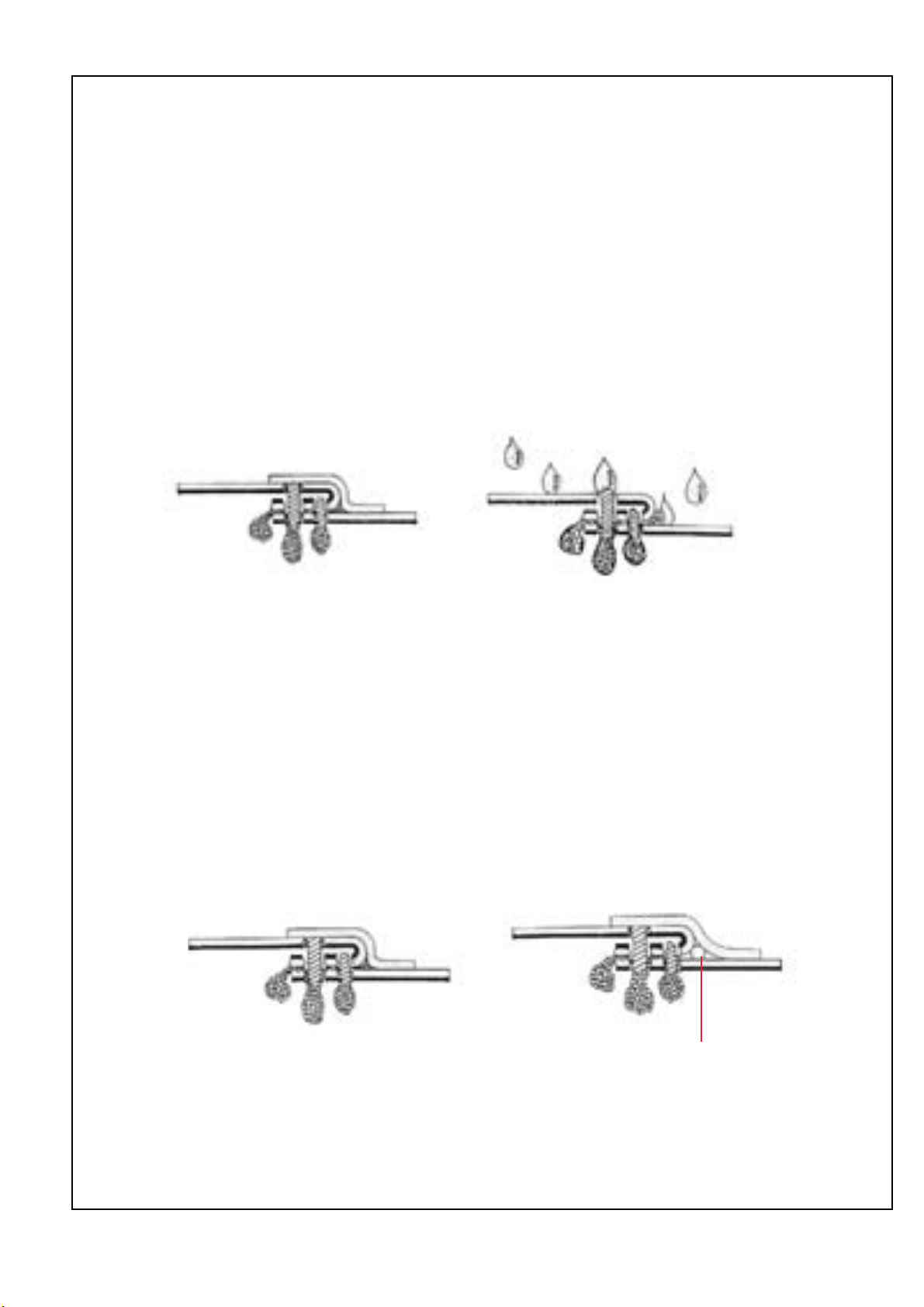

□ With proper lubrication and electric facilities, endurance of the machine

should be improved and any possible accident should be prevented.

□ A supervisor should always be dutiful in enhancing endurance of

equipment and preventing occupational accident.

Y