Set pushbutton 1 to "toggle" the SWA output (disables pushbutton 2):

NCE Power ProTM or PowerCabTM users can use the PROG ACCESSORIES

feature of your system. Set CV548 = 1 (use the accessory address of SWA) to

enable the ‘toggle’ option or set CV548 = 0 to disable it.

If you have another brand of DCC system use the following procedure:

1) Disconnect track power to the Switch-It.

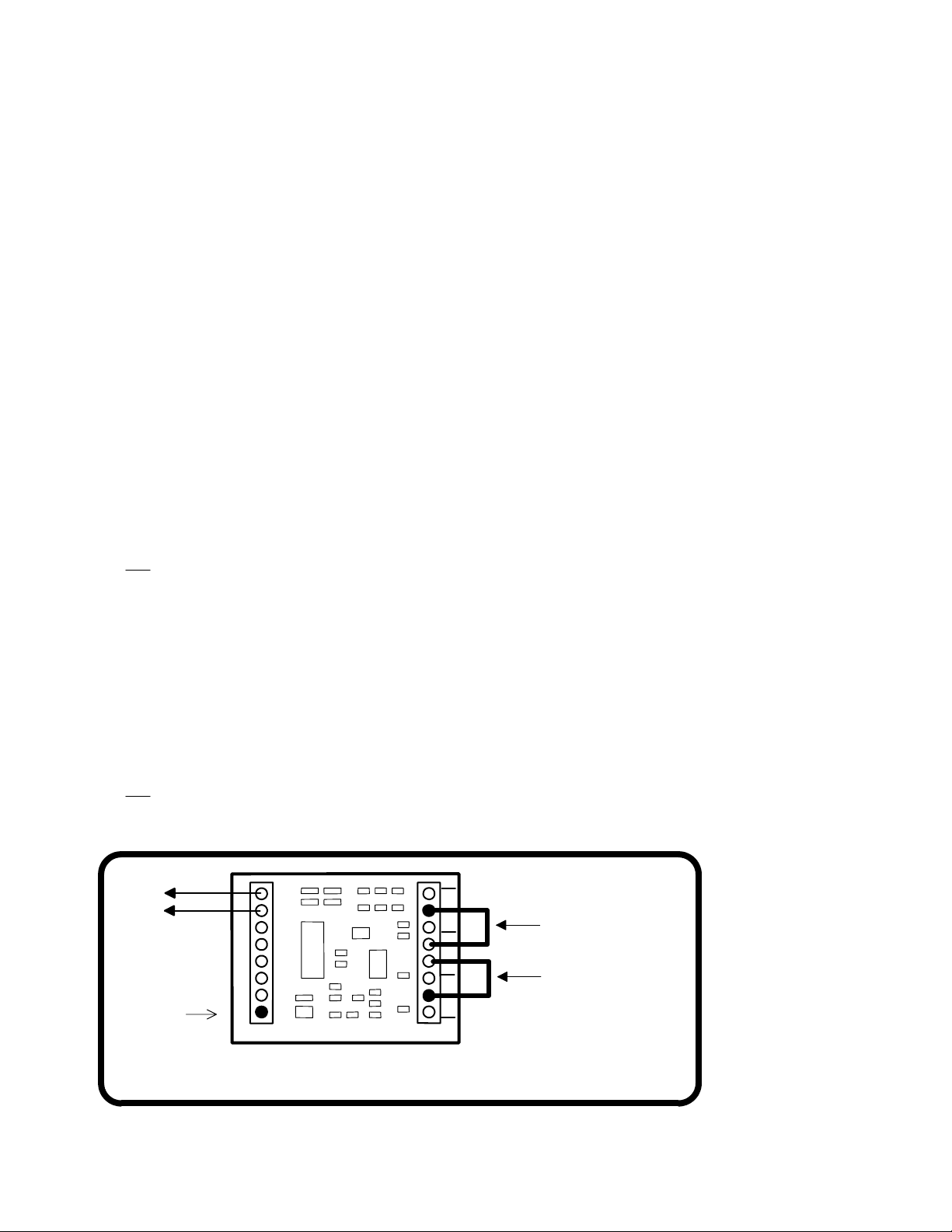

2) Connect PA to the right hand RST terminal indicated by the arrow in the above

figure.

3) Reconnect track power to the Switch-It

4) Remove the PA to RST jumper

Set pushbutton 4 to "toggle" the SWB output (disables pushbutton 3):

NCE Power ProTM or PowerCabTM users can use the PROG ACCESSORIES

feature of your system. Set CV549 = 1 (use the accessory address of SWB) to

enable the ‘toggle’ option or set CV549 = 0 to disable it.

If you have another brand of DCC system use the following procedure:

1) Disconnect track power to the Switch-It.

2) Connect PB to the right hand RST terminal indicated by the arrow in the above

figure.

3) Reconnect track power to the Switch-It

4) Remove the PB to RST jumper

To set the Switch-It to "exercise" the switch points at each power up:

NCE Power ProTM or PowerCabTM users can use the PROG ACCESSORIES

feature of your system. Set CV547 = 1 (use the accessory address of SWA) to

enable the ‘exercise’ option or set CV547 = 0 to disable it.

If you have another brand of DCC system consult your manual for programming of

accessories in Operations mode.

Legacy OPS programming disable (CV554):

There are two methods for programming accessory decoders “on the main” (OPS

mode programming). Legacy mode, in use since 1995, is being phased out by the

NMRA and replaced by the current, newer method. The Switch-It supports both

kinds of programming on the main.

NCE Power ProTM or PowerCabTM users can use the PROG ACCESSORIES

feature of your system. Disable Legacy mode by setting CV554 to a value of 1. If

you disable legacy mode and find you can no longer program the decoder with your

system, your system only supports legacy mode. You can re-enable Legacy mode

by resetting the Switch-It back to factory defaults as described below.

If you have another brand of DCC system consult your manual for programming of

accessories in Operations mode.

Pushbutton lockout (CV556):

On some layouts it may be desirable to disable operation of the local control

pushbuttons. NCE Power ProTM or PowerCabTM users can use the PROG

ACCESSORIES feature of your system.

Set CV556 = 1 to disable the optional pushbutton inputs. CV556 = 0 enables the

buttons.

You can disable or enable ALL decoders on the layout at the same time by using

the accessory decoder broadcast address of 2044 when programming CV556.

If you have another brand of DCC system consult your manual for programming of

accessories in Operations mode.

Last revised: 15 March 2007 Page4