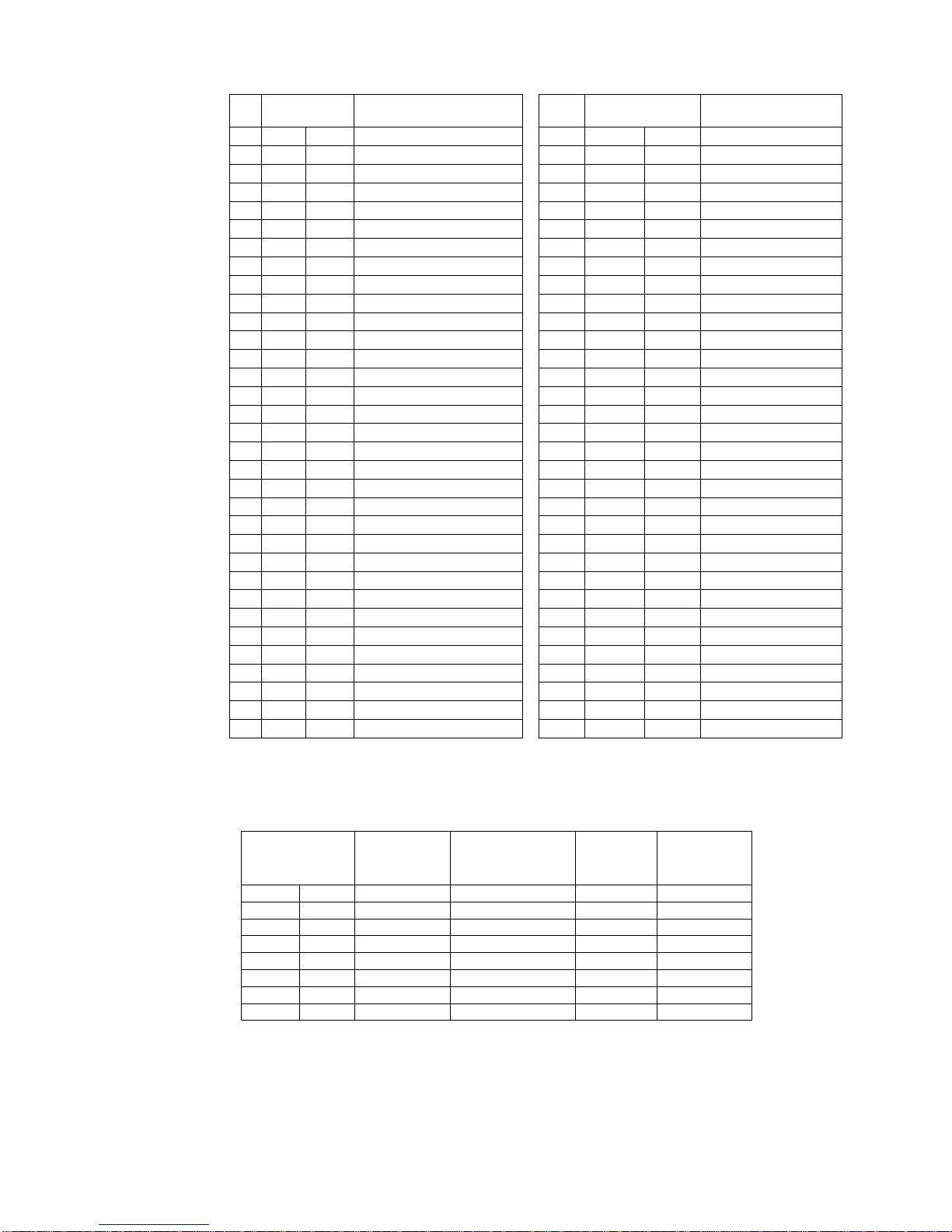

Configuration Variables used by V3.5 Decoders

CV1 Short decoder address; 1-127 valid

CV2 Start Voltage (useful range 0-100)

CV3 Acceleration rate (each unit = 7mS between speed steps) 255 max.

CV4 Deceleration rate (each unit = 7mS between speed steps) 255 max.

CV5 Vmax, speed at highest speed step. 0=use factory default of 255

CV6 Vmid, speed (on a scale of 1-255) at speed step 7,14,or 63. 0=use default of 127

CV7 Decoder version number. This decoder is 35 which means version 3.5

CV8 Manufactuer ID. NCE = 11 (0B hex)

CV11 Packet timeout value (in ½ second increments) Time the decoder will wait before braking to a

stop after running into a section of track with DC power. 0=Don’t brake

CV15 Decoder programming lock “KEY”. This CV is always programmable even when “locked”

CV16 Decoder programming lock ID. When CV15=CV16, programming is unlocked and the

decoder will respond to programming commands. If CV15 is not equal to CV16 then

decoder programming is locked and it will not program (except CV15) or read.

CV17 High byte of long (4 digit) address

- bit 6,7 always= 1

- bits 0-5 are upper 6 bits of address

CV18 Low byte of long (4 digit) address

CV19 Consist address. (0 or 128 = no consist active)

- bits 0-6 short consist address (1-127 valid)

- bit 7 0= direction is normal, 1= direction is reversed

CV21 Functions active in consist mode. Bit 0 controls F1,bit 1=F2, bit 2=F3, etc.

- bit 0 - 1=function can be controlled at consist address, 0 = no consist control

CV22 Functions active in consist mode. Bits 0,1 control FLF and FLR respectively

each bit 1=function can be controlled at consist address, 0 = no consist control

CV29 -bit 0 1= direction of operation is reversed, 0= direction is normal

- bit 1 1=28 speed mode (always enabled)

- bit 2 1= analog operation mode enabled, 0 = disabled

- bit 4 1= alternate speed table active, 0= use table defined by CV2,5,6

- bit 5 1= use long address in CV17/18, 0= use short address CV1

- bits 3,6,7 are ignored by the decoder

CV30 Set this CV to 2 on the programming track and the decoder will reset to factory settings.

CV33-CV39 function mapping CVs for F0-F5

CV67-CV94 Uploadable speed table steps 1-28 (128 speed mode calculates intermediate steps)

CV95 Reverse trim, values 1-127 add to reverse speed, values 129-255 add to forward speed

CV116 Torque kick rate - number of 16ms periods in a row that motor is ‘kicked’ with voltage pulse

CV117 Torque kick strength - how much voltage is used to kick the motor at slow speeds. Reduces

to 0 as speed is increased.

CV118 Ditch light hold time (in ¼ second increments) after F2 goes off.

CV120-CV124 Effects configuration registers for outputs 1-5

CV NOTES: All CV numbers not listed above may be programmed but not used by the decoder. This

decoder supports all DCC programming methods.

Formula for computing the long address if using a Lenz SET01 or SET02:

If using a Lenz SET01, SET02, SET90, SET100 or other entry level system, use paged programming

mode and see below for programming long addresses.

CV17 = 192 + (the whole number portion of the long address divided by 256)

CV18 = the remainder after the long address is divided by 256

CV29 = 34 if analog mode disabled, 38 if analog mode enabled

Decoder Warranty

This decoder is fully factory tested and warranted against manufacturing defects for a period of 1 year. As the

circumstances under which this decoder is installed can not be controlled, failure of the decoder due to installation

problems can not be warranted. This includes misuse, miswiring, operation under loads beyond the design range

of the decoder or short ciruits in the locomotive manufacturer’s factory wiring. If the decoder fails for non-warranted

reasons NCE will replace the decoder, no questions asked, for $10 U.S. plus $2 shipping. For warranty or

non-warranty replacement send the decoder (and any payment, if required) to:

NCE Warranty Center

899 Ridge Road

Webster, New York 14580

The terms Silent Running, Powerhouse Pro, Power Pro,SmartCab, ProCab, Switch-It, Snap-It, theNCE logo with “Power of DCC”

slogan and EFX are trademarks of NCE Corporation. Digitrax is a trademark of Digitrax Inc.

**Last revised: 17 November 2003 Page 8 D15SR

Bar Code