M&H IRP40.02

INFRARED TOUCH PROBE

OPERATING INSTRUCTIONS

NCT Ipari Elektronikai Zrt. 2 / 25 23 May 2023

H-1148 Budapest, Fogarasi út 7.

Phone: +36 1 467 6300

www.nct.hu

TABLE OF CONTENTS

1DESCRIPTION ................................................................................................................3

1.1 General.........................................................................................................................3

1.1.1 Preface..................................................................................................................3

1.1.2 Safety Instructions................................................................................................3

1.1.3 Declaration of Conformity ...................................................................................4

1.1.4 Validity.................................................................................................................4

1.2 Purpose ........................................................................................................................4

1.3 System Components ....................................................................................................4

1.4 Technical Data.............................................................................................................5

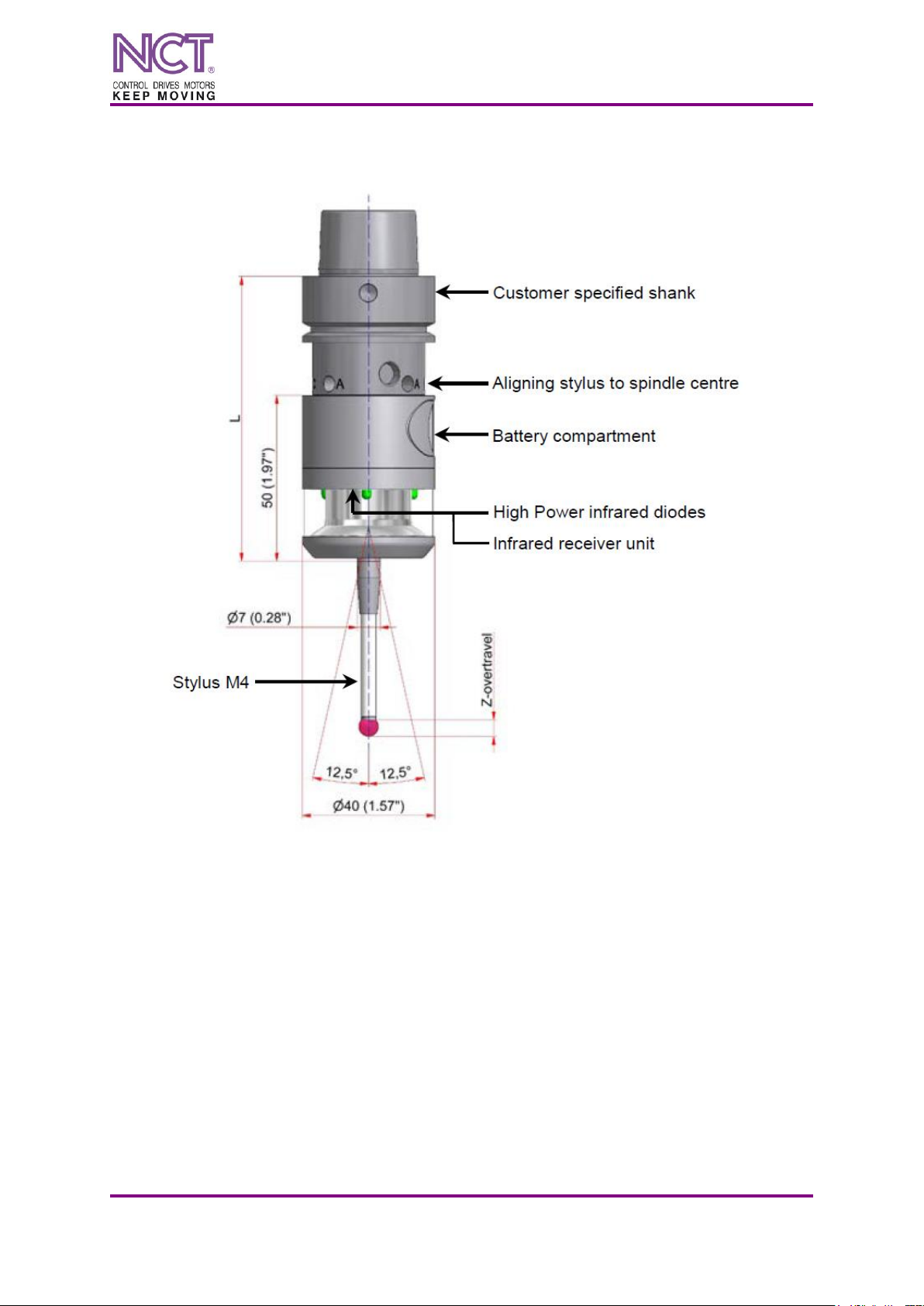

1.5 Dimensions..................................................................................................................6

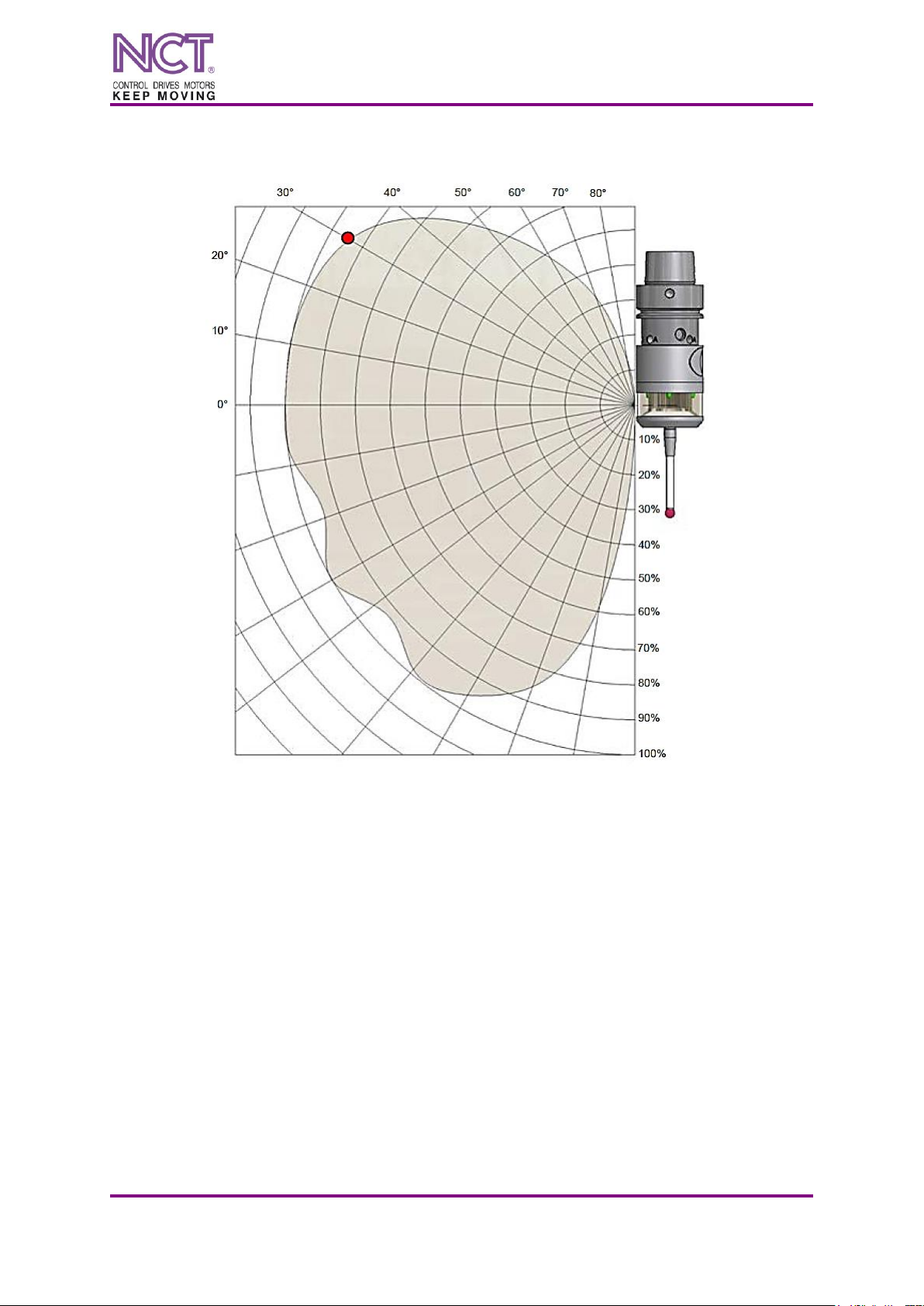

1.6 Transmission-/Reception Angles.................................................................................7

1.6.1 Transmission Angles............................................................................................7

1.6.2 Reception Angles .................................................................................................8

1.7 Delivery Contents, Accessories and Spares ................................................................9

1.7.1 Delivery Contents.................................................................................................9

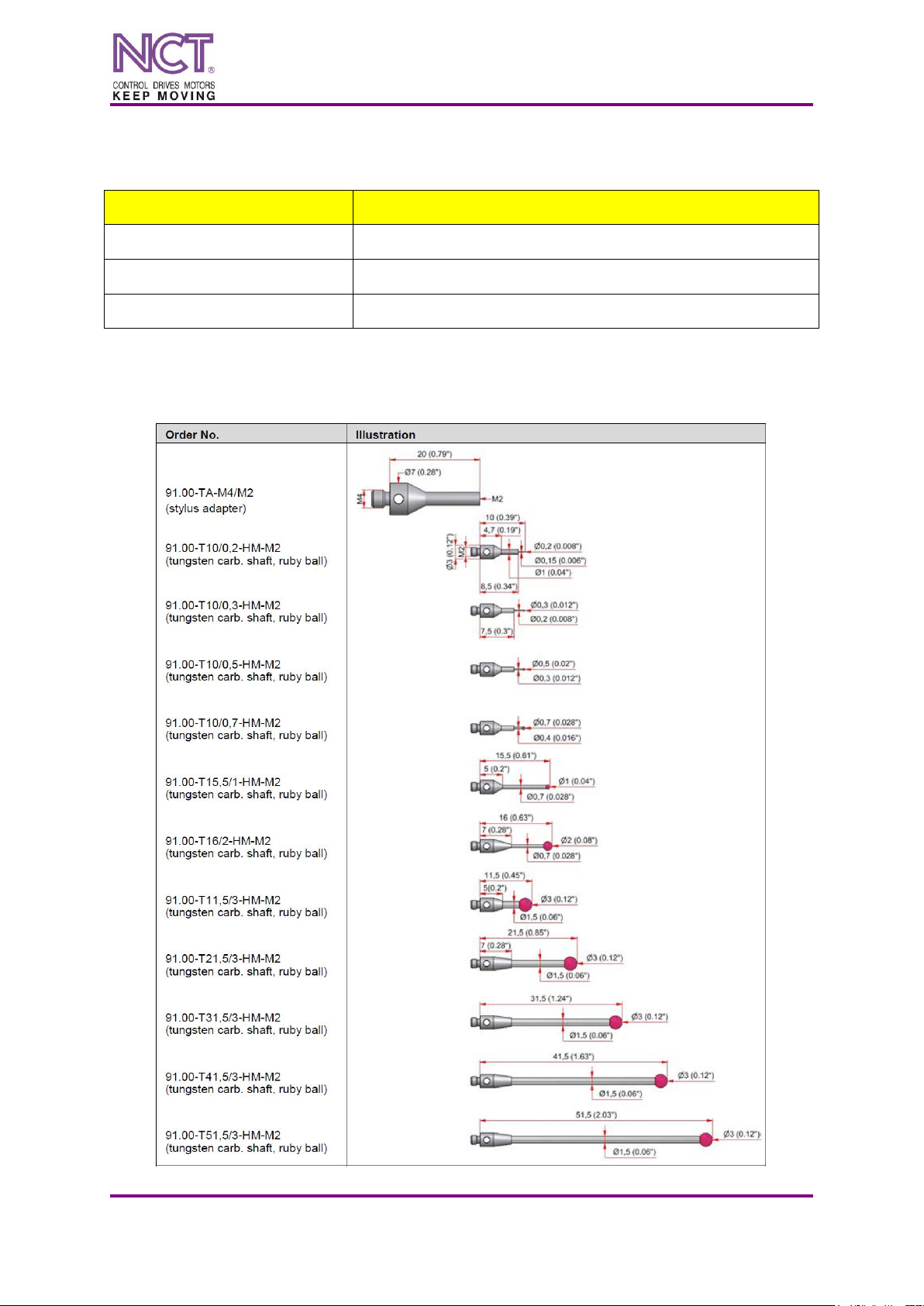

1.7.2 Styli ......................................................................................................................9

1.7.3 Shanks ................................................................................................................12

1.7.4 Accessories, general...........................................................................................17

1.7.5 Spare Parts..........................................................................................................17

2OPERATION..................................................................................................................18

2.1 Tools, Measurement- and Test-Equipment ...............................................................18

2.2 Changing Stylus.........................................................................................................18

2.3 Mounting/Dismounting the Shank.............................................................................19

2.3.1 Mounting shanks 20........................................................................................19

2.3.2 Mounting shanks 28........................................................................................20

2.4 Replacing Battery ......................................................................................................21

2.5 Aligning Stylus to Spindle Centre.............................................................................22

2.6 Aligning Probe in Shank with 90° Adapter...............................................................23

2.7 Optical Status Display ...............................................................................................23

2.8 Maintenance and Cleaning of Infrared Touch Probe IRP40.02 ................................24