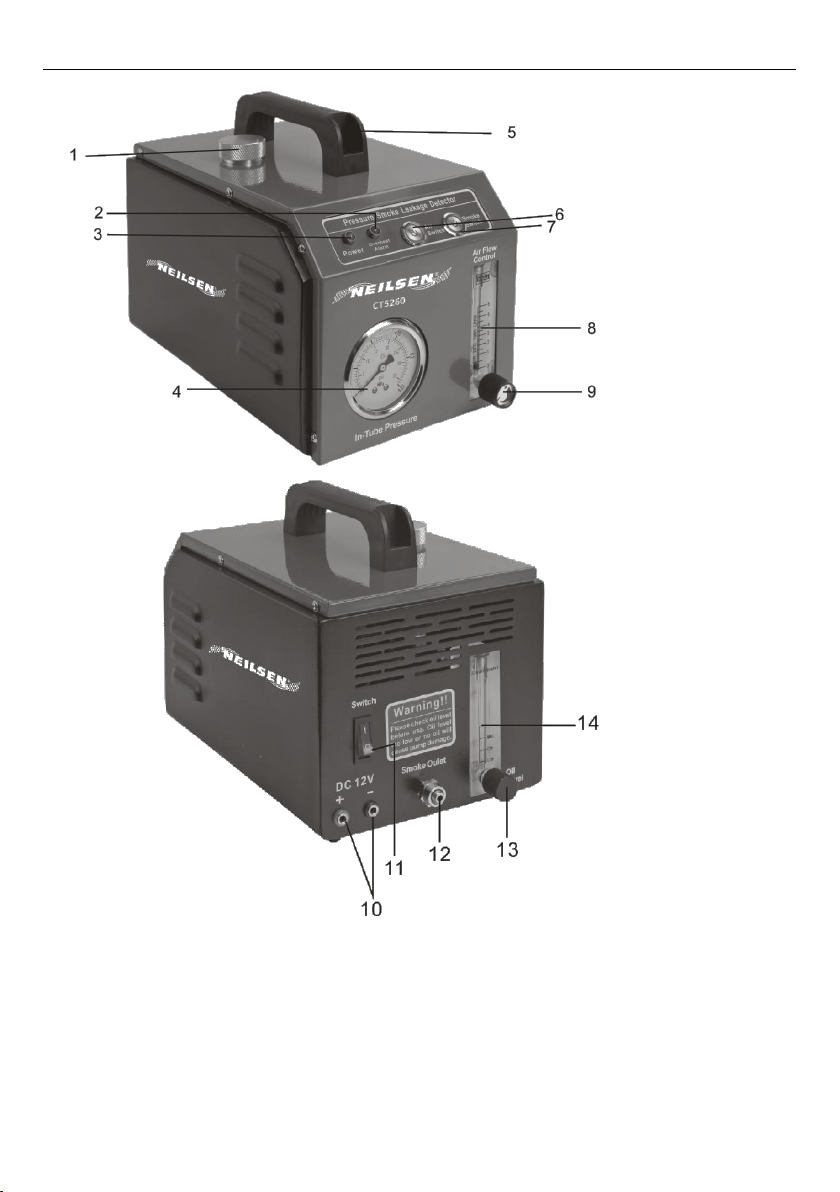

5. OPERATION

1.When you use this detector for the first time, please fill 20 -30ml mineral

(baby )oil .

2. Disconnect the pipe that needs to be connected with detector. If the pipe needs

to be disconnected in the middle, please secure the other side with a rubber

stopple.

3 . Secure this side with proper taper stopple/ pipe, and connect it with smoke

output tube.

4. Connect detector with DC12V battery: red with positive, black with negative.Do

not connect in a contrary way.

5. Turn on the power switch, and the detector starts to work.

6. In about 3 minutes, the pipe will be filled with smoke. Check the leak points.

Please use head lamp if necessary.

7. After leak detection, please store well the wires and pipe.

Notes:

* Please do leak detection away from smoke sensitive parts.

* Do not run the detector over 8 minutes. It needs interval rest.

*The detector has protector. If it exceeds working limit, it will power off

automatically. In this condition, please operate it later.

* The round part of this detector is with temperature, be careful to avoid scalding

injury.

How to do leakage test?

1. Turn on device then block smoke exhaust port, then record pressure gauge

value.

2. Connect smoke exhaust port to the pipe system you want to test.

3. Wait for a while.Pressure gauge value decrease means the pipe system have

leakage,pressure gauge value show '0' means diameter of leakage point is

more than 0 3mm.