VESDA-E VEA Installation Instructions

Wiring: Power, Relays, GPI, VESDAnet, Expansion StaX, Relay StaX

Warning: Always disconnect detector power before plugging/unplugging electrical, relay

or network connections. Failure to do so may cause data corruption and/or

component failure.

Avertissement : Eteignez toujours détecteur avant de brancher/débrancher les relais électriques, ou de

connexions réseau. Au cas contraire vous pouver entraîner la défaillance corruption et/ou

élément de données.

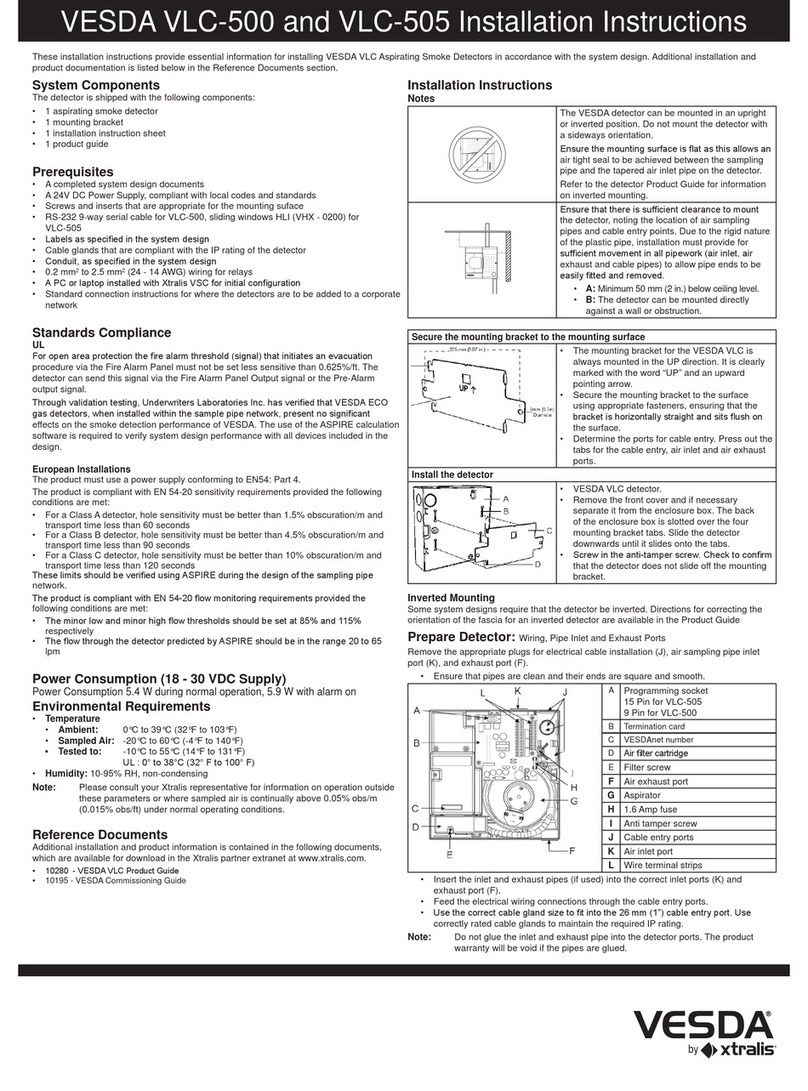

SHSH

E

F

N

O

Q

P

NC C NO NC C NO NC C NO

2 [MINOR F] NC C NO

1 [ISOL]

5 [ACTION]

NO C NC 6 - FIRE 1

NO C NC 7 [FIRE 2]

NO C NC

J

I

H

G

K

L

M

4 [ALERT]

3 - URGENT F

A

C

B

R

S

D

Power

AEXP (Expansion)

BRV (Rotary Valve)

CPower In

DGround Reference

Terminal

VESDAnet

EVESDAnet B

FVESDAnet A

Relays

G1 - Disable (Isolate)

H2 - Minor Fault

I3 - Urgent Fault

J4 - Alert

K5 - Action

L6 - Fire 1

M7 - Fire 2

Communications

NEthernet

OUSB

GPI

PMonitored GPI

QUnmonitored GPI

Internal Components

RSmoke Sensor

Expansion

SData

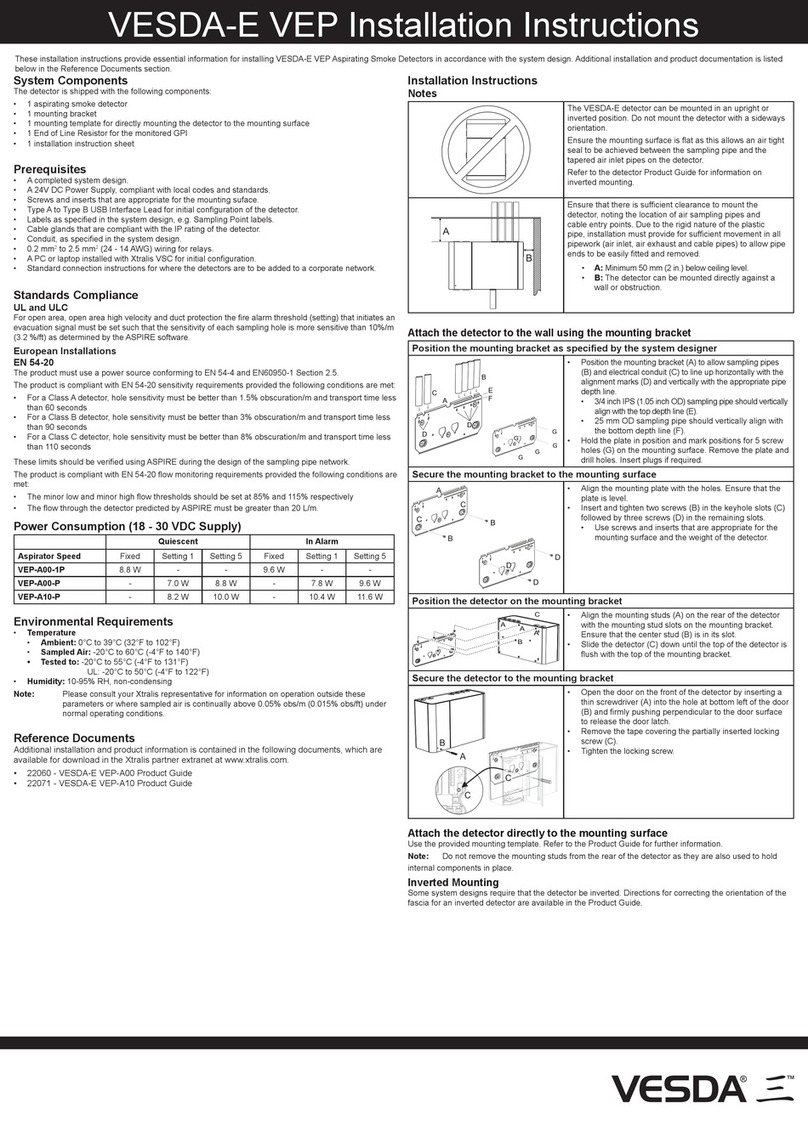

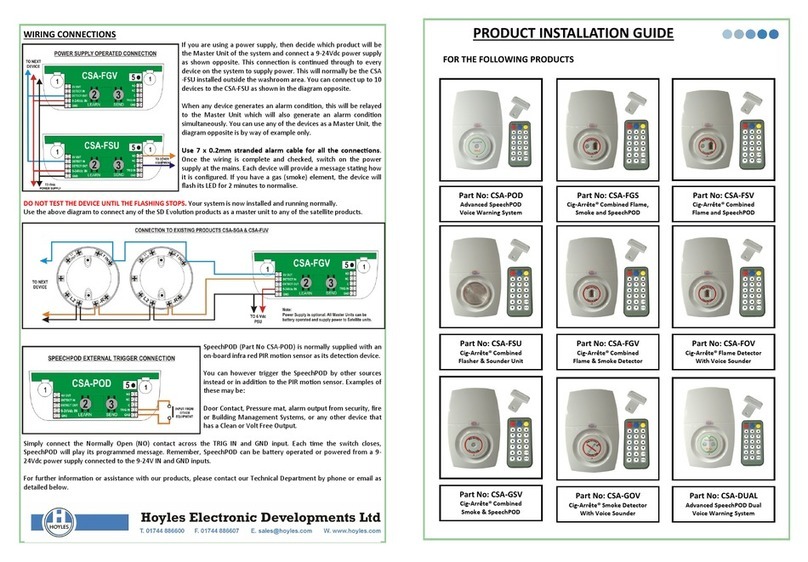

Power and Relay Wiring

Power: Connect a 24 VDC power supply which is compliant with local re protection codes

and standards to the PWR IN socket (C).

Relays: The relays interface to the Fire Alarm Control Panel (FACP) to communicate

faults, alarms and disabled states. Relay contacts are rated 2 A @ 30 VDC, resistive.

Connect as required by the system design. Use electrical wire sizes from 0.2 mm² to

2.5 mm² (24 -12 AWG). Refer to the Addressable Loop Module example.

Warning: Ensure that all wiring complies with manufacturer’s instructions and local and

national re detection code requirements. Refer to Codes and Standards

Information for Air Sampling Smoke Detection section of the detector product

guide for further information on wiring compliance.

Avertissement : Verier que toute les cables ont passé au nombres d’instructions du fabricant et locaux et au

feu national de securited’incendie sois exiger. Adresser aux codes informations sur les normes

et reglementations de detection de fume par prelevement d’air par le notice descriptive du

produit pour plus de renseignements au conformite du cablage.

Caution: DO NOT LOOP WIRE UNDER TERMINALS WHEN WIRING DETECTORS.

BREAK WIRE RUNS TO PROVIDE SYSTEM SUPERVISION OF CONNECTIVITY.

Attention : NE PAS RALIER LES CABLES TERMINAUX PENDANT LES CABLAGES DES FILS. POUR

TOUTES LES CONNECTIONSA RELAIS, INTERROMPRE LES FILS POUR PERMETTRE LA

SUPERVISION DU CABLAGE.

Note: For information on wiring for other types of devices that may be required by

the system design, refer to the detector Product Guide and documentation

accompanying the device.

Unmonitored GPI

The Unmonitored GPI is a programmable input which can be congured to initiate a

number of different actions, including, by default, a Remote Reset function.

Monitored GPI

The monitored GPI senses contact closure and is congurable to initiate the same actions

as the unmonitored GPI. “Mains OK” is the default setting. A closed contact signals GPI

ON and open contact signals GPI OFF.

A 10K end of line resistor is used to allow the detector to monitor for open circuit faults in

the wiring from the detector to the contact.

Connection to Addressable Loop Module for Reporting Alarms and Faults

Normally Closed (NC)

Common (C)FIRE 1 (NO)Normally Open

Normally Closed (NC)

Common (C)ACTION (NO)Normally Open

Dete torc

Fire Input

EOL = Normal

Short = Fire

Open = Wiring Fault

3 Inputs Loop Module

Pre Alarm

EOL = Normal

Short = Fire

Open = Wiring Fault

Fault Input

EOL = Normal

Short = Detector Fault

Open = Wiring Fault

EOL*

EOL*

EOL*

Normally Closed (NC)

Common (C)FAULT (NO)Normally Open

Relay shown energized, which

is the no-fault condition

This wiring example is for wiring VESDA

detectors to a typical third party Input Loop

Module with three inputs.

This is an example drawing. Refer to the

appropriate product manual for the exact

wiring details of the third party equipment.

Connection to VESDAnet

A+

A-

B-

Shield

Module 1 Module 2 Module 3

B+

A+

A-

B-

Shield

B+

A+

A-

B-

Shield

B+

A+

A-

B-

Shield

Shield

B+

A+

A-

B-

Shield

Shield

B+

The diagram shows an example of the

wiring for a closed VESDAnet loop,

which is the recommended conguration.

Remove the factory default links from

the VESDAnet sockets (E and F) prior to

connecting the detector to the VESDAnet.

It is recommended that 120 Ohm twisted

pair cables (e.g. Belden 9841) be used for

including the devices in the network, with

a maximum length between devices of

1.2 km The polarity of the data wires must

be maintained throughout the network.

Standalone Detector

A-

A+

B-

B+

The diagram below shows the factory default wiring for VESDAnet

sockets (E and F) as required for a detector that is not connected to a

VESDAnet.

• Leave as is, or replace if it has been removed.

Communications

• USB: The USB port (O) is used for initial conguration and local maintenance or

servicing of the detector using a PC installed with Xtralis VSC software. Install Xtralis

VSC prior to connecting the detector to the computer to ensures that the required USB

drivers are present.

• Ethernet: The Ethernet port (N) is used for permanent network connection to the

detector, and provides a gateway to any other devices on the VESDAnet network. An

Ethernet lead can be routed through the cable entry ports and plugged into the Ethernet

port. Use a standard Ethernet lead when connecting the detector to a network switch,

router or directly to a PC or laptop. Ethernet connection must be congured using a

USB connection prior to use. Set the detector access password using Xtralis VSC.

• WiFi: The WiFi module allows connection of laptops installed with Xtralis VSC to the

detector, and provides a gateway to any other devices on the VESDAnet network. WiFi

must be enabled and congured using a USB connection prior to use. Set the detector

access password using Xtralis VSC.

Sampling Network

Complete the sampling network installation in accordance with the system design.

All tubes must have equal airow impedance. This is

achieved either by making them all equal in length,

or adhering to specications determined by the VEA

Microbore Tube Length Calculator (Document 29261)

for combinations of normal and reduced diameter

tube congurations. Where the tube length calculator

requires a tube to be comprised of a combination

of normal and reduced diameter microbore tube, a

reducer piece must be used between the two tubes

(P/N VSP-1000).

Tube inlets are numbered on the detector (see left).

Label each tube corresponding to its inlet. Unused

inlets on the detector should be blocked using

blanking plugs (P/N VSP-998).

it is recommended that excess tubing be coiled close to the sampling point end, and that

an additional 2 to 3 m (6 to 10 ft) of tubing be coiled to allow for future repositioning of the

sampling point.

Ensure that Microbore tubes are never glued anywhere in the tube network, including to

the inlets of the detector. Tubes can be joined using appropriate joiners.

Ensure that the exhaust is open and that tubes are clear.

Power Up

Connect 24 VDC power to the PWR IN terminal. Close front door.

On power up:

• The Power LED illuminates and the detector runs a series of self-diagnostic tests.

• If there is a fault, the Fault LED illuminates. To identify the fault, check the Active Event

List for the detector using Xtralis VSC or iVESDA.

• The pump starts up and air may be felt owing out of the exhaust port.

Conguration

For initial conguration, use a USB connection and the Xtralis VSC software.

• For networked detectors, set the IP address and subnet mask according to standard

building instructions.

• Normalize the airow. This takes approximately 30 minutes, after which the tube ow

rates (%) should be close to 100%.

• Reset the detector. It should now be running without faults.

• If a ow fault is present, the detector will re-scan for ow faults after a Reset is

performed. If required, cancel using Xtralis VSC.

Commissioning

• Carry out a smoke test, conrm that the transport time is as expected and test the

relays. Refer to the VESDA Commissioning Guide for further information.

12

1

2

3

4

5

76

8

9

10

11

13 14

15

16

17

18

19

20 22

21 23

24 26 27

28 29

30 31

32 33

34 35

36

37

38

39

40

25

www.acornfiresecurity.com

www.acornfiresecurity.com