nekos FLIK User manual

4420079 - Rev. 1 of 5/2020

FLIK

INSTRUCTION MANUAL -

TRANSLATION OF ORIGINAL INSTRUCTIONS

AUTOMATION FOR SLIDING WINDOWS AND

DOORS

Force 100N (230V) / 120N (24V) – Maximum door/sash weight 400 Kg

Electrical supply: █ 110÷230V~ 50/60Hz, █ 24V

NEKOS

S.r.l. - Via Capitoni, 7/5 - 36064 Colceresa (VI) – ITALY

EN

Nekos

products have been manufactured in accordance with safety standards and conforms to

the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they will not

generate any danger for persons, animals or items.

Symbols used in the manual

CAUTION

This indication highlights potential hazards for the safety and

health of humans and animals.

INFORMATION

Information providing further suggestions.

WARNING

This indication highlights potential damage to property or to the

product and its correct use.

CONTENTS

G

ENERAL INFORMATION

................................

U

SER INSTRUCTIONS

................................

I

NSTALLER INSTRUCTIONS

................................

1. Safety standards

................................

2. Field of application

................................

3.

Technical operating information

4.

Manufacture and regulatory framework

5.

Nameplate data and marking

6. Technical data

................................

7. Electrical power supply

................................

7.1.

Choice of power cable diameter

8. Risk analysis

................................

9. Installation instructions

................................

9.1. Fitting the rack

................................

9.2.

Mounting the gearmotor on the frame

9.2.1. Preparing for

mounting

9.2.2.

Preparation and mounting of the gearmotor

10. Electrical connection

................................

10.1.

Machine electrical connections

10.2.

Connection with a K

11.

Programming and resetting the gearmotor

11.1. Stroke end position

11.2. Troubleshooting

................................

12. Checking

correct installation

13.

Emergency and maintenance manoeuvres

14.

Disposal and environmental protection

15.

Reminder of the Warranty conditions

16.

Declaration of Incorporation and

2

products have been manufactured in accordance with safety standards and conforms to

the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they will not

generate any danger for persons, animals or items.

Symbols used in the manual

This indication highlights potential hazards for the safety and

health of humans and animals.

Information providing further suggestions.

This indication highlights potential damage to property or to the

product and its correct use.

................................

................................

..........................

................................

................................

..............................

................................

................................

................................

................................

................................

................................

................................

................................

Technical operating information

................................

................................

Manufacture and regulatory framework

................................

................................

Nameplate data and marking

................................

................................

................................

................................

................................

................................

................................

.........................

Choice of power cable diameter

................................

................................

................................

................................

................................

................................

................................

..........................

................................

................................

..........................

Mounting the gearmotor on the frame

................................

mounting

................................

................................

Preparation and mounting of the gearmotor

................................

................................

................................

...........................

Machine electrical connections

................................

................................

Connection with a K

-LOCK electromechanical lock

................................

Programming and resetting the gearmotor

................................

..........................

setting procedure

................................

................................

................................

correct installation

................................

................................

Emergency and maintenance manoeuvres

- Release device

..............................

Disposal and environmental protection

................................

...............................

Reminder of the Warranty conditions

................................

................................

Declaration of Incorporation and

Conformity

................................

products have been manufactured in accordance with safety standards and conforms to

When correctly assembled, installed and used according to the present instructions, they will not

This indication highlights potential hazards for the safety and

This indication highlights potential damage to property or to the

..........................

3

..............................

3

................................

...................... 4

................................

... 4

................................

5

................................

........... 5

................................

5

................................

............... 6

................................

...... 6

.........................

7

................................

. 7

................................

........ 7

..........................

8

..........................

8

................................

........................ 9

................................

.......... 9

................................

......... 10

...........................

11

................................

11

................................

... 12

..........................

12

................................

...................... 12

................................

...................... 14

................................

............... 14

..............................

14

...............................

15

................................

. 15

................................

.................. 16

GENERAL INFORMATION

Carefully read this instruction manual for installation and use before putting the FLIK

sliding system into operation; this will help to prevent errors and time

in maximum safety.

This documentation is intended for specialised companies and end users. All installation,

maintenance and repair work should be carried out by suitably trained technical personnel.

After installation and testing, the technician must provide

a short demonstration of the use of the FLIK automated sliding door device.

USER INSTRUCTIONS

CAUTION: Carefully observe all the following installation instructions to

ensure personal safety.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge.

Do not allow children to play with the fixed controls and keep any remote

units out of their reach.

Have installation checks performed periodically by qualified personnel from a

service centre authorised by the manufacturer. Do not use if repair or adjustment is

required.

CAUTION: if the power cable is damaged, it must be replaced by quali

personnel from a service centre authorised by the manufacturer.

CAUTION. Disconnect the power supply during cleaning or maintenance

operations. Do not use solvents or jets of water to wash the appliance; the

appliance should not be submerged in

In the event of fault or malfunction, switch off the device at the main switch. All

repairs and adjustments (e.g. setting the stroke) must only be performed by

qualified personnel from a service centre authorised by the manufacturer.

Always reques

t exclusive use of original spare parts. Failure to respect this

condition could compromise safety and invalidate the benefits contained in the

warranty for the appliance. In the event of any problems or queries, consult your

agent or contact the manufactu

The A-

weighted sound pressure level is less than 70dB(A).

Carefully preserve these instructions after installation.

3

GENERAL INFORMATION

Carefully read this instruction manual for installation and use before putting the FLIK

sliding system into operation; this will help to prevent errors and time

This documentation is intended for specialised companies and end users. All installation,

maintenance and repair work should be carried out by suitably trained technical personnel.

After installation and testing, the technician must provide

the user with these instructions and give

a short demonstration of the use of the FLIK automated sliding door device.

USER INSTRUCTIONS

CAUTION: Carefully observe all the following installation instructions to

ensure personal safety.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge.

Do not allow children to play with the fixed controls and keep any remote

Have installation checks performed periodically by qualified personnel from a

service centre authorised by the manufacturer. Do not use if repair or adjustment is

CAUTION: if the power cable is damaged, it must be replaced by quali

personnel from a service centre authorised by the manufacturer.

CAUTION. Disconnect the power supply during cleaning or maintenance

operations. Do not use solvents or jets of water to wash the appliance; the

appliance should not be submerged in

water.

In the event of fault or malfunction, switch off the device at the main switch. All

repairs and adjustments (e.g. setting the stroke) must only be performed by

qualified personnel from a service centre authorised by the manufacturer.

t exclusive use of original spare parts. Failure to respect this

condition could compromise safety and invalidate the benefits contained in the

warranty for the appliance. In the event of any problems or queries, consult your

agent or contact the manufactu

rer directly.

weighted sound pressure level is less than 70dB(A).

Carefully preserve these instructions after installation.

Carefully read this instruction manual for installation and use before putting the FLIK

sliding system into operation; this will help to prevent errors and time

-wasting and to work

This documentation is intended for specialised companies and end users. All installation,

maintenance and repair work should be carried out by suitably trained technical personnel.

the user with these instructions and give

a short demonstration of the use of the FLIK automated sliding door device.

CAUTION: Carefully observe all the following installation instructions to

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge.

Do not allow children to play with the fixed controls and keep any remote

-control

Have installation checks performed periodically by qualified personnel from a

service centre authorised by the manufacturer. Do not use if repair or adjustment is

CAUTION: if the power cable is damaged, it must be replaced by quali

fied

personnel from a service centre authorised by the manufacturer.

CAUTION. Disconnect the power supply during cleaning or maintenance

operations. Do not use solvents or jets of water to wash the appliance; the

In the event of fault or malfunction, switch off the device at the main switch. All

repairs and adjustments (e.g. setting the stroke) must only be performed by

qualified personnel from a service centre authorised by the manufacturer.

t exclusive use of original spare parts. Failure to respect this

condition could compromise safety and invalidate the benefits contained in the

warranty for the appliance. In the event of any problems or queries, consult your

INSTALLER INSTRUCTIONS

1. SECURITY RULES

CAREFULLY

OBSERVE

INSTRUCTIONS

TO

INSTALLATION

CAN

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard IEC

60335-2-

103 (Particular requirements for drives for gates, doors and windows) and other directives

and regulations indicated in the attached Declarations of Incor

end of the manual). According to the Machinery Directive, actuators are “partly completed

machinery” intended for incorporation into doors and windows.

The manufacturer/supplier of the window is

compliance of the entire system with the applicable standards and to issue

strongly discourage any use of the actuators other than that specified and ther

the supplier of the complete system retains full liability.

MANDATORY

RISK

ANALYSIS

For systems installed at a height of less than 2.5 m above floor level or other levels accessible to

users, the manufacturer/supplier of the window must conduct

harm (violent blows, crushing, wounds) caused to people by no

accidental breakage of the automated windows, and to implement suitable

view of these. Such measures include those recommended by the specified standard:

-

controlling the actuators via a “deadman’s

operator’s field of view, to ensure that people are out of the way during operation. The button

must be placed at a height of 1.5 m and operated by key if accessible to the public; or:

use contact safety syste

ms (also included in the devices) that ensure a maximum closing force

of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of IEC 60335

or:

- use of non-

contact safety systems (lasers, light grids); or:

-

use of fixed safety barriers that

Automated windows are deemed adequately protected if they:

are installed at a height of >2.5 m; or:

have a leading-

edge opening of <200 mm and a closing speed of <15 mm/s; or:

are part of a smoke and heat evacuation system

The device is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lacking experience and knowledge. Do not allow

children to play with the fixed controls and keep any remo

reach.

The actuator is destined exclusively for installation indoors. For any special application we

recommend you consult the manufacturer beforehand.

After removing packaging, check for any damage on the appliance.

Always

request exclusive use of original spare parts. Failure to respect this condition

could compromise safety and invalidate the benefits contained in the warranty for the

appliance.

In the event of any problems or queries, consult your agent or contact

directly.

4

INSTALLER INSTRUCTIONS

OBSERVE

ALL

THE

FOLLOWING

TO

ENSURE

PERSONAL

SAFETY.

CAN

SERIOUSLY

ENDANGER

SAFETY.

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard IEC

103 (Particular requirements for drives for gates, doors and windows) and other directives

and regulations indicated in the attached Declarations of Incor

poration and

end of the manual). According to the Machinery Directive, actuators are “partly completed

machinery” intended for incorporation into doors and windows.

The manufacturer/supplier of the window is

required, with exclusive responsibility, to ensure the

compliance of the entire system with the applicable standards and to issue

strongly discourage any use of the actuators other than that specified and ther

the supplier of the complete system retains full liability.

ANALYSIS

AND

PROTECTION

MEASURES.

For systems installed at a height of less than 2.5 m above floor level or other levels accessible to

users, the manufacturer/supplier of the window must conduct

risk analysis

harm (violent blows, crushing, wounds) caused to people by no

rmal use or possible malfunction or

accidental breakage of the automated windows, and to implement suitable

view of these. Such measures include those recommended by the specified standard:

controlling the actuators via a “deadman’s

button” placed near the system and within the

operator’s field of view, to ensure that people are out of the way during operation. The button

must be placed at a height of 1.5 m and operated by key if accessible to the public; or:

ms (also included in the devices) that ensure a maximum closing force

of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of IEC 60335

contact safety systems (lasers, light grids); or:

use of fixed safety barriers that

prevent access to moving parts.

Automated windows are deemed adequately protected if they:

are installed at a height of >2.5 m; or:

edge opening of <200 mm and a closing speed of <15 mm/s; or:

are part of a smoke and heat evacuation system

for emergency use only

The device is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lacking experience and knowledge. Do not allow

children to play with the fixed controls and keep any remo

te-

control units out of their

The actuator is destined exclusively for installation indoors. For any special application we

recommend you consult the manufacturer beforehand.

After removing packaging, check for any damage on the appliance.

request exclusive use of original spare parts. Failure to respect this condition

could compromise safety and invalidate the benefits contained in the warranty for the

In the event of any problems or queries, consult your agent or contact

INSTALLER INSTRUCTIONS

FOLLOWING

INSTALLATION

SAFETY.

IMPROPER

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard IEC

103 (Particular requirements for drives for gates, doors and windows) and other directives

poration and

Conformity (at the

end of the manual). According to the Machinery Directive, actuators are “partly completed

required, with exclusive responsibility, to ensure the

compliance of the entire system with the applicable standards and to issue

certification. We

strongly discourage any use of the actuators other than that specified and ther

efore, in any case,

MEASURES.

For systems installed at a height of less than 2.5 m above floor level or other levels accessible to

risk analysis

regarding potential

rmal use or possible malfunction or

accidental breakage of the automated windows, and to implement suitable

protective measures in

view of these. Such measures include those recommended by the specified standard:

button” placed near the system and within the

operator’s field of view, to ensure that people are out of the way during operation. The button

must be placed at a height of 1.5 m and operated by key if accessible to the public; or:

ms (also included in the devices) that ensure a maximum closing force

of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of IEC 60335

-2-103;

edge opening of <200 mm and a closing speed of <15 mm/s; or:

for emergency use only

.

The device is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lacking experience and knowledge. Do not allow

control units out of their

The actuator is destined exclusively for installation indoors. For any special application we

After removing packaging, check for any damage on the appliance.

request exclusive use of original spare parts. Failure to respect this condition

could compromise safety and invalidate the benefits contained in the warranty for the

In the event of any problems or queries, consult your agent or contact

the manufacturer

5

2. FIELD OF APPLICATION

The FLIK system is installed on the interior side of the upper part of the frame, and is used

for sliding doors, windows, shutters, blinds, etc., that are NOT intended for intensive use

or as escape routes. With the 24V FLIK you have the option of using one or more

systems on the same frame.

Doors/sashes Opening Lock

1 internal door/sash RH or LH 1

2 opposite doors/sashes 1 RH + 1 LH 2

2 telescopic sliding

doors/sashes 2 RH or 2 LH 2

To operate two doors/sashes of unequal width, whether opposite or telescopic, you must

ask the factory for the FLIK version with special programming when ordering.

3. TECHNICAL OPERATING INFORMATION

FLIK is an electric gearmotor with electronic control, fitted with a transmission shaft with a

pinion that is coupled to a rack fixed on the door/sash.

Several doors/sashes can be operated in the same door frame/window and moved in a

synchronised manner, following staggered closing times, and electric anti-burglary locks

can also be fitted. The driving force of each device is sufficient to operate a door/sash with

a maximum weight of 400 kg.

The movement is provided by an electrically powered gearmotor controlled by an electronic

device that operates inside the machine.

The FLIK 24V gearmotors use Nekos’ patented Syncro³ technology, which allows the creation

of synchronised systems of up to eight machines without any central control unit; it is particularly

used in applications with double/triple sliding doors/sashes and one or more electric locks.

Door/sash opening is easily programmed during installation, by memorising the two stroke end

positions. The mechanism includes a starting and arrival ramp for gentle end-positioning as well

as a safety device compliant with standard EN 60335-2-103.

The gearmotor structure is made of highly durable composite material (Pa6 + 35%GF) and

the rack is from a special polymer alloy (Pa66 + mineral fibres) with high mechanical

strength and wear resistance. The support bracket is metal and is fixed to the door/window

frame with cushioned screws. Before installing the device, it is highly recommended to

make a preliminary study of the door/window system in use.

4. MANUFACTURE AND REGULATORY FRAMEWORK

INTENDED USE: The FLIK gearmotor is designed and built for opening and closing sliding

doors and windows. Its specific use is for non-intensive access points, ventilation, indoor

climate control and, when combined with an electromechanical lock, as an anti-burglary

security system; any other use is not recommended without prior approval from the

manufacturer.

It should be noted, however, that the manufacturer of the entire system has sole responsibility

for the application, as stated by the Machinery Directive.

The device is manufactured in accordance with the Directives and Standards listed in the

Declaration of Incorporation and Conformity included at the end of this manual.

The electrical connection must meet current standards for the design and installation of

electrical systems.

6

The gearmotor is individually packaged in a cardboard box. Each package contains:

An electric gearmotor complete with power cable;

Instruction manual;

Standard motor mounting bracket and screw pack.

5. NAMEPLATEPLATE AND MARKING

The gear motors have CE marking and comply with the Standards listed in the

Declaration of Conformity. They also come with a Declaration of Incorporation, due to their

classification by the Machinery Directive as “partly completed machines”.

Both declarations are included in the final pages of this manual. The plate data is displayed

on an adhesive label placed on the outside of the casing, which must remain intact and

visible. The main information it displays includes: manufacturer's address, product name -

model number, technical characteristics, production date and serial number. In the event of

a complaint, please indicate the serial number (SN) displayed on the label.

An explanation of the symbols used on the label to abbreviate the technical characteristics

is given in the table in the chapter on “TECHNICAL DATA”.

6. TECHNICAL DATA

FLIK model 230 V 24 V

Driving force (F

N

) 100 N 120 N

Stroke (S

V

) max 4 m

Supply voltage (U

N

) 110÷230V~50/60Hz 24 V SELV

Current absorbed at rated load (I

N

) 0,32 / 0,22 A 0,95 A

Power absorbed at rated load (P

N

) 27 / 29 W 23 W

Electrical insulation Class II Class III

Average speed (excluding starting and braking

ramps) 45 mm/s

Maximum weight of operated door/sash 4.000 N

Maximum door/sash span 4 m

Stroke end position stop Electronic with magnetic switch

Anti-crush safety stop force 100 N

Ramp duration (start and stop) 200 mm

Service type (D

R

) 2 cycles 5 cycles

Operating temperature - 20 °C + 70 ºC

Electrical device protection rating IP42

Stroke end position stop Electronic

Parallel power supply YES

Compatible with: K-LOCK and AUX accessory NO YES

Synchronisation (Syncro³ patent) NO YES (max 8)

Power cable length 2 m

Noise level 45 dB-(A)

No. of test cycles - Standard EN12400(2004) 20.000

Fault or black-out release YES – Fitted on request

Dimensions (mm) 175x46x41 220x46x41

Device weight 0,313 Kg 0,295 Kg

Any data reported in this table is not binding and may be susceptible to variations without notice.

7

7. ELECTRICAL POWER SUPPLY

The FLIK system is powered with a voltage of:

110÷230V~ 50/60Hz - Three-wire power cable with BLUE: neutral common; BLACK: open

phase; BROWN: close phase;

24V SELV - Three-wire power cable with RED connected to + (positive) CLOSE; BLACK

connected to + (positive) OPEN; GREEN is the wire for the communication signal.

The gearmotor in the 24V version can also be powered by a control unit with emergency

batteries or a safety power supply of at least Class II, with an output voltage of 24V (min.

20.4V , max. 30V ), sized according to the number of connected systems.

7.1. Choice of power cable diameter

The voltage drop caused by the flow of current in conductors is a critical aspect for the safety

and proper functioning of the device. It is therefore important to correctly calculate the

diameter of the conductors in relation to the length of the cables.

The following table shows the cable lengths for a gearmotor connected to a rated load.

CABLE DIAMETER Gearmotor power supply

24V

110V~

230V~

0.50 mm

2

~20 m ~300 m ~1400 m

0.75 mm

2

~30 m ~450 m ~2100 m

1.00 mm

2

~40 m ~600 m ~2800 m

1.50 mm

2

~60 m ~900 m ~4000 m

2.50 mm

2

~100 m ~1500 m ~6800 m

4.00 mm

2

~160 m ~2500 m ~11000 m

6.00 mm

2

~240 m ~3700 m ~15000 m

8. RISK ANALYSIS

To estimate the risk potential of the motorised door/window and therefore implement the

necessary protective measures, a risk assessment must already be conducted in the

design stage. Risk analysis provides the information necessary for evaluating risk, in order

to make decisions regarding the safety of the doors/windows.

The machine as a whole may create crushing and shearing points on the sliding

door/window and therefore a risk analysis must be made, in compliance with the guidelines

of the sector associations and the Machinery Directive.

It should be noted that, according to the Machinery Directive, the manufacturer of

the entire system has sole responsible for the application and must also ensure

perfect installation, in accordance with regulations.

Before installation, you must analyse and determine the ideal mounting position for the

gearmotor, the position of the support brackets and the path of the electrical cables, and

the cables must be protected in a flexible conduit and secured in junction boxes easily

accessible for maintenance operations.

9.

INSTALLATION INSTRUCTIONS

These guidelines are intended for technical and

comments are made on basic work and safety methods.

All preparation, installation and electrical connection operations must be carried out by a

competent technician; this will ensure the optimal performance and proper f

the system.

If the system also includes an electromechanical lock, thought must be given at this

stage to the installation of the lock and its electrical connection, which must be

carried out together with that of the gearmotor.

First

ensure that the following basic conditions are met:

Before installation, check that the moving parts of the door/window on which the product

is to be installed are in perfect working condition, that they open and close properly and

slide freely

without any “stiff points”; max

The motor capacity must be sufficient for the movement of the door/sash, without

encountering difficulties any kind; the limits indicated in the product technical data table

(p. 6) cannot be exceeded; oth

Caution.

Check that the electrical supply used corresponds to that specified on the

“technical data” label on the device.

Check that the gearmotor has not been damaged during transportation, first visually and

then by pow

ering it in both directions.

Once the gearmotor is installed and the

the door/sash is perfectly in position (closed or open). Otherwise reprogram the

end positions.

In the case of doubts, uncertainty or

For correct installation, carefully follow the instructions given below.

9.1. Fitting the rack

This operation is performed before installing the FLIK system.

The rack is fitted to the top of the interior side

door/sash, ensuring that it is not interrupted by the carriage

fixing plates if the door/sash is supported from the top of the

frame. If the carriages are at the bottom of the door/sash,

check that there are no obstacles to fitting the rack

The rack is composed of several sections 300 mm in length,

each of which has 3 pre-

drilled fixing points.

The rack sections have a "male" end and a "female" end; to create the rack for a

door/sash, the various sections must be fitted together

It is recommended to position the first section at one side of the door/sash and fix it with

the screws, then the second, third and so forth until the entire width of the door/sash is

completed. If the final piece extends beyond t

hacksaw or electric mitre saw.

The following drawings show rack

8

INSTALLATION INSTRUCTIONS

These guidelines are intended for technical and

specialised personnel; therefore, no

comments are made on basic work and safety methods.

All preparation, installation and electrical connection operations must be carried out by a

competent technician; this will ensure the optimal performance and proper f

If the system also includes an electromechanical lock, thought must be given at this

stage to the installation of the lock and its electrical connection, which must be

carried out together with that of the gearmotor.

ensure that the following basic conditions are met:

Before installation, check that the moving parts of the door/window on which the product

is to be installed are in perfect working condition, that they open and close properly and

without any “stiff points”; max

imum permitted 50N.

The motor capacity must be sufficient for the movement of the door/sash, without

encountering difficulties any kind; the limits indicated in the product technical data table

(p. 6) cannot be exceeded; oth

erwise eliminate any difficulties.

Check that the electrical supply used corresponds to that specified on the

“technical data” label on the device.

Check that the gearmotor has not been damaged during transportation, first visually and

ering it in both directions.

Once the gearmotor is installed and the

stroke end position

s programmed, check that

the door/sash is perfectly in position (closed or open). Otherwise reprogram the

In the case of doubts, uncertainty or

different applications, consult the manufacturer.

For correct installation, carefully follow the instructions given below.

This operation is performed before installing the FLIK system.

The rack is fitted to the top of the interior side

of the sliding

door/sash, ensuring that it is not interrupted by the carriage

fixing plates if the door/sash is supported from the top of the

frame. If the carriages are at the bottom of the door/sash,

check that there are no obstacles to fitting the rack

at the top.

The rack is composed of several sections 300 mm in length,

drilled fixing points.

The rack sections have a "male" end and a "female" end; to create the rack for a

door/sash, the various sections must be fitted together

(s

ee figure at the side

It is recommended to position the first section at one side of the door/sash and fix it with

the screws, then the second, third and so forth until the entire width of the door/sash is

completed. If the final piece extends beyond t

he side of the door/sash, cut it with a

hacksaw or electric mitre saw.

The following drawings show rack

-

fitting solutions on different sliding door profiles.

specialised personnel; therefore, no

All preparation, installation and electrical connection operations must be carried out by a

competent technician; this will ensure the optimal performance and proper f

unctioning of

If the system also includes an electromechanical lock, thought must be given at this

stage to the installation of the lock and its electrical connection, which must be

Before installation, check that the moving parts of the door/window on which the product

is to be installed are in perfect working condition, that they open and close properly and

The motor capacity must be sufficient for the movement of the door/sash, without

encountering difficulties any kind; the limits indicated in the product technical data table

Check that the electrical supply used corresponds to that specified on the

Check that the gearmotor has not been damaged during transportation, first visually and

s programmed, check that

the door/sash is perfectly in position (closed or open). Otherwise reprogram the

stroke

different applications, consult the manufacturer.

For correct installation, carefully follow the instructions given below.

The rack sections have a "male" end and a "female" end; to create the rack for a

ee figure at the side

).

It is recommended to position the first section at one side of the door/sash and fix it with

the screws, then the second, third and so forth until the entire width of the door/sash is

he side of the door/sash, cut it with a

fitting solutions on different sliding door profiles.

9

PVC door/sash Wooden door/sash Aluminium door/sash

This step requires a certain precision in the drilling and driving of the screws that secure

the various sections of the rack so that it is properly fitted to the door/sash and perfectly

aligned, and to therefore ensure that the gearmotor works perfectly.

9.2. Mounting the gearmotor on the frame

9.2.1. Preparing for mounting

A previous section (section 9 - Risk analysis) recommends making a prior analysis of

where to position the gearmotor, the path of the power cables and where to fix the support

brackets. The following description is a recommendation by the manufacturer and

describes the main installation steps, the sequence of which also depends on the type of

sliding door/window used and its structure.

The gearmotor is supplied with a flat bracket for the standard fitting (the most common),

although a bracket for 90° fitting (on the reveal of the frame) is also available. In the event

of special anchoring requirements, appropriate solutions can be studied.

Horizontal installation of the motor on the door/window frame:

TO THE RIGHT TO THE LEFT

Vertical installation of the motor on the door/window frame:

TO THE RIGHT TO THE LEFT

10

The screws for fixing the bracket to the gearmotor are supplied (M5x14 metric flat head

screws) and the bracket should be assembled on the gearmotor in the exact position

shown in the figures above, depending on how the gearmotor is mounted on the door/sash

(to the right or to the left).

9.2.2. Preparation and mounting of the gearmotor

For a professional, inexpensive and precise job, we recommend preparing the following

additional material: screws, equipment and tools.

Fixing on metal frames: M5 threaded inserts (2 pieces), 2 M5x12 metric flat head

screws.

Fixing on wooden frames: Ø4.5 self-tapping wood screws (2 pieces) of a suitable

length for the type of frame.

Fixing on PVC frames: Ø4.8 self-tapping metal screws (2 pieces) of a suitable length

for the type of frame.

Equipment and tools: tape measure, pencil, electric drill/screwdriver, set of metal drill

bits, screwdriver bit, electrician's scissors, screwdrivers.

Before mounting the gearmotor on the frame or on the reveal of the door/window frame,

the fixing points must first be marked and drilled as indicated below:

a) The gearmotor must be prepared by first inserting the pinion (z = 13) with the

hexagonal hole into the drive shaft and then the guide bushing (Ø4x6x6); take care

not to drop or lose the bushing as it is essential for correct and silent coupling of the

pinion with the rack.

b) Insert the end of the shaft (with the bushing) into the housing on the rack.

c) Align the gearmotor as desired in accordance with the analysis made earlier; it is

recommended to place it in a horizontal or vertical position.

d) Mark the position of the holes for the bracket on the frame or the reveal with extreme

precision. It is very important to achieve maximum precision at this stage in order for

the device to operate perfectly.

e) Drill with a drill bit of the right size for the provided inserts or the right diameter for the

fixing screws.

On aluminium profile frames, it is recommended to use metric screws with threaded

inserts.

Once this is done, the gearmotor can then be mounted. For this step, it is advisable to

keep the door/sash open by at least 20 cm to facilitate start-up when setting the stroke end

positions.

Insert the power cable into the provided conduit until it reaches the inside of the

electrical junction box.

Insert the end of the drive shaft (with the bushing) into the housing on the rack.

Fix the gearmotor to the frame or to the reveal of the door/window frame with the

provided screws.

Adjust the position of the power cables and protect them inside a flexible conduit.

Carry out the electrical connections following the instructions in section 8.

C

AUTION

:

choose the appropriate diagram for the type of application, which can be:

One FLIK,

One FLIK plus one lock,

Two FLIKs connected and synchronis

Two FLIKs connected and synchronised plus one or two locks.

IMPORTANT

: Where one or more electric locks (K

door/window, the electrical connections must be made at the same time; therefore, before

connecting the cables, fit

10.

ELECTRICAL CONNECTION

W

ARNING

:

Electrically powered device

Danger of death from electric shock or fire. Disconnect the main switch before

starting work to connect the device.

The power

cable can be routed in one of two ways:

A)

Visible cable. In this case, the cable must be protected by an electrical conduit or

channel in order to protect it from getting caught up in the moving parts;

B)

Hidden cable. Running it beneath the surface is more sui

it is protected not only by the electrical conduit but also by a solid structure.

The machines are fitted with a 2

safety regulations and radio interference protection requirem

conductors of 0.5 mm² in diameter

specifications of the cable supplied with the machine.

E

ACH ACTUATOR MODEL H

VOLTAGE

.

(see section 7

Before making the electrical connection, check the following table to ensure

that the power cable corresponds with the voltage data shown in the label on

the gearmotor.

Supply voltage

110÷230V~ 50/60Hz

24V

Syncro³

10.1.

Machine electrical connections

C

AUTION

:

Where several machines are connected in a Syncro³ system, always

follow the correct electrical

machines and create a hazardous situation.

11

choose the appropriate diagram for the type of application, which can be:

One FLIK plus one lock,

Two FLIKs connected and synchronis

ed,

Two FLIKs connected and synchronised plus one or two locks.

: Where one or more electric locks (K

-

LOCK) are included on the

door/window, the electrical connections must be made at the same time; therefore, before

connecting the cables, fit

the lock following the instructions in the relevant manual.

ELECTRICAL CONNECTION

Electrically powered device

.

Danger of death from electric shock or fire. Disconnect the main switch before

starting work to connect the device.

cable can be routed in one of two ways:

Visible cable. In this case, the cable must be protected by an electrical conduit or

channel in order to protect it from getting caught up in the moving parts;

Hidden cable. Running it beneath the surface is more sui

table for safety purposes, as

it is protected not only by the electrical conduit but also by a solid structure.

The machines are fitted with a 2

-

metre power cable manufactured in compliance with

safety regulations and radio interference protection requirem

ents, with PVC sheaths and

conductors of 0.5 mm² in diameter

.

Any cable extensions must comply with the colours and

specifications of the cable supplied with the machine.

ACH ACTUATOR MODEL H

AS ITS OWN SPECIFIC CABLE

,

IN RELATION TO THE S

(see section 7

– Electrical supply)

.

Before making the electrical connection, check the following table to ensure

that the power cable corresponds with the voltage data shown in the label on

Cable

length

Number

of wires Power wires

2 m 3

B

LUE

,

B

LACK

B

ROWN

2 m 3

R

ED

,

B

LACK

Machine electrical connections

Where several machines are connected in a Syncro³ system, always

follow the correct electrical

connections; incorrect connection can damage the

machines and create a hazardous situation.

choose the appropriate diagram for the type of application, which can be:

Two FLIKs connected and synchronised plus one or two locks.

LOCK) are included on the

door/window, the electrical connections must be made at the same time; therefore, before

the lock following the instructions in the relevant manual.

Danger of death from electric shock or fire. Disconnect the main switch before

Visible cable. In this case, the cable must be protected by an electrical conduit or

channel in order to protect it from getting caught up in the moving parts;

table for safety purposes, as

it is protected not only by the electrical conduit but also by a solid structure.

metre power cable manufactured in compliance with

ents, with PVC sheaths and

Any cable extensions must comply with the colours and

IN RELATION TO THE S

UPPLY

Before making the electrical connection, check the following table to ensure

that the power cable corresponds with the voltage data shown in the label on

Power wires

Communication

wires

LACK

LACK

G

REEN

Where several machines are connected in a Syncro³ system, always

connections; incorrect connection can damage the

The electrical connection for communication and synchronisation (

be made with a simple unipolar

supplied).

A stable and safe connection, with a good electrical contact (copper to copper) is

essential to prevent communication disturbances as the forward voltage is very low.

The communication wires can

Wiring diagram 110÷230V~

SCHWARZHELLBLAU BRAUN

F N

BLEU CLAIR

AZUL

MARRON

MARRÓNNEGRO

NOIRE

1

32

AZZURRO

LIGHT BLUE

1

MARRONENERO

BLACK

2

BROWN

3

110/230V ~

100-230V~ 50/60Hz

IMPORTANT FOR PRODUCT SAFETY

G

reen wire "3" is not used,

10.2.

Connection with a K

24V

+

-

11. PROGRAMMING AND

11.1. Stroke

end position

Before carrying out the

ensure that the electrical supply is of the same kind as that specified on the

technical data label on the machine,

check that the wires are correctly connected, in accordance with the wiring diagram

in this manual.

12

The electrical connection for communication and synchronisation (

be made with a simple unipolar

terminal of an appropriate size (the terminal is

A stable and safe connection, with a good electrical contact (copper to copper) is

essential to prevent communication disturbances as the forward voltage is very low.

The communication wires can

have a maximum length of 10 metres.

Wiring diagram 110÷230V~

Wiring diagram 24V

110/230V ~

-+

24V

1

2

1 2

ROT

ROJO

ROUGE

RED

ROSSO

SCHWARZ

NEGRO

NOIRE

BLACK

NERO

IMPORTANT FOR PRODUCT SAFETY

: in motors with a 24V

reen wire "3" is not used,

it must be insulated.

Connection with a K

-LOCK electromechanical lock

Wiring diagram 24V

2

3

1

N

V

R

K-LOCK

FLIK

(24V - 24V SYNCRO

RESETTING THE GEARMOTOR

end position

setting procedure

Before carrying out the

stroke end position setting procedure,

ensure that the electrical supply is of the same kind as that specified on the

technical data label on the machine,

check that the wires are correctly connected, in accordance with the wiring diagram

The electrical connection for communication and synchronisation (

Green cable) must

terminal of an appropriate size (the terminal is

A stable and safe connection, with a good electrical contact (copper to copper) is

essential to prevent communication disturbances as the forward voltage is very low.

have a maximum length of 10 metres.

Wiring diagram 24V

31

2

3

GRÜN

VERDE

VERT

GREEN

VERDE

24V

CÂBLE DE CONTRÔLE

CABLE DE CONTROL

LEITUNGSÜBER-WACHUNG

CONTROL WIRE

FILO DI COMUNICAZIONE

SYNCRO

supply voltage, if the

K-LOCK

(24V - 24V SYNCRO

3

)

ensure that the electrical supply is of the same kind as that specified on the

check that the wires are correctly connected, in accordance with the wiring diagram

13

The stroke end position setting process has already been programmed into the machine’s

internal memory during production testing.

Determining the stroke end position is a simple operation, carried out during initial

installation of the door/window to set the control parameters and define the exact position

of the two stroke ends that will be utilised during normal use.

At this stage, the machine has no stroke end position parameter programmed, and so the

setting and RESET procedure consists of the following steps, performed in succession.

IMPORTANT : Where two or more machines are connected in a Syncro³ system,

the recognition of the group is completely automatic and occurs in the first

manoeuvre when programming the stroke end positions.

Programming:

1. Remove the magnet from a gearmotor by loosening the screw on top of it

(see picture at the side): extract it completely. Be careful not to misplace it.

NOTE: with several gearmotors in a Syncro³ system, this motor

will be the one that always starts first when opening;

2. Supply power to move the door/sash.

CAUTION: when a K-LOCK lock is fitted, you must wait about 4 seconds for it to

switch to OPEN position;

3. The door/sash (or doors/sashes) move automatically to the OPEN stroke end position

and then (automatically) to the CLOSE stroke end position. At this stage, the door/sash

rests against the mechanical stops on the frame, thereby setting the natural stroke

end position;

BE CAREFUL OF DIRECTION ERRORS: if the machines start to move in the CLOSE

direction, shut off the power, wait a few seconds (~ 5 s), then supply power with a

command in the opposite direction and check that the doors/sashes move in the

OPEN direction.

4. At the end of the procedure you can check the flashing of the LEDs and thus the

identifier acquired by each machine, as well as faults detected during the setting

process (see the "LED DIAGNOSTICS DURING OPERATION" section);

5. Refit the screw with the magnet and screw it into its housing;

6. End of the procedure. In the event of errors in the previous steps, repeat the

procedure.

This procedure is carried out the first time the device performs a complete stroke or

following a RESET operation and it is stored as an operating parameter.

IMPORTANT. If a K-Lock electromechanical lock is connected at a later moment, i.e.

after acquisition of the stroke end positions, a new setting procedure must be carried

out.

CAUTION. In the event that, for whatever reason, the gearmotor has not closed the

door/sash correctly, stopping before completing its stroke, the setting procedure must

be repeated.

14

11.2. Troubleshooting

In the event of a malfunction, never open the unit or try to repair it. If the problem

encountered in your machine is not described in the table below, contact your retailer or

the manufacturer directly.

The following LED signals indicate possible machine operation errors.

LED DIAGNOSTICS DURING OPERATION

Number of

Flashes Type of error Possible solution

1

Overload error:

the actuator has detected an overcurrent in the

motor

Make sure there are no obstructions preventing

completion of the stroke. Check also that the

actuator is correctly installed: there should be no stiff

points during the movement of the door/sash.

2

Communication error:

communication between devices is interrupted

or the devices being used have been RESET

separately

Check the condition of the connection cables and

repeat the RESET procedure

3 Electric lock error

Check the electric lock

4

RESET procedure error:

the RESET procedure has not been successful

or was interrupted

Repeat the RESET procedure

5 Encoder error:

the internal encoder has had a counting error Repeat the RESET procedure

6 Power supply error:

the supply voltage is outside the permissible

range or is unstable

Check the supply voltage

7

Memory error:

the internal memory writing process has not

been successful

Repeat the RESET procedure

8 The RESET procedure is active The procedure ends correctly if the LED remains lit

throughout the travel acquisition manoeuvre

12. CHECKING CORRECT INSTALLATION

After completing the installation, it is always necessary to check that the work has been done

professionally, with no completion tasks left pending, and that the equipment is working properly.

Therefore, ensure that:

After a closing command, the door/sash is perfectly closed, also in the corners, and that there

are no hindrances due to an inaccurate mounting position.

When the door/sash is closed, the seals are properly compressed. Otherwise, there is no

certainty of a perfect closure.

The rack and support staff are firmly united to the frame and the screws are properly tightened.

Where the K-LOCK electric lock is also installed, check that the lock is activated at the close

stroke end position, with a closing time of around 4 seconds.

Any casing covering the mechanisms is fitted so that it does not hinder the proper opening /

closing operation of the door/sash.

The power cables of the gearmotor and any locks are secured and protected in order to

prevent dangling or interference with moving parts.

13. EMERGENCY AND MAINTENANCE MANOEUVRES – Release device

NOTE The FLIK gearmotor can be equipped with a release device for the drive

mechanism; as this is an accessory mechanism, if it is not installed, it should be

requested from the manufacturer when ordering.

15

To open the door/window manually in the event of a power failure or fault in the

mechanism, if the release device is installed, follow the procedure described below. If an

electromechanical lock is installed, to release it, see the indications given in the relevant

instruction manual.

1. Remove the cover from the upper part of the gearmotor with a small screwdriver.

2. With a larger 5.5x1 screwdriver, loosen the screw on the shaft by six turns.

3. Move the sliding door/sash with small jumps in order to disengage the balls that block

the rotation.

4. Open the door/sash manually.

5. Once the emergency is resolved or the maintenance completed, carry out the operation

in reverse, namely:

a. Slide the door/sash until it is almost fully OPENED (about 10 cm short).

b. Tighten the screw six turns, ending with slight force. If the screw offers some

resistance, move the door/sash slightly forward/back to cause the balls inside the

coupling mechanism to engage.

c. Snap the cover into place.

d. The new command will be OPEN and the gearmotor will move the door/sash to the

stroke end position, where it stops immediately. With the next CLOSE command, the

door/sash will close completely, reaching the preset stroke end position.

e. Normal operation is now fully restored.

14. ENVIRONMENTAL PROTECTION

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent to a centre for

ecological recycling as established from laws in force on recycling. The device is mainly made

from the following materials: aluminium, zinc, iron, plastic of various type, cuprum. Dispose

materials in conformity with local regulations about removal.

15. CERTIFICATE OF GUARANTEE

The manufacturer will guarantee good function of the appliance. The manufacturer shall undertake

to replace defective parts due to poor quality materials or manufacturing defects in accordance

with article 1490 of the Civil Code.

The guarantee covers products and individual parts for 5 years from the date of purchase. The

latter is valid as long as the purchaser possesses proof of purchase and completion of all agreed

conditions of payment. Guarantee of good function of appliances agreed by the manufacturer

implies that the latter undertakes to repair or replace free of charge and in the shortest period

possible any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect damage or other

expenses incurred. Attempt to repair by personnel unauthorised by the manufacture shall render

the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or corrosion,

overload, however temporary etc. The manufacturer will accept no responsibility for eventual

damage incurred by erroneous assembly, manoeuvre or insertion, excessive stress or inexpert

use.

Repairs performed under guarantee are always "ex factory of the manufacturer". Respective

transport expenses (out/back) are the responsibility of the purchaser.

16

16. DICHIARAZIONE DI INCORPORAZIONE (PER UNA QUASI MACCHINA) e

DICHIARAZIONE CE DI CONFORMITÀ / Declaration of incorporation (for a

partly completed machine) and EC Declaration of Conformity.

Con la presente il / Hereby the

Costruttore:

Manufacturer:

Nekos S.r.l.

Via Capitoni 7/5- 36064 COLCERESA (Vicenza) - Italy

Tel +39 0424 411011 – Email info@nekos.it

dichiara sotto la propria responsabilità che i seguenti prodotti / declare under its own responsibility that the following products:

Descrizione prodotto :

Product Designation:

Motoriduttore per finestre

scorrevoli

Gearmotor for sliding windows

Modello:

Type :

FLIK 230 V

FLIK 24 V – FLIK 24V Syncro³

Anno di costruzione dal / Year of manufacturing from: 2019

Soddisfano gli applicabili requisiti essenziali della

Direttiva Macchine 2006/42/EC,

Allegato I

Fulfil the essential requirements of the Machinery Directive 2006/42/EC, Annex I, Art. 1.1.2, 1.1.3, 1.1.5, 1.2.1,1.2.3, 1.2.6; 1.3.2,

1.3.4, 1.3.9, 1.5.1, 1.5.2, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.5.10, 1.5.11, 1.7.1, 1.7.1.1, 1.7.3, 1.7.4.2, 1.7.4.3

La documentazione tecnica pertinente è compilata secondo l’Allegato VII, sezione B

The relevant technical documentation is compiled in accordance with Annex VII, Part B

La persona autorizzata a costituire la documentazione tecnica pertinente è:

The person authorised to compile the relevant technical documentation is: ing. Matteo Stefani – Nekos S.r.l.

Su richiesta adeguatamente motivata delle autorità nazionali, la documentazione tecnica dei citati prodotti sarà resa disponibile, via e-

mail, entro un tempo compatibile con la sua importanza.

In response to a reasoned request by the national authorities, we will provide, via e-mail, the relevant information on the product listed

above within an adequate period proportional to its importance.

Inoltre i succitati prodotti sono conformi alle disposizioni pertinenti delle seguenti Direttive:

Furthermore the products listed above complies with the provisions of followings Directives :

2014/30/EU Direttiva Compatibilità Elettromagnetica / ElectroMagnetic Compatibility Directive (EMCD)

2014/35/EU Direttiva Bassa Tensione / Low Voltage Directive (LVD)

2011/65/EU Direttiva sulla restrizione dell’uso di determinate sostanze pericolose nelle apparecchiature elettriche ed

elettroniche (Direttiva RoHS) / Restriction of the use of certain hazardous substances Directive (RoHS Directive)

2015/863/UE Direttiva Delegata recante modifica dell’allegato II della Direttiva 2011/65/UE del Parlamento Europeo e del

Consiglio per quanto riguarda l’elenco delle sostanze con restrizioni d’uso / Delegated Directive amending Annex II of

Directive 2011/65/EU of the European Parliament and of the Council regarding the list of substances with usage

restrictions

e delle seguenti norme armonizzate e/o specifiche tecniche / and of the following harmonised standards and/or technical specifications:

EN 60335-2-103; EN 61000-6-3:2007 + A1:2011+ AC:2012; EN IEC 61000-6-2:2019;

EN 60335-1:2012 + AC:2014 + A11:2014; EN 50581:2012

La messa in moto di una macchina completa che includa la quasi macchina sopra menzionata, da noi fornita, non è permessa finché non

sia accertato che l’installazione sia stata fatta secondo le specifiche e le indicazioni di installazione contenute nel “Manuale d’istruzioni”

fornito con la quasi-macchina e che sia stata espletata e documentata, in apposito protocollo, una procedura di accettazione da parte di

un tecnico abilitato.

Commissioning of the complete machinery including the above mentioned drives delivered by us is not allowed until it is ascertained that

the installation of the complete machinery was performed in accordance with the specifications and the operating and installation advice

given in our Mounting Instructions, and that the acceptance procedure was duly carried out and documented in an acceptance protocol by

a specialist.

Questa dichiarazione è fatta dal costruttore / This is declared by the manufacturer:

NEKOS SRL - Via Capitoni 7/5 - 36064 Colceresa (Vicenza) - Italy

Rappresentato da / Represented by: Giuliano Galliazzo – A.D. Presidente / President CEO

Luogo e data / Place and date : Colceresa 15/05/2020 Firma / Valid signature

NEKOS S.r.l. - Via Capitoni, 7/5

36064 Colceresa (VI) – ITALY

+39 0424 411011 – +39 0424 411013

Popular Door Opening System manuals by other brands

Synergy Hardware

Synergy Hardware S300 Series Fixing instructions

White Rose

White Rose FORSA Installation and operating manual

CES

CES EB3200 Assembly and operating manual

Autoslide

Autoslide AutoSwing ASW8-1 installation manual

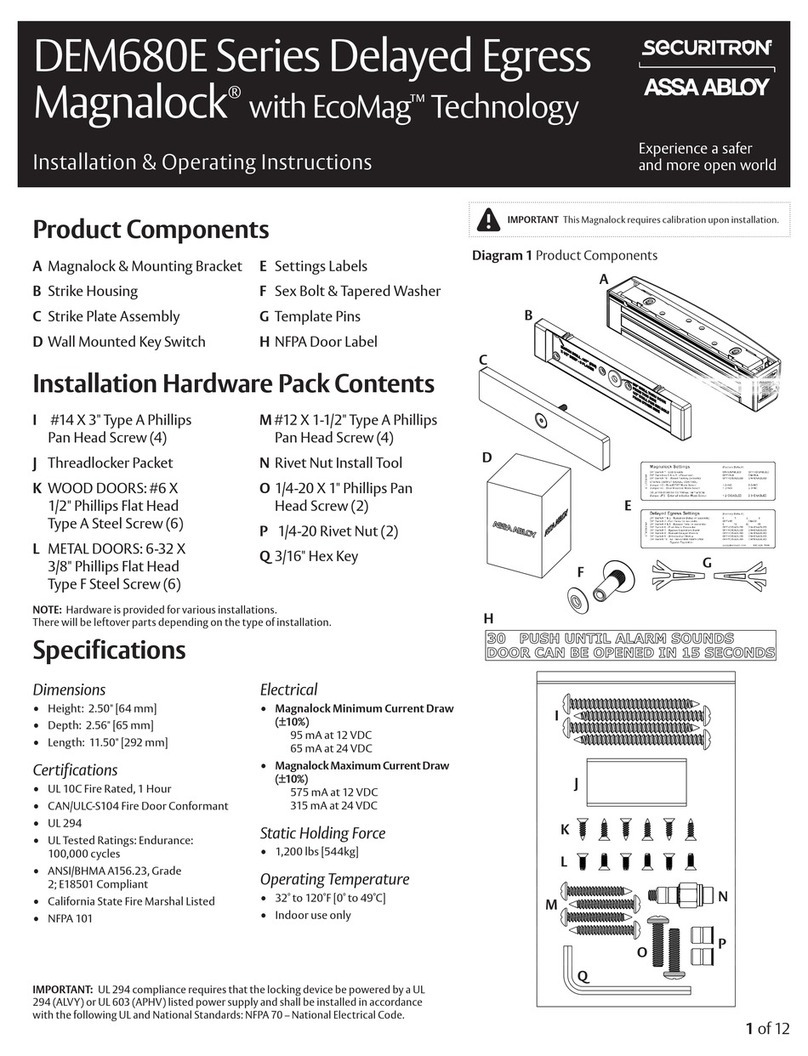

Assa Abloy

Assa Abloy SECURITRON DEM680E Series Installation & operating instructions

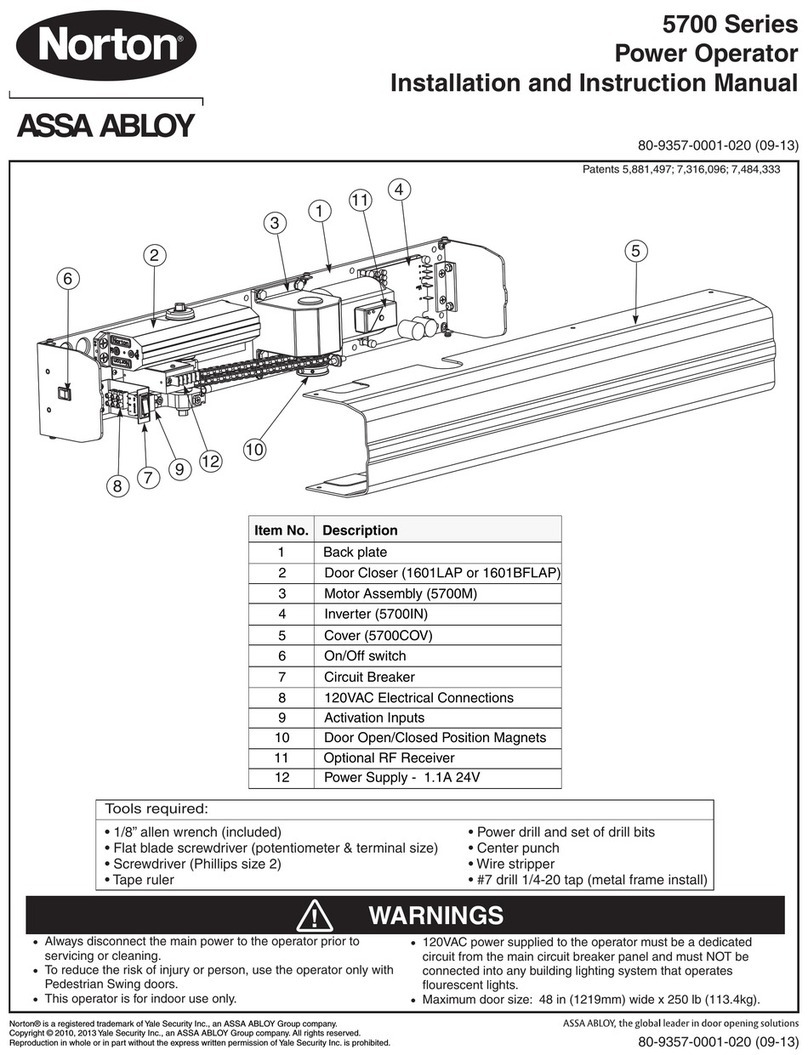

Assa Abloy

Assa Abloy Norton 5700 Series Installation and instruction manual

Detex

Detex Advantex 10 Series Maintenance manual

GEZE

GEZE TS 5000 L-E-ISM VPK installation instructions

CAME

CAME 803XA-0320 instructions

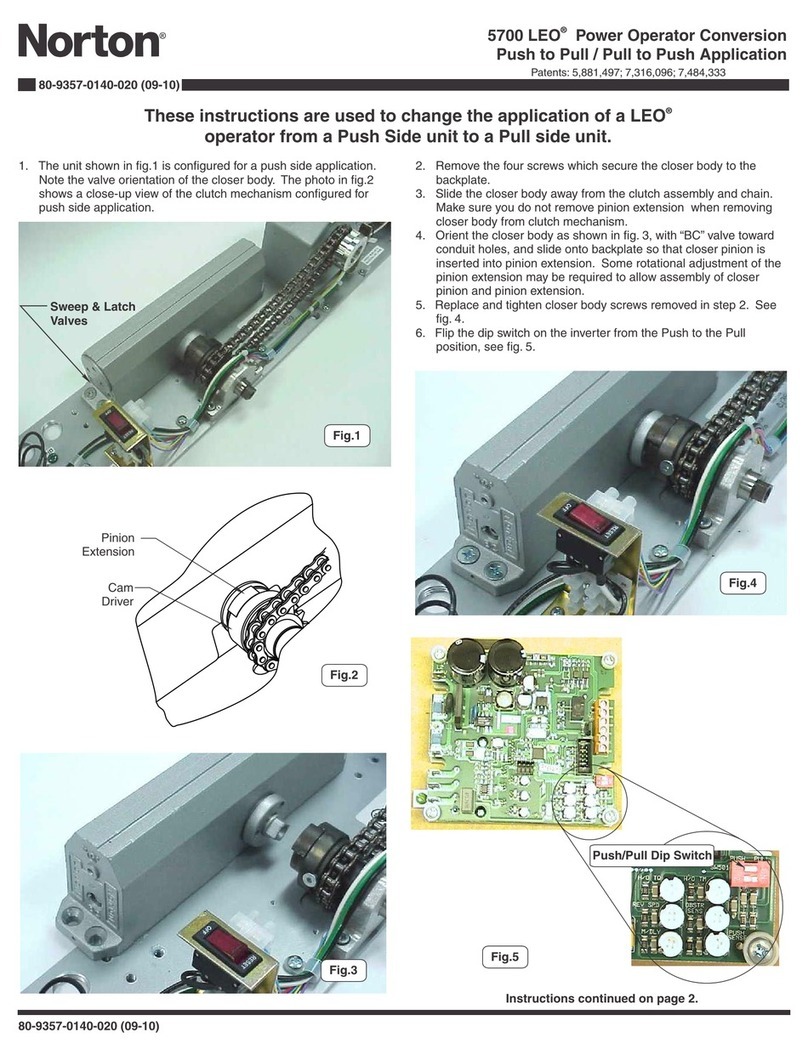

Assa Abloy

Assa Abloy Norton LEO 5700 Series instructions

Dorma

Dorma TS 99 FLR Fixing instructions

Assa Abloy

Assa Abloy SARGENT 351 POWERGLIDE Series Instructions for installing