Assa Abloy SARGENT 351 POWERGLIDE Series Instruction Manual

Other Assa Abloy Door Opening System manuals

Assa Abloy

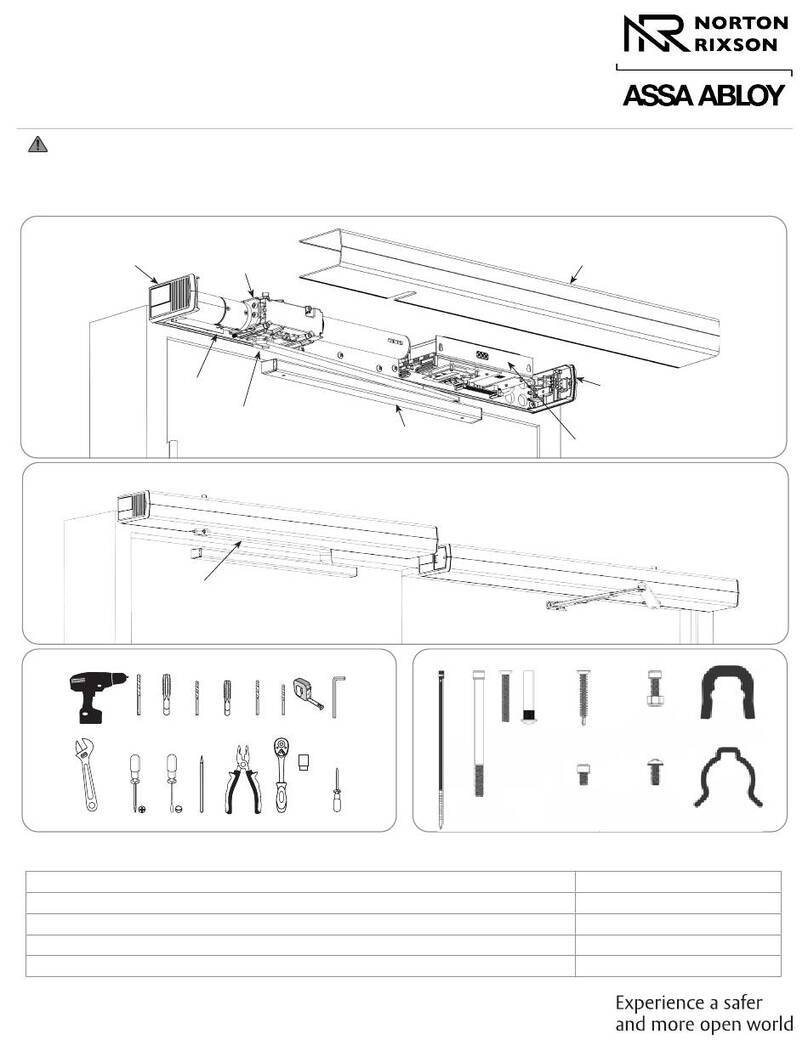

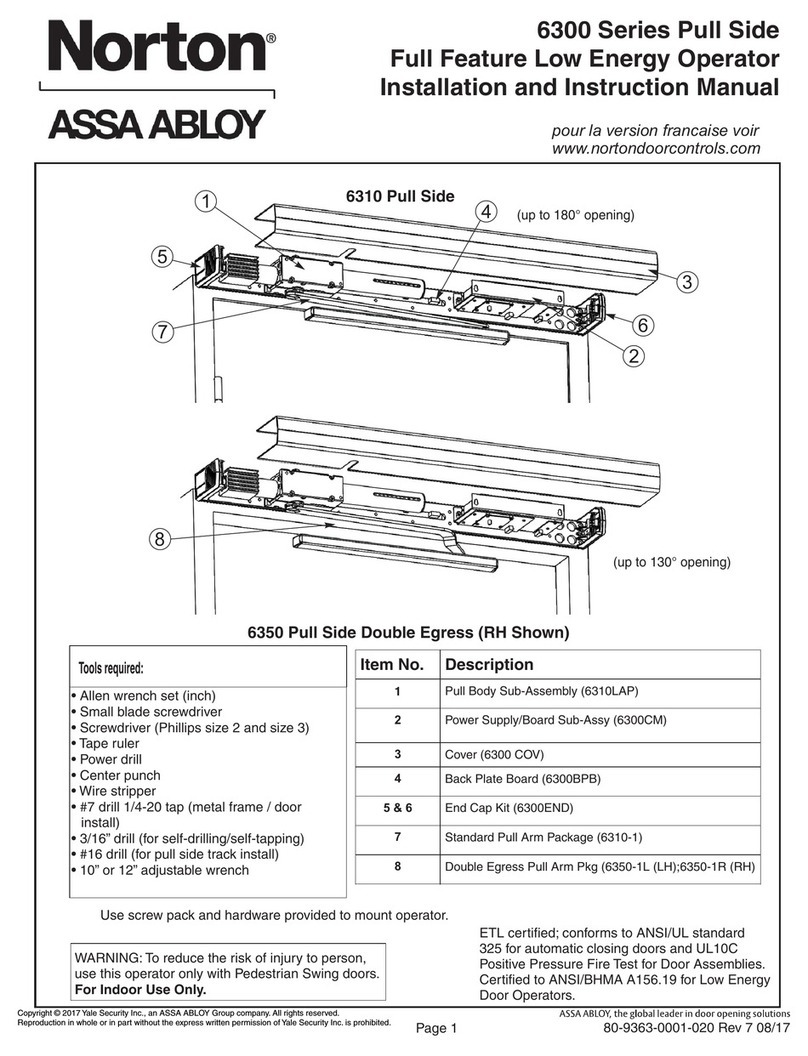

Assa Abloy NORTON RIXSON 6300 Series User manual

Assa Abloy

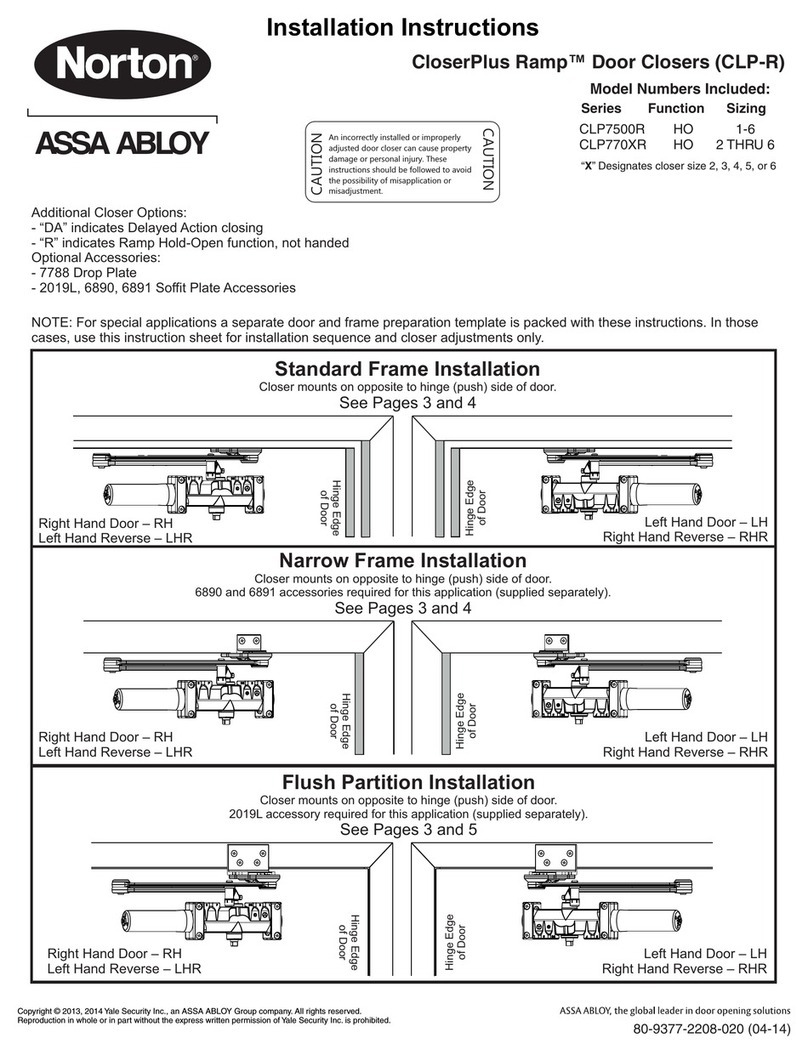

Assa Abloy CloserPlus Ramp Norton XF460 User manual

Assa Abloy

Assa Abloy G-CO-C User manual

Assa Abloy

Assa Abloy RIXSON 91DCP User manual

Assa Abloy

Assa Abloy Norton 6300 Series Quick guide

Assa Abloy

Assa Abloy SARGENT 1431 Series User manual

Assa Abloy

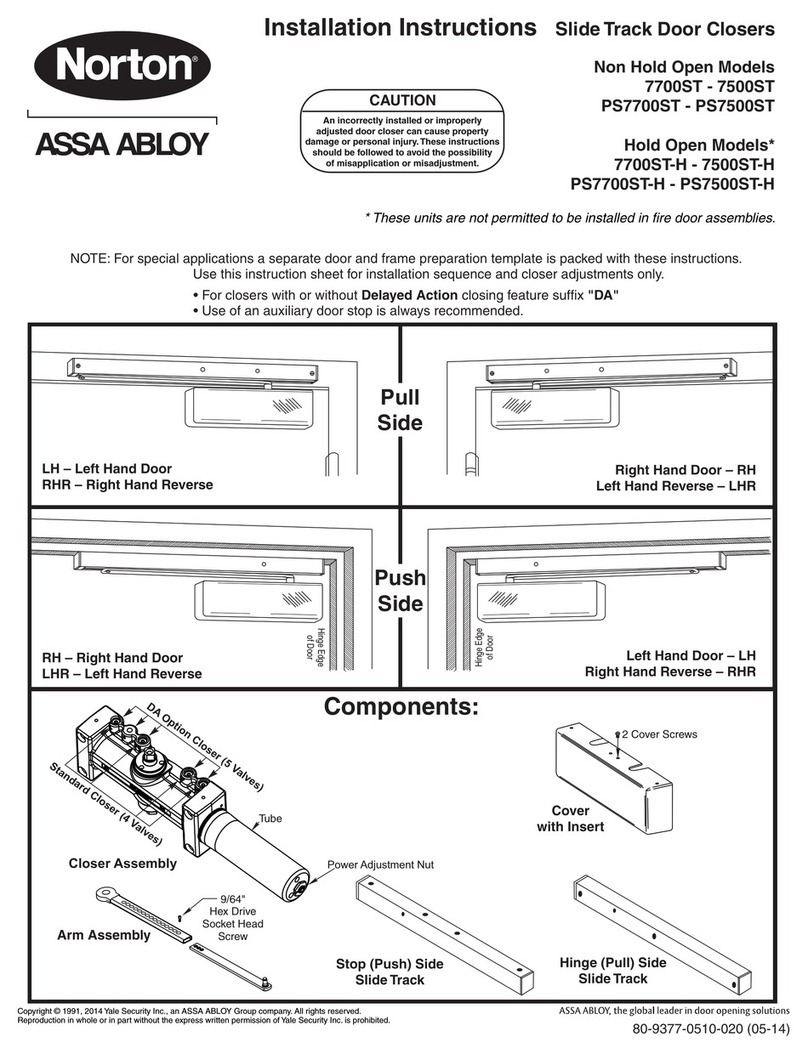

Assa Abloy Norton 7700ST User manual

Assa Abloy

Assa Abloy SARGENT 351 Series User manual

Assa Abloy

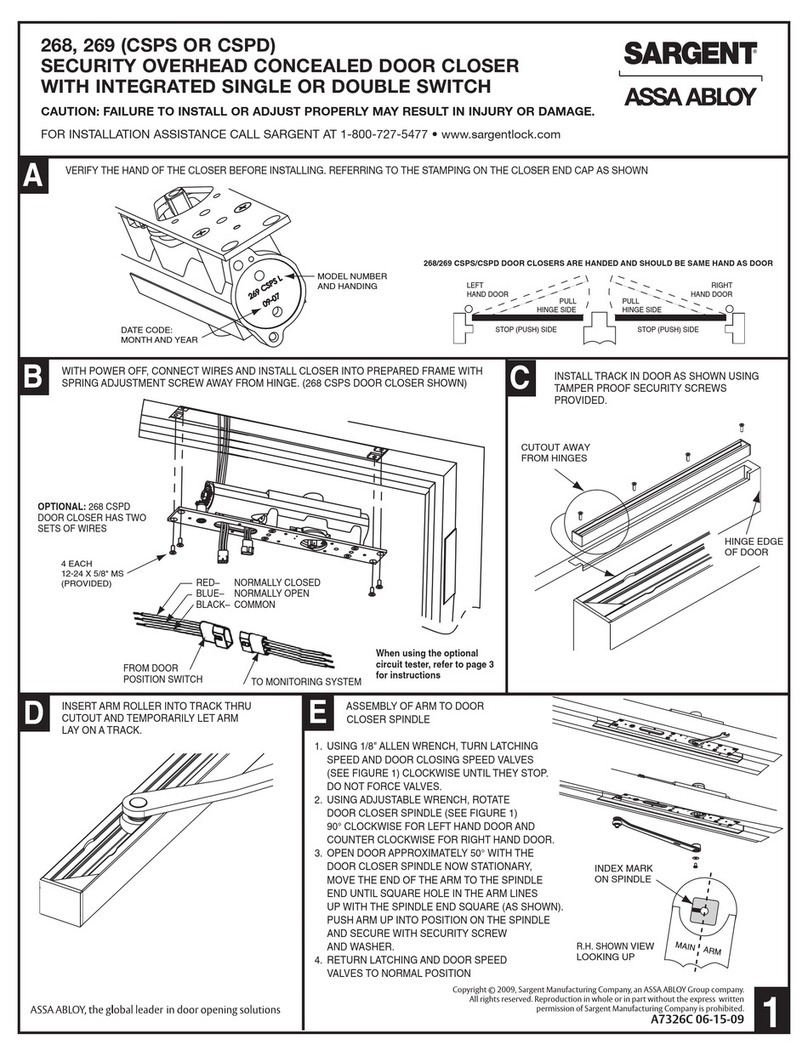

Assa Abloy SARGENT 268 Series User manual

Assa Abloy

Assa Abloy SW200 User manual

Assa Abloy

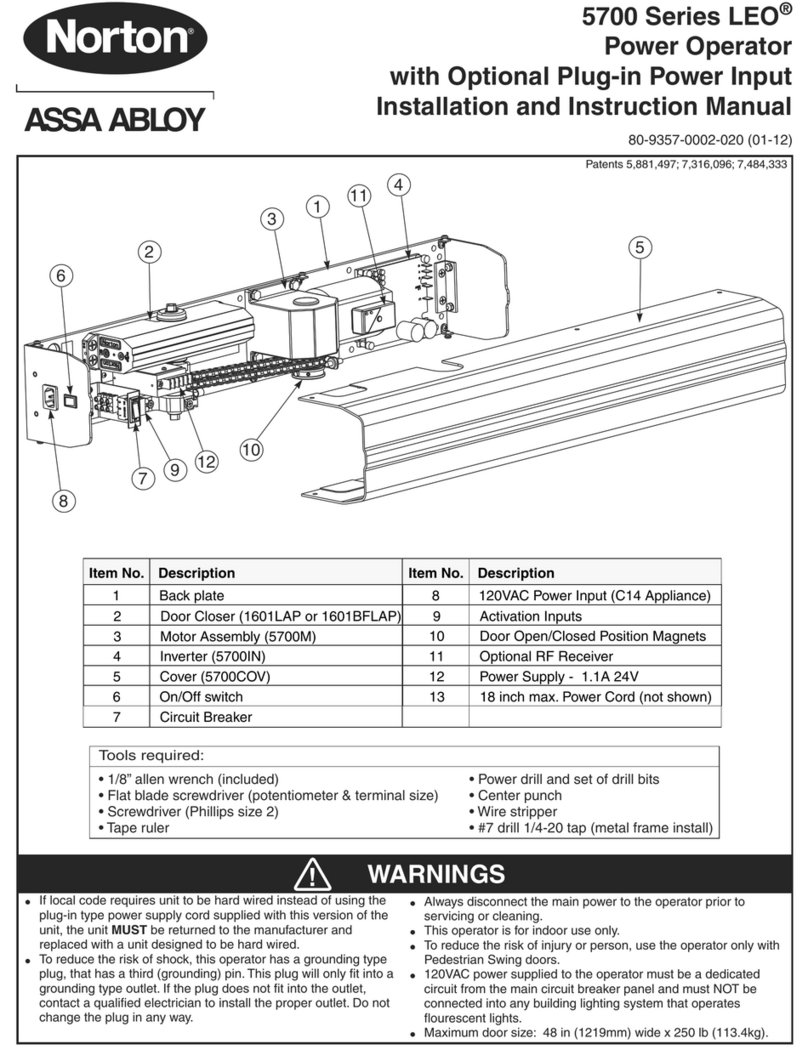

Assa Abloy Norton LEO 5700 Series Quick guide

Assa Abloy

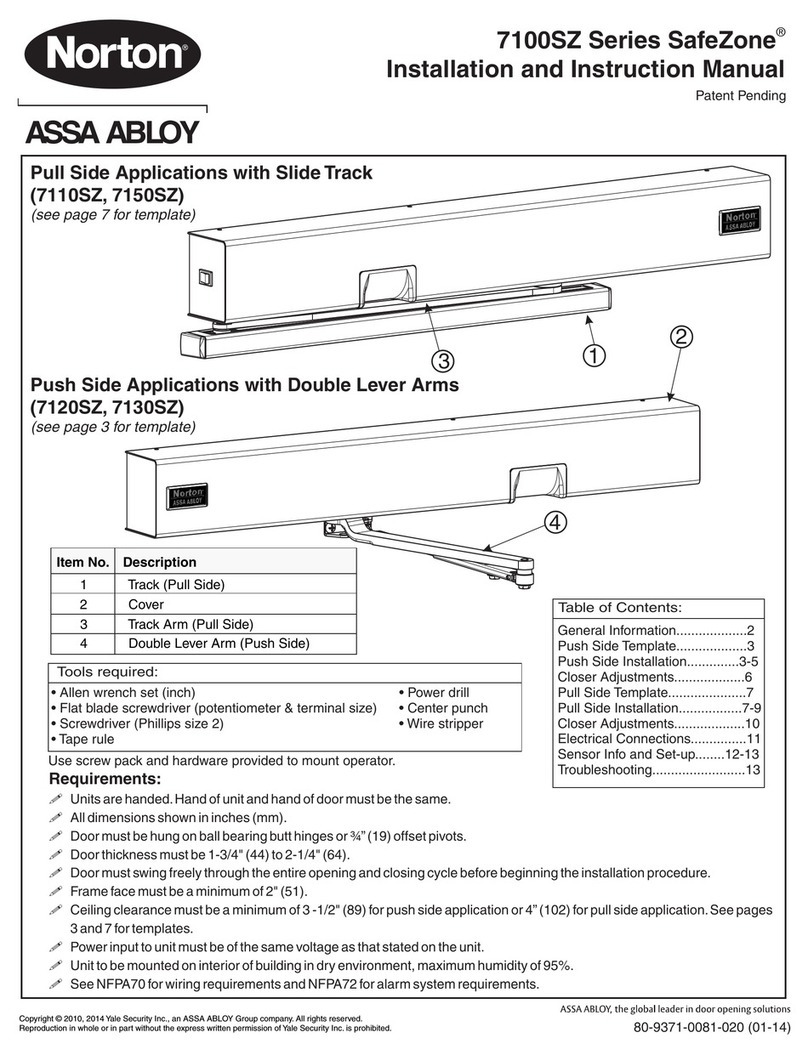

Assa Abloy Norton SafeZone 7110SZ Quick guide

Assa Abloy

Assa Abloy G-CO-FMS User manual

Assa Abloy

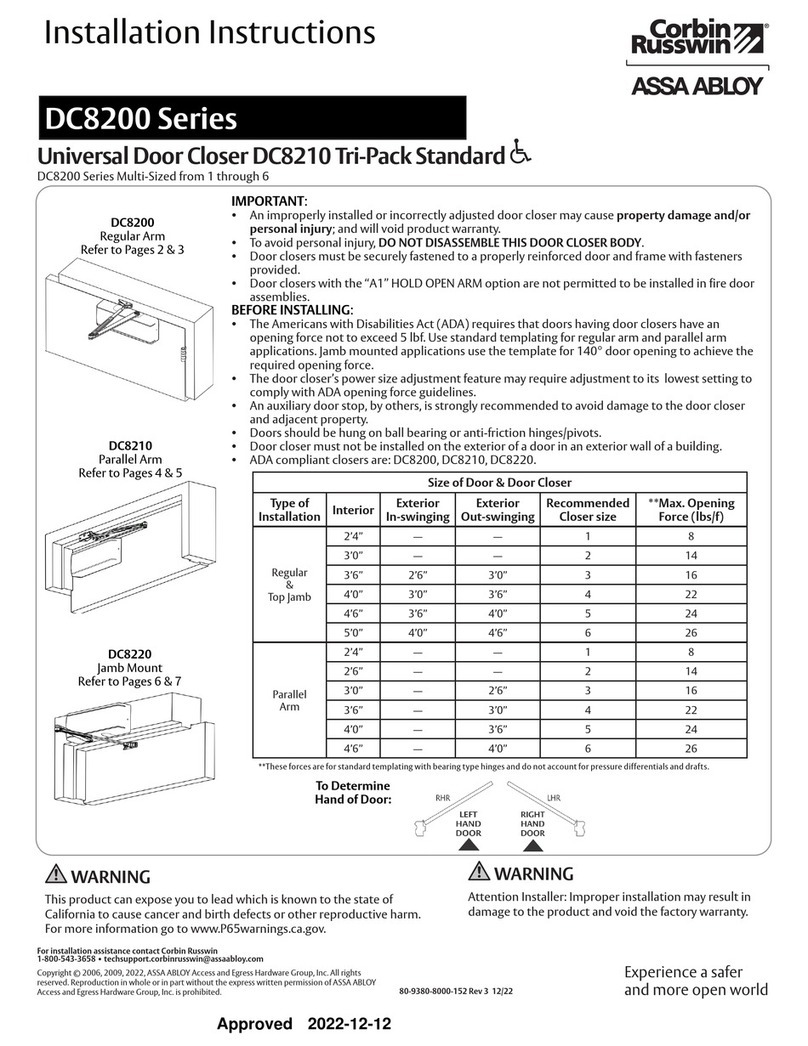

Assa Abloy Corbin Russwin DC8200 Series User manual

Assa Abloy

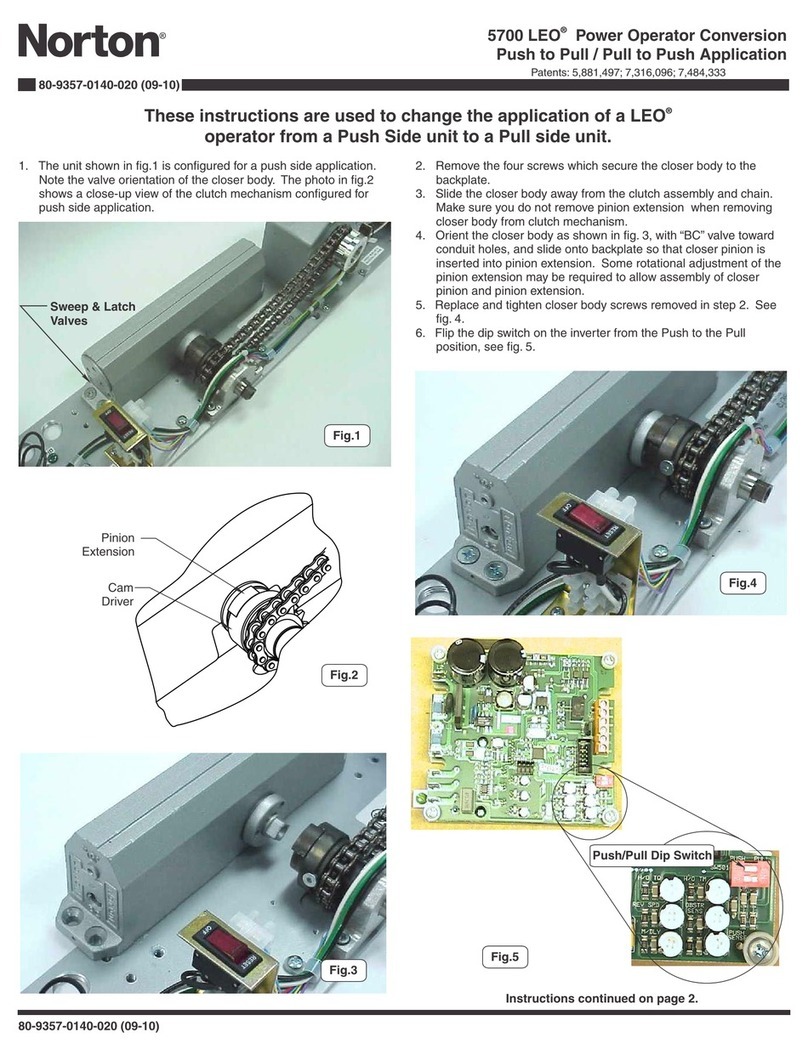

Assa Abloy Norton LEO 5700 Series User manual

Assa Abloy

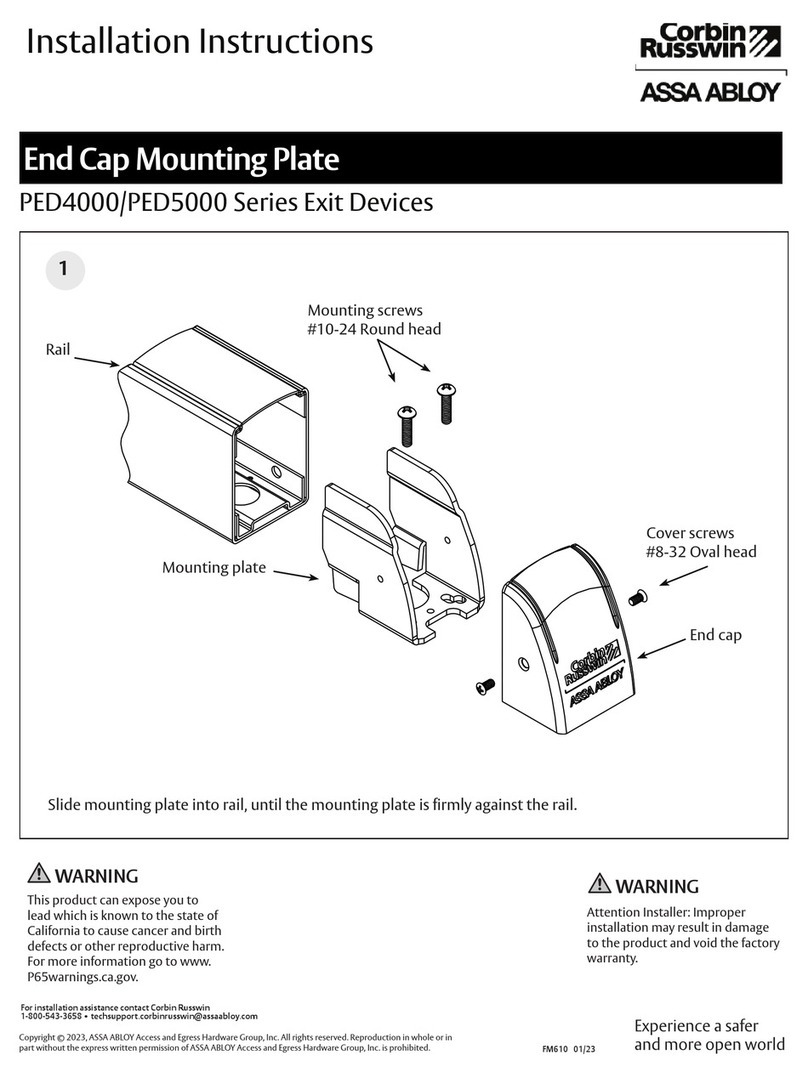

Assa Abloy Corbin Russwin PED5000 DB Series User manual

Assa Abloy

Assa Abloy h.e.s. 9100 Series Manual

Assa Abloy

Assa Abloy Corbin Russwin PED5000 DB Series User manual

Assa Abloy

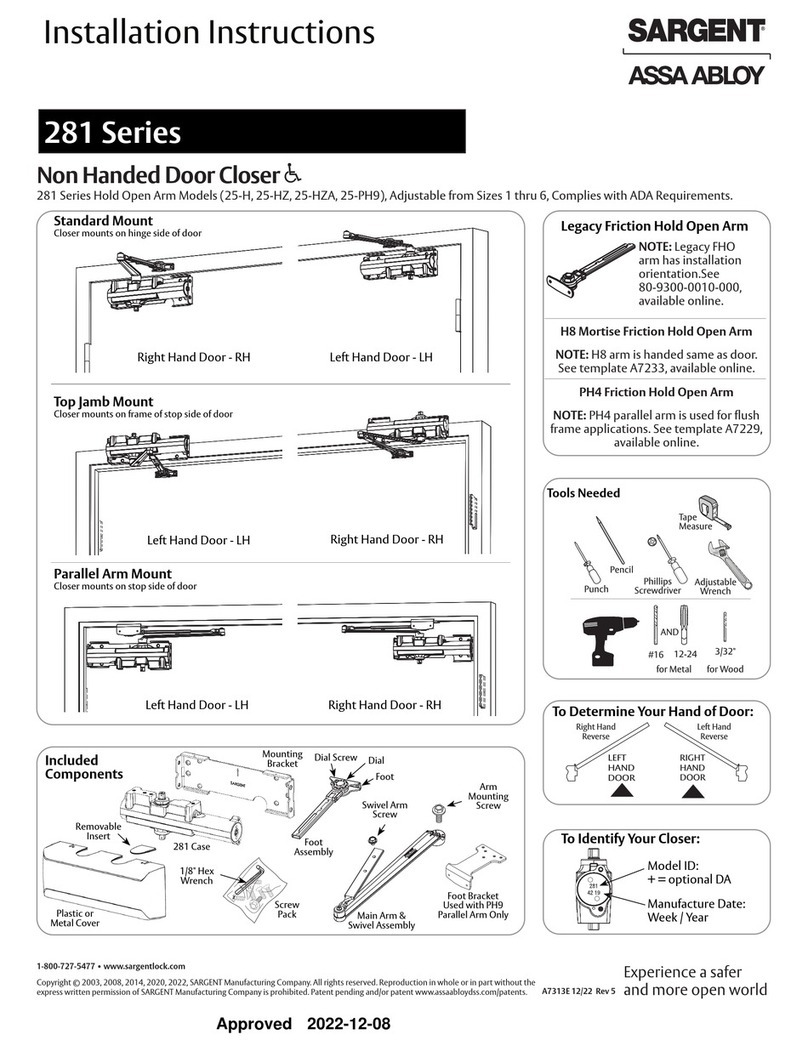

Assa Abloy 281 Series User manual

Assa Abloy

Assa Abloy DC200 User manual

Popular Door Opening System manuals by other brands

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual

Chamberlain

Chamberlain T user guide